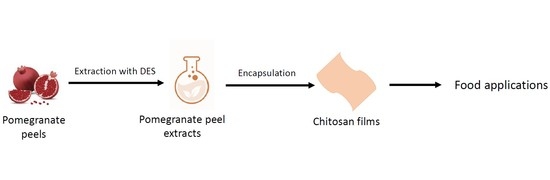

Physical Properties of Chitosan Films Containing Pomegranate Peel Extracts Obtained by Deep Eutectic Solvents

Abstract

:1. Introduction

2. Materials and Methods

2.1. Chemicals and Reagents

2.2. Plant Material

2.3. Extraction Procedure

2.4. Total Polyphenol Yield

2.5. Total Flavonoid Yield

2.6. Experimental Design

2.7. Statistical Analysis

2.8. Preparation of the Plasticized or Non-Plasticized Chitosan Films

2.9. Film Characterization

2.9.1. Sorption Behavior-Moisture Content

2.9.2. Large Deformation Mechanical Test (Tensile Strength)

2.9.3. Color Parameters

3. Results

3.1. Optimization of the Extraction Process

3.2. Membrane Water Adsorption

3.3. Large Deformation Mechanical Test (Tensile Strength)

3.4. Color Parameters

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Conflicts of Interest

References

- Al-Zoreky, N.S. Antimicrobial Activity of Pomegranate (Punica granatum L.) Fruit Peels. Int. J. Food Microbiol. 2009, 134, 244–248. [Google Scholar] [CrossRef]

- Kaderides, K.; Goula, A.M.; Adamopoulos, K.G. A Process for Turning Pomegranate Peels into a Valuable Food Ingredient Using Ultrasound-Assisted Extraction and Encapsulation. Innov. Food Sci. Emerg. Technol. 2015, 31, 204–215. [Google Scholar] [CrossRef]

- Akhtar, S.; Ismail, T.; Fraternale, D.; Sestili, P. Pomegranate Peel and Peel Extracts: Chemistry and Food Features. Food Chem. 2015, 174, 417–425. [Google Scholar] [CrossRef]

- Diamanti, A.C.; Igoumenidis, P.E.; Mourtzinos, I.; Yannakopoulou, K.; Karathanos, V.T. Green Extraction of Polyphenols from Whole Pomegranate Fruit Using Cyclodextrins. Food Chem. 2017, 214, 61–66. [Google Scholar] [CrossRef] [PubMed]

- Masci, A.; Coccia, A.; Lendaro, E.; Mosca, L.; Paolicelli, P.; Cesa, S. Evaluation of Different Extraction Methods from Pomegranate Whole Fruit or Peels and the Antioxidant and Antiproliferative Activity of the Polyphenolic Fraction. Food Chem. 2016, 202, 59–69. [Google Scholar] [CrossRef] [PubMed]

- Mastrodi Salgado, J.; Baroni Ferreira, T.R.; de Oliveira Biazotto, F.; dos Santos Dias, C.T. Increased Antioxidant Content in Juice Enriched with Dried Extract of Pomegranate (Punica Granatum) Peel. Plant Foods Hum. Nutr. 2012, 67, 39–43. [Google Scholar] [CrossRef] [PubMed]

- Kalaycıoğlu, Z.; Erim, F.B. Total Phenolic Contents, Antioxidant Activities, and Bioactive Ingredients of Juices from Pomegranate Cultivars Worldwide. Food Chem. 2017, 221, 496–507. [Google Scholar] [CrossRef] [PubMed]

- Lantzouraki, D.Z.; Sinanoglou, V.J.; Zoumpoulakis, P.G.; Glamočlija, J.; Ćirić, A.; Soković, M.; Heropoulos, G.; Proestos, C. Antiradical–Antimicrobial Activity and Phenolic Profile of Pomegranate (Punica granatum L.) Juices from Different Cultivars: A Comparative Study. RSC Adv. 2015, 5, 2602–2614. [Google Scholar] [CrossRef]

- Spilmont, M.; Léotoing, L.; Davicco, M.-J.; Lebecque, P.; Miot-Noirault, E.; Pilet, P.; Rios, L.; Wittrant, Y.; Coxam, V. Pomegranate Peel Extract Prevents Bone Loss in a Preclinical Model of Osteoporosis and Stimulates Osteoblastic Differentiation In Vitro. Nutrients 2015, 7, 9265–9284. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Hasnaoui, N.; Wathelet, B.; Jiménez-Araujo, A. Valorization of Pomegranate Peel from 12 Cultivars: Dietary Fibre Composition, Antioxidant Capacity and Functional Properties. Food Chem. 2014, 160, 196–203. [Google Scholar] [CrossRef] [PubMed]

