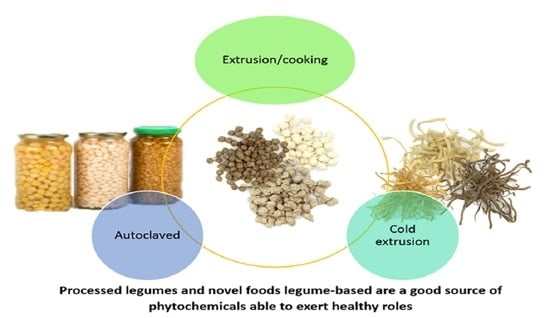

Autoclaved and Extruded Legumes as a Source of Bioactive Phytochemicals: A Review

Abstract

:1. Introduction

2. Methodology

3. Content of Some Bioactive Compounds in Raw Pulses and Their Health Effects in Humans

3.1. α-Galactosides

3.2. Myo-Inositol Phosphates

3.3. Protease Inhibitors

3.4. Phenolic Compounds

4. Effect of Autoclaving on the Bioactive Compounds of Pulses

4.1. Autoclaving Process

4.2. Autoclaving Effect on the α-Galactosides of Pulses

4.3. Autoclaving Effect on the Myo-Inositol Phosphates of Pluses

4.4. Autoclaving Effect on the Protease Inhibitors of Pulses

4.5. Autoclaving Effect on the Phenolic Compounds of Pulses and Their Antioxidant Activity

5. Effect of Extrusion/Cooking on the Bioactive Compounds of Pulses

5.1. Extrusion/Cooking Process

5.2. Extrusion/Cooking Effect on the α-Galactosides of Pulses

5.3. Extrusion/Cooking Effect on the Myo-Inositol Phosphates of Pulses

5.4. Extrusion/Cooking Effect on the Protease Inhibitors of Pulses

5.5. Extrusion/Cooking Effect on the Phenolic Compounds of Pulses and Their Antioxidant Activity

6. Effect of Cold Extrusion on the Bioactive Compounds of Pulses

6.1. Cold Extrusion Process

6.2. Cold Extrusion Effect on the α-Galactosides of Pasta Fortified with Legumes

6.3. Cold Extrusion Effects on the Myo-Inositol Phosphate Content of Pasta Fortified with Legumes

6.4. Cold Extrusion Effects on the Protease Inhibitors of Pasta Fortified with Legumes

6.5. Cold Extrusion Effects on the Phenols and Their Antioxidant Activity of Pasta Fortified with legumes

7. Concluding Remarks

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Conflicts of Interest

References

- Boye, J.; Zare, F.; Pletch, A. Pulse proteins: Processing, characterization, functional properties and applications in food and feed. Food Res. Int. 2010, 43, 414–431. [Google Scholar] [CrossRef]

- Duranti, M. Grain legume proteins and nutraceutical properties. Fitoterapia 2006, 77, 67–82. [Google Scholar] [CrossRef] [PubMed]

- Sparvoli, F.; Bollini, R.; Cominelli, E. Nutritional Value. In Grain Legumes; Ron, A.M.D., Ed.; Springer: New Work, NY, USA, 2015; pp. 291–326. [Google Scholar] [CrossRef]

- Dogan, H.; Gueven, A.; Hicsasmaz, Z. Extrusion Cooking of Lentil Flour (Lens Culinaris–Red)–Corn Starch–Corn Oil Mixtures. Int. J. Food Prop. 2013, 16, 341–358. [Google Scholar] [CrossRef] [Green Version]

- Pedrosa, M.M.; Cuadrado, C.; Burbano, C.; Muzquiz, M.; Cabellos, B.; Olmedilla-Alonso, B.; Asensio-Vegas, C. Effects of industrial canning on the proximate composition, bioactive compounds contents and nutritional profile of two Spanish common dry beans (Phaseolus vulgaris L.). Food Chem. 2015, 166, 68–75. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Maphosa, Y.; Jideani, V.A. The Role of Legumes in Human Nutrition. In Functional Food—Improve Health through Adequate Food; Hueda, M.C., Ed.; IntechOpen: London, UK, 2017. [Google Scholar] [CrossRef] [Green Version]

- FAO. Resolution 68/231. International Year of Pulses. 2016. Available online: http://www.fao.org/ (accessed on 6 May 2020).

- US Dietary Guidelines for Americans; U.S. Department of Health and Human Services: Washington, DC, USA, 2005; Volume 2011.

- Muzquiz, M.; Varela, A.; Burbano, C.; Cuadrado, C.; Guillamón, E.; Pedrosa, M.M. Bioactive compounds in legumes: Pronutritive and antinutritive actions. Implications for nutrition and health. Phyt. Rev. 2012, 11, 227–244. [Google Scholar] [CrossRef]

- Carbonaro, M. 14-Role of pulses in nutraceuticals. In Pulse Foods; Tiwari, B.K., Gowen, A., McKenna, B., Eds.; Academic Press: San Diego, CA, USA, 2011; pp. 385–418. [Google Scholar] [CrossRef]

- Singh, B.; Singh, J.P.; Shevkani, K.; Singh, N.; Haur, A. Bioactive constituents in pulses and their health benefits. J. Food Sci. Technol. 2017, 54, 858–870. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Aguilera, Y.; Diaz, M.F.; Jimenez, T.; Benitez, V.; Herrera, T.; Cuadrado, C.; Martin-Pedrosa, M.; Martin-Cabrejas, M.A. Changes in nonnutritional factors and antioxidant activity during germination of non-conventional legumes. J. Agric. Food Chem. 2013. [Google Scholar] [CrossRef]

- Berrios, J. Extrusion Cooking: Legume Pulses. In Encyclopedia of Agricultural, Food, and Biological Engineering, 2nd ed.; CRC Press: Boca Raton, FL, USA, 2010; pp. 453–464. [Google Scholar] [CrossRef]

- Carvalho, A.; de Andrade Mattietto, R.; Bassinello, P.; Nakamoto Koakuzu, S.; Rios, A.; Maciel, R.; Nunes Carvalho, R. Processing and characterization of extruded breakfast meal formulated with broken rice and bean flour. Ciência e Tecnologia de Alimentos 2012, 32, 515–524. [Google Scholar] [CrossRef] [Green Version]

- Dueñas, M.; Sarmento, T.; Aguilera, Y.; Benitez, V.; Mollá, E.; Esteban, R.M.; Martín-Cabrejas, M.A. Impact of cooking and germination on phenolic composition and dietary fibre fractions in dark beans (Phaseolus vulgaris L.) and lentils (Lens culinaris L.). LWT-Food Sci. Technol. 2016, 66, 72–78. [Google Scholar] [CrossRef]

- El Siddig, O.; El Tinay, A.; Abd Alia, A.; Elkhalifa, A. Proximate composition, minerals, tannins, in vitro protein digestibility and effect of cooking on protein fractions of hyacinth bean (Dolichos lablab). J. Food Sci. Technol. 2002, 39, 111–115. [Google Scholar]

- Kamau, E.H.; Nkhata, S.G.; Ayua, E.O. Extrusion and nixtamalization conditions influence the magnitude of change in the nutrients and bioactive components of cereals and legumes. Food Sci. Nutr. 2020, 8, 1753–1765. [Google Scholar] [CrossRef]

- Arribas, C.; Cabellos, B.; Cuadrado, C.; Guillamón, E.; Pedrosa, M. The effect of extrusion on the bioactive compounds and antioxidant capacity of novel gluten-free expanded products based on carob fruit, pea and rice blends. Innov. Food Sci. Emer. Technol. 2019, 52, 100–107. [Google Scholar] [CrossRef]

- Pasqualone, A.; Costantini, M.; Coldea, T.E.; Summo, C. Use of legumes in extrusion cooking: A review. Foods 2020, 9, 958. [Google Scholar] [CrossRef]

- van Boekel, M.; Fogliano, V.; Pellegrini, N.; Stanton, C.; Scholz, G.; Lalljie, S.; Somoza, V.; Knorr, D.; Jasti, P.R.; Eisenbrand, G. A review on the beneficial aspects of food processing. Mol. Nutr. Food Res. 2010, 54, 1215–1247. [Google Scholar] [CrossRef]

- Singh, S.; Gamlath, S.; Wakeling, L. Nutritional aspects of food extrusion: A review. Int. J. Food Sci. Technol. 2007, 42, 916–929. [Google Scholar] [CrossRef]

- Barman, A.; Marak, C.M.; Barman, R.M.; Sangma, C.S. Nutraceutical Properties of Legume Seeds and Their Impact on Human Health, Legume Seed Nutraceutical Research. In Legume Seed Nutraceutical Research; Jimenez-Lopez, J.C., Clemente, A., Eds.; IntechOpen: London, UK, 2018. [Google Scholar] [CrossRef] [Green Version]

- Sanchez-Chino, X.; Jimenez-Martinez, C.; Davila-Ortiz, G.; Alvarez-Gonzalez, I.; Madrigal-Bujaidar, E. Nutrient and nonnutrient components of legumes, and its chemopreventive activity: A review. Nutr. Cancer 2015, 67, 401–410. [Google Scholar] [CrossRef] [PubMed]

