The Performance and Exhaust Emissions of a Diesel Engine Fuelled with Calophyllum inophyllum—Palm Biodiesel

Abstract

:1. Introduction

2. Materials and Methods

2.1. Crude Oils

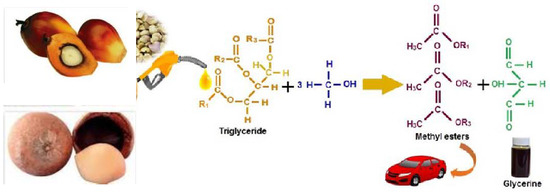

2.2. Production of CPME

2.3. Production of Methyl Ester

2.4. Characteristics of the CPME

2.5. Experimental Set-Up

2.6. Uncertainties of the Experimental

3. Results and Discussion

3.1. Physicochemical Properties

3.2. Fatty Acid Methyl Ester (FAME) Composition

3.3. Brake Specific Fuel Consumption (BSFC)

3.4. Brake Thermal Efficiency (BTE)

3.5. Nitrogen Oxide Emissions (NOx) Emission

3.6. Carbon Monoxide (CO) Emissions

3.7. Hydrocarbon (HC) Emissions

4. Conclusions

- The physicochemical properties of CPME meet ASTM D6751 and EN 14214 standards

- The blended fuel results in lower BTE and higher BSFC compared the diesel fuel because of its higher KV, density, and lower HHV.

- The use of blended fuel as a partial replacement of diesel significantly decreased the CO and HC emission, which is likely due to the fact that this blend promotes complete combustion whereas there is a slight increase in NOx emissions due to higher oxygen contents.

- Among the blends, CPME5 showed a better performance compared to the other blends.

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

Abbreviations

| CIME | Calophyllum inophyllum methyl ester |

| CIME5 | 5% Calophyllum inophyllum methyl ester + 95% of diesel |

| CIME10 | 10% Calophyllum inophyllum methyl ester + 90% of diesel |

| CPME | Calophyllum inophyllum–palm oil methyl ester |

| CPME5 | 5% Calophyllum inophyllum–palm oil methyl ester + 95% of diesel |

| CPME10 | 10% Calophyllum inophyllum–palm oil methyl ester + 90% of diesel |

| BSFC | Brake Specific Fuel Consumption |

| CO | Carbon monoxides |

| HC | Hydrocarbon |

| NOx | Nitrogen oxides |

References

- Norhasyima, R.S.; Mahlia, T.M.I. Advances in CO2 utilization technology: A patent landscape review. J. CO2 Util. 2018, 26, 323–335. [Google Scholar] [CrossRef]

- Mofijur, M.; Masjuki, H.H.; Kalam, M.A.; Hazrat, M.A.; Liaquat, A.M.; Shahabuddin, M.; Varman, M. Prospects of biodiesel from Jatropha in Malaysia. Renew. Sustain. Energy Rev. 2012, 16, 5007–5020. [Google Scholar] [CrossRef]

- Anwar, M.; Rasul, M.G.; Ashwath, N.; Rahman, M.M. Optimisation of second-generation biodiesel production from Australian native stone fruit oil using response surface method. Energies 2018, 11, 2566. [Google Scholar] [CrossRef]

- Ismail, M.S.; Moghavvemi, M.; Mahlia, T.M.I. Techno-economic analysis of an optimized photovoltaic and diesel generator hybrid power system for remote houses in a tropical climate. Energy Convers. Manag. 2013, 69, 163–173. [Google Scholar] [CrossRef]

- Milano, J.; Ong, H.C.; Masjuki, H.H.; Silitonga, A.S.; Chen, W.-H.; Kusumo, F.; Dharma, S.; Sebayang, A.H. Optimization of biodiesel production by microwave irradiation-assisted transesterification for waste cooking oil-Calophyllum inophyllum oil via response surface methodology. Energy Convers. Manag. 2018, 158, 400–415. [Google Scholar] [CrossRef]

