Optimum Parameters for Extracting Three Kinds of Carotenoids from Pepper Leaves by Response Surface Methodology

Abstract

:1. Introduction

2. Materials and Methods

2.1. Plants and Growth Conditions

2.2. Reagents and Chemicals

2.3. HPLC Analytical Conditions

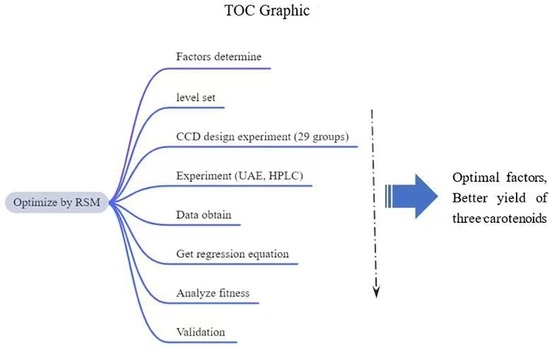

2.4. Experimental Design for Carotenoid Extraction

2.5. Validation of Working Curves and Standard Solutions

2.6. Determination of Carotenoid Content

2.7. Statistical Analysis

3. Results

3.1. Carotenoid Contents

3.2. Variance and Significance Analysis of Regression Model

3.3. Analysis of Response Surface Optimization Test on Contour and Surface Diagrams

3.4. Optimum Extraction Process

3.5. Validation Test

4. Discussion and Conclusions

4.1. Discussion

4.2. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Li, X.; Kang, S.; Li, F.; Zhang, X.; Huo, Z.; Ding, R.; Tong, L.; Du, T.; Li, S. Light Supplement and Carbon Dioxide Enrichment Affect Yield and Quality of Off-Season Pepper. Agron. J. 2017, 109, 2107–2118. [Google Scholar] [CrossRef]

- Pan, T.; Ding, J.; Qin, G.; Wang, Y.; Xi, L.; Yang, J.; Li, J.; Zhang, J.; Zou, Z. Interaction of Supplementary Light and CO2 Enrichment Improves Growth, Photosynthesis, Yield, and Quality of Tomato in Autumn through Spring Greenhouse Production. Hortscience 2019, 54, 246–252. [Google Scholar] [CrossRef] [Green Version]

- Rodriguez, E.; Sanchez-Prieto, M.; Olmedilla-Alonso, B. Assessment of carotenoid concentrations in red peppers (Capsicum annuum) under domestic refrigeration for three weeks as determined by HPLC-DAD. Food Chem. X 2020, 6, 100092. [Google Scholar] [CrossRef] [PubMed]

- Gomez-Garcia, M.D.; Ochoa-Alejo, N. Biochemistry and Molecular Biology of Carotenoid Biosynthesis in Chili Peppers (Capsicum spp.). Int. J. Mol. Sci. 2013, 14, 19025–19053. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Jing, L.; Jianming, X.; Jihua, Y.; Jian, L.; Junfeng, Z.; Xiaolong, W.; Cheng, W.; Chaonan, T.; Yingchun, Z.; Mujitaba, D.M.; et al. Reversed-Phase High-Performance Liquid Chromatography for the Quantification and Optimization for Extracting 10 Kinds of Carotenoids in Pepper (Capsicum annuum L.) Leaves. J. Agric. Food Chem. 2017, 65, 8475–8488. [Google Scholar]

- Xie, J.; Yu, J.; Huang, G.; Feng, Z. Relationship Between Carotenoid 784 Content and Low-Light-Tolerance or Chilling-and Low-Light-Tolerance of Pepper 785 Varieties. Sci. Agric. Sin. 2010, 43, 4036–4044. [Google Scholar]

- Langi, P.; Kiokias, S.; Varzakas, T.; Proestos, C. Carotenoids: From Plants to Food and Feed Industries. Methods Mol. Biol 2018, 1852, 57–71. [Google Scholar] [PubMed]