- Amarowicz, R.; Pegg, R.B. Legumes as a source of natural antioxidants. Eur. J. Lipid Sci. Technol. 2008, 110, 865–878. [Google Scholar] [CrossRef]

- Martínez-Villaluenga, C.; Frias, J.; Vidal-Valverde, C. Alpha-galactosides: Antinutritional factors or functional ingredients? Crit. Rev. Food Sci. Nutr. 2008, 48, 301–316. [Google Scholar] [CrossRef] [PubMed]

- Burbano, C.; Muzquiz, M.; Ayet, G.; Cuadrado, C.; Pedrosa, M.M. Evaluation of antinutritional factors of selected varieties of Phaseolus vulgaris. J. Sci. Food Agric. 1999, 79, 1468–1472. [Google Scholar] [CrossRef]

- Greiner, R.; Konietzny, U. Improving enzymatic reduction of myo-inositol phosphates with inhibitory effects on mineral absortion in black beans (Phaseolus vulgaris var. Preto). J. Food Process. Preserv. 1999, 23, 249–261. [Google Scholar] [CrossRef]

- Schlemmer, U.; Frølich, W.; Prieto, R.M.; Grases, F. Phytate in foods and significance for humans: Food sources, intake, processing, bioavailability, protective role and analysis. Mol. Nutr. Food Res. 2009, 53, S330–S375. [Google Scholar] [CrossRef]

- Fredrikson, M.; Biot, P.; Alminger, M.; Carlsson, N.; Sandberg, A. Production Process for High-Quality Pea-Protein Isolate with Low Content of Oligosaccharides and Phytate. J. Agric. Food Chem. 2001, 49, 1208–1212. [Google Scholar] [CrossRef]

- Hurrell, R.F.; Juillerat, M.A.; Reddy, M.B.; Lynch, S.R.; Dassenko, S.A.; Cook, J.D. Soy protein, phytate, and iron absorption in humans. Am. J. Clin. Nutr. 1992, 56, 573–578. [Google Scholar] [CrossRef] [PubMed]

- Guillamón, E.; Pedrosa, M.M.; Burbano, C.; Cuadrado, C.; Sánchez, M.C.; Muzquiz, M. The trypsin inhibitors present in seed of different grain legume species and cultivar. Food Chem. 2008, 107, 68–74. [Google Scholar] [CrossRef]

- Clemente, A.; Mackenzie, D.; Johnson, I.T.; Domoney, C. Investigation of legume seed protease inhibitors as potential anticarcinogenic proteins. In Recent Advances of Research in Antinutritional Factors in Legume Seeds and Oilseeds; Muzquiz, M.C., Cuadrado, M.M.P., Burbano, C., Hill, G.D., Eds.; EAAP Publication: Toledo, Spain, 2004; pp. 137–142. [Google Scholar]

- Kennedy, A.R. Chemopreventive agents: Protease inhibitors. Pharm. Ther. 1998, 78, 167–209. [Google Scholar] [CrossRef]

- Clemente, A.; Sonnante, G.; Domoney, C. Bowman-Birk Inhibitors from Legumes and Human Gastrointestinal Health: Current Status and Perspectives. Curr. Protein Pept. Sci. 2011, 12, 358–373. [Google Scholar] [CrossRef]

- Kennedy, A.R. The Bowman-Birk inhibitor from soybeans as an anticarcinogenic agent. Am. J. Clin. Nutr. 1998, 68, 1406s–1412s. [Google Scholar] [CrossRef] [Green Version]

- Roy, F.; Boye, J.I.; Simpson, B.K. Bioactive proteins and peptides in pulse crops: Pea, chickpea and lentil. Food Res. Int. 2010, 43, 432–442. [Google Scholar] [CrossRef]

- Anton, A.; Fulcher, R.; Arntfield, S. Physical and nutritional impact of fortification of corn starch based extruded snacks with common bean (Phaseolus vulgaris L.) flour: Effects of bean addition and extrusion cooking. Food Chem. 2009, 133, 989–996. [Google Scholar] [CrossRef]

- Oomah, B.D.; Cardadro-Martínez, A.; Loarca-Piña, G. Phenolics and antioxidative activities in common beans (Phaseolus vulgaris L.). J. Sci. Food Agric. 2005, 85, 935–942. [Google Scholar] [CrossRef]

- Amarowicz, R.; Estrella, I.; Hernández, T.; Robredo, S.; Troszyńska, A.; Kosińska, A.; Pegg, R.B. Free radical-scavenging capacity, antioxidant activity, and phenolic composition of green lentil (Lens culinaris). Food Chem. 2010, 121, 705–711. [Google Scholar] [CrossRef]

- Amarowicz, R.; Shahidi, F. Antioxidant activity of broad bean seed extract and its phenolic composition. J. Func. Foods 2017, 38, 656–662. [Google Scholar] [CrossRef]

- Singh, B.; Singh, J.P.; Kaur, A.; Singh, N. Phenolic composition and antioxidant potential of grain legume seeds: A review. Food Res. Int. 2017, 101, 1–16. [Google Scholar] [CrossRef] [PubMed]

- Yeo, J.; Shahidi, F. Identification and quantification of soluble and insoluble-bound phenolics in lentil hulls using HPLC-ESI-MS/MS and their antioxidant potential. Food Chem. 2020, 315, 126202. [Google Scholar] [CrossRef]

- Cardador-Martinez, A.; Castano-Tostado, E.; Loarca-Pina, G. Antimutagenic activity of natural phenolic compounds present in the common bean (Phaseolus vulgaris) against aflatoxin B1. Food Addit. Contam. 2002, 19, 62–69. [Google Scholar] [CrossRef]

- Zhang, J.; Li, L.; Kim, S.H.; Hagerman, A.E.; Lü, J. Anti-cancer, anti-diabetic and other pharmacologic and biological activities of penta-galloyl-glucose. Pharm. Res. 2009, 26, 2066–2080. [Google Scholar] [CrossRef] [Green Version]

- Del Bo’, C.; Bernardi, S.; Marino, M.; Porrini, M.; Tucci, M.; Guglielmetti, S.; Cherubini, A.; Carrieri, B.; Kirkup, B.; Kroon, P.; et al. Systematic Review on Polyphenol Intake and Health Outcomes: Is there Sufficient Evidence to Define a Health-Promoting Polyphenol-Rich Dietary Pattern? Nutrients 2019, 11, 1355. [Google Scholar] [CrossRef] [Green Version]

- Khatoon, N.; Prakash, J. Nutritional quality of microwave-cooked and pressure-cooked legumes. Int. J. Food Sci. Nutr. 2004, 55, 441–448. [Google Scholar] [CrossRef]

- Alajaji, S.A.; El-Adawy, T.A. Nutritional composition of chickpea (Cicer arietinum L.) as affected by microwave cooking and other traditional cooking methods. J. Food Compos. Anal. 2006, 19, 806–812. [Google Scholar] [CrossRef]

- Khalil, A.H.; Mansour, E.H. The effect of cooking, autoclaving and germination on the nutritional quality of faba beans. Food Chem. 1995, 54, 177–182. [Google Scholar] [CrossRef]

- Alvarez-Alvarez, J.; Guillamón, E.; Crespo, J.F.; Cuadrado, C.; Burbano, C.; Rodríguez, J.; Fernández, C.; Muzquiz, M. Effects of extrusion, boiling, autoclaving, and microwave heating on lupine allergenicity. J. Agric. Food Chem. 2005, 53, 1294–1298. [Google Scholar] [CrossRef]

- Cuadrado, C.; Cabanillas, B.; Pedrosa, M.M.; Varela, A.; Guillamón, E.; Muzquiz, M.; Crespo, J.F.; Rodriguez, J.; Burbano, C. Influence of thermal processing on IgE reactivity to lentil and chickpea proteins. Mol. Nutr. Food Res. 2009, 53, 1462–1468. [Google Scholar] [CrossRef]

- Luhovyy, B.L.; Mollard, R.C.; Panahi, S.; Nunez, M.F.; Cho, F.; Anderson, G.H. Canned Navy Bean Consumption Reduces Metabolic Risk Factors Associated with Obesity. Can. J. Diet. Pract. Res. 2015, 76, 33–37. [Google Scholar] [CrossRef]

- Martínez-Pineda, M.; Yagüe-Ruiz, C.; Caverni-Muñoz, A.; Vercet-Tormo, A. Cooking Legumes: A Way for Their Inclusion in the Renal Patient Diet. J. Ren. Nutr. 2019, 29, 118–125. [Google Scholar] [CrossRef] [PubMed]

- Choi, W.C.; Parr, T.; Lim, Y.S. The impact of four processing methods on trypsin-, chymotrypsin- and alpha-amylase inhibitors present in underutilised legumes. J. Food Sci. Technol. 2019, 56, 281–289. [Google Scholar] [CrossRef]