- Tehranifar, A.; Selahvarzi, Y.; Kharrazi, M.; Bakhsh, V.J. High Potential of Agro-Industrial by-Products of Pomegranate (Punica granatum L.) as the Powerful Antifungal and Antioxidant Substances. Ind. Crops Prod. 2011, 34, 1523–1527. [Google Scholar] [CrossRef]

- Fawole, O.A.; Makunga, N.P.; Opara, U.L. Antibacterial, Antioxidant and Tyrosinase-Inhibition Activities of Pomegranate Fruit Peel Methanolic Extract. BMC Complement. Altern. Med. 2012, 12, 1178. [Google Scholar] [CrossRef] [Green Version]

- Zhang, Q.; De Oliveira Vigier, K.; Royer, S.; Jérôme, F. Deep Eutectic Solvents: Syntheses, Properties and Applications. Chem. Soc. Rev. 2012, 41, 7108–7146. [Google Scholar] [CrossRef]

- Abbott, A.P.; Harris, R.C.; Ryder, K.S.; D’Agostino, C.; Gladden, L.F.; Mantle, M.D. Glycerol Eutectics as Sustainable Solvent Systems. Green Chem. 2011, 13, 82–90. [Google Scholar] [CrossRef]

- Dutta, S.; Nath, K. Prospect of Ionic Liquids and Deep Eutectic Solvents as New Generation Draw Solution in Forward Osmosis Process. J. Water Process Eng. 2018, 21, 163–176. [Google Scholar] [CrossRef]

- Smith, E.L.; Abbott, A.P.; Ryder, K.S. Deep Eutectic Solvents (DESs) and Their Applications. Chem. Rev. 2014, 114, 11060–11082. [Google Scholar] [CrossRef] [Green Version]

- Tomé, L.I.N.; Baião, V.; da Silva, W.; Brett, C.M.A. Deep Eutectic Solvents for the Production and Application of New Materials. Appl. Mater. Today 2018, 10, 30–50. [Google Scholar] [CrossRef]

- Abbott, A.P.; Harris, R.C.; Ryder, K.S. Application of Hole Theory to Define Ionic Liquids by Their Transport Properties. J. Phys. Chem. B 2007, 111, 4910–4913. [Google Scholar] [CrossRef]

- Ilgen, F.; Ott, D.; Kralisch, D.; Reil, C.; Palmberger, A.; König, B. Conversion of Carbohydrates into 5-Hydroxymethylfurfural in Highly Concentrated Low Melting Mixtures. Green Chem. 2009, 11, 1948. [Google Scholar] [CrossRef]

- Weaver, K.D.; Kim, H.J.; Sun, J.; MacFarlane, D.R.; Elliott, G.D. Cyto-Toxicity and Biocompatibility of a Family of Choline Phosphate Ionic Liquids Designed for Pharmaceutical Applications. Green Chem. 2010, 12, 507. [Google Scholar] [CrossRef]

- Paiva, A.; Craveiro, R.; Aroso, I.; Martins, M.; Reis, R.L.; Duarte, A.R.C. Natural Deep Eutectic Solvents—Solvents for the 21st Century. ACS Sustain. Chem. Eng. 2014, 2, 1063–1071. [Google Scholar] [CrossRef]

- Yu, J.; Wang, J.; Wu, X.; Zhu, P. Effect of Glycerol on Water Vapor Sorption and Mechanical Properties of Starch/Clay Composite Films. Starch-Stärke 2008, 60, 257–262. [Google Scholar] [CrossRef]

- Chemat, F.; Vian, M.A.; Ravi, H.K.; Khadhraoui, B.; Hilali, S.; Perino, S.; Tixier, A.S.F. Review of Alternative Solvents for Green Extraction of Food and Natural Products: Panorama, Principles, Applications and Prospects. Molecules 2019, 24, 3007. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Nayik, G.A.; Majid, I.; Kumar, V. Characterization of Indian Honeys View Project Sprouted Onion View Project Developments in Edible Films and Coatings for the Extension of Shelf Life of Fresh Fruits. Am. J. Nutr. Food Sci. 2015, 2, 16–20. [Google Scholar] [CrossRef]