- Ong, H.C.; Masjuki, H.H.; Mahlia, T.M.I.; Silitonga, A.S.; Chong, W.T.; Leong, K.Y. Optimization of biodiesel production and engine performance from high free fatty acid Calophyllum inophyllum oil in CI diesel engine. Energy Convers. Manag. 2014, 81, 30–40. [Google Scholar] [CrossRef]

- Silitonga, A.S.; Masjuki, H.H.; Mahlia, T.M.I.; Ong, H.C.; Chong, W.T. Experimental study on performance and exhaust emissions of a diesel engine fuelled with Ceiba pentandra biodiesel blends. Energy Convers. Manag. 2013, 76, 828–836. [Google Scholar]

- Silitonga, A.S.; Masjuki, H.H.; Ong, H.C.; Sebayang, A.H.; Dharma, S.; Kusumo, F.; Siswantoro, J.; Milano, J.; Daud, K.; Mahlia, T.M.I.; et al. Evaluation of the engine performance and exhaust emissions of biodiesel-bioethanol-diesel blends using kernel-based extreme learning machine. Energy 2018, 159, 1075–1087. [Google Scholar] [CrossRef]

- Uddin, M.; Techato, K.; Taweekun, J.; Rahman, M.; Rasul, M.; Mahilia, T.; Ashrafur, S. An overview of recent developments in biomass pyrolysis technologies. Energies 2018, 11, 3115. [Google Scholar] [CrossRef]

- Mofijur, M.; Mahlia, T.M.I.; Silitonga, A.S.; Ong, H.C.; Silakhori, M.; Hasan, M.H.; Putra, N.; Rahman, S.M.A. Phase change materials (PCM) for solar energy usages and storage: An overview. Energies 2019, 12, 3167. [Google Scholar] [CrossRef]

- Aricò, A.S.; Bruce, P.; Scrosati, B.; Tarascon, J.M.; van Schalkwijk, W. Nanostructured materials for advanced energy conversion and storage devices. Nat. Mater. 2005, 4, 366–377. [Google Scholar] [CrossRef] [PubMed]

- Liu, C.; Li, F.; Ma, L.P.; Cheng, H.M. Advanced materials for energy storage. Adv. Mater. 2010, 22, E28–E62. [Google Scholar] [CrossRef] [PubMed]

- Amin, M.; Putra, N.; Kosasih, E.A.; Prawiro, E.; Luanto, R.A.; Mahlia, T.M.I. Thermal properties of beeswax/graphene phase change material as energy storage for building applications. Appl. Therm. Eng. 2017, 112, 273–280. [Google Scholar] [CrossRef]

- Mehrali, M.; Latibari, S.T.; Mehrali, M.; Mahlia, T.M.I.; Metselaar, H.S.C.; Naghavi, M.S.; Sadeghinezhad, E.; Akhiani, A.R. Preparation and characterization of palmitic acid/graphene nanoplatelets composite with remarkable thermal conductivity as a novel shape-stabilized phase change material. Appl. Therm. Eng. 2013, 61, 633–640. [Google Scholar] [CrossRef]

- Colombo, G.; Ocampo-Duque, W.; Rinaldi, F. Challenges in bioenergy production from sugarcane mills in developing countries: A case study. Energies 2014, 7, 5874–5898. [Google Scholar] [CrossRef]

- Chia, S.R.; Ong, H.C.; Chew, K.W.; Show, P.L.; Phang, S.-M.; Ling, T.C.; Nagarajan, D.; Lee, D.-J.; Chang, J.-S. Sustainable approaches for algae utilisation in bioenergy production. Renew. Energy 2018, 129, 838–852. [Google Scholar] [CrossRef]

- Dharma, S.; Masjuki, H.H.; Ong, H.C.; Sebayang, A.H.; Silitonga, A.S.; Kusumo, F.; Mahlia, T.M.I. Optimization of biodiesel production process for mixed Jatropha curcas-Ceiba pentandra biodiesel using response surface methodology. Energy Convers. Manag. 2016, 115, 178–190. [Google Scholar] [CrossRef]