- Song, D.; Chang, S.K. Enzymatic degradation of oligosaccharides in pinto bean flour. J. Agric. Food Chem. 2006, 54, 1296–1301. [Google Scholar] [CrossRef]

- Shimelis, E.A.; Rakshit, S.K. Effect of processing on antinutrients and in vitro protein digestibility of kidney bean (Phaseolus vulgaris L.) varieties grown in East Africa. Food Chem. 2007, 103, 161–172. [Google Scholar] [CrossRef]

- Díaz-Batalla, L.; Widholm, J.M.; Fahey, G.C., Jr.; Castaño-Tostado, E.; Paredes-López, O. Chemical components with health implications in wild and cultivated Mexican common bean seeds (Phaseolus vulgaris L.). J. Agric. Food Chem. 2006, 54, 2045–2052. [Google Scholar] [CrossRef] [PubMed]

- Genovese, M.I.; Lajolo, F.M. Inibidores de tripsina do feijaõ (Phaseolus vulgaris): Isoformas e estabilidade térmica. In Proceedings of the Anais XVI Congresso Brasileiro de Ciencia e Tecnologia de Alimentos, Rio de Janeiro, Brazil, 15–17 July 1998; pp. 1335–1338. [Google Scholar]

- Teixeira-Guedesa, C.I.; Oppolzer, D.; Barros, A.I.; Pereira-Wilso, C. Impact of cooking method on phenolic composition and antioxidant potential of four varieties of Phaseolus vulgaris L. and Glycine max L. LWT-Food Sci. Technol. 2019, 103, 238–246. [Google Scholar] [CrossRef] [Green Version]

- Piecyk, M.; Wołosiak, R.; Drużynska, B.; Worobiej, E. Chemical composition and starch digestibility in flours from Polish processed legume seeds. Food Chem. 2012, 135, 1057–1064. [Google Scholar] [CrossRef]

- Hussain, B.; Khan, S.; Ismail, M.; Sattar, A. Effect of roasting and autoclaving on phytic acid content of chickpea. Nahrung 1989, 33, 345–348. [Google Scholar] [CrossRef]

- Vijayakumari, K.; Siddhuraju, P.; Janardhanan, K. Effects of various water or hydrothermal treatments on certain antinutritional compounds in the seeds of the tribal pulse, Dolichos lablab var. vulgaris L. Plant Foods Hum. Nutr. 1995, 48, 17–29. [Google Scholar] [CrossRef] [PubMed]

- Luo, Y.-W.; Xie, W.-H. Effect of different processing methods on certain antinutritional factors and protein digestibility in green and white faba bean (Vicia faba L.). CyTA J. Food Sci. 2013, 11, 43–49. [Google Scholar] [CrossRef] [Green Version]

- Siah, S.; Wood, J.A.; Agboola, S.; Konczak, I.; Blanchard, C.L. Effects of soaking, boiling and autoclaving on the phenolic contents and antioxidant activities of faba beans (Vicia faba L.) differing in seed coat colours. Food Chem. 2014, 142, 461–468. [Google Scholar] [CrossRef] [PubMed]

- Hefnawy, T.H. Effect of processing methods on nutritional composition and anti-nutritional factors in lentils (Lens culinaris). Ann. Agric. Sci. 2011, 56, 57–61. [Google Scholar] [CrossRef] [Green Version]

- Ai, Y.; Cichy, K.A.; Harte, J.B.; Kelly, J.D.; Ng, P.K.W. Effects of extrusion cooking on the chemical composition and functional properties of dry common bean powders. Food Chem. 2016, 211, 538–545. [Google Scholar] [CrossRef] [Green Version]

- Adeparusi, E.O. Effect of processing on the nutrients and anti-nutrients of lima bean (Phaseolus lunatus L.) flour. Nahrung 2001, 45, 94–96. [Google Scholar] [CrossRef]

- Malki, E.; Waisel, Y. Effects of pressure on germination of seeds of wheat (Triticum aestivum cv. Barqai) in saline and in non-saline media. Physiol. Plant. 1987, 70, 73–77. [Google Scholar] [CrossRef]

- Abbas, Y.; Ahmad, A. Impact of processing on nutritional and antinutritional factors of legumes: A review. Ann. Food Sci. Technol. 2018, 19, 199–215. [Google Scholar]

- Fabbri, A.D.T.; Crosby, G.A. A review of the impact of preparation and cooking on the nutritional quality of vegetables and legumes. Int. J. Gastr. Food Sci. 2016, 3, 2–11. [Google Scholar] [CrossRef] [Green Version]

- Rehman, Z.U.; Shah, W.H. Thermal heat processing effects on antinutrients, protein and starch digestibility of food legumes. Food Chem. 2005, 91, 327–331. [Google Scholar] [CrossRef]

- Margier, M.; Georgé, S.; Hafnaoui, N.; Remond, D.; Nowicki, M.; Du Chaffaut, L.; Amiot, M.J.; Reboul, E. Nutritional Composition and Bioactive Content of Legumes: Characterization of Pulses Frequently Consumed in France and Effect of the Cooking Method. Nutrients 2018, 10, 1668. [Google Scholar] [CrossRef] [Green Version]

- Kumar, K.G.; Venkataraman, L.V.; Java, T.V.; Krishnamurthy, K.S. Cooking characteristics of some germinated legumes: Changes in phytins, Ca++, Mg++ and pectins. J. Food Sci. 1978, 43, 85–88. [Google Scholar] [CrossRef]

- Wang, N.; Hatcher, D.W.; Gawalko, E.J. Effect of variety and processing on nutrients and certain anti-nutrients in field peas (Pisum sativum). Food Chem. 2008, 2008, 132–138. [Google Scholar] [CrossRef]

- Avilés-Gaxiola, S.; Chuck-Hernández, C.; Serna-Saldívar, S.O. Inactivation Methods of Trypsin Inhibitor in Legumes: A Review. J. Food Sci. 2018, 83, 17–29. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Alonso, R.; Orue, E.; Marzo, F. Effects of extrusion and conventional processing methods on protein and antinutritional factor contents in pea seeds. Food Chem. 1998, 63, 505–512. [Google Scholar] [CrossRef]

- Kozlowska, H.; Borowska, J.; Scheneider, C. Preparation of faba bean (Vicia faba, L. minor) products. V. Effect of hydrothermal treatment of faba bean on the quality of flour. Acta Aliment. Pol. 1990, 15, 171–177. [Google Scholar]

- Jourdan, G.A.; Noreña, C.P.Z.; Brandelli, A. Inactivation of Trypsin Inhibitor Activity from Brazilian Varieties of Beans (Phaseolus vulgaris L.). Food Sci. Technol. Int. 2007, 13, 195–198. [Google Scholar] [CrossRef]

- Jiratanan, T.; Liu, R.H. Antioxidant activity of processed table beets (Beta vulgaris var, conditiva) and green beans (Phaseolus vulgaris L.). J. Agric. Food Chem. 2004, 52, 2659–2670. [Google Scholar] [CrossRef]

- Ranilla, L.; Genovese, M.I.; Lajolo, F.M. Effect of different cooking conditions on phenolic compounds and antioxidant capacity of some selected brazilian bean (Phaseolus vulgaris L.) cultivars. J. Agric. Food Chem. 2009, 57, 5734–5742. [Google Scholar] [CrossRef]

- Rocha-Guzmán, N.E.; González-Laredo, R.F.; Ibarra-Pérez, F.J.; Nava-Berúmen, C.A.; Gallegos-Infante, J.A. Effect of pressure cooking on the antioxidant activity of extracts from three common bean (Phaseolus vulgaris L.) cultivars. Food Chem. 2007, 100, 31–35. [Google Scholar] [CrossRef]

- Sarmento, A.; Barros, L.; Fernandes, Â.; Carvalho, A.M.; Ferreira, I.C. Valorization of traditional foods: Nutritional and bioactive properties of Cicer arietinum L. and Lathyrus sativus L. pulses. J. Sci. Food Agric. 2015, 95, 179–185. [Google Scholar] [CrossRef] [Green Version]

- Babar, V.S.; Chavan, J.K.; Kadam, S.S. Effects of heat treatments and germination on trypsin inhibitor activity and polyphenols in jack bean (Canavalia ensiformis L. DC). Plant Foods Hum. Nutr. 1988, 38, 319–324. [Google Scholar] [CrossRef] [PubMed]

- Osman, M.A. Effect of different processing methods, on nutrient composition, antinutritional factors and in vitro protein digestibility of Dolichos Lablab bean (Lablab purpureus (L) sweet). Pak. J. Nutr. 2007, 6, 299–303. [Google Scholar] [CrossRef] [Green Version]

- Vijayakumari, K.; Siddhuraju, P.; Pugalenthi, M.; Janardhanan, K. Effect of soaking and heat processing on the levels of antinutrients and digestible proteins in seeds of Vigna aconitifolia and Vigna sinensis. Food Chem. 1998, 63, 259–264. [Google Scholar] [CrossRef]

