Algae-Assisted Microbial Desalination Cell: Analysis of Cathode Performance and Desalination Efficiency Assessment

Abstract

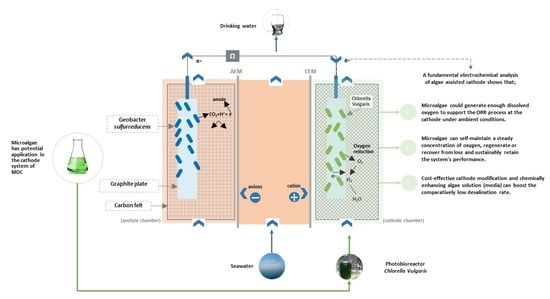

:1. Introduction

2. Materials and Methods

2.1. Microbial Culture: Algae (Photobioreactor) and Electroactive Biofilm (Anode)

2.2. MDC Construction and Setup

2.3. Start-Up and Operation Conditions

2.4. Parameter Calculations

3. Results

3.1. Algae Growth and the Electrochemical Behaviour of Algae Assisted Cathode

3.2. Desalination and COD Removal

3.2.1. Oxygen Concentration and Electric Current Generation

3.2.2. Desalination and COD Degradation Performance

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Conflicts of Interest

References

- Cao, X.; Huang, X.; Liang, P.; Xiao, K.; Zhou, Y.; Zhang, X.; Logan, B.E. A New Method for Water Desalination Using Microbial Desalination Cells. Environ. Sci. Technol. 2009, 43, 7148–7152. [Google Scholar] [CrossRef]

- Jingyu, H.; Ewusi-Mensah, D.; Norgbey, E. Microbial desalination cells technology: A review of the factors affecting the process, performance and efficiency. Desalin. Water Treat. 2017, 87, 140–159. [Google Scholar] [CrossRef]

- Luo, H.; Xu, P.; Ren, Z. Long-term performance and characterization of microbial desalination cells in treating domestic wastewater. Bioresour. Technol. 2012, 120, 187–193. [Google Scholar] [CrossRef]

- Ge, Z.; Dosoretz, C.G.; He, Z. Effects of number of cell pairs on the performance of microbial desalination cells. Desalination 2014, 341, 101–106. [Google Scholar] [CrossRef]

- Luo, H.; Xu, P.; Roane, T.M.; Jenkins, P.E.; Ren, Z. Microbial desalination cells for improved performance in wastewater treatment, electricity production, and desalination. Bioresour. Technol. 2012, 105, 60–66. [Google Scholar] [CrossRef] [PubMed]

- Ramírez-Moreno, M.; Rodenas, P.; Aliaguilla, M.; Bosch-Jimenez, P.; Borràs, E.; Zamora, P.; Monsalvo, V.; Rogalla, F.; Ortiz, J.M.; Esteve-Núñez, A. Comparative Performance of Microbial Desalination Cells Using Air Diffusion and Liquid Cathode Reactions: Study of the Salt Removal and Desalination Efficiency. Front. Energy Res. 2019, 7, 135. [Google Scholar] [CrossRef] [Green Version]

- Borjas, Z.; Esteve-Núñez, A.; Ortiz, J.M. Strategies for merging microbial fuel cell technologies in water desalination processes: Start-up protocol and desalination efficiency assessment. J. Power Sources 2017, 356, 519–528. [Google Scholar] [CrossRef]

- Ragab, M.; Elawwad, A.; Abdel-Halim, H. Evaluating the performance of Microbial Desalination Cells subjected to different operating temperatures. Desalination 2019, 462, 56–66. [Google Scholar] [CrossRef]

- Microbial Desalination Cells for Low Energy Drinking Water; Salinas-Rodríguez, S.G.; Arévalo, J.; Ortiz, J.M.; Borràs-Camps, E.; Monsalvo-Garcia, V.; Kennedy, M.D.; Esteve-Núñez, A. (Eds.) IWA Publishing: London, UK, 2021; ISBN 9781789062120. [Google Scholar]

- Ramírez-Moreno, M.; Esteve-Núñez, A.; Ortiz, J.M. Desalination of brackish water using a microbial desalination cell: Analysis of the electrochemical behaviour. Electrochim. Acta 2021, 388, 138570. [Google Scholar] [CrossRef]

