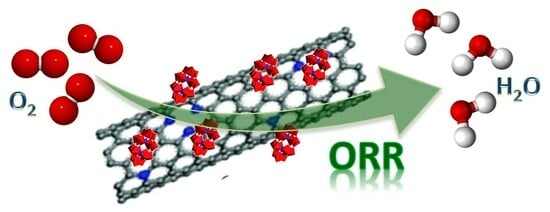

Hybrids Composed of an Fe-Containing Wells–Dawson Polyoxometalate and Carbon Nanomaterials as Promising Electrocatalysts for the Oxygen Reduction Reaction

Abstract

:1. Introduction

2. Experimental Section

Materials Preparation and Characterisation Methods

3. Results and Discussion

3.1. Materials Characterisation

3.2. Electrochemical Performance towards the ORR

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Perera, F. Pollution from Fossil-Fuel Combustion is the Leading Environmental Threat to Global Pediatric Health and Equity: Solutions Exist. Int. J. Environ. Res. Public Health 2018, 15, 16. [Google Scholar] [CrossRef] [PubMed]

- Nie, Y.; Li, L.; Wei, Z. Recent advancements in Pt and Pt-free catalysts for oxygen reduction reaction. Chem. Soc. Rev. 2015, 44, 2168–2201. [Google Scholar] [CrossRef] [PubMed]

- Stacy, J.; Regmi, Y.N.; Leonard, B.; Fan, M. The recent progress and future of oxygen reduction reaction catalysis: A review. Renew. Sustain. Energy Rev. 2017, 69, 401–414. [Google Scholar] [CrossRef]

- Xia, W.; Mahmood, A.; Liang, Z.; Zou, R.; Guo, S. Earth-Abundant Nanomaterials for Oxygen Reduction. Angew. Chem. Int. Ed. 2016, 55, 2650–2676. [Google Scholar] [CrossRef]

- Kuang, M.; Zheng, G. Nanostructured Bifunctional Redox Electrocatalysts. Small 2016, 12, 5656–5675. [Google Scholar] [CrossRef]

- Parvez, K.; Yang, S.; Hernandez, Y.; Winter, A.; Turchanin, A.; Feng, X.; Müllen, K. Nitrogen-Doped Graphene and Its Iron-Based Composite As Efficient Electrocatalysts for Oxygen Reduction Reaction. ACS Nano 2012, 6, 9541–9550. [Google Scholar] [CrossRef]

- Stamenkovic, V.R.; Mun, B.S.; Mayrhofer, K.J.J.; Ross, P.N.; Markovic, N.M. Effect of Surface Composition on Electronic Structure, Stability, and Electrocatalytic Properties of Pt-Transition Metal Alloys: Pt-Skin versus Pt-Skeleton Surfaces. J. Am. Chem. Soc. 2006, 128, 8813–8819. [Google Scholar] [CrossRef]

- Marković, N.M.; Ross, P.N. Surface science studies of model fuel cell electrocatalysts. Surf. Sci. Rep. 2002, 45, 117–229. [Google Scholar] [CrossRef]

- Nørskov, J.K.; Bligaard, T.; Rossmeisl, J.; Christensen, C.H. Towards the computational design of solid catalysts. Nat. Chem. 2009, 1, 37–46. [Google Scholar] [CrossRef]

- Cao, R.; Lee, J.-S.; Liu, M.; Cho, J. Recent Progress in Non-Precious Catalysts for Metal-Air Batteries. Adv. Energy Mater. 2012, 2, 816–829. [Google Scholar] [CrossRef]

- Jasinski, R. A New Fuel Cell Cathode Catalyst. Nature 1964, 201, 1212–1213. [Google Scholar] [CrossRef]

- Kuo, M.-C.; Stanis, R.J.; Ferrell, J.R., III; Turner, J.A.; Herring, A.M. Electrocatalyst materials for fuel cells based on the polyoxometalates—K7 or H7[(P2W17O61)FeIII(H2O)] and Na12 or H12[(P2W15O56)2FeIII4(H2O)2]. Electrochim. Acta 2007, 52, 2051–2061. [Google Scholar] [CrossRef]

- Samsudin, A.M.; Bodner, M.; Hacker, V. A Brief Review of Poly(Vinyl Alcohol)-Based Anion Exchange Membranes for Alkaline Fuel Cells. Polymers 2022, 14, 3565. [Google Scholar] [CrossRef]