- Granito, M.; Brito, Y.; Torres, A. Chemical composition, antioxidant capacity and functionality of raw and processed Phaseolus lunatus. J. Sci. Food Agric. 2007, 87, 2801–2809. [Google Scholar] [CrossRef]

- Granito, M.; Torres, A.; Frias, J.; Guerra, M.; Vidal-valverde, C. Influence of fermentation on the nutritional value of two varieties of Vigna sinensis. J. Eur. Food Res. Technol. 2005, 220, 176–181. [Google Scholar] [CrossRef]

- Turkmen, N.; Sari, F.; Velioglu, Y. The effect of cooking methods on total phenolics and antioxidant activity of selected green vegetables. J. Food Chem. 2005, 93, 713–718. [Google Scholar] [CrossRef]

- Andlauer, W.; Stumpf, C.; Hubert, M.; Rings, A.; Fürst, P. Influence of Cooking Process on Phenolic Marker Compounds of Vegetables. Int. J. Vitam. Nutr. Res. 2003, 73, 152–159. [Google Scholar] [CrossRef]

- Maheshu, V.; Priyadarsini, D.T.; Sasikumar, J.M. Effects of processing conditions on the stability of polyphenolic contents and antioxidant capacity of Dolichos lablab L. J. Food Sci. Technol. 2013, 50, 731–738. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Satwadhar, P.N.; Kadam, S.S.; Salunkhe, D.K. Effects of germination and cooking on polyphenols and in vitro protein digestibility of horse gram and moth bean. Plant Foods Hum. Nutr. 1981, 31, 71–76. [Google Scholar] [CrossRef]

- Giczewska, G.A.; Borowska, J. Physical properties of selected legume seeds as indicators of technological suitability of small-seed broad bean. Pol. J. Food Nutr. Sci. 2003, 12, 9–13. [Google Scholar]

- Yeo, J.; Shahidi, F. Effect of hydrothermal processing on changes of insoluble-bound phenolics of lentils. J. Funct. Foods 2017, 38, 716–722. [Google Scholar] [CrossRef]

- Alam, M.S.; Kaur, J.; Khaira, H.; Gupta, K. Extrusion and Extruded Products: Changes in Quality Attributes as Affected by Extrusion Process Parameters: A Review. Crit. Rev. Food Sci. Nutr. 2016, 56, 445–473. [Google Scholar] [CrossRef]

- Castells, M.; Marín, S.; Sanchis, V.; Ramos, A.J. Fate of mycotoxins in cereals during extrusion cooking: A review. Food Addit. Contam. 2005, 22, 150–157. [Google Scholar] [CrossRef] [PubMed]

- Dalbhagat, C.G.; Mahato, D.K.; Mishra, H.N. Effect of extrusion processing on physicochemical, functional and nutritional characteristics of rice and rice-based products: A review. Trends Food Sci. Tech. 2019, 85, 226–240. [Google Scholar] [CrossRef]

- Camire, M.E.; Camire, A.; Krumhar, K. Chemical and nutritional changes in foods during extrusion. Crit. Rev. Food Sci. Nutr. 1990, 29, 35–57. [Google Scholar] [CrossRef] [PubMed]

- Ciudad-Mulero, M.; Barros, L.; Fernandes, Â.; Berrios, J.; Cámara, M.; Morales, P.; Fernández-Ruiz, V.; Ferreira, I.C.F.R. Bioactive compounds and antioxidant capacity of extruded snack-type products developed from novel formulations of lentil and nutritional yeast flours. Food Funct. 2018, 9, 819–829. [Google Scholar] [CrossRef] [Green Version]

- Allen, K.E.; Carpenter, C.E.; Walsh, M.K. Influence of protein level and starch type on an extrusion-expanded whey product. Int. J. Food Sci. Technol. 2007, 42, 953–960. [Google Scholar] [CrossRef]

- Alonso, R.; Grant, G.; Dewey, P.; Marzo, F. Nutritional Assessment in vitro and in vivo of raw and extruded peas (Pisum sativum L.). J. Agric. Food Chem. 2000, 48, 2286–2290. [Google Scholar] [CrossRef] [PubMed]

- Arribas, C.; Cabellos, B.; Cuadrado, C.; Guillamón, E.; Pedrosa, M.M. Bioactive Compounds, Antioxidant Activity, and Sensory Analysis of Rice-Based Extruded Snacks-Like Fortified with Bean and Carob Fruit Flours. Foods 2019, 8, 381. [Google Scholar] [CrossRef] [Green Version]

- Arribas, C.; Pereira, E.; Barros, L.; Alves, M.J.; Calhelha, R.C.; Guillamón, E.; Pedrosa, M.M.; Ferreira, I.C.F.R. Healthy novel gluten-free formulations based on beans, carob fruit and rice: Extrusion effect on organic acids, tocopherols, phenolic compounds and bioactivity. Food Chem. 2019, 292, 304–313. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Brennan, C.; Brennan, M.; Derbyshire, E.; Tiwari, B. Effects of extrusion on the polyphenols, vitamins and antioxidant activity of foods. Trends Food Sci. Technol. 2011, 22, 570–575. [Google Scholar] [CrossRef]

- Ciudad-Mulero, M.; Fernández-Ruiz, V.; Cuadrado, C.; Arribas, C.; Pedrosa, M.M.; De, J. Berrios, J.; Pan, J.; Morales, P. Novel gluten-free formulations from lentil flours and nutritional yeast: Evaluation of extrusion effect on phytochemicals and non-nutritional factors. Food Chem. 2020, 315, 126175. [Google Scholar] [CrossRef]

- El-Hady, E.A.; Habiba, R.A. Effect of soaking and extrusion conditions on antinutrients and protein digestibility of legume seeds. LWT-Food Sci. Technol. 2003, 36, 285–293. [Google Scholar] [CrossRef]

- Pedrosa, M.M.; Cuadrado, C. The nutritional and nutraceutical values of some ’ready-to-eat’ expanded legume products. In Legumes for Global Food Security; Clemente, A., Jimenez-Lopez, J.C., Eds.; Nova Science: Hauppauge, NY, USA, 2017; pp. 41–73. [Google Scholar]

- Alonso, R.; Rubio, L.A.; Muzquiz, M.; Marzo, F. The effect of extrusion cooking on mineral bioavailability in pea and kidney bean seed meals. Anim. Feed Sci. Technol. 2001, 94, 1–13. [Google Scholar] [CrossRef]

- Borejszo, Z.; Khan, k. Reduction of flatulence-causing sugars by high temperature extrusion of pinto bean high starch fractions. J. Food Sci. 1992, 57, 771–777. [Google Scholar] [CrossRef]

- Kelkar, S.; Siddiq, M.; Harte, J.B.; Dolan, K.D.; Nyombaire, G.; Suniaga, H. Use of low-temperature extrusion for reducing phytohemagglutinin activity (PHA) and oligosaccharides in beans (Phaseolus vulgaris L.) cv. Navy and Pinto. Food Chem. 2012, 133, 1636–1639. [Google Scholar] [CrossRef]

- Korus, J.; Gumul, D.; Czechowska, K. Effect of extrusion on the phenolic composition and antioxidant activity of dry beans of Phaseolus vulgaris L. Food Technol. Biotechnol. 2007, 45, 139–146. [Google Scholar]

- Zamora, N. Effect of extrusion on the activity of anti-nutritional factors and in vitro digestibility of protein and starch in flours of Canavalia ensiformis. Arch. Latinoam. Nutr. 2003, 53, 293–298. [Google Scholar]

- Berrios, J.; Morales, P.; Cámara, M.; Sánchez-Mata, M.C. Carbohydrate composition of raw and extruded pulse flours. Food Res. Int. 2010, 40, 531–536. [Google Scholar] [CrossRef]

- Poltronieri, F.; Arêas, J.A.G.; Colli, C. Extrusion and iron bioavailability in chickpea (Cicer arietinum L.). Food Chem. 2000, 70, 175–180. [Google Scholar] [CrossRef]

- Hegazy, H.S.; El-Bedawey, A.E.-F.A.; Rahma, E.-S.H.; Gaafar, A.M. Effect of Extrusion Processs on Nutritional, Functional Properties and Antioxidant Activity of Germinated Chickpea Incorporated Corn Extrudates. Am. J. Food Sci. Nutr. Res. 2017, 4, 59–66. [Google Scholar]

- Rathod, R.P.; Annapure, U.S. Effect of extrusion process on antinutritional factors and protein and starch digestibility of lentil splits. LWT-Food Sci. Technol. 2016, 66, 114–123. [Google Scholar] [CrossRef]

- Varela, A.; Guillamón, E.; Cuadrado, C.; Marzo, F.; Burbano, C.; Muzquiz, M.; Pedrosa, M.M. Changes in nutritional active factors and protein in different legumes by extrusion/cooking. In Proceedings of the 6th European Conference of Grain Legumes, Lisboa, Portugal, 12–17 November 2007. [Google Scholar]