- Davinelli, S.; Nielsen, M.E.; Scapagnini, G. Astaxanthin in Skin Health, Repair, and Disease: A Comprehensive Review. Nutrients 2018, 10, 522. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Bernstein, P.S.; Li, B.; Vachali, P.P.; Gorusupudi, A.; Shyam, R.; Henriksen, B.S.; Nolan, J.M. Lutein, zeaxanthin, and meso-zeaxanthin: The basic and clinical science underlying carotenoid-based nutritional interventions against ocular disease. Prog. Retin. Eye Res. 2016, 50, 34–66. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Mares, J. Lutein and Zeaxanthin Isomers in Eye Health and Disease. Annu Rev. Nutr. 2016, 36, 571–602. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Zacarias-Garcia, J.; Rey, F.; Gil, J.-V.; Rodrigo, M.J.; Zacarias, L. Antioxidant capacity in fruit of Citrus cultivars with marked differences in pulp coloration: Contribution of carotenoids and vitamin C. Food Sci. Technol. Int. 2020, 27, 210–222. [Google Scholar] [CrossRef]

- Wisutiamonkul, A.; Ampomah-Dwamena, C.; Allan, A.C.; Ketsa, S. Carotenoid accumulation and gene expression during durian (Durio zibethinus) fruit growth and ripening. Sci. Hortic. 2017, 220, 233–242. [Google Scholar] [CrossRef]

- Lu, Q.; Huang, X.; Lv, S.; Pan, S. Carotenoid profiling of red navel orange "Cara Cara" harvested from five regions in China. Food Chem. 2017, 232, 788–798. [Google Scholar] [CrossRef]

- Etzbach, L.; Pfeiffer, A.; Weber, F.; Schieber, A. Characterization of carotenoid profiles in goldenberry (Physalis peruviana L.) fruits at various ripening stages and in different plant tissues by HPLC-DAD-APCI-MSn. Food Chem. 2018, 245, 508–517. [Google Scholar] [CrossRef]

- Rosalie, R.; Lechaudel, M.; Dhuique-Mayer, C.; Dufosse, L.; Joas, J. Antioxidant and enzymatic responses to oxidative stress induced by cold temperature storage and ripening in mango (Mangifera indica L. cv. ‘Cogshall’) in relation to carotenoid content. J. Plant. Physiol. 2018, 224, 75–85. [Google Scholar] [CrossRef] [PubMed]

- Mostofian, B.; Johnson, Q.R.; Smith, J.C.; Cheng, X. Carotenoids promote lateral packing and condensation of lipid membranes. Phys. Chem. Chem. Phys. 2020, 22, 12281–12293. [Google Scholar] [CrossRef]

- Seel, W.; Baust, D.; Sons, D.; Albers, M.; Etzbach, L.; Fuss, J.; Lipski, A. Carotenoids are used as regulators for membrane fluidity by Staphylococcus xylosus. Sci. Rep. 2020, 10, 330. [Google Scholar] [CrossRef] [PubMed]

- Sowa, M.; Yu, J.; Palacios-Rojas, N.; Goltz, S.R.; Howe, J.A.; Davis, C.R.; Rocheford, T.; Tanumihardjo, S.A. Retention of Carotenoids in Biofortified Maize Flour and beta-Cryptoxanthin-Enhanced Eggs after Household Cooking. ACS Omega 2017, 2, 7320–7328. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Skupien, J.; Wojtowicz, J.; Kowalewska, L.; Mazur, R.; Garstka, M.; Gieczewska, K.; Mostowska, A. Dark-chilling induces substantial structural changes and modifies galactolipid and carotenoid composition during chloroplast biogenesis in cucumber (Cucumis sativus L) cotyledons. Plant. Physiol. Biochem. 2017, 111, 107–118. [Google Scholar] [CrossRef] [PubMed]

- He, W.W.; Wang, Y.X.; Luo, H.; Li, D.J.; Liu, C.Q.; Song, J.F.; Zhang, Z.Y.; Liu, C.J.; Niua, L.Y. Effect of NaCl stress and supplemental CaCl2 on carotenoid accumulation in germinated yellow maize kernels. Food Chem. 2020, 309, 125779. [Google Scholar] [CrossRef] [PubMed]