- Zhang, X.; Li, H.; Yang, J.; Lei, Y.; Wang, C.; Wang, J.; Tang, Y.; Mao, Z. Recent advances in Pt-based electrocatalysts for PEMFCs. RSC Adv. 2021, 11, 13316–13328. [Google Scholar] [CrossRef] [PubMed]

- Yu, E.H.; Scott, K.; Reeve, R.W. Electrochemical Reduction of Oxygen on Carbon Supported Pt and Pt/Ru Fuel Cell Electrodes in Alkaline Solutions. Fuel Cells 2003, 3, 169–176. [Google Scholar] [CrossRef]

- Yin, H.; Liu, S.; Zhang, C.; Bao, J.; Zheng, Y.; Han, M.; Dai, Z. Well-Coupled Graphene and Pd-Based Bimetallic Nanocrystals Nanocomposites for Electrocatalytic Oxygen Reduction Reaction. ACS Appl. Mater. Interfaces 2014, 6, 2086–2094. [Google Scholar] [CrossRef]

- Lima, F.H.B.; Ticianelli, E.A. Oxygen electrocatalysis on ultra-thin porous coating rotating ring/disk platinum and platinum–cobalt electrodes in alkaline media. Electrochim. Acta 2004, 49, 4091–4099. [Google Scholar] [CrossRef]

- Todoroki, N.; Wadayama, T. Oxygen Reduction Reaction Activity for Cobalt-Deposited Pt(111) Model Catalyst Surfaces in Alkaline Solution. Denki Kagaku Oyobi Kōgyō Butsuri Kagaku 2018, 86, 243–245. [Google Scholar] [CrossRef]

- Wohlgemuth, S.-A.; White, R.J.; Willinger, M.-G.; Titirici, M.-M.; Antonietti, M. A one-pot hydrothermal synthesis of sulfur and nitrogen doped carbon aerogels with enhanced electrocatalytic activity in the oxygen reduction reaction. Green Chem. 2012, 14, 1515–1523. [Google Scholar] [CrossRef]

- Zheng, Y.; Jiao, Y.; Jaroniec, M.; Jin, Y.; Qiao, S.Z. Nanostructured Metal-Free Electrochemical Catalysts for Highly Efficient Oxygen Reduction. Small 2012, 8, 3550–3566. [Google Scholar] [CrossRef]

- Qu, L.; Liu, Y.; Baek, J.-B.; Dai, L. Nitrogen-Doped Graphene as Efficient Metal-Free Electrocatalyst for Oxygen Reduction in Fuel Cells. ACS Nano 2010, 4, 1321–1326. [Google Scholar] [CrossRef] [PubMed]

- Chen, Z.; Higgins, D.; Chen, Z. Nitrogen doped carbon nanotubes and their impact on the oxygen reduction reaction in fuel cells. Carbon 2010, 48, 3057–3065. [Google Scholar] [CrossRef]

- Debe, M.K. Electrocatalyst approaches and challenges for automotive fuel cells. Nature 2012, 486, 43–51. [Google Scholar] [CrossRef] [PubMed]

- Steele, B.C.H.; Heinzel, A. Materials for fuel-cell technologies. Nature 2001, 414, 345–352. [Google Scholar] [CrossRef] [PubMed]

- Gasteiger, H.A.; Kocha, S.S.; Sompalli, B.; Wagner, F.T. Activity benchmarks and requirements for Pt, Pt-alloy, and non-Pt oxygen reduction catalysts for PEMFCs. Appl. Catal. B Environ. 2005, 56, 9–35. [Google Scholar] [CrossRef]

- Wang, H.; Grabstanowicz, L.R.; Barkholtz, H.M.; Rebollar, D.; Kaiser, Z.B.; Zhao, D.; Chen, B.-H.; Liu, D.-J. Impacts of Imidazolate Ligand on Performance of Zeolitic-Imidazolate Framework-Derived Oxygen Reduction Catalysts. ACS Energy Lett. 2019, 4, 2500–2507. [Google Scholar] [CrossRef]

- Wang, X.; Fan, X.; Lin, H.; Fu, H.; Wang, T.; Zheng, J.; Li, X. An efficient Co–N–C oxygen reduction catalyst with highly dispersed Co sites derived from a ZnCo bimetallic zeolitic imidazolate framework. RSC Adv. 2016, 6, 37965–37973. [Google Scholar] [CrossRef]

- Freire, C.; Fernandes, D.M.; Nunes, M.; Abdelkader, V.K. POM & MOF-based Electrocatalysts for Energy-Related Reactions. ChemCatChem 2018, 10, 1703–1730. [Google Scholar] [CrossRef]