- Berrios, J.; Cámara, M.; Torija, M.E.; Alonso, M. Effect of extrusion cooking and sodium bicarbonate addition on the carbohydrate composition of black bean flours. J. Food Process. Preserv. 2002, 26, 113–128. [Google Scholar] [CrossRef]

- Delgado-Licon, E.; Ayala, A.L.M.; Rocha-Guzman, N.E.; Gallegos-Infante, J.-A.; Atienzo-Lazos, M.; Drzewiecki, J.; Martínez-Sánchez, C.E.; Gorinstein, S. Influence of extrusion on the bioactive compounds and the antioxidant capacity of the bean/corn mixtures. Int. J. Food Sci. Nutr. 2009, 60, 522–532. [Google Scholar] [CrossRef] [PubMed]

- Yağcı, S.; Altan, A.; Doğan, F. Effects of extrusion processing and gum content on physicochemical, microstructural and nutritional properties of fermented chickpea-based extrudates. LWT-Food Sci. Technol. 2020, 124, 109150. [Google Scholar] [CrossRef]

- Morales, P.; Cebadera-Miranda, L.; Cámara, R.M.; Reis, F.S.; Barros, L.; Berrios, J.D.J.; Ferreira, I.C.F.R.; Cámara, M. Lentil flour formulations to develop new snack-type products by extrusion processing: Phytochemicals and antioxidant capacity. J. Funct. Foods 2015, 19, 537–544. [Google Scholar] [CrossRef]

- Morales, P.; Berrios, J.; Varela, A.; Burbano, C.; Cuadrado, C.; Muzquiz, M.; Pedrosa, M.M. Novel fiber-rich lentil flours as snack-type functional foods: An extrusion cooking effect on bioactive compounds. Food Funct. 2015, 6, 3135–3143. [Google Scholar] [CrossRef] [Green Version]

- Berrios, J.; Pan, J. Evaluation of extruded black bean (Phaseolus vulgaris L.) processed under different screw speeds and particle sizes. In Proceedings of the Annual meeting of the Institute of Food technologist, New Orleans, LA, USA, 23–27 June 2001; p. 30. [Google Scholar]

- Nikmaram, N.; Leong, S.Y.; Koubaa, M.; Zhu, Z.; Barba, F.J.; Greiner, R.; Oey, I.; Roohinejad, S. Effect of extrusion on the anti-nutritional factors of food products: An overview. Food Control 2017, 79, 62–73. [Google Scholar] [CrossRef]

- Lombardi-Boccia, G.; Lullo, G.D.; Carnovale, E. In-vitro iron dialysability from legumes: Influence of phytate and extrusion cooking. J. Sci. Food Agric. 1991, 55, 599–605. [Google Scholar] [CrossRef]

- Butron, J. Effect of extrusion of legumes and enzyme supplementation on the animal growth and their metabolism/ Efecto_de_la_suplementacion_enzimatica_y_extrusion_de_leguminosas_en_el_crecimiento_y_metabolismo_animal. Ph.D. Thesis, Universidad Pública de Navarra, Navarra, Spain, 2002. Available online: https://www.researchgate.net/publication/45219512_Efecto_de_la_suplementacion_enzimatica_y_extrusion_de_leguminosas_en_el_crecimiento_y_metabolismo_animal (accessed on 9 February 2021).

- Adeleye, O.O.; Awodiran, S.T.; Ajayi, A.O.; Ogunmoyela, T.F. Effect of high-temperature, short-time cooking conditions on in vitro protein digestibility, enzyme inhibitor activity and amino acid profile of selected legume grains. Heliyon 2020, 6, e05419. [Google Scholar] [CrossRef]

- Korus, J.; Gumul, D.; Folta, M.; Barton, H. Antioxidant and antiradical activity of raw and extruded commons beans. Electron. J. Pol. Agric. Univ. 2007, 10, 6. Available online: http://www.ejpau.media.pl/volume10/issue4/art-06.html (accessed on 9 February 2021).

- Díaz-Batalla, L.; Hernández-Uribe, J.P.; Gutiérrez-Dorado, R.; Téllez-Jurado, A.; Castro-Rosas, J.; Pérez-Cadena, R.; Gómez-Aldapa, C.A. Nutritional characterization of Prosopis Laevigata legume tree (mesquite) seed flour and the effect of extrusion cooking on its bioactive components. Foods 2018, 7, 124. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Marti, A.; Seetharaman, K.; Pagani, M.A. Rice-based pasta: A comparison between conventional pasta-making and extrusion-cooking. J. Cereal Sci. 2010, 52, 404–409. [Google Scholar] [CrossRef]

- Onwulata, C.I.; Tunick, M.H.; Qi, P.X. Extrusion texturized dairy proteins: Processing and application. In Advances in Food and Nutrition Research; Elsevier: Amsterdam, The Netherlands, 2011; Volume 62, pp. 173–200. [Google Scholar]

- Boyaci, B.B.; Han, J.Y.; Masatcioglu, M.T.; Yalcin, E.; Celik, S.; Ryu, G.H.; Koksel, H. Effects of cold extrusion process on thiamine and riboflavin contents of fortified corn extrudates. Food Chem. 2012, 132, 2165–2170. [Google Scholar] [CrossRef]

- Di Stefano, V.; Pagliaro, A.; Nobile, M.; Conte, A.; Melilli, M. Lentil Fortified Spaghetti: Technological Properties and Nutritional Characterization. Foods 2020, 10, 4. [Google Scholar] [CrossRef]

- Lorenzo, G.; Sosa, M.; Califano, A. Alternative Proteins and Pseudocereals in the Development of Gluten-Free Pasta. In Alternative and Replacement Foods; Elsevier: San Diego, CA, USA, 2018; pp. 433–458. [Google Scholar] [CrossRef]

- Sissons, M. Pasta. In Reference Module in Food Science; Elsevier: Amsterdam, The Netherlands, 2016. [Google Scholar] [CrossRef]

- De Pilli, T.; Alessandrino, O. Effects of different cooking technologies on biopolymers modifications of cereal-based foods: Impact on nutritional and quality characteristics review. Crit. Rev. Food Sci. Nutr. 2020, 60, 556–565. [Google Scholar] [CrossRef]

- Murray, J.; Kiszonas, A.; Morris, C.F. Pasta Production: Complexity in Defining Processing Conditions for Reference Trials and Quality Assessment Methods. Cereal Chem. J. 2017, 94, 791–797. [Google Scholar] [CrossRef]

- Petitot, M.; Boyer, L.; Minier, C.; Micard, V. Fortification of pasta with split pea and faba bean flours: Pasta processing and quality evaluation. Food Res. Int. 2010, 43, 634–641. [Google Scholar] [CrossRef]

- Bahnassey, Y.; Khan, K. Fortification of spaghetti with edible legumes. II. Rheological, processing, and quality evaluation studies. Cereal Chem. 1986, 63, 216–219. [Google Scholar]

- Bilgicli, N. Some chemical and sensory properties of gluten-free noodle prepared with different legume, pseudocereal and cereal flour blends. J. Food Nutr. Res. 2013, 52, 251–255. [Google Scholar]

- Bouasla, A.; Wójtowicz, A.; Zidoune, M.N. Gluten-free precooked rice pasta enriched with legumes flours: Physical properties, texture, sensory attributes and microstructure. LWT-Food Sci. Technol. 2017, 75, 569–577. [Google Scholar] [CrossRef]

- Bouasla, A.; Wojtowicz, A.; Zidoune, M.N.; Olech, M.; Nowak, R.; Mitrus, M.; Oniszczuk, A. Gluten-free precooked rice-yellow pea pasta: Effect of extrusion-cooking conditions on phenolic acids composition, selected properties and microstructure. J. Food Sci. 2016, 81, C1070–C1079. [Google Scholar] [CrossRef] [PubMed]

- Chillo, S.; Monro, J.; Mishra, S.; Henry, C. Effect of incorporating legume flour into semolina spaghetti on its cooking quality and glycaemic impact measured in vitro. Int. J. Food Sci. Nutr. 2010, 61, 149–160. [Google Scholar] [CrossRef]

- Flores-Silva, P.C.; Berrios, J.D.J.; Pan, J.; Agama-Acevedo, E.; Monsalve-Gonzalez, A.; Bello-Perez, L.A. Gluten-free spaghetti with unripe plantain, chickpea and maize: Physicochemical, texture and sensory properties. CyTA-J. Food Sci. 2015, 13, 159–166. [Google Scholar] [CrossRef]

- Flores-Silva, P.C.; Berrios, J.D.J.; Pan, J.; Osorio-Diaz, P.; Bello-Pérez, L.A. Gluten-free spaghetti made with chickpea, unripe plantain and maize flours: Functional and chemical properties and starch digestibility. Int. J. Food Sci. Technol. 2014, 49, 1985–1991. [Google Scholar] [CrossRef]

- Giuberti, G.; Gallo, A.; Cerioli, C.; Fortunati, P.; Masoero, F. Cooking quality and starch digestibility of gluten free pasta using new bean flour. Food Chem. 2015, 175, 43–49. [Google Scholar] [CrossRef] [PubMed]