- Kumar, P.; Yadav, S.; Singh, M.P. Possible involvement of xanthophyll cycle pigments in heat tolerance of chickpea (Cicer arietinum L.). Physiol. Mol. Biol. Plants 2020, 26, 1773–1785. [Google Scholar] [CrossRef] [PubMed]

- Corcuera, L.; Morales, F.; Abadia, A.; Gil-Pelegrin, E. Seasonal changes in photosynthesis and photoprotection in a Quercus ilex subsp. ballota woodland located in its upper altitudinal extreme in the Iberian Peninsula. Tree Physiol. 2005, 25, 599–608. [Google Scholar] [CrossRef]

- Sung, H.Y.; Jo, L.K.; Chun, J.H.; Woo, H.N.; Kim, S.J. Effects of Various Light Sources on the Carotenoid and Glucosinolate Contents in Chinese Cabbage (Brassica rapa L. ssp. pekinensis). Korean J. Environ. Agric. 2018, 37, 79–86. [Google Scholar] [CrossRef] [Green Version]

- Kumar, K.; Srivastav, S.; Sharanagat, V.S. Ultrasound assisted extraction (UAE) of bioactive compounds from fruit and vegetable processing by-products: A review. Ultrason. Sonochem. 2021, 70, 105325. [Google Scholar] [CrossRef] [PubMed]

- Peng, L. Optimization of ethanol fermentation with reducing sugars from camellia (camella oleifera) seed meal using response surface methodology. Therm. Sci. 2018, 22, S639–S647. [Google Scholar] [CrossRef] [Green Version]

- Jensen, W.A. Response Surface Methodology: Process and Product Optimization Using Designed Experiments 4th edition. J. Qual. Technol. 2017, 49, 186–187. [Google Scholar] [CrossRef]

- Alrweili, H.; Georgiou, S.; Stylianou, S. A New Class of Second-Order Response Surface Designs. IEEE Access 2020, 8, 115123–115132. [Google Scholar] [CrossRef]

- Yolmeh, M.; Jafari, S.M. Applications of Response Surface Methodology in the Food Industry Processes. Food Bioprocess. Technol. 2017, 10, 413–433. [Google Scholar] [CrossRef]

- Wen, H.; Kang, J.; Li, D.; Wen, W.; Yang, F.; Hu, H.; Liu, C. Antifungal activities of anthocyanins from purple sweet potato in the presence of food preservatives. Food Sci. Biotechnol. 2016, 25, 165–171. [Google Scholar] [CrossRef]

- Varadharajan, V.; Shanmugam, S.; Ramaswamy, A. Model generation and process optimization of microwave-assisted aqueous extraction of anthocyanins from grape juice waste. J. Food Process. Eng. 2017, 40, e12486. [Google Scholar] [CrossRef]

- Liaudanskas, M.; Zymone, K.; Viskelis, J.; Janulis, V. Optimisation of the Extraction of Flavonoids from Apples Using Response Surface Methodology. Ital. J. Food Sci. 2018, 30, 89–101. [Google Scholar]

- Yang, J.; Zhao, R.; Song, L.; Yin, J.; You, Y.; Sun, C.; Li, Y. Optimized Ultrasonic-Assisted Extraction of Aflatoxin B1 in Peanuts with Response Surface Methodology. Anal. Lett. 2017, 50, 629–640. [Google Scholar] [CrossRef]

- Zia, S.; Khan, M.R.; Shabbir, M.A.; Aslam Maan, A.; Khan, M.K.I.; Nadeem, M.; Khalil, A.A.; Din, A.; Aadil, R.M. An Inclusive Overview of Advanced Thermal and Nonthermal Extraction Techniques for Bioactive Compounds in Food and Food-related Matrices. Food Rev. Int. 2020, 1–31. [Google Scholar] [CrossRef]