- Dargam, F.; Perz, E.; Bergmann, S.; Rodionova, E.; Sousa, P.; Souza, F.A.A.; Matias, T.; Ortiz, J.M.; Esteve-Nuñez, A.; Rodenas, P.; et al. Supporting Operational Decisions on Desalination Plants from Process Modelling and Simulation to Monitoring and Automated Control with Machine Learning. In Lecture Notes in Business Information Processing; Springer: Cham, Switzerland, 2020; Volume 384, pp. 150–164. ISBN 9783030462239. [Google Scholar]

- Ebrahimi, A.; Najafpour, G.D.; Yousefi Kebria, D. Performance of microbial desalination cell for salt removal and energy generation using different catholyte solutions. Desalination 2018, 432, 1–9. [Google Scholar] [CrossRef]

- Rahimnejad, M.; Ghoreyshi, A.A.; Najafpour, G.; Jafary, T. Power generation from organic substrate in batch and continuous flow microbial fuel cell operations. Appl. Energy 2011, 88, 3999–4004. [Google Scholar] [CrossRef]

- Kokabian, B.; Gude, V.G. Photosynthetic microbial desalination cells (PMDCs) for clean energy, water and biomass production. Environ. Sci. Process. Impacts 2013, 15, 2178–2185. [Google Scholar] [CrossRef]

- Rismani-Yazdi, H.; Carver, S.M.; Christy, A.D.; Tuovinen, O.H. Cathodic limitations in microbial fuel cells: An overview. J. Power Sources 2008, 180, 683–694. [Google Scholar] [CrossRef]

- Lu, M.; Li, S.F.Y. Cathode Reactions and Applications in Microbial Fuel Cells: A Review. Crit. Rev. Environ. Sci. Technol. 2012, 42, 2504–2525. [Google Scholar] [CrossRef]

- Li, Y.; Lu, A.; Ding, H.; Jin, S.; Yan, Y.; Wang, C.; Zen, C.; Wang, X. Cr(VI) reduction at rutile-catalyzed cathode in microbial fuel cells. Electrochem. Commun. 2009, 11, 1496–1499. [Google Scholar] [CrossRef]

- Oh, S.; Min, B.; Logan, B.E. Cathode Performance as a Factor in Electricity Generation in Microbial Fuel Cells. Environ. Sci. Technol. 2004, 38, 4900–4904. [Google Scholar] [CrossRef]

- ter Heijne, A.; Hamelers, H.V.M.; de Wilde, V.; Rozendal, R.A.; Buisman, C.J.N. A Bipolar Membrane Combined with Ferric Iron Reduction as an Efficient Cathode System in Microbial Fuel Cells. Environ. Sci. Technol. 2006, 40, 5200–5205. [Google Scholar] [CrossRef] [PubMed]

- Ucar, D.; Zhang, Y.; Angelidaki, I. An Overview of Electron Acceptors in Microbial Fuel Cells. Front. Microbiol. 2017, 8, 643. [Google Scholar] [CrossRef] [Green Version]

- Lefebvre, O.; Al-Mamun, A.; Ng, H.Y. A microbial fuel cell equipped with a biocathode for organic removal and denitrification. Water Sci. Technol. 2008, 58, 881–885. [Google Scholar] [CrossRef]

- Sun, Y.; Wei, J.; Liang, P.; Huang, X. Microbial community analysis in biocathode microbial fuel cells packed with different materials. AMB Express 2012, 2, 21. [Google Scholar] [CrossRef] [Green Version]

- Arana, T.J.; Gude, V.G. A microbial desalination process with microalgae biocathode using sodium bicarbonate as an inorganic carbon source. Int. Biodeterior. Biodegrad. 2018, 130, 91–97. [Google Scholar] [CrossRef]

- Wong, Y. Growth Medium Screening for Chlorella vulgaris Growth and Lipid Production. J. Aquac. Mar. Biol. 2017, 6, 143. [Google Scholar] [CrossRef] [Green Version]

- Borjas, Z.; Ortiz, J.; Aldaz, A.; Feliu, J.; Esteve-Núñez, A. Strategies for Reducing the Start-up Operation of Microbial Electrochemical Treatments of Urban Wastewater. Energies 2015, 8, 14064–14077. [Google Scholar] [CrossRef]