- Hassan, B.; Chatha, S.A.S.; Hussain, A.I.; Zia, K.M.; Akhtar, N. Recent Advances on Polysaccharides, Lipids and Protein Based Edible Films and Coatings: A Review. Int. J. Biol. Macromol. 2018, 109, 1095–1107. [Google Scholar] [CrossRef]

- Bourtoom, T. Plasticizer Effect on the Properties of Biodegradable Blend Film from Rice Starch-Chitosan. Songklanakarin J. Sci. Technol. 2008, 30, 149–165. [Google Scholar]

- Menezes, J.; Athmaselvi, K.A. Report on Edible Films and Coatings. In Food Packaging and Preservation; Grumezescu, A.M., Holban, A.M., Eds.; Academic Press: Cambridge, MA, USA, 2018; pp. 177–212. [Google Scholar] [CrossRef]

- Cerqueira, M.A.; Bourbon, A.I.; Pinheiro, A.C.; Martins, J.T.; Souza, B.W.S.; Teixeira, J.A.; Vicente, A.A. Galactomannans Use in the Development of Edible Films/Coatings for Food Applications. Trends Food Sci. Technol. 2011, 22, 662–671. [Google Scholar] [CrossRef] [Green Version]

- Otoni, C.G.; Avena-Bustillos, R.J.; Azeredo, H.M.C.; Lorevice, M.V.; Moura, M.R.; Mattoso, L.H.C.; McHugh, T.H. Recent Advances on Edible Films Based on Fruits and Vegetables—A Review. Compr. Rev. Food Sci. Food Saf. 2017, 16, 1151–1169. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Karakashov, B.; Grigorakis, S.; Loupassaki, S.; Makris, D.P. Optimisation of Polyphenol Extraction from Hypericum Perforatum (St. John’s Wort) Using Aqueous Glycerol and Response Surface Methodology. J. Appl. Res. Med. Aromat. Plants 2015, 2, 1–8. [Google Scholar] [CrossRef]

- Surana, A.R.; Kumbhare, M.R.; Wagh, R.D. Estimation of Total Phenolic and Total Flavonoid Content and Assessment of In Vitro Antioxidant Activity of Extracts of Hamelia Patens Jacq. Stems. Res. J. Phytochem. 2016, 10, 67–74. [Google Scholar] [CrossRef] [Green Version]

- Karvela, E.; Makris, D.P.; Kalogeropoulos, N.; Karathanos, V.T. Deployment of Response Surface Methodology to Optimise Recovery of Grape (Vitis Vinifera) Stem Polyphenols. Talanta 2009, 79, 1311–1321. [Google Scholar] [CrossRef]

- Kiassos, E.; Mylonaki, S.; Makris, D.P.; Kefalas, P. Implementation of Response Surface Methodology to Optimise Extraction of Onion (Allium Cepa) Solid Waste Phenolics. Innov. Food Sci. Emerg. Technol. 2009, 10, 246–252. [Google Scholar] [CrossRef]

- Lu, S.; Song, X.; Cao, D.; Chen, Y.; Yao, K. Preparation of Water-Soluble Chitosan. J. Appl. Polym. Sci. 2004, 91, 3497–3503. [Google Scholar] [CrossRef]

- Brunauer, S.; Emmett, P.H.; Teller, E. Adsorption of Gases in Multimolecular Layers. J. Am. Chem. Soc. 1938, 60, 309–319. [Google Scholar] [CrossRef]

- Van den Berg, C.; Bruin, S. Water Activity and Its Estimation in Food Systems: Theoretical Aspects. In Water Activity: Influences on Food Quality; Rdocklan, L.B., Stewart, G.F., Eds.; Academic Press: Cambridge, MA, USA, 1981; pp. 2–61. [Google Scholar]

- Arvanitoyannis, I.; Psomiadou, E. Composites of Anionic (Co)Polyamides (Nylon 6/Nylon 12) with Short Glass E-Fibers. Preparation and Properties. J. Appl. Polym. Sci. 1994, 51, 1883–1899. [Google Scholar] [CrossRef]

- Pal, J.; Raju, C.V.; Lakshmisha, I.P.; Pandey, G.; Raj, R.; Singh, R.R. Antioxidant Activity of Pomegranate Peel Extract and Its Effect on Storage Stability of Cooked Meat Model System of Indian Mackerel (Rastrelliger kanagurta) Stored at 4 ± 2 °C. Biochem. Cell. Arch. 2017, 17, 183–187. [Google Scholar]