- Yahya, N.A.; Attana, N.; Wahab, R.A. An overview of cosmeceutically relevant plant extracts and strategies for extraction of plant-based bioactive compounds. Food Bioprod. Process. 2018, 112, 69–85. [Google Scholar] [CrossRef]

- Lu, J.; Feng, X.; Han, Y.; Xue, C. Optimization of subcritical fluid extraction of carotenoids and chlorophyll a from Laminaria japonica Aresch by response surface methodology. J. Sci Food Agric. 2014, 94, 139–145. [Google Scholar] [CrossRef]

- Wang, L.; Lu, W.; Li, J.; Hu, J.; Ding, R.; Lv, M.; Wang, Q. Optimization of Ultrasonic-Assisted Extraction and Purification of Zeaxanthin and Lutein in Corn Gluten Meal. Molecules 2019, 24, 2994. [Google Scholar] [CrossRef] [Green Version]

- Briones-Labarca, V.; Giovagnoli-Vicuna, C.; Canas-Sarazua, R. Optimization of extraction yield, flavonoids and lycopene from tomato pulp by high hydrostatic pressure-assisted extraction. Food Chem 2019, 278, 751–759. [Google Scholar] [CrossRef]

- Wang, X.L. Study on the Separation and Content Determination of Different Carotene Components in Pepper Leaves [D]; Gansu Agricultural University: Lanzhou, China, 2015. [Google Scholar]

- Jo, J.; Shin, S.; Jung, H.; Min, B.; Kim, S.; Kim, J. Process Development for Production of Antioxidants from Lipid Extracted Microalgae Using Ultrasonic-assisted Extraction. Korean Chem. Eng. Res. 2017, 55, 542–547. [Google Scholar]

- Takemura, M.; Kubo, A.; Higuchi, Y.; Maoka, T.; Sahara, T.; Yaoi, K.; Ohdan, K.; Umeno, D.; Misawa, N. Pathway engineering for efficient biosynthesis of violaxanthin in Escherichia coli. Appl. Microbiol. Biotechnol. 2019, 103, 9393–9399. [Google Scholar] [CrossRef]

- Nasir, N.T.B.M.; Sahin, S.; Cakmak, Z.E.; Cakmak, T. Optimization of ultrasonic-assisted extraction via multiresponse surface for high antioxidant recovery from Chlorella vulgaris (Chlorophyta). Phycologia 2017, 56, 561–569. [Google Scholar] [CrossRef]

- Gunathilake, K.D.P.P.; Ranaweera, K.K.D.S.; Rupasinghe, H.P.V. Response surface optimization for recovery of polyphenols and carotenoids from leaves of Centella asiatica using an ethanol-based solvent system. Food Sci. Nutr. 2019, 7, 528–536. [Google Scholar] [CrossRef] [Green Version]

- Li, T.; Xu, J.; Wu, H.; Wang, G.; Dai, S.; Fan, J.; He, H.; Xiang, W. A Saponification Method for Chlorophyll Removal from Microalgae Biomass as Oil Feedstock. Mar. Drugs 2016, 14, 162. [Google Scholar] [CrossRef]

- Larsen, E.; Christensen, L.P. Simple saponification method for the quantitative determination of carotenoids in green vegetables. J. Agric. Food Chem. 2005, 53, 6598–6602. [Google Scholar] [CrossRef] [PubMed]

- Derrien, M.; Badr, A.; Gosselin, A.; Desjardins, Y.; Angers, P. Optimization of a sustainable purification protocol for lutein and chlorophyll from spinach updates by-products by a saponification procedure using Box Behnken design and desirability function. Food Bioprod. Process. 2019, 116, 54–62. [Google Scholar] [CrossRef]

- Kang, J.H.; Kim, S.; Moon, B. Optimization by response surface methodology of lutein recovery from paprika leaves using accelerated solvent extraction. Food Chem 2016, 205, 140–145. [Google Scholar] [CrossRef]