- Schmiele, M.; Jaekel, L.Z.; Ishida, P.M.G.; Chang, Y.K.; Steel, C.J. Massa alimenticia sem gluten com elevado teor proteico obtida por processo convencional. Ciencia Rural 2013, 43, 908–914. [Google Scholar] [CrossRef] [Green Version]

- Segura-Campos, M.R.; Garcia-Rodriguez, K.; Ruiz-Ruiz, J.C.; Chel-Guerrero, L.; Betancur-Ancona, D. In vitro bioactivity, nutritional and sensory properties of semolina pasta added with hard-to-cook bean (Phaseolus vulgaris L.) protein hydrolysate. J. Funct. Foods 2014, 8, 1–8. [Google Scholar] [CrossRef]

- Susanna, S.; Prabhasankar, P. A study on development of Gluten free pasta and its biochemical and immunological validation. LWT-Food Sci. Technol. 2013, 50, 613–621. [Google Scholar] [CrossRef]

- Gao, Y.; Janes, M.E.; Chaiya, B.; Brennan, M.A.; Brennan, C.S.; Prinyawiwatkul, W. Gluten-free bakery and pasta products: Prevalence and quality improvement. Int. J. Food Sci. Technol. 2018, 53, 19–32. [Google Scholar] [CrossRef] [Green Version]

- Rani, S.; Singh, R.; Kamble, D.B.; Upadhyay, A.; Kaur, B.P.J.F.B. Structural and quality evaluation of soy enriched functional noodles. Food Biosci. 2019, 32, 100465. [Google Scholar] [CrossRef]

- Sofi, S.A.; Singh, J.; Chhikara, N.; Panghal, A. Effect of incorporation of germinated flour and protein isolate from chickpea on different quality characteristics of rice-based noodle. Cereal Chem. 2020, 97, 85–94. [Google Scholar] [CrossRef] [Green Version]

- Frias, J.; Kovacs, E.; Sotomayor, C.; Hedley, C.; Vidal-Valverde, C. Processing peas for producing macaroni. LWT-Food Sci. Technol. 1997, 204, 66–71. [Google Scholar] [CrossRef]

- Yoshimoto, J.; Kato, Y.; Ban, M.; Kishi, M.; Horie, H.; Yamada, C.; Nishizaki, Y. Palatable Noodles as a Functional Staple Food Made Exclusively from Yellow Peas Suppressed Rapid Postprandial Glucose Increase. Nutrients 2020, 12, 1839. [Google Scholar] [CrossRef]

- Torres, A.; Frias, J.; Granito, M.; Vidal-Valverde, C.n. Fermented pigeon pea (Cajanus cajan) ingredients in pasta products. J. Agric. Food Chem. 2006, 54, 6685–6691. [Google Scholar] [CrossRef]

- Herken, E.N.; Äbanolu, Å.; Aner, M.D.; Bilgili, N.; Gazel, S. Effect of storage on the phytic acid content, total antioxidant capacity and organoleptic properties of macaroni enriched with cowpea flour. J. Food Eng. 2007, 78, 366–372. [Google Scholar] [CrossRef]

- Laleg, K.; Cassan, D.; Barron, C.; Prabhasankar, P.; Micard, V. Structural, culinary, nutritional and anti-nutritional properties of high protein, gluten free, 100% legume pasta. PLoS ONE 2016, 11, e0160721. [Google Scholar] [CrossRef]

- Carcea, M.; Narducci, V.; Turfani, V.; Giannini, V. Polyphenols in raw and cooked cereals/pseudocereals/legume pasta and couscous. Foods 2017, 6, 80. [Google Scholar] [CrossRef] [Green Version]

- Arribas, C.; Cabellos, B.; Guillamón, E.; Pedrosa, M.M. Cooking and sensorial quality, nutritional composition and functional properties of cold-extruded rice/white bean gluten-free fettuccine fortified with whole carob fruit flour. Food Funct. 2020, 11, 7913–7924. [Google Scholar] [CrossRef]

- Drago, S.R.; Franco-Miranda, H.; Cian, R.l.E.; Betancur-Ancona, D.; Chel-Guerrero, L. Bioactive properties of Phaseolus lunatus (Lima Bean) and Vigna unguiculata (Cowpea) hydrolyzates incorporated into pasta. Residual activity after pasta cooking. Plant Foods Hum. Nutr. 2016, 71, 339–345. [Google Scholar] [CrossRef] [PubMed]

- Turco, I.; Bacchetti, T.; Bender, C.; Zimmermann, B.; Oboh, G.; Ferretti, G. Polyphenol content and glycemic load of pasta enriched with faba bean flour. Funct. Foods Health Dis. 2016, 6, 291–305. [Google Scholar] [CrossRef] [Green Version]

- Torres, A.; Frias, J.; Granito, M.; Vidal-Valverde, C. Germinated Cajanus cajan seeds as ingredients in pasta products: Chemical, biological and sensory evaluation. Food Chem. 2007, 101, 202–211. [Google Scholar] [CrossRef]

- Turco, I.; Bacchetti, T.; Morresi, C.; Padalino, L.; Ferretti, G. Polyphenols and glycaemic index of legume pasta. Food Funct. 2019, 10. [Google Scholar] [CrossRef]

- Gallegos-Infante, J.A.; Rocha-Guzman, N.E.; Gonzalez-Laredo, R.F.; Ochoa-Martínez, L.A.; Corzo, N.; Bello-Perez, L.A.; Medina-Torres, L.; Peralta-Alvarez, L.E. Quality of spaghetti pasta containing Mexican common bean flour (Phaseolus vulgaris L.). Food Chem. 2010, 119, 1544–1549. [Google Scholar] [CrossRef]

- Biernacka, B.; Dziki, D.; Gawlik-Dziki, U.; Rayao, R.; Siasta, M. Physical, sensorial, and antioxidant properties of common wheat pasta enriched with carob fiber. LWT-Food Sci. Technol. 2017, 77, 186–192. [Google Scholar] [CrossRef]

- Seczyk, Å.U.; Åšwieca, M.; Gawlik-Dziki, U. Effect of carob (Ceratonia siliqua L.) flour on the antioxidant potential, nutritional quality, and sensory characteristics of fortified durum wheat pasta. Food Chem. 2016, 194, 637–642. [Google Scholar] [CrossRef]

| Legumes | Autoclaving Conditions | α-Galactosides | Inositol Phosphates | Protease Inhibitors | Phenolic Compounds | Antioxidant Activity | References |

|---|---|---|---|---|---|---|---|

| Adzuki bean | 121 °C; 15 min | 0.10 TIU/mg ↑ | [53] | ||||

| Pre-soaked bean (two vars.) | 116 °C; 42 min | 30.2–24.25 mg/g ↓ | 10.59–10.53 mg/g ↓ | 0.47–0,43 TIU/mg ↓ | Total phenols: 9.65–11.80 µg/g ↓ | ORAC: 16.03–16.03 µmol TE/g ↓ | [5] |

| Pre-soaked pinto bean | 116 °C;10–30 min | 46.9–57.6 g/100 g ↑ | [54] | ||||

| Unsoaked kidney bean (three vars.) | 121 °C; 30 min | 0.55–0.65 g/100 g ↓ | 6.94–8.43 mg/g ↓ | n.d. * ↓ | Tannins: 1.51-14.37 mg/g ↓ | [55] | |

| Pre-soaked kidney bean (three vars.) | 121 °C; 30 min | 0.36–0.49 g/100 g ↓ | 6.59–8.90 mg/g ↓ | n.d. ↓ | Tannins: 1.34–12.91 mg/g ↓ | [55] | |

| Wild and cultivated Mexican bean | 20 min | 60.4 mg/g (mean) ↓ | 8.7 mg/g (mean) ↓ | [56] | |||

| Brazilian bean (eight vars.) | 121 °C; 15 min | 0.48–1.00 TIU/mg ↓ | [57] | ||||

| Pre-soaked Brazilian bean (five vars.) | 121 °C; 15 min | n.d. ↓ | [57] | ||||

| Pre-soaked kidney, pinto, black and borlotti bean | 115 °C; 20 min | Total phenols: 0.38–0.94 mg GAE/100 g = | DPPH: 2.29–5.20 µmolTE/g = ABTS: 0.41–1.56 µmol TE/g = FRAP: 4.24–7.91 µmol TE/g ↓ | [58] | |||

| Bean (two vars.) | 121 °C; 7–12 min | Total phenols: 77.1–78.6 mg GAE/100 g ↓ | [59] | ||||

| Pre-soaked chickpeas | 121 °C; 35 min | 2.27 g/100 g ↓ | 0.71 g/100 g ↓ | 0.44 TIU/mg protein ↓ | Tannins: 2.42 mg/g ↓ | [47] | |

| Whole chickpea (five cvs.) | 120 °C; 60 min | 112–335 mg/100 g ↓ | [60] | ||||

| Dehulled chickpea (five cvs.) | 120 °C; 60 min | 105–241 mg/100 g ↓ | [60] | ||||