- Vikkisk, M.; Kruusenberg, I.; Ratso, S.; Joost, U.; Shulga, E.; Kink, I.; Rauwel, P.; Tammeveski, K. Enhanced electrocatalytic activity of nitrogen-doped multi-walled carbon nanotubes towards the oxygen reduction reaction in alkaline media. RSC Adv. 2015, 5, 59495–59505. [Google Scholar] [CrossRef]

- Jahnke, H.; Schönborn, M.; Zimmermann, G. Organic dyestuffs as catalysts for fuel cells. Top. Curr. Chem. 1976, 61, 133–181. [Google Scholar] [CrossRef]

- Gupta, S.; Tryk, D.; Bae, I.; Aldred, W.; Yeager, E. Heat-Treated Polyacrylonitrile-Based Catalysts for Oxygen Electroreduction. J. Appl. Electrochem. 1989, 19, 19–27. [Google Scholar] [CrossRef]

- Lefèvre, M.; Proietti, E.; Jaouen, F.; Dodelet, J.P. Iron-based catalysts with improved oxygen reduction activity in polymer electrolyte fuel cells. Science 2009, 324, 71–74. [Google Scholar] [CrossRef] [PubMed]

- Pylypenko, S.; Mukherjee, S.; Olson, T.S.; Atanassov, P. Non-platinum oxygen reduction electrocatalysts based on pyrolyzed transition metal macrocycles. Electrochim. Acta 2008, 53, 7875–7883. [Google Scholar] [CrossRef]

- Wu, G.; More, K.L.; Johnston, C.M.; Zelenay, P. High-performance electrocatalysts for oxygen reduction derived from polyaniline, iron, and cobalt. Science 2011, 332, 443–447. [Google Scholar] [CrossRef] [PubMed]

- Lin, H.; Wang, J.-W.; Guo, X.-W.; Yao, S.; Liu, M.; Zhang, Z.-M.; Lu, T.-B. Phosphorized polyoxometalate-etched iron-hydroxide porous nanotubes for efficient electrocatalytic oxygen evolution. J. Mater. Chem. A 2018, 6, 24479–24485. [Google Scholar] [CrossRef]

- Zhang, S.; Oms, O.; Hao, L.; Liu, R.; Wang, M.; Zhang, Y.; He, H.-Y.; Dolbecq, A.; Marrot, J.; Keita, B.; et al. High Oxygen Reduction Reaction Performances of Cathode Materials Combining Polyoxometalates, Coordination Complexes, and Carboneous Supports. ACS Appl. Mater. Interfaces 2017, 9, 38486–38498. [Google Scholar] [CrossRef]

- Fernandes, D.M.; Araújo, M.P.; Haider, A.; Mougharbel, A.S.; Fernandes, A.J.S.; Kortz, U.; Freire, C. Polyoxometalate-graphene Electrocatalysts for the Hydrogen Evolution Reaction. ChemElectroChem 2018, 5, 273–283. [Google Scholar] [CrossRef]

- Fernandes, D.M.; Novais, H.C.; Bacsa, R.; Serp, P.; Bachiller-Baeza, B.; Rodríguez-Ramos, I.; Guerrero-Ruiz, A.; Freire, C. Polyoxotungstate@Carbon Nanocomposites As Oxygen Reduction Reaction (ORR) Electrocatalysts. Langmuir 2018, 34, 6376–6387. [Google Scholar] [CrossRef]

- He, S.; Liu, Q.; Wang, X. Polyoxometalate-based materials: Quasi-homogeneous single-atom catalysts with atomic-precision structures. J. Mater. Chem. A 2022, 10, 5758–5770. [Google Scholar] [CrossRef]

- Shen, H.; Thomas, T.; Rasaki, S.A.; Saad, A.; Hu, C.; Wang, J.; Yang, M. Oxygen Reduction Reactions of Fe–N–C Catalysts: Current Status and the Way Forward. Electrochem. Energy Rev. 2019, 2, 252–276. [Google Scholar] [CrossRef]

- Jarrais, B.; Guedes, A.; Freire, C. Heteroatom-Doped Carbon Nanomaterials as Metal-Free Catalysts for the Reduction of 4-Nitrophenol. ChemistrySelect 2018, 3, 1737–1748. [Google Scholar] [CrossRef]

- Navaee, A.; Salimi, A.; Soltanian, S.; Servati, P. Facile one-pot synthesis of platinum nanoparticles decorated nitrogen-graphene with high electrocatalytic performance for oxygen reduction and anodic fuels oxidation. J. Power Sources 2015, 277, 268–276. [Google Scholar] [CrossRef]