- Zaghdoudi, K.; Framboisier, X.; Frochot, C.; Vanderesse, R.; Barth, D.; Kalthoum-Cherif, J.; Blanchard, F.; Guiavarc’h, Y. Response surface methodology applied to Supercritical Fluid Extraction (SFE) of carotenoids from Persimmon (Diospyros kaki L.). Food Chem 2016, 208, 209–219. [Google Scholar] [CrossRef]

| Level | Ultrasound Time min (A) | Solid–Liquid Ratiog/mL (B) | Saponification Time min (C) | Saponification Solution Concentration V % (D) |

|---|---|---|---|---|

| −1 | 20 | 1/12 | 10 | 10 |

| 0 | 40 | 1/8 | 30 | 20 |

| 1 | 60 | 1/4 | 50 | 30 |

| Run Order | A | B | C | D |

|---|---|---|---|---|

| 1 | 30 | 1:6 | 40 | 25 |

| 2 | 40 | 1:8 | 30 | 20 |

| 3 | 60 | 1:8 | 30 | 20 |

| 4 | 50 | 1:10 | 40 | 15 |

| 5 | 30 | 1:10 | 20 | 25 |

| 6 | 40 | 1:8 | 30 | 10 |

| 7 | 50 | 1:6 | 20 | 15 |

| 8 | 30 | 1:6 | 40 | 15 |

| 9 | 50 | 1:6 | 40 | 15 |

| 10 | 30 | 1:6 | 20 | 15 |

| 11 | 30 | 1:10 | 40 | 15 |

| 12 | 40 | 1:4 | 30 | 20 |

| 13 | 40 | 1:8 | 10 | 20 |

| 14 | 40 | 1:12 | 30 | 20 |

| 15 | 30 | 1:10 | 40 | 25 |

| 16 | 40 | 1:8 | 50 | 20 |

| 17 | 50 | 1:10 | 20 | 25 |

| 18 | 50 | 1:10 | 40 | 25 |

| 19 | 40 | 1:8 | 30 | 20 |

| 20 | 50 | 1:10 | 20 | 15 |

| 21 | 20 | 1:8 | 30 | 20 |

| 22 | 40 | 1:8 | 30 | 20 |

| 23 | 30 | 1:6 | 20 | 25 |

| 24 | 40 | 1:8 | 30 | 20 |

| 25 | 40 | 1:8 | 30 | 30 |

| 26 | 50 | 1:6 | 20 | 25 |

| 27 | 40 | 1:8 | 30 | 20 |

| 28 | 30 | 1:10 | 20 | 15 |

| 29 | 50 | 1:6 | 40 | 25 |

| Order | Zeaxanthin μg/g | Lutein Epoxide μg/g | Violaxanthin μg/g |

|---|---|---|---|

| 1 | 0.6458 | 0.7242 | 9.2004 |

| 2 | 0.8118 | 3.9497 | 16.1590 |

| 3 | 0.6297 | 0.3069 | 4.1704 |

| 4 | 0.6497 | 1.6688 | 9.5840 |

| 5 | 0.7290 | 0.3723 | 2.6644 |

| 6 | 0.4750 | 0.7214 | 9.7940 |

| 7 | 0.1640 | 0.3456 | 8.6202 |

| 8 | 0.5035 | 1.0197 | 6.1351 |

| 9 | 0.4063 | 0.3554 | 6.3390 |

| 10 | 0.8059 | 1.0344 | 9.2515 |

| 11 | 0.6928 | 3.1546 | 11.3549 |

| 12 | 0.2260 | 0.4184 | 3.7583 |

| 13 | 0.5273 | 1.2497 | 9.1722 |

| 14 | 0.7886 | 0.5488 | 8.5340 |

| 15 | 0.6631 | 0.9658 | 8.1411 |

| 16 | 0.4951 | 2.2707 | 5.7207 |

| 17 | 0.5398 | 1.8681 | 13.5851 |

| 18 | 0.4673 | 3.8501 | 11.4879 |

| 19 | 0.8118 | 3.9497 | 16.1590 |

| 20 | 0.2683 | 1.2786 | 12.5240 |

| 21 | 0.5922 | 0.7547 | 7.7989 |

| 22 | 0.8118 | 3.9497 | 16.1590 |

| 23 | 0.5393 | 0.7326 | 9.6992 |

| 24 | 0.8118 | 3.9497 | 16.1590 |