- Derakhshan, Z.; Ferrante, M.; Tadi, M.; Ansari, F.; Heydari, A.; Hosseini, M.S.; Conti, G.O.; Sadrabad, E.K. Antioxidant Activity and Total Phenolic Content of Ethanolic Extract of Pomegranate Peels, Juice and Seeds. Food Chem. Toxicol. 2018, 114, 108–111. [Google Scholar] [CrossRef]

- Xi, J.; He, L.; Yan, L.G. Continuous Extraction of Phenolic Compounds from Pomegranate Peel Using High Voltage Electrical Discharge. Food Chem. 2017, 230, 354–361. [Google Scholar] [CrossRef]

- Ambigaipalan, P.; De Camargo, A.C.; Shahidi, F. Phenolic Compounds of Pomegranate Byproducts (Outer Skin, Mesocarp, Divider Membrane) and Their Antioxidant Activities. J. Agric. Food Chem. 2016, 64, 6584–6604. [Google Scholar] [CrossRef] [PubMed]

- Mushtaq, M.; Sultana, B.; Anwar, F.; Adnan, A.; Rizvi, S.S.H. Enzyme-Assisted Supercritical Fluid Extraction of Phenolic Antioxidants from Pomegranate Peel. J. Supercrit. Fluids 2015, 104, 122–131. [Google Scholar] [CrossRef]

- Rajha, H.N.; Mhanna, T.; El Kantar, S.; El Khoury, A.; Louka, N.; Maroun, R.G. Innovative Process of Polyphenol Recovery from Pomegranate Peels by Combining Green Deep Eutectic Solvents and a New Infrared Technology. LWT 2019, 111, 138–146. [Google Scholar] [CrossRef]

- Mouratoglou, E.; Malliou, V.; Makris, D.P. Novel Glycerol-Based Natural Eutectic Mixtures and Their Efficiency in the Ultrasound-Assisted Extraction of Antioxidant Polyphenols from Agri-Food Waste Biomass. Waste Biomass Valorization 2016, 7, 1377–1387. [Google Scholar] [CrossRef]

- Yoo, D.E.; Jeong, K.M.; Han, S.Y.; Kim, E.M.; Jin, Y.; Lee, J. Deep Eutectic Solvent-Based Valorization of Spent Coffee Grounds. Food Chem. 2018, 255, 357–364. [Google Scholar] [CrossRef]

- Athanasiadis, V.; Grigorakis, S.; Lalas, S.; Makris, D.P. Highly Efficient Extraction of Antioxidant Polyphenols from Olea Europaea Leaves Using an Eco-Friendly Glycerol/Glycine Deep Eutectic Solvent. Waste Biomass Valorization 2018, 9, 1985–1992. [Google Scholar] [CrossRef]

- Bakirtzi, C.; Triantafyllidou, K.; Makris, D.P. Novel Lactic Acid-Based Natural Deep Eutectic Solvents: Efficiency in the Ultrasound-Assisted Extraction of Antioxidant Polyphenols from Common Native Greek Medicinal Plants. J. Appl. Res. Med. Aromat. Plants 2016, 3, 120–127. [Google Scholar] [CrossRef]

- Benvenutti, L.; Zielinski, A.A.F.; Ferreira, S.R.S. Which Is the Best Food Emerging Solvent: IL, DES or NADES? Trends Food Sci. Technol. 2019, 90, 133–146. [Google Scholar] [CrossRef]

- de los Ángeles Fernández, M.; Boiteux, J.; Espino, M.; Gomez, F.J.V.; Silva, M.F. Natural Deep Eutectic Solvents-Mediated Extractions: The Way Forward for Sustainable Analytical Developments. Anal. Chim. Acta 2018, 1038, 1–10. [Google Scholar] [CrossRef] [PubMed]

- Ozturk, B.; Parkinson, C.; Gonzalez-Miquel, M. Extraction of Polyphenolic Antioxidants from Orange Peel Waste Using Deep Eutectic Solvents. Sep. Purif. Technol. 2018, 206, 1–13. [Google Scholar] [CrossRef]

- Dai, Y.; Verpoorte, R.; Choi, Y.H. Natural Deep Eutectic Solvents Providing Enhanced Stability of Natural Colorants from Safflower (Carthamus Tinctorius). Food Chem. 2014, 159, 116–121. [Google Scholar] [CrossRef] [PubMed]

- Castelló, M.E.; Anbinder, P.S.; Amalvy, J.I.; Peruzzo, P.J. Production and Characterization of Chitosan and Glycerol-Chitosan Films. MRS Adv. 2018, 3, 3601–3610. [Google Scholar] [CrossRef]