- Olalde, B.; Aizpurua, J.M.; García, A.; Bustero, I.; Obieta, I.; Jurado, M.J. Single-Walled Carbon Nanotubes and Multiwalled Carbon Nanotubes Functionalized with Poly(l-lactic acid): A Comparative Study. J. Phys. Chem. C 2008, 112, 10663–10667. [Google Scholar] [CrossRef]

- Fernandes, D.M.; Freire, C. Carbon Nanomaterial–Phosphomolybdate Composites for Oxidative Electrocatalysis. ChemElectroChem 2015, 2, 269–279. [Google Scholar] [CrossRef]

- Daems, N.; Sheng, X.; Vankelecom, I.F.J.; Pescarmona, P.P. Metal-free doped carbon materials as electrocatalysts for the oxygen reduction reaction. J. Mater. Chem. A 2014, 2, 4085–4110. [Google Scholar] [CrossRef]

- Lee, D.W.; De Los Santos, V.L.; Seo, J.W.; Felix, L.L.; Bustamante, D.A.; Cole, J.M.; Barnes, C.H.W. The Structure of Graphite Oxide: Investigation of Its Surface Chemical Groups. J. Phys. Chem. B 2010, 114, 5723–5728. [Google Scholar] [CrossRef]

- Kumarasinghe, A.R.; Samaranayake, L.; Bondino, F.; Magnano, E.; Kottegoda, N.; Carlino, E.; Ratnayake, U.N.; de Alwis, A.A.P.; Karunaratne, V.; Amaratunga, G.A.J. Self-Assembled Multilayer Graphene Oxide Membrane and Carbon Nanotubes Synthesized Using a Rare Form of Natural Graphite. J. Phys. Chem. C 2013, 117, 9507–9519. [Google Scholar] [CrossRef]

- Lyon, D.K.; Miller, W.K.; Novet, T.; Domaille, P.J.; Evitt, E.; Johnson, D.C.; Finke, R.G. Highly oxidation resistant inorganic-porphyrin analog polyoxometalate oxidation catalysts. 1. The synthesis and characterization of aqueous-soluble potassium salts of α2-P2W17O61(Mn+·OH2)(n−10) and organic solvent soluble tetra-n-butylammonium salts of α2-P2W17O61(Mn+·Br)(n−11) (M = Mn3+, Fe3+, Co2+, Ni2+, Cu2+). J. Am. Chem. Soc. 1991, 113, 7209–7221. [Google Scholar] [CrossRef]

- Amiri, A.; Saadati-Moshtaghin, H.R.; Zonoz, F.M.; Targhoo, A. Preparation and characterization of magnetic Wells–Dawson heteropoly acid nanoparticles for magnetic solid-phase extraction of aromatic amines in water samples. J. Chromatogr. A 2017, 1483, 64–70. [Google Scholar] [CrossRef]

- Aricò, A.S.; Bruce, P.; Scrosati, B.; Tarascon, J.-M.; van Schalkwijk, W. Nanostructured materials for advanced energy conversion and storage devices. Nat. Mater. 2005, 4, 366–377. [Google Scholar] [CrossRef]

- Huang, M.-C.; Teng, H. Nitrogen-containing carbons from phenol–formaldehyde resins and their catalytic activity in NO reduction with NH3. Carbon 2003, 41, 951–957. [Google Scholar] [CrossRef]

- Artyushkova, K.; Serov, A.; Rojas-Carbonell, S.; Atanassov, P. Chemistry of Multitudinous Active Sites for Oxygen Reduction Reaction in Transition Metal–Nitrogen–Carbon Electrocatalysts. J. Phys. Chem. C 2015, 119, 25917–25928. [Google Scholar] [CrossRef]

- Limani, N.; Marques, I.S.; Jarrais, B.; Fernandes, A.J.S.; Freire, C.; Fernandes, D.M. Cobalt Phosphotungstate-Based Composites as Bifunctional Electrocatalysts for Oxygen Reactions. Catalysts 2022, 12, 357. [Google Scholar] [CrossRef]

- Estrade-Szwarckopf, H. XPS photoemission in carbonaceous materials: A “defect” peak beside the graphitic asymmetric peak. Carbon 2004, 42, 1713–1721. [Google Scholar] [CrossRef]

- Lipińska, M.E.; Rebelo, S.L.H.; Pereira, M.F.R.; Gomes, J.A.N.F.; Freire, C.; Figueiredo, J.L. New insights into the functionalization of multi-walled carbon nanotubes with aniline derivatives. Carbon 2012, 50, 3280–3294. [Google Scholar] [CrossRef]