| 25 | 0.5270 | 0.4200 | 11.7098 |

| 26 | 0.2153 | 0.3043 | 1.9771 |

| 27 | 0.8118 | 3.9497 | 16.1590 |

| 28 | 0.3669 | 0.5481 | 10.4746 |

| 29 | 0.1835 | 0.2056 | 15.0405 |

| Source | Sum of Squares | Df | Mean Square | f-Value | p-Value Prob > f | Difference Significant |

|---|---|---|---|---|---|---|

| Model | 0.90 | 14 | 0.064 | 3.16 | 0.0197 | ** |

| A | 0.15 | 1 | 0.15 | 7.36 | 0.0169 | ** |

| B | 0.16 | 1 | 0.16 | 7.84 | 0.0142 | ** |

| C | 0.015 | 1 | 0.015 | 0.73 | 0.4069 | |

| D | 9.428 × 10−4 | 1 | 9.428 × 10−4 | 0.046 | 0.8329 | |

| AB | 0.073 | 1 | 0.073 | 3.56 | 0.0801 | |

| AC | 8.837 × 10−3 | 1 | 8.837 × 10−3 | 0.43 | 0.5211 | |

| AD | 2.784 × 10−3 | 1 | 2.784 × 10−3 | 0.14 | 0.7174 | |

| BC | 0.025 | 1 | 0.025 | 1.23 | 0.2861 | |

| BD | 0.025 | 1 | 0.025 | 1.25 | 0.2829 | |

| CD | 0.025 | 1 | 0.025 | 1.22 | 0.2876 | |

| A2 | 0.088 | 1 | 0.088 | 4.30 | 0.0571 | |

| B2 | 0.18 | 1 | 0.18 | 8.98 | 0.0096 | ** |

| C2 | 0.18 | 1 | 0.18 | 8.78 | 0.0103 | ** |

| D2 | 0.19 | 1 | 0.19 | 9.32 | 0.0086 | ** |

| Residual | 0.29 | 14 | 0.020 | |||

| Lack of Fit | 0.29 | 10 | 0.029 | 2.960 × 10+8 | <0.0001 | *** |

| Pure Error | 3.859 × 10−10 | 4 | 9.649 × 10−11 | |||

| Cor Total | 1.19 | 28 | ||||

| R2 | 0.7595 |

| Source | Sum of Squares | Df | Mean Square | F-Value | p-Value Prob > F | Difference Significant |

|---|---|---|---|---|---|---|

| Model | 49.40 | 14 | 3.53 | 9.24 | <0.0001 | *** |

| A | 7.679 | 1 | 7.679 | 0.020 | 0.8892 | |

| B | 3.56 | 1 | 3.56 | 9.33 | 0.0086 | ** |

| C | 2.35 | 1 | 2.35 | 6.14 | 0.0265 | |

| D | 0.040 | 1 | 0.040 | 0.11 | 0.7497 | |

| AB | 2.19 | 1 | 2.19 | 5.75 | 0.0310 | ** |

| AC | 0.050 | 1 | 0.050 | 0.13 | 0.7231 | |

| AD | 1.92 | 1 | 1.92 | 5.03 | 0.0417 | ** |

| BC | 2.02 | 1 | 2.02 | 5.29 | 0.0374 | ** |

| BD | 0.089 | 1 | 0.089 | 0.23 | 0.6363 | |

| CD | 0.017 | 1 | 0.017 | 0.045 | 0.8353 | |

| A2 | 16.70 | 1 | 16.70 | 43.73 | <0.0001 | *** |

| B2 | 17.19 | 1 | 17.19 | 45.02 | <0.0001 | *** |

| C2 | 6.35 | 1 | 6.35 | 16.64 | 0.0011 | ** |

| D2 | 16.28 | 1 | 16.28 | 42.65 | <0.0001 | *** |

| Residual | 5.35 | 14 | 0.38 | |||

| Lack of Fit | 5.35 | 10 | 0.53 | 3.5214 | 0.052 | |

| Pure Error | 1.26 | 4 | 0.24 | |||

| Cor Total | 54.75 | 28 | ||||

| R2 | 0.9024 |

| Source | Sum of Squares | Df | Mean Square | F-Value | p-Value Prob > F | Difference Significant |