- Silitonga, A.S.; Mahlia, T.M.I.; Kusumo, F.; Dharma, S.; Sebayang, A.H.; Sembiring, R.W.; Shamsuddin, A.H. Intensification of Reutealis trisperma biodiesel production using infrared radiation: Simulation, optimisation and validation. Renew. Energy 2019, 133, 520–527. [Google Scholar] [CrossRef]

- Ayodele, O.O.; Dawodu, F.A. Production of biodiesel from Calophyllum inophyllum oil using a cellulose-derived catalyst. Biomass Bioenergy 2014, 70, 239–248. [Google Scholar] [CrossRef]

- Kusumo, F.; Silitonga, A.S.; Masjuki, H.H.; Ong, H.C.; Siswantoro, J.; Mahlia, T.M.I. Optimization of transesterification process for Ceiba pentandra oil: A comparative study between kernel-based extreme learning machine and artificial neural networks. Energy 2017, 134, 24–34. [Google Scholar] [CrossRef]

- Kusumo, F.; Silitonga, A.S.; Ong, H.C.; Masjuki, H.H.; Mahlia, T.M.I. A comparative study of ultrasound and infrared transesterification of Sterculia foetida oil for biodiesel production. Energy Sour. Part A Recovery Util. Environ. Eff. 2017, 39, 1339–1346. [Google Scholar] [CrossRef]

- Goh, B.H.H.; Ong, H.C.; Cheah, M.Y.; Chen, W.-H.; Yu, K.L.; Mahlia, T.M.I. Sustainability of direct biodiesel synthesis from microalgae biomass: A critical review. Renew. Sustain. Energy Rev. 2019, 107, 59–74. [Google Scholar] [CrossRef]

- Hayyan, A.; Mjalli, F.S.; Hashim, M.A.; Hayyan, M.; AlNashef, I.M.; Al-Wahaibi, T.; Al-Wahaib, Y.M. A Solid organic acid catalyst for the pretreatment of low-grade crude palm oil and biodiesel production. Int. J. Green Energy 2014, 11, 129–140. [Google Scholar] [CrossRef]

- Halim, I.F. Cost-Benefit Analysis of Biodiesel Related Policies: The Assessment of Applicability. Master’s Thesis, Delft University of Technology, Delft, The Netherland, 2015. [Google Scholar]

- Ong, H.C.; Masjuki, H.H.; Mahlia, T.M.I.; Silitonga, A.S.; Chong, W.T.; Yusaf, T. Engine performance and emissions using Jatropha curcas, Ceiba pentandra and Calophyllum inophyllum biodiesel in a CI diesel engine. Energy 2014, 69, 427–445. [Google Scholar]

- Prasad, J.; Shrivastava, A.; Khanna, A.K.; Bhatia, G.; Awasthi, S.K.; Narender, T. Antidyslipidemic and antioxidant activity of the constituents isolated from the leaves of Calophyllum inophyllum. Phytomedicine 2012, 19, 1245–1249. [Google Scholar] [CrossRef] [PubMed]

- Sahoo, P.K.; Das, L.M.; Babu, M.K.G.; Naik, S.N. Biodiesel development from high acid value polanga seed oil and performance evaluation in a CI engine. Fuel 2007, 86, 448–454. [Google Scholar] [CrossRef]

- Pullen, J.; Saeed, K. Experimental study of the factors affecting the oxidation stability of biodiesel FAME fuels. Fuel Process. Technol. 2014, 125, 223–235. [Google Scholar] [CrossRef]

- Silitonga, A.S.; Masjuki, H.H.; Ong, H.C.; Yusaf, T.; Kusumo, F.; Mahlia, T.M.I. Synthesis and optimization of Hevea brasiliensis and Ricinus communis as feedstock for biodiesel production: A comparative study. Ind. Crops Prod. 2016, 85, 274–286. [Google Scholar] [CrossRef]