- Ai, W.; Luo, Z.; Jiang, J.; Zhu, J.; Du, Z.; Fan, Z.; Xie, L.; Zhang, H.; Huang, W.; Yu, T. Nitrogen and Sulfur Codoped Graphene: Multifunctional Electrode Materials for High-Performance Li-Ion Batteries and Oxygen Reduction Reaction. Adv. Mater. 2014, 26, 6186–6192. [Google Scholar] [CrossRef]

- Liu, Y.; Qiao, Y.; Wei, G.; Li, S.; Lu, Z.; Wang, X.; Lou, X. Sodium storage mechanism of N, S co-doped nanoporous carbon: Experimental design and theoretical evaluation. Energy Storage Mater. 2018, 11, 274–281. [Google Scholar] [CrossRef]

- Novais, H.C.; Jarrais, B.; Haider, A.; Kortz, U.; Guerrero-Ruiz, A.; Rodríguez-Ramos, I.; Freire, C.; Fernandes, D.M. Electrocatalytic Oxygen Reduction Reaction on 48-Tungsto-8-Phosphate Wheel Anchored on Carbon Nanomaterials. Electrocatalysis 2022, 14, 294–305. [Google Scholar] [CrossRef]

- Imar, S.; Yaqub, M.; Maccato, C.; Dickinson, C.; Laffir, F.; Vagin, M.; McCormac, T. Nitrate and Nitrite Electrocatalytic Reduction at Layer-by-Layer Films Composed of Dawson-Type Heteropolyanions Mono-Substituted with Transitional Metal Ions and Silver Nanoparticles. Electrochim. Acta 2015, 184, 323–330. [Google Scholar] [CrossRef]

- Li, X.-H.; Chen, W.-L.; He, P.; Wang, T.; Liu, D.; Li, Y.-W.; Li, Y.-G.; Wang, E.-B. Dawson-type polyoxometalate-based vacancies g-C3N4 composite-nanomaterials for efficient photocatalytic nitrogen fixation. Inorg. Chem. Front. 2019, 6, 3315–3326. [Google Scholar] [CrossRef]

- Dai, L.; Xue, Y.; Qu, L.; Choi, H.-J.; Baek, J.-B. Metal-free catalysts for oxygen reduction reaction. Chem. Rev. 2015, 115, 4823–4892. [Google Scholar] [CrossRef] [PubMed]

- Ni, S.; Li, Z.; Yang, J. Oxygen molecule dissociation on carbon nanostructures with different types of nitrogen doping. Nanoscale 2012, 4, 1184–1189. [Google Scholar] [CrossRef] [PubMed]

- Subramanian, N.P.; Li, X.; Nallathambi, V.; Kumaraguru, S.P.; Colon-Mercado, H.; Wu, G.; Lee, J.-W.; Popov, B.N. Nitrogen-modified carbon-based catalysts for oxygen reduction reaction in polymer electrolyte membrane fuel cells. J. Power Sources 2009, 188, 38–44. [Google Scholar] [CrossRef]

- Fernandes, D.M.; Mathumba, P.; Fernandes, A.J.S.; Iwuoha, E.I.; Freire, C. Towards efficient oxygen reduction reaction electrocatalysts through graphene doping. Electrochim. Acta 2019, 319, 72–81. [Google Scholar] [CrossRef]

- Kakaei, K.; Esrafili, M.D.; Ehsani, A. (Eds.) Chapter 6—Oxygen Reduction Reaction. In Interface Science and Technology; Elsevier: Amsterdam, The Netherlands, 2019; Volume 27, pp. 203–252. [Google Scholar]

- Zheng, Y.; Jiao, Y.; Ge, L.; Jaroniec, M.; Qiao, S.Z. Two-step boron and nitrogen doping in graphene for enhanced synergistic catalysis. Angew. Chem. 2013, 125, 3192–3198. [Google Scholar] [CrossRef]

- Mamlouk, M.; Kumar, S.S.; Gouerec, P.; Scott, K. Electrochemical and fuel cell evaluation of Co based catalyst for oxygen reduction in anion exchange polymer membrane fuel cells. J. Power Sources 2011, 196, 7594–7600. [Google Scholar] [CrossRef]

- Zhou, R.; Zheng, Y.; Jaroniec, M.; Qiao, S.-Z. Determination of the electron transfer number for the oxygen reduction reaction: From theory to experiment. ACS Catal. 2016, 6, 4720–4728. [Google Scholar] [CrossRef]