|---|---|---|---|---|---|---|

| Model | 364.48 | 14 | 26.03 | 2.82 | 0.0309 | ** |

| A | 1.03 | 1 | 1.03 | 0.11 | 0.7428 | |

| B | 22.24 | 1 | 22.24 | 2.41 | 0.1427 | |

| C | 0.10 | 1 | 0.10 | 0.011 | 0.9167 | |

| D | 0.075 | 1 | 0.075 | 8.163 | 0.9293 | |

| AB | 17.76 | 1 | 17.76 | 1.93 | 0.1870 | |

| AC | 0.56 | 1 | 0.56 | 0.061 | 0.8083 | |

| AD | 9.82 | 1 | 9.82 | 1.06 | 0.3196 | |

| BC | 2.14 | 1 | 2.14 | 0.23 | 0.6377 | |

| BD | 11.61 | 1 | 11.61 | 1.26 | 0.2807 | |

| CD | 34.23 | 1 | 34.23 | 3.71 | 0.0746 | |

| A2 | 135.54 | 1 | 135.54 | 14.70 | 0.0018 | ** |

| B2 | 130.80 | 1 | 130.80 | 14.18 | 0.0021 | ** |

| C2 | 95.67 | 1 | 95.67 | 10.37 | 0.0062 | ** |

| D2 | 31.04 | 1 | 31.04 | 3.37 | 0.0879 | |

| Residual | 129.12 | 14 | 9.22 | |||

| Lack of Fit | 129.12 | 10 | 12.91 | 1.29457 | 0.0687 | |

| Pure Error | 1.08 | 4 | 0.47 | |||

| Cor Total | 493.6 | 28 | ||||

| R2 | 0.7384 |

| Average Data | Extraction of Carotenoids (μg/g) | ||

|---|---|---|---|

| Zeaxanthin | Lutein Epoxide | Violaxanthin | |

| Predict value | 0.8230 | 4.0368 | 16.1972 |

| Actual value | 0.8118 | 3.9497 | 16.1590 |

| Relative deviation(%) | 1.36 | 2.16 | 0.24 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Li, N.; Li, J.; Ding, D.; Xie, J.; Zhang, J.; Li, W.; Ma, Y.; Gao, F.; Niu, T.; Wang, C.; et al. Optimum Parameters for Extracting Three Kinds of Carotenoids from Pepper Leaves by Response Surface Methodology. Separations 2021, 8, 134. https://doi.org/10.3390/separations8090134

Li N, Li J, Ding D, Xie J, Zhang J, Li W, Ma Y, Gao F, Niu T, Wang C, et al. Optimum Parameters for Extracting Three Kinds of Carotenoids from Pepper Leaves by Response Surface Methodology. Separations. 2021; 8(9):134. https://doi.org/10.3390/separations8090134

Chicago/Turabian StyleLi, Nenghui, Jing Li, Dongxia Ding, Jianming Xie, Jing Zhang, Wangxiong Li, Yufeng Ma, Feng Gao, Tianhang Niu, Cheng Wang, and et al. 2021. "Optimum Parameters for Extracting Three Kinds of Carotenoids from Pepper Leaves by Response Surface Methodology" Separations 8, no. 9: 134. https://doi.org/10.3390/separations8090134

APA StyleLi, N., Li, J., Ding, D., Xie, J., Zhang, J., Li, W., Ma, Y., Gao, F., Niu, T., Wang, C., & Bakpa, E. P. (2021). Optimum Parameters for Extracting Three Kinds of Carotenoids from Pepper Leaves by Response Surface Methodology. Separations, 8(9), 134. https://doi.org/10.3390/separations8090134