- Kombe, G.G. Re-esterification of high free fatty acid oils for biodiesel production. Biofuels 2015, 6, 31–36. [Google Scholar] [CrossRef]

- Yaakob, Z.; Narayanan, B.N.; Padikkaparambil, S.; Unni, K.S.; Akbar, P.M. A review on the oxidation stability of biodiesel. Renew. Sustain. Energy Rev. 2014, 35, 136–153. [Google Scholar] [CrossRef]

- Dinkov, R.; Hristov, G.; Stratiev, D.; Boynova Aldayri, V. Effect of commercially available antioxidants over biodiesel/diesel blends stability. Fuel 2009, 88, 732–737. [Google Scholar] [CrossRef]

- Kirk-Othmer. Esterification. Kirk-Othmer Encyclopedia of Chemical Technology, 4th ed.; John Wiley & Sons, Inc.: Hoboken, NJ, USA, 2004. [Google Scholar]

- Kumar, N.R.; Reddy, J.S.; Gopikrishna, G.; Solomon, K.A. GC-MS determination of bioactive constituent of cycas beddomei cones. Int. J. Pharm. Bio Sci. 2012, 3, 344–350. [Google Scholar]

- Nantha Gopal, K.; Thundil Karupparaj, R. Effect of Pongamia biodiesel on emission and combustion characteristics of DI compression ignition engine. Ain Shams Eng. J. 2015, 6, 297–305. [Google Scholar] [CrossRef]

- Mofijur, M.; Masjuki, H.H.; Kalam, M.A.; Atabani, A.E. Evaluation of biodiesel blending, engine performance and emissions characteristics of Jatropha curcas methyl ester: Malaysian perspective. Energy 2013, 55, 879–887. [Google Scholar] [CrossRef]

- Mofijur, M.; Masjuki, H.H.; Kalam, M.A.; Atabani, A.E.; Fattah, I.M.R.; Mobarak, H.M. Comparative evaluation of performance and emission characteristics of Moringa oleifera and Palm oil based biodiesel in a diesel engine. Ind. Crops Prod. 2014, 53, 78–84. [Google Scholar] [CrossRef]

- Öztürk, E. Performance, emissions, combustion and injection characteristics of a diesel engine fuelled with canola oil–hazelnut soapstock biodiesel mixture. Fuel Process. Technol. 2015, 129, 183–191. [Google Scholar] [CrossRef]

- Mofijur, M.; Masjuki, H.H.; Kalam, M.A.; Atabani, A.E.; Arbab, M.I.; Cheng, S.F.; Gouk, S.W. Properties and use of Moringa oleifera biodiesel and diesel fuel blends in a multi-cylinder diesel engine. Energy Convers. Manag. 2014, 82, 169–176. [Google Scholar] [CrossRef]

- Syed, A.; Quadri, S.A.P.; Rao, G.A.P.; Mohd, W. Experimental investigations on DI (direct injection) diesel engine operated on dual fuel mode with hydrogen and mahua oil methyl ester (MOME) as injected fuels and effects of injection opening pressure. Appl. Therm. Eng. 2017, 114, 118–129. [Google Scholar] [CrossRef]

- Rahman, M.M.; Rasul, M.G.; Hassan, N.M.S.; Azad, A.K.; Uddin, N. Effect of small proportion of butanol additive on the performance, emission, and combustion of Australian native first- and second-generation biodiesel in a diesel engine. Environ. Sci. Pollut. Res. 2017, 24, 22402–22413. [Google Scholar] [CrossRef]

- Sharma, L.; Grover, N.K.; Bhardwaj, M.; Kaushal, I. Comparison of engine performance of mixed Jatropha and cottonseed derived biodiesel blends with conventional diesel. Int. J. Emerg. Technol. 2012, 3, 29–32. [Google Scholar]