- Ramaswamy, N.; Mukerjee, S. Fundamental mechanistic understanding of electrocatalysis of oxygen reduction on Pt and non-Pt surfaces: Acid versus alkaline media. Adv. Phys. Chem. 2012, 2012, 491604. [Google Scholar] [CrossRef]

- Fletcher, S. Tafel slopes from first principles. J. Solid State Electrochem. 2009, 13, 537–549. [Google Scholar] [CrossRef]

- Zúñiga, C.; Candia-Onfray, C.; Venegas, R.; Muñoz, K.; Urra, J.; Sánchez-Arenillas, M.; Marco, J.F.; Zagal, J.H.; Recio, F.J. Elucidating the mechanism of the oxygen reduction reaction for pyrolyzed Fe–N–C catalysts in basic media. Electrochem. Commun. 2019, 102, 78–82. [Google Scholar] [CrossRef]

- Jiao, Y.; Zheng, Y.; Jaroniec, M.; Qiao, S.Z. Design of electrocatalysts for oxygen- and hydrogen-involving energy conversion reactions. Chem. Soc. Rev. 2015, 44, 2060–2086. [Google Scholar] [CrossRef] [PubMed]

- Liu, X.; Liu, Y.; Fan, L.-Z. MOF-derived CoSe2 microspheres with hollow interiors as high-performance electrocatalysts for the enhanced oxygen evolution reaction. J. Mater. Chem. A 2017, 5, 15310–15314. [Google Scholar] [CrossRef]

- Liu, S.; Wang, Z.; Zhou, S.; Yu, F.; Yu, M.; Chiang, C.Y.; Zhou, W.; Zhao, J.; Qiu, J. Metal–organic-framework-derived hybrid carbon nanocages as a bifunctional electrocatalyst for oxygen reduction and evolution. Adv. Mater. 2017, 29, 1700874. [Google Scholar] [CrossRef] [PubMed]

- Lach, J.; Wróbel, K.; Wróbel, J.; Podsadni, P.; Czerwiński, A. Applications of carbon in lead-acid batteries: A review. J. Solid State Electrochem. 2019, 23, 693–705. [Google Scholar] [CrossRef]

- Liang, Y.; Wang, H.; Zhou, J.; Li, Y.; Wang, J.; Regier, T.; Dai, H. Covalent Hybrid of Spinel Manganese–Cobalt Oxide and Graphene as Advanced Oxygen Reduction Electrocatalysts. J. Am. Chem. Soc. 2012, 134, 3517–3523. [Google Scholar] [CrossRef]

- Araújo, M.P.; Nunes, M.; Rocha, I.M.; Pereira, M.F.R.; Freire, C. Co3O4 Nanoparticles Anchored on Selectively Oxidized Graphene Flakes as Bifunctional Electrocatalysts for Oxygen Reactions. ChemistrySelect 2018, 3, 10064–10076. [Google Scholar] [CrossRef]

- Lei, Z.; Feng, W.; Feng, C.; Zhou, W.; Wei, C.; Wang, X. Nitrified coke wastewater sludge flocs: An attractive precursor for N,S dual-doped graphene-like carbon with ultrahigh capacitance and oxygen reduction performance. J. Mater. Chem. A 2017, 5, 2012–2020. [Google Scholar] [CrossRef]

- Wang, Z.; Lu, Y.; Yan, Y.; Larissa, T.Y.P.; Zhang, X.; Wuu, D.; Zhang, H.; Yang, Y.; Wang, X. Core-shell carbon materials derived from metal-organic frameworks as an efficient oxygen bifunctional electrocatalyst. Nano Energy 2016, 30, 368–378. [Google Scholar] [CrossRef]

- Xia, S.; Guo, W.; Cai, N.; Sun, L.; Zhou, H.; Lu, W.; Chen, X.; Zhang, J.; Chen, Y.; Yang, H.; et al. Synthesis and application in oxygen reduction reaction of N-doping porous graphitic carbon from biomass waste. Fuel Process. Technol. 2021, 224, 107028. [Google Scholar] [CrossRef]

- Olah, G.A. Towards Oil Independence Through Renewable Methanol Chemistry. Angew. Chem. Int. Ed. 2013, 52, 104–107. [Google Scholar] [CrossRef]

- Kumar, A.; Daw, P.; Milstein, D. Homogeneous Catalysis for Sustainable Energy: Hydrogen and Methanol Economies, Fuels from Biomass, and Related Topics. Chem. Rev. 2022, 122, 385–441. [Google Scholar] [CrossRef] [PubMed]