| Chickpea | 121 °C; 15 min | 0.10 TIU/mg ↑ | [53] | ||||

| Dolichos lablab (Vulgaris var) | 121 °C; 15–45 min | 452–482 mg/100 g ↓ | 0.85–2.36 g/100 g ↓ | Tannins: 0.05–0.13 g/100 g ↓ Total free phenols: 0.22–0.98 g/100 g ↓ | [61] | ||

| Pre-soaked faba bean | 120 °C; 30 min | 1.43 g/100 g ↓ | 0.23 g/100 g ↓ | 0.35 TIU/mg ↓ | Tannins: 0.58 g/100 mg ↓ | [48] | |

| Unsoaked faba bean (white and green) | 121 °C; 15 min | 8.90–9.27 mg/g ↑ | 0.46–1.23 mg/g ↓ | Tannins: 4.72–6.51 mg/g ↑ in green; ↓ in white | [62] | ||

| Pre-soaked faba bean (white and green) | 121 °C; 15 min | 5.12–9.21 mg/g ↓ in green; ↑ in white | 0.74–1.86 mg/g ↓ | Tannins: 2.21–4.02 mg/g ↓ | [62] | ||

| Pre-soaked faba bean (three genotypes) | 115 °C; 20 min | Total phenols: 0.7–1.9 mg GAE/100 g ↓ | DPPH: 4.6–9.9 µmol TE/g ↑ TEAC: 8.35–11.25 µmol TE/g ↓ ORAC: 20.54–33.25µmol TE/g ↓ | [63] | |||

| Hyacinth bean | 121 °C; 15 min | 0.23 TIU/mg ↑ | [53] | ||||

| Pre-soaked lentil | 121 °C; 35 min | 1.42 g/100 g ↓ | 2.4 g/ g ↓ | 0.19 TIU/mg ↓ | Tannins: 0.82 g/100 g ↓ | [64] | |

| Lentil (two vars.) | 121 °C; 7 min | Total phenols: 318.3–533.4 mg GAE/100 g ↓ | [65] | ||||

| Lima bean | 121 °C; 10–20 min | 8.89 mg/ g ↓ | n.d. ↓ | Tannins: 0.23–0.32 g/100 g ↓ | [66] | ||

| Black-eyed pea | 121 °C; 15 min | 0.22 TIU/mg ↑ | [53] | ||||

| Pea (two vars.) | 121 °C; 12 min | Total phenols: 80.0–162.1 mg GAE/100 g ↓ | [59] | ||||

| Pigeon pea | 121 °C;15 min | 0.41 TIU/mg ↑ | [53] | ||||

| Mung bean | 121 °C; 15 min | 0.11 TIU/mg ↑ | [53] | ||||

| Soybean | 121 °C; 15 min | 0.09 TIU/mg ↑ | [53] | ||||

| Pre-soaked soybean | 115 °C; 20 min | Total phenols: 0.71 mg GAE/100 g ↓ | DPPH: 0.91µmol TE/g ↓ ABTS: 0.27 µmol TE/g ↓ FRAP: 2.18 µmol TE/g ↓ | [58] |

| Legumes | Extrusion Conditions | α-Galactosides | Inositol Phosphates | Protease Inhibitors | Phenolic Compounds | Antioxidant Activity | References |

|---|---|---|---|---|---|---|---|

| Kidney bean (unsoaked) | 140 °C and 180 °C; 18% and 22% moisture | 9.64–10.90 mg/g ↓ | n.d. * | Tannins: 196–223 mg/100 g ↓ Total phenols: 539–621 mg/100 g ↓ | [104] | ||

| Kidney bean (pre-soaked) | 140 °C and 180 °C; 18% and 22% moisture | 9.53–10.41 mg/g ↑ | n.d. | Tannins: 171–190 mg/100 g ↓ Total phenols: 413–494 mg/100 g ↓ | [104] | ||

| Bean (four varieties) | 120–140 °C; 25–30% moisture | 27.75–36.20 mg/g ↑ | [65] | ||||

| Kidney bean var. Pinto | 150–155 °C; 20% moisture | 37.7 mg/g ↓ | 4.71 mg/g ↓ | Tannins:2.75 g eq cat/kg ↓ | [106] | ||

| Pinto bean | 110 °C to 163 °C. 18.8 to 28.95% moisture | 33.3–47.8 mg/g ↑ | [107] | ||||

| Navy and pinto bean (pre-soaked) | 85 °C 36% moisture | 30.45–33.65 mg/g ↓ | [108] | ||||

| Bean (three cultivars) | 120 °C-180 °C. 14%-20% moisture | Total Phenols: 24.12–102.68 mg/100 g | TEAC: 69.26–77.88 µM Trolox/g ↓ | [109] | |||

| Canavalia ensiformis | 155 °C; 20% moisture | 1.40 TIU/mg | [110] | ||||

| Chickpea (unsoaked) | 140 °C and 180 °C; 18% and 22% moisture | 7.33–8.16 mg/g ↓ | n.d. | Tannins: 190–245 mg/100 g ↓ Total phenols: 190–245 mg/100 g ↓ | [104] | ||

| Chickpea (pre-soaked) | 140 °C and 180 °C; 18% and 22% moisture | 7.35–8.00 mg/g ↓ = | n.d. | Tannins: 195–214 mg/100 g ↑ Total phenols: 270–380 mg/100 g ↓ | [104] | ||

| Chickpea | 160 °C; 17% moisture | 26.39 mg/g ↓ | [111] | ||||

| Chickpea (deffated) | 130 °C; 14% moisture | 12.6 µmol/g ↓ | Total Phenols: 48.7 mg/100 mg ↑ | [112] | |||

| Chickpea (germinated and dehulled) | 180 °C; 16% moisture | 1.33 mg/g ↓ | Total phenols: 7.35 mg GAE/g ↑ | DPPH: 45.46% ↑ | [113] | ||

| Faba bean (unsoaked) | 140 °C and 180 °C; 18% and 22% moisture | 6.05–6.86 mg/g ↑ | n.d. | Tannins: 397–438 mg/100 g ↓ Total phenols: 635–750 mg/100 g ↓ | [104] | ||

| Faba bean (pre-soaked) | 140 °C and 180 °C; 18% and 22% moisture | 4.80–5.00 mg/g ↑ | n.d. | Tannins: 362–426 mg/100 g Total phenols: 618–644 mg/100 g ↓ | [104] | ||

| Lentil | 160 °C 17% moisture | 14.02 mg/g ↓ | [111] | ||||

| Split lentils | 140 °C-160 °C-180 °C; 14%-18%-22% moisture | 0.08–0.57 mg/g ↓ | 0.013–0.049 TIU/mg ↓ | Tannins: 0.011–0.065 mg CE/100 g ↓ Total phenols 2.4–5.1 mg GAE/g ↓ | [114] | ||

| Pea cv Ballet | 145 °C-25% moisture | 46.9 mg/g ↑ | 11.23 mg/g ↓ | 0.34 TIU/g ↓ | Tannins: 0.02 g CE/kg ↓ Total Phenols: 0.23 g/kg ↓ | [106] | |

| Pea (unsoaked) | 140 °C and 180 °C; 18% and 22% moisture | 7.90–8.34 mg/g ↓ | n.d. | Tannins: 236–278 mg/100 g ↓ Total phenols: 392–430 mg/100 g ↓ | [104] | ||

| Pea (pre-soaked) | 140 °C and 180 °C; 18% and 22% moisture | 7.14–7.60 mg/g↓ | n.d. | Tannins. 200–233 mg/100 g ↓ Total phenols: 343–379 mg/100 g ↓ | [96] | ||

| Pea | 160 °C 17% moisture | 23.45 mg/g ↓ | [111] | ||||

| Pea | 150–155 °C; 20% moisture | 46.9 mg/g = | 4.10 mg/g ↓ | Tannins: 0.02 g CE/kg ↓ | [106] |

| Legume Mixtures | Extrusion Conditions | α-Galactosides | Inositol Phosphates | Protease Inhibitors | Phenolic Compounds | Antioxidant Activity | References |

|---|---|---|---|---|---|---|---|

| Bean/rice (30/70) | 80 °C; 14% moisture | 16.59 mg/g | Tannins: 7.57 mg/g | [14] | |||

| Red common bean (15, 30 and 45%)/corn starch | 160 °C; 22% moisture | 0.54–2.33 mg/g ↓ | n.d. * | 40.94–94.82 mg FAE/100 g ↓ | DPPH: 213.93–642.33 µmol TE/100 g ↓ ORAC: 388.69–1527.27 µmol TE/100 g ↓ | [37] | |

| Navy common bean (15. 30 and 45%)/corn starch | 160 °C; 22% moisture | 0.56–2.19 mg/g ↓ | n.d. | 28.27–45.96 mg FAE/100 g ↓ | DPPH: 41.42–126.23 µmol TE/100 g ↓ ORAC: 254.36–584.46 µmol TE/100 g ↓ | [37] | |