- Özçelik, A.E.; Aydoğan, H.; Acaroğlu, M. Determining the performance, emission and combustion properties of camelina biodiesel blends. Energy Convers. Manag. 2015, 96, 47–57. [Google Scholar] [CrossRef]

- Kalam, M.A.; Masjuki, H.H.; Jayed, M.H.; Liaquat, A.M. Emission and performance characteristics of an indirect ignition diesel engine fuelled with waste cooking oil. Energy 2011, 36, 397–402. [Google Scholar] [CrossRef]

- Pinto, A.C.; Guarieiro, L.L.N.; Rezende, M.J.C.; Ribeiro, N.M.; Torres, E.A.; Lopes, W.A.; Pereira, P.A.d.; de Andrade, J.B. Biodiesel: An overview. J. Braz. Chem. Soc. 2005, 16, 1313–1330. [Google Scholar] [CrossRef]

- Dinesha, P.; Mohanan, P. Combined effect of oxygen enrichment and exhaust gas recirculation on the performance and emissions of a diesel engine fueled with biofuel blends. Biofuels 2018, 9, 45–51. [Google Scholar] [CrossRef]

- Man, X.J.; Cheung, C.S.; Ning, Z.; Wei, L.; Huang, Z.H. Influence of engine load and speed on regulated and unregulated emissions of a diesel engine fueled with diesel fuel blended with waste cooking oil biodiesel. Fuel 2016, 180, 41–49. [Google Scholar] [CrossRef]

- Kegl, B. Influence of biodiesel on engine combustion and emission characteristics. Appl. Energy 2011, 88, 1803–1812. [Google Scholar] [CrossRef]

| Brand | Yanmar |

| Model | 2500CX-A 170 F |

| Type | 1-cylinder, DI |

| Displacement (cc) | 211 |

| Speed (rpm) | 3000 |

| Maximum output(HP) | 4.2 |

| Cont. output (HP) | 3.8 |

| Governor System | Centrifugal weight system |

| Starting system | Recoil or electric |

| Lube oil capacity(L) | 0.75 |

| Fuel tank capacity(L) | 12.5 |

| Operational capacity (hrs.) | 14 |

| Measured Quantity | Measurement Range | Accuracy | Type of Instrument | Percentage Uncertainty (%) |

|---|---|---|---|---|

| Load | ±8 Nm | ±0.1 Nm | Strain gauge type load cell | ±1.27 |

| Speed | 1400–2800 rpm | ±1 rpm | Magnetic pickup type speed sensor | ±0.1 |

| Time | - | ±0.1 s | - | ±0.2 |

| Fuel flow measurement | 1–25 L/h | ±0.1 L/h | Positive displacement gear wheel flow meter | ±1.53 |

| CO | 0%–10% by vol. | ±0.001% | Non-dispersive infrared gas sensor | ±1.13 |

| HC | 0–9,999 ppm | ±1 ppm | Heated flame ionization detector | ±1.4 |

| NOx | 0–5,000 ppm vol | ±1 ppm vol | Electrochemical gas sensor | ±1.1 |

| BSFC | - | ±0.1 L/kWh | - | ±1.5 |

| BTE | - | ±0.2% | - | ±1.5 |

| Property | Limit | Diesel | Biodiesel | Biodiesel Blends | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| ASTM D6751 | EN 14214 | POME | CIME | CPME | CSO + WSO (Fadhil, 2017) | JCME (Dharma, 2016) | NSME + CPME (Yunus khan, 2014) | CIME5 | CIME10 | CPME5 | CPME10 | JCB10 (Dharma, 2016) | NSCPB (Yunus khan, 2014) | ||

| Density at 15 °C (kg/m3) | 880.0 | 860.0–900.0 | 846.3 | 874.0 | 884.0 | 880.0 | 898.9 | 831.2 | 884.8 | 852.0 | 854.0 | 853.0 | 854.0 | 854 | 854.0 |