- Lo Vecchio, C.; Sebastián, D.; Lázaro, M.J.; Aricò, A.S.; Baglio, V. Methanol-Tolerant M–N–C Catalysts for Oxygen Reduction Reactions in Acidic Media and Their Application in Direct Methanol Fuel Cells. Catalysts 2018, 8, 650. [Google Scholar] [CrossRef]

- Mathumba, P.; Fernandes, D.M.; Matos, R.; Iwuoha, E.I.; Freire, C. Metal Oxide (Co3O4 and Mn3O4) Impregnation into S, N-doped Graphene for Oxygen Reduction Reaction (ORR). Materials 2020, 13, 1562. [Google Scholar] [CrossRef] [PubMed]

- Hoang, S.; Guo, S.; Hahn, N.T.; Bard, A.J.; Mullins, C.B. Visible Light Driven Photoelectrochemical Water Oxidation on Nitrogen-Modified TiO2 Nanowires. Nano Lett. 2012, 12, 26–32. [Google Scholar] [CrossRef]

- Tuci, G.; Zafferoni, C.; Rossin, A.; Milella, A.; Luconi, L.; Innocenti, M.; Phuoc, L.T.; Duong-Viet, C.; Pham-Huu, C.; Giambastiani, G. Chemically functionalized carbon nanotubes with pyridine groups as easily tunable N-decorated nanomaterials for the oxygen reduction reaction in alkaline medium. Chem. Mater. 2014, 26, 3460–3470. [Google Scholar] [CrossRef]

- Muthuswamy, N.; Buan, M.E.M.; Walmsley, J.C.; Rønning, M. Evaluation of ORR active sites in nitrogen-doped carbon nanofibers by KOH post treatment. Catal. Today 2018, 301, 11–16. [Google Scholar] [CrossRef]

- Chen, X.; Zhang, W.; Qu, Y.; Chen, X.; Liu, Y.; Lu, C. Solvent-free synthesis of honeycomb-like N-doped porous carbon derived from biomass pine sawdust as an efficient metal-free electrocatalyst for oxygen reduction reaction. J. Electroanal. Chem. 2022, 926, 116909. [Google Scholar] [CrossRef]

- Ingavale, S.; Patil, I.; Prabakaran, K.; Swami, A. Microwave-assisted synthesis of cobalt-polyoxometalate@ carbon black nanocomposites and their electrocatalytic ability toward oxygen reduction reaction. Int. J. Energy Res. 2021, 45, 7366–7379. [Google Scholar] [CrossRef]

- Fernandes, D.M.; Mestre, A.S.; Martins, A.; Nunes, N.; Carvalho, A.P.; Freire, C. Biomass-derived nanoporous carbons as electrocatalysts for oxygen reduction reaction. Catal. Today 2020, 357, 269–278. [Google Scholar] [CrossRef]

- Nunes, M.; Fernandes, D.M.; Rocha, I.M.; Pereira, M.F.; Mbomekalle, I.M.; de Oliveira, P.; Freire, C. Phosphomolybdate@ Carbon-Based Nanocomposites as Electrocatalysts for Oxygen Reduction Reaction. ChemistrySelect 2016, 1, 6257–6266. [Google Scholar] [CrossRef]

- Su, Y.; Jiang, H.; Zhu, Y.; Yang, X.; Shen, J.; Zou, W.; Chen, J.; Li, C. Enriched graphitic N-doped carbon-supported Fe3O4 nanoparticles as efficient electrocatalysts for oxygen reduction reaction. J. Mater. Chem. A 2014, 2, 7281–7287. [Google Scholar] [CrossRef]

- Zhang, H.; Li, H.; Wang, H.; He, K.; Wang, S.; Tang, Y.; Chen, J. NiCo2O4/N-doped graphene as an advanced electrocatalyst for oxygen reduction reaction. J. Power Sources 2015, 280, 640–648. [Google Scholar] [CrossRef]

- Yang, Z.; Wu, J.; Zheng, X.; Wang, Z.; Yang, R. Enhanced catalytic activity for the oxygen reduction reaction with co-doping of phosphorus and iron in carbon. J. Power Sources 2015, 277, 161–168. [Google Scholar] [CrossRef]

- Ning, R.; Tian, J.; Asiri, A.M.; Qusti, A.H.; Al-Youbi, A.O.; Sun, X. Spinel CuCo2O4 nanoparticles supported on N-doped reduced graphene oxide: A highly active and stable hybrid electrocatalyst for the oxygen reduction reaction. Langmuir 2013, 29, 13146–13151. [Google Scholar] [CrossRef]