| Bean/carob/rice (different formulas: 20–40%/0–10%/50–80%) | 125 °C; 20% moisture | 19.73–34.30 mg/g ↑ | 3.65–6.11 mg/.g ↓ | n.d. | Total phenols: 0.92–3.25 mg CE/g ↓ | ORAC: 8.92–11.89 µmol Trolox/g ↑ | [100] |

| Kidney bean/corn starch (80/20) | 150 °C. 20% moisture | 45.63 mg/g ↓ | 7.08 mg/g ↓ | 0.25 TIU/mg ↓ | [115] | ||

| Black bean with (0–4%) sodium bicarbonate | 160 °C; 20% moisture | 15.2–22.5 mg/g ↑ | [116] | ||||

| Bean/corn (60/40) | from 150 °C to 190 °C; from 14.5% to 18.0% moisture | Phenols: 6.46–17.40 mg GAE/g | CUPRAC: 9.55–37.02 µM Trolox eq/g; β-carotene 8.94–34.20% | [117] | |||

| Chickpea mixed with starch and fiber | 150 °C. 20% moisture | 14.38 mg/g ↓ | [111] | ||||

| Chickpea/corn starch (80/20) | 150 °C. 20% moisture | 44.21 mg/g ↓ | 5.62 mg/g ↑ | 2.52 TIU/mg ↓ | [115] | ||

| Chickpea (germinated and dehulled) (10–30%)/corn/tomato pomace (5%) | 180 °C; 16% moisture | 1.20–1.00 mg/g ↓ | n.d. | 9.37–11.11 mg GAE/g ↑ | DPPH: 53.82–56.33% ↑ | [113] | |

| Fermented chickpea/yogurt/locus bean gum | 140 °C and 150 °C; 17% moisture | 6.12–10.38 mg/g↓ | 2.02–8.82 TIU/mg ↓ | Tannins: 0.37–1.03 mg CE/g ↓ | [118] | ||

| Faba bean/corn starch (80/20) | 150 °C; 20% moisture | 31.66 mg/g ↓ | 6.25 mg/g ↓ | 0.44 TIU/mg ↓ | [115] | ||

| Lentil mixed with nutritional yeast | 160 °C; 17% moisture | 33.35–49.55 mg/g ↑ | 2.72–3.94 mg/g ↓ | 0.20–0.28 TIU/mg ↓ | [97] | ||

| Lentil mixed with starch and fiber | 150 °C. 20% moisture | 12.82 mg/g ↓ | [111] | ||||

| Red lentil (dehulled)/fiber (wheat, apple, nutriose®) (4 different formulations with at least 68% lentil) | 160 °C; 17% moisture | 24.60–42.52 mg/g ↑ | 1.38–4.62 mg/g ↓ | n.d | 4.51–9.38 mg GAE/g ↑ | DPPH 6.63–63.56 EC50 mg/mL ↓ β-carotene assay 2.66–9.75 EC50 mg/mL ↑ ↓ TBARS: 1.52–4.59 EC50 mg/mL ↓ | [119,120] |

| Lupin/corn starch (80/20) | 150 °C; 20% moisture | 83.76 mg/g ↓ | 5.99 mg/g ↑ | 0.29 TIU/mg ↓ | [115] | ||

| Pea/carob/rice (different formulas: 20–40%/0–10%/50–80%) | 125 °C; 20% moisture | 24.80–50.21 mg/g ↑ | 3.14–4.60 mg/g ↓ | n.d*. | Total phenols: 2.19–5.55 mg CE/g ↓ | ORAC:9.81–12.00 µmol Trolox/g ↑ | [18] |

| Pea mixed with starch and fiber | 150 °C. 20% moisture | 38.7 mg/g ↑ | [111] | ||||

| Pea/corn starch (80/20) | 150 °C. 20% moisture | 74.63 mg/g ↑ | 7.86 mg/g ↑ | 0.24 TIU/mg ↓ | [115] |

| Legumes | α-Galactosides | Inositol Phosphates | Protease Inhibitors | Phenolic Compounds | Antioxidant Activity | References |

|---|---|---|---|---|---|---|

| 100% legume (faba, lentil or black-gram flours) | 44–57 mg/g | 14.5–18 IP6 mg/g | 7.8–11.3 TIU/mg | [155] | ||

| Commercial samples manufactured with lentil, bean and pea | Total phenols: 632–1743 mg GAE./100 g | [156] | ||||

| Bean and carob fruit/rice | 10–45 mg/g | 3–9 mg/g IP total 2–5 mg/g IP6 | 2–13 TIU/mg 2–17 CIU/mg | Total phenols: 2.9–7.3 mg CE/g | ORAC: 5.3–13.7 µmol Trolox/g | [157] |

| Hard-to-cook bean protein hydrolysate/wheat semolina | ABTS: 15–31 mM/mg | [146] | ||||

| Lima bean and cowpea/wheat | TAC: 26.09–31.84 mg Trolox eq./g | [158] | ||||

| Faba bean/wheat | Total phenols: 185 mg GAE/100 g | ORAC: 1017 mg Trolox eq./100 g | [159] | |||

| Germinated and fermented cowpea flour/wheat semolina | 677 mg IP6/g | TAC:31.9 µmol Trolox eq./g | [160] | |||

| Lentil | Total phenols: 1.42–2.14 mg GAE/g | [131] | ||||

| Pea | 0.45–1.09 TIU/mg | [151] | ||||

| Pea flour, red lentil flour or 60% grass pea and 40% chickpea flour | Total phenols: 87–176 mg GAE/100 g | ORAC: 1851–3789 mg Trolox eq./100 g | [161] |

| Legumes | α-Galactosides | Inositol Phosphates | Protease Inhibitors | Phenolic Compounds | Antioxidant Activity | References |

|---|---|---|---|---|---|---|

| 100% legume (faba, lentil or black-gram flours) | 12–34 mg/g ↓ | 12.8–15 IP6 mg/g ↓ | 1.52–2.5 TIU/mg ↓ | [155] | ||

| Commercial samples manufactured with lentil, bean and pea | Total phenols: 323–814 mg GAE/100 g ↓ | [156] | ||||

| Bean and carob fruit/rice | 4–27 mg/g ↓ | 3–8 mg/g IP total = 2–5 mg/g IP6 = | 2–17 TIU/mg ↓ 3–17 CIU/mg ↑ | Total phenols: 2.3–5.8 mg CE/g ↓ | ORAC: 5.1–10.3 µmol Trolox/g ↓ | [157] |

| Bean/semolina | Total phenols: 6.45–9.68 mg CE/g | [162] | ||||

| Lima bean and cowpea/wheat | TAC: 16.63–21.39 mg Trolox eq./g ↓ | [158] | ||||

| Hard-to-cook bean protein hydrolysate/wheat semolina | ABTS: 6.6.-7.9 mM/mg ↓ | [146] | ||||

| Carob fiber/wheat semolina | Total phenols: 3.21–4.8 mg GAE/g | [163] | ||||

| Carob pod/wheat semolina | Total phenols: 5.3–12.2 mg GAE/g | ABTS: 0.25–1.35 mg Trolox eq./g FRAP: 2.05–6.9 mg Trolox eq./g | [164] | |||

| Chickpea/soya/different cereals | 1050–9640 mg IP6/Kg | [138] | ||||

| Germinated and fermented cowpea flour/wheat semolina | 574 mg IP6/g ↓ | TAC: 27.5 µmol Trolox eq./g | [154] | |||

| Lentil | Total phenols: 0.93–1.42 mg GAE/g ↓ | [131] | ||||

| Pea | 0.23–0.29 TIU/mg ↓ | [151] | ||||

| Fermented pigeon pea/wheat semolina | n.d. * | 0.24 g/100 g | n.d. | Tannins: 0.28 g GAE/100 g | TAC: 3.35 µmol Trolox eq./g | [153] |

| Germinated pigeon pea/wheat semolina | 0.27 g/100 g | 1.57 TIU/mg | Tannins: 0.19 g GAE/100 g | TAC: 5.8 µmol Trolox eq./g | [160] |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Pedrosa, M.M.; Guillamón, E.; Arribas, C. Autoclaved and Extruded Legumes as a Source of Bioactive Phytochemicals: A Review. Foods 2021, 10, 379. https://doi.org/10.3390/foods10020379

Pedrosa MM, Guillamón E, Arribas C. Autoclaved and Extruded Legumes as a Source of Bioactive Phytochemicals: A Review. Foods. 2021; 10(2):379. https://doi.org/10.3390/foods10020379

Chicago/Turabian StylePedrosa, Mercedes M., Eva Guillamón, and Claudia Arribas. 2021. "Autoclaved and Extruded Legumes as a Source of Bioactive Phytochemicals: A Review" Foods 10, no. 2: 379. https://doi.org/10.3390/foods10020379

APA StylePedrosa, M. M., Guillamón, E., & Arribas, C. (2021). Autoclaved and Extruded Legumes as a Source of Bioactive Phytochemicals: A Review. Foods, 10(2), 379. https://doi.org/10.3390/foods10020379