- Khazraee Zamanpour, M.; Kariminia, H.R.; Vosoughi, M.; Zamanpour, M.K.; Kariminia, H.R.; Vosoughi, M.; Khazraee Zamanpour, M.; Kariminia, H.R.; Vosoughi, M.; Zamanpour, M.K.; et al. Electricity generation, desalination and microalgae cultivation in a biocathode-microbial desalination cell. J. Environ. Chem. Eng. 2017, 5, 843–848. [Google Scholar] [CrossRef] [Green Version]

- Edmundson, S.J.; Huesemann, M.H. The dark side of algae cultivation: Characterizing night biomass loss in three photosynthetic algae, Chlorella sorokiniana, Nannochloropsis salina and Picochlorum sp. Algal Res. 2015, 12, 470–476. [Google Scholar] [CrossRef] [Green Version]

- Lee, H.-S.; Parameswaran, P.; Kato-Marcus, A.; Torres, C.I.; Rittmann, B.E. Evaluation of energy-conversion efficiencies in microbial fuel cells (MFCs) utilizing fermentable and non-fermentable substrates. Water Res. 2008, 42, 1501–1510. [Google Scholar] [CrossRef]

- Sforza, E.; Simionato, D.; Giacometti, G.M.; Bertucco, A.; Morosinotto, T. Adjusted light and dark cycles can optimize photosynthetic efficiency in algae growing in photobioreactors. PLoS ONE 2012, 7, e38975. [Google Scholar] [CrossRef]

- Si, F.; Zhang, Y.; Yan, L.; Zhu, J.; Xiao, M.; Liu, C.; Xing, W.; Zhang, J. Electrochemical Oxygen Reduction Reaction. In Rotating Electrode Methods and Oxygen Reduction Electrocatalysts; Elsevier: Amsterdam, The Netherlands, 2014; pp. 133–170. ISBN 9780444632784. [Google Scholar]

- Ling, J.; Xu, Y.; Lu, C.; Lai, W.; Xie, G.; Zheng, L.; Talawar, M.P.; Du, Q.; Li, G. Enhancing Stability of Microalgae Biocathode by a Partially Submerged Carbon Cloth Electrode for Bioenergy Production from Wastewater. Energies 2019, 12, 3229. [Google Scholar] [CrossRef] [Green Version]

- Jaroo, S.S.; Jumaah, G.F.; Abbas, T.R. Photosynthetic Microbial Desalination Cell to Treat Oily Wastewater Using Microalgae Chlorella Vulgaris. Civ. Eng. J. 2019, 5, 2686–2699. [Google Scholar] [CrossRef] [Green Version]

- Bahareh Kokabian, V.G.G. Beneficial Bioelectrochemical Systems for Energy, Water, and Biomass Production. J. Microb. Biochem. Technol. 2013, S6, 1–14. [Google Scholar] [CrossRef] [Green Version]

- Hui, W.J.; David, E.-M.M.; Huang, J. Using C. vulgaris assisted microbial desalination cell as a green technology in landfill leachate pre-treatment: A factor-performance relation study. J. Water Reuse Desalin. 2020, 10, 1–16. [Google Scholar] [CrossRef]

- Kakarla, R.; Min, B. Photoautotrophic microalgae Scenedesmus obliquus attached on a cathode as oxygen producers for microbial fuel cell (MFC) operation. Int. J. Hydrogen Energy 2014, 39, 10275–10283. [Google Scholar] [CrossRef]

- Lee, M.; Kondaveeti, S.; Jeon, T.; Kim, I.; Min, B. Influence of Humidity on Performance of Single Chamber Air-Cathode Microbial Fuel Cells with Different Separators. Processes 2020, 8, 861. [Google Scholar] [CrossRef]

- Lee, M.; Kakarla, R.; Min, B. Performance of an air-cathode microbial fuel cell under varied relative humidity conditions in the cathode chamber. Bioprocess Biosyst. Eng. 2019, 42, 1247–1254. [Google Scholar] [CrossRef] [PubMed]