| KV at 40 °C (mm2/s) | 1.90–6.00 | 3.50–5.00 | 2.98 | 4.40 | 4.80 | 4.50 | 3.61 | 3.95 | 4.44 | 3.76 | 4.00 | 3.82 | 4.00 | 3.55 | 3.70 |

| FP (°C) | >130.0 | Min. 101.0 | 80.0 | 246.5 | 179.0 | 160.0 | 246.5 | 84 | 186.5 | 86.0 | 88.0 | 79.9 | 82.0 | 76.5 | 87.5 |

| HHV (MJ/kg) | – | 35.0 | 45.3 | 36.4 | 37.3 | 37.9 | 36.4 | 40.88 | 39.94 | 43.1 | 42.9 | 44.1 | 43.9 | 42.76 | 44.2 |

| AV (mg KOH/g) | <0.50 | <0.50 | – | 0.1 | 0.5 | 0.4 | 0.1 | 0.06 | 0.14 | 0.1 | 0.5 | 0.4 | 0.1 | 0.36 | 0.1 |

| Water content (%v) | Max. 0.05 | - | - | 0.025 | 0.015 | 0.018 | - | - | - | 0.015 | 0.0015 | 0.002 | 0.0018 | - | - |

| Fatty Acid | CIME (wt.%) | POME (wt.%) | CPME (wt.%) |

|---|---|---|---|

| Lauric acid | 0.10 | 0.10 | 0.10 |

| Myristic acid | 0.75 | 1.52 | 0.93 |

| Palmitic acid | 16.85 | 25.10 | 28.22 |

| Palmitoleic acid | 0.70 | 0.67 | 0.75 |

| Stearic acid | 15.57 | 22.46 | 31.99 |

| Oleic acid | 41.5 | 56.29 | 52.94 |

| Linoleic acid | 15.10 | 6.85 | 16.35 |

| Linolenic acid | 0.13 | 7.61 | 5.32 |

| Arachidic acid | 0.10 | 0.10 | 0.10 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Damanik, N.; Ong, H.C.; Mofijur, M.; Tong, C.W.; Silitonga, A.S.; Shamsuddin, A.H.; Sebayang, A.H.; Mahlia, T.M.I.; Wang, C.-T.; Jang, J.-H. The Performance and Exhaust Emissions of a Diesel Engine Fuelled with Calophyllum inophyllum—Palm Biodiesel. Processes 2019, 7, 597. https://doi.org/10.3390/pr7090597

Damanik N, Ong HC, Mofijur M, Tong CW, Silitonga AS, Shamsuddin AH, Sebayang AH, Mahlia TMI, Wang C-T, Jang J-H. The Performance and Exhaust Emissions of a Diesel Engine Fuelled with Calophyllum inophyllum—Palm Biodiesel. Processes. 2019; 7(9):597. https://doi.org/10.3390/pr7090597

Chicago/Turabian StyleDamanik, Natalina, Hwai Chyuan Ong, M. Mofijur, Chong Wen Tong, Arridina Susan Silitonga, Abd Halim Shamsuddin, Abdi Hanra Sebayang, Teuku Meurah Indra Mahlia, Chin-Tsan Wang, and Jer-Huan Jang. 2019. "The Performance and Exhaust Emissions of a Diesel Engine Fuelled with Calophyllum inophyllum—Palm Biodiesel" Processes 7, no. 9: 597. https://doi.org/10.3390/pr7090597

APA StyleDamanik, N., Ong, H. C., Mofijur, M., Tong, C. W., Silitonga, A. S., Shamsuddin, A. H., Sebayang, A. H., Mahlia, T. M. I., Wang, C. -T., & Jang, J. -H. (2019). The Performance and Exhaust Emissions of a Diesel Engine Fuelled with Calophyllum inophyllum—Palm Biodiesel. Processes, 7(9), 597. https://doi.org/10.3390/pr7090597