- Hossen, M.M.; Artyushkova, K.; Atanassov, P.; Serov, A. Synthesis and characterization of high performing Fe-NC catalyst for oxygen reduction reaction (ORR) in Alkaline Exchange Membrane Fuel Cells. J. Power Sources 2018, 375, 214–221. [Google Scholar] [CrossRef]

- Lu, F.; Fan, K.; Cui, L.; Li, B.; Yang, Y.; Zong, L.; Wang, L. Engineering FeN4 active sites onto nitrogen-rich carbon with tubular channels for enhanced oxygen reduction reaction performance. Appl. Catal. B Environ. 2022, 313, 121464. [Google Scholar] [CrossRef]

| Material | XPS Atomic % a | |||||

|---|---|---|---|---|---|---|

| C1s | O1s | N1s | P2p | W4f | Fe 2p | |

| GF | 96.8 | 3.2 | - | - | - | -- |

| MWCNT | 98.9 | 1.1 | - | - | - | - |

| GF_N8 | 97.0 | 2.0 | 1.0 | - | - | - |

| MWCNT_N8 | 98.0 | 1.0 | 1.0 | - | - | - |

| P2W17Fe@GF_N8 | 92.6 | 6.0 | 0.62 | 0.10 | 0.61 | 0.16 |

| P2W17Fe@MWCNT_N8 | 95.0 | 3.4 | 0.68 | 0.12 | 0.63 | 0.12 |

| Samples | Eonset vs. RHE (V) | jL (mA cm−2) | Tafel Slope (mV dec−1) | nO2 |

|---|---|---|---|---|

| Pt/C | 0.94 | −4.7 | 89 | 4.0 |

| GF | 0.72 | −2.0 | 63 | 2.4 |

| MWCNT | 0.69 | −2.0 | 54 | 2.1 |

| GF_N8 | 0.83 | −3.3 | 70 | 2.5 |

| MWCNT_N8 | 0.83 | −4.0 | 47 | 3.5 |

| P2W17Fe@GF_N8 | 0.83 | −3.3 | 58 | 3.1 |

| P2W17Fe@MWCNT_N8 | 0.84 | −3.9 | 48 | 3.4 |

| CM Support | Cdl (mF cm−2) | Composite | Cdl (mF cm−2) | Composite/Carbon Support Cdl Ratio |

|---|---|---|---|---|

| GF_N8 | 0.0228 | P2W17Fe@GF_N8 | 0.0317 | 1.39 |

| MWCNT_N8 | 0.0203 | P2W17Fe@MWCNT_N8 | 0.0808 | 3.98 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Novais, H.C.; Jarrais, B.; Mbomekallé, I.-M.; Teillout, A.-L.; Oliveira, P.d.; Freire, C.; Fernandes, D.M. Hybrids Composed of an Fe-Containing Wells–Dawson Polyoxometalate and Carbon Nanomaterials as Promising Electrocatalysts for the Oxygen Reduction Reaction. Inorganics 2023, 11, 388. https://doi.org/10.3390/inorganics11100388

Novais HC, Jarrais B, Mbomekallé I-M, Teillout A-L, Oliveira Pd, Freire C, Fernandes DM. Hybrids Composed of an Fe-Containing Wells–Dawson Polyoxometalate and Carbon Nanomaterials as Promising Electrocatalysts for the Oxygen Reduction Reaction. Inorganics. 2023; 11(10):388. https://doi.org/10.3390/inorganics11100388

Chicago/Turabian StyleNovais, Hugo C., Bruno Jarrais, Israël-Martyr Mbomekallé, Anne-Lucie Teillout, Pedro de Oliveira, Cristina Freire, and Diana M. Fernandes. 2023. "Hybrids Composed of an Fe-Containing Wells–Dawson Polyoxometalate and Carbon Nanomaterials as Promising Electrocatalysts for the Oxygen Reduction Reaction" Inorganics 11, no. 10: 388. https://doi.org/10.3390/inorganics11100388

APA StyleNovais, H. C., Jarrais, B., Mbomekallé, I. -M., Teillout, A. -L., Oliveira, P. d., Freire, C., & Fernandes, D. M. (2023). Hybrids Composed of an Fe-Containing Wells–Dawson Polyoxometalate and Carbon Nanomaterials as Promising Electrocatalysts for the Oxygen Reduction Reaction. Inorganics, 11(10), 388. https://doi.org/10.3390/inorganics11100388