- Fujimoto, S.; Uemura, S.; Imanishi, N.; Hirai, S. Oxygen concentration measurement in the porous cathode of a lithium-air battery using a fine optical fiber sensor. Mech. Eng. Lett. 2019, 5, 19-00095. [Google Scholar] [CrossRef] [Green Version]

- Kazbar, A.; Cogne, G.; Urbain, B.; Marec, H.; Le-Gouic, B.; Tallec, J.; Takache, H.; Ismail, A.; Pruvost, J. Effect of dissolved oxygen concentration on microalgal culture in photobioreactors. Algal Res. 2019, 39, 101432. [Google Scholar] [CrossRef] [Green Version]

- Kokabian, B.; Gude, V.G. Sustainable photosynthetic biocathode in microbial desalination cells. Chem. Eng. J. 2015, 262, 958–965. [Google Scholar] [CrossRef]

- González del Campo, A.; Cañizares, P.; Rodrigo, M.A.; Fernández, F.J.; Lobato, J. Microbial fuel cell with an algae-assisted cathode: A preliminary assessment. J. Power Sources 2013, 242, 638–645. [Google Scholar] [CrossRef]

- Wu, Y.; Wang, Z.; Zheng, Y.; Xiao, Y.; Yang, Z.; Zhao, F. Light intensity affects the performance of photo microbial fuel cells with Desmodesmus sp. A8 as cathodic microorganism. Appl. Energy 2014, 116, 86–90. [Google Scholar] [CrossRef]

- Lovley, D.R.; Ueki, T.; Zhang, T.; Malvankar, N.S.; Shrestha, P.M.; Flanagan, K.A.; Aklujkar, M.; Butler, J.E.; Giloteaux, L.; Rotaru, A.-E.; et al. Geobacter: The microbe electric’s physiology, ecology, and practical applications. Adv. Microb. Physiol. 2011, 59, 1–100. [Google Scholar] [CrossRef]

- Jafary, T.; Daud, W.R.W.; Aljlil, S.A.; Ismail, A.F.; Al-Mamun, A.; Baawain, M.S.; Ghasemi, M. Simultaneous organics, sulphate and salt removal in a microbial desalination cell with an insight into microbial communities. Desalination 2018, 445, 204–212. [Google Scholar] [CrossRef]

- Vandamme, D.; Foubert, I.; Fraeye, I.; Meesschaert, B.; Muylaert, K. Flocculation of Chlorella vulgaris induced by high pH: Role of magnesium and calcium and practical implications. Bioresour. Technol. 2012, 105, 114–119. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Ihnken, S.; Beardall, J.; Kromkamp, J.; Gómez Serrano, C.; Torres, M.; Masojídek, J.; Malpartida, I.; Abdala, R.; Jerez, C.; Malapascua, J.; et al. Light acclimation and pH perturbations affect photosynthetic performance in Chlorella mass culture. Aquat. Biol. 2014, 22, 95–110. [Google Scholar] [CrossRef] [Green Version]

- An, Z.; Zhang, H.; Wen, Q.; Chen, Z.; Du, M. Desalination combined with hexavalent chromium reduction in a microbial desalination cell. Desalination 2014, 354, 181–188. [Google Scholar] [CrossRef]

- Venkata Mohan, S.; Sunita, V.; Pandey, A. (Eds.) Microbial Electrochemical Technology, 1st ed.; Elsevier: Amsterdam, The Netherlands, 2019; ISBN 9780444640529. [Google Scholar]

- Toczyłowska-Mamińska, R. Limits and perspectives of pulp and paper industry wastewater treatment—A review. Renew. Sustain. Energy Rev. 2017, 78, 764–772. [Google Scholar] [CrossRef]

- Ortiz, J.; Exposito, E.; Gallud, F.; Garciagarcia, V.; Montiel, V.; Aldaz, A. Desalination of underground brackish waters using an electrodialysis system powered directly by photovoltaic energy. Sol. Energy Mater. Sol. Cells 2008, 92, 1677–1688. [Google Scholar] [CrossRef]

- Fornero, J.J.; Rosenbaum, M.; Angenent, L.T. Electric Power Generation from Municipal, Food, and Animal Wastewaters Using Microbial Fuel Cells. Electroanalysis 2010, 22, 832–843. [Google Scholar] [CrossRef]

- Gadhamshetty, V.; Belanger, D.; Gardiner, C.-J.; Cummings, A.; Hynes, A. Evaluation of Laminaria-based microbial fuel cells (LbMs) for electricity production. Bioresour. Technol. 2013, 127, 378–385. [Google Scholar] [CrossRef]

- Rana, A.; Baig, N.; Saleh, T.A. Electrochemically pretreated carbon electrodes and their electroanalytical applications—A review. J. Electroanal. Chem. 2019, 833, 313–332. [Google Scholar] [CrossRef]

- Zhao, F.; Harnisch, F.; Schröder, U.; Scholz, F.; Bogdanoff, P.; Herrmann, I. Challenges and Constraints of Using Oxygen Cathodes in Microbial Fuel Cells. Environ. Sci. Technol. 2006, 40, 5193–5199. [Google Scholar] [CrossRef]

- Wen, Q.; Zhang, H.; Chen, Z.; Li, Y.; Nan, J.; Feng, Y. Using bacterial catalyst in the cathode of microbial desalination cell to improve wastewater treatment and desalination. Bioresour. Technol. 2012, 125, 108–113. [Google Scholar] [CrossRef] [PubMed]

- Jacobson, K.S.; Drew, D.M.; He, Z. Efficient salt removal in a continuously operated upflow microbial desalination cell with an air cathode. Bioresour. Technol. 2011, 102, 376–380. [Google Scholar] [CrossRef] [PubMed]

- Mehanna, M.; Saito, T.; Yan, J.; Hickner, M.; Cao, X.; Huang, X.; Logan, B.E. Using microbial desalination cells to reduce water salinity prior to reverse osmosis. Energy Environ. Sci. 2010, 3, 1114. [Google Scholar] [CrossRef]

| Setup/Startup Material/Condition | Details |

|---|---|

| Anode compartment | |

| Electrode | RVG 2000 MERSEN Carbon Felt |

| Electric collector | Graphite plate (4.6 mm thickness) |

| Chamber size | 1 unit, 100 cm2 cross section (10 × 10 cm) with neoprene joints |

| Chamber thickness | 9 mm |

| Anolyte | FWM + 1.65 g/L Acetate, 2 L volume |

| Bioanode | Geobacter sulfurreducens |

| Reference electrode | Ag/AgCl 3.5 M KCl reference electrodes unit located in the geometrical center of the compartment |

| Saline compartment | |

| Chamber size | 1 unit, 100 cm2 cross section (10 × 10 cm) |

| Saline water | NaCl, concentration 4.30 g/L, 200 mL volume |

| Chamber thickness | 9 mm |

| Cathode compartment | |

| Electrode | RVG 2000 MERSEN Carbon Felt |

| Electric collector | Graphite plate (10 × 10 cm) |

| Chamber size | 1 unit, 100 cm2 cross section (10 × 10 cm) |

| Chamber thickness | 9 mm |

| Catholyte | Algae in Bold’s Basal Media (BBM) solution, 2 L volume |

| Biocathode | Chlorella vulgaris |

| Reference electrode | Ag/AgCl 3.5 M KCl reference electrodes unit located in the geometrical center of the compartment |

| Lumen/light and dark regime | 400 lm/24 h/12 h |

| Ion Exchange Membranes | |

| Anionic membrane | Neosepta AMX (perm selectivity of >93% and a thickness of 0.14 µm) |

| Cationic membrane | Neosepta CMX (perm selectivity of >90% and a thickness of 0.17 µm) |

| Operational conditions | |

| Flow rate | 142.1 mL/min |

| External resistance | 2.5, 9, and 100 Ω |

| Flow mode | Continuous fed-batch |

| Temperature | 25 ± 2 °C |

| Electric Conductivity (mS/cm) | COD (mg/L) | pH | ||||||

|---|---|---|---|---|---|---|---|---|

| Initial | Final | Removal | Initial | Final | Removal | Initial | Final | |

| Anolyte tank | 9.53 ± 0.19 | 9.98 ± 0.20 | - | 2496 ± 124 | 1676 ± 33 | 28% | 7.8 ± 0.4 | 7.6 ± 0.4 |

| Catholyte tank | 2.03 ± 0.04 | 0.9 ± 0.02 | - | - | - | - | 10.3 ± 0.5 | 9.5 ± 0.5 |

| Saline tank | 7.93 ± 0.16 | 0.96 ± 0.02 | 88% | - | - | - | 7.6 ± 0.4 | 7.9 ± 0.4 |

| Parameter | Value |

|---|---|

| Current density (mA/cm2) | 0.12 |

| Desalination time (h) | 31 |

| Current efficiency (%) | 60.15 |

| Salt removal (%) | 88 |

| Nominal Desalination Rate (L/m2/h) | 0.623 |

| Electric Power (kWh/m3) | 0.11 |

| COD removal (%) | 32.89 |

| COD removal rate (kg/m3/day) | 6.38 ** |

| Coulombic efficiency (%) | 9 |

| Catholyte | Electrochemical Output | Ref. | |||||

|---|---|---|---|---|---|---|---|

| Initial Conditions | Current Density (mA/cm2) /Electric Power (W/m3) | Current Efficiency (%) | Desalination (%) | Nominal Desalination Rate (L/m2/h)/ Desalination Rate (g/L/d) | Coulombic Efficiency (%) | ||

| Air Cathode | Salinity: 35 g/L The volume of saline water: 39 mL COD: 1500 mg/L Desalination time: ~48 h | 2.37 (mA)/8.74 W/m3 | - | 76.7 | 1.95 L/m2/h * | - | [55] |

| Air Cathode (air diffusion) | Salinity: 10 g/L The volume of saline water: 200 mL COD: 500 mg/L Desalination time: 25 h | 85 W/m3 * | - | 24.2 | 0.076 g/L/d | - | [14] |

| Air Cathode (air diffusion) | Salinity: 10 g/L COD: 1000 mg/L Desalination time: 96 h | 62 mA/ 30.8 W/m3 | - | 99 | - | 17 | [56] |

| Air Cathode (air diffusion) | Salinity: 10.7 g/L COD: 2500 mg/L Desalination time: 205 h | 0.20 mA/cm2 | 162 | 93.6 | 0.17 | 6.5 | [6] |

| Air Cathode (air diffusion) with Pt | Salinity: 20 g/L COD: 2 Acetate/g/L | 0.09 mA/cm2 | - | 50 | - | 57 | [57] |

| Micro-algae (Chlorella vulgaris) | Salinity: 10 g/L COD: 500 mg/L Desalination time: 1080 h | 1.1 W/m3 | - | 30 | - | 68.02 | [40] |

| Micro-algae (Chlorella vulgaris) | Salinity: 2 g/L COD: 2500 mg/L Desalination time: 31 h | 0.12 mA/cm2 | 60.15 | 85 | 0.63 | 9 | This study |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ewusi-Mensah, D.; Huang, J.; Chaparro, L.K.; Rodenas, P.; Ramírez-Moreno, M.; Ortiz, J.M.; Esteve-Núñez, A. Algae-Assisted Microbial Desalination Cell: Analysis of Cathode Performance and Desalination Efficiency Assessment. Processes 2021, 9, 2011. https://doi.org/10.3390/pr9112011

Ewusi-Mensah D, Huang J, Chaparro LK, Rodenas P, Ramírez-Moreno M, Ortiz JM, Esteve-Núñez A. Algae-Assisted Microbial Desalination Cell: Analysis of Cathode Performance and Desalination Efficiency Assessment. Processes. 2021; 9(11):2011. https://doi.org/10.3390/pr9112011

Chicago/Turabian StyleEwusi-Mensah, David, Jingyu Huang, Laura Katherin Chaparro, Pau Rodenas, Marina Ramírez-Moreno, Juan Manuel Ortiz, and Abraham Esteve-Núñez. 2021. "Algae-Assisted Microbial Desalination Cell: Analysis of Cathode Performance and Desalination Efficiency Assessment" Processes 9, no. 11: 2011. https://doi.org/10.3390/pr9112011

APA StyleEwusi-Mensah, D., Huang, J., Chaparro, L. K., Rodenas, P., Ramírez-Moreno, M., Ortiz, J. M., & Esteve-Núñez, A. (2021). Algae-Assisted Microbial Desalination Cell: Analysis of Cathode Performance and Desalination Efficiency Assessment. Processes, 9(11), 2011. https://doi.org/10.3390/pr9112011