- Roos, Y.H. Phase Transitions in Foods; American Press: Cambridge, MA, USA, 1995. [Google Scholar] [CrossRef]

- Galvis-Sánchez, A.C.; Castro, M.C.R.; Biernacki, K.; Gonçalves, M.P.; Souza, H.K.S. Natural Deep Eutectic Solvents as Green Plasticizers for Chitosan Thermoplastic Production with Controlled/Desired Mechanical and Barrier Properties. Food Hydrocoll. 2018, 82, 478–489. [Google Scholar] [CrossRef]

- Platzer, N.A.J. Plasticization and Plasticizer Processes; Platzer, N.A.J., Ed.; Advances in Chemistry; American Chemical Society: Washington, DC, USA, 1965; Volume 48. [Google Scholar] [CrossRef] [Green Version]

- Almeida, C.M.R.; Magalhães, J.M.C.S.; Souza, H.K.S.; Gonçalves, M.P. The Role of Choline Chloride-Based Deep Eutectic Solvent and Curcumin on Chitosan Films Properties. Food Hydrocoll. 2018, 81, 456–466. [Google Scholar] [CrossRef]

- Ojagh, S.M.; Rezaei, M.; Razavi, S.H.; Hosseini, S.M.H. Development and Evaluation of a Novel Biodegradable Film Made from Chitosan and Cinnamon Essential Oil with Low Affinity toward Water. Food Chem. 2010, 122, 161–166. [Google Scholar] [CrossRef]

- Wang, L.; Dong, Y.; Men, H.; Tong, J.; Zhou, J. Preparation and Characterization of Active Films Based on Chitosan Incorporated Tea Polyphenols. Food Hydrocoll. 2013, 32, 35–41. [Google Scholar] [CrossRef]

- Siripatrawan, U.; Vitchayakitti, W. Improving Functional Properties of Chitosan Films as Active Food Packaging by Incorporating with Propolis. Food Hydrocoll. 2016, 61, 695–702. [Google Scholar] [CrossRef]

- Ma, Q.; Du, L.; Wang, L. Tara Gum/Polyvinyl Alcohol-Based Colorimetric NH3 Indicator Films Incorporating Curcumin for Intelligent Packaging. Sens. Actuators B Chem. 2017, 244, 759–766. [Google Scholar] [CrossRef]

| Independent Variables | Coded Units | Levels of Coded Variables | ||||

|---|---|---|---|---|---|---|

| −1.682 | −1 | 0 | 1 | 1.682 | ||

| CW (%. v/v) | X1 | 5 | 15 | 30 | 45 | 55 |

| RL/S (mL g−1) | X2 | 13 | 20 | 30 | 40 | 47 |

| t (min) | X3 | 36 | 50 | 70 | 90 | 103 |

| Samples | Composition (% Dry Matter) | ||

|---|---|---|---|

| Chitosan | DES | DES Extract | |

| Ch | 100 | - | - |

| 25DES | 75 | - | 25 |

| 50DES | 50 | - | 50 |

| 25DES0 | 75 | 25 | - |

| 50DES0 | 50 | 50 | - |

| Dependent Variable | 2nd Degree Polynomial Equations | R2 | p |

|---|---|---|---|

| YTP (mg GAE g−1 dw) | 221.50 − 30.78 × X2 | 0.93 | 0.0030 |

| YTF (mg QE g−1 dw) | 11.70 − 0.6 × X1 + 1.64 × X2 + 1.69 × (X2)2 − 0.65 × (X3)2 | 0.89 | 0.0119 |

| Sample | BET (aw Range 0.11–0.64) | GAB (aw Range 0.11–0.94) | |||||

|---|---|---|---|---|---|---|---|

| mm (g Water/100 g dw) | K | r2 (n = 6) | mm (g Water/100 g dw) | K’ | C | r2 (n = 9) | |

| Ch | 5.3 | 7.9 | 0.98 | 6.6 | 0.87 | 5. 7 | 0.90 |

| 25DES | 5.6 | 5.0 | 0.93 | 6.8 | 0.90 | 4.0 | 0.88 |

| 50DES | 7.4 | 4.4 | 0.92 | 10.3 | 0.87 | 2.8 | 0.92 |

| 25DES0 | 6.4 | 3.5 | 0.94 | 9.6 | 0.86 | 2.3 | 0.95 |

| 50DES0 | 9.1 | 3.2 | 0.99 | 12.8 | 0.84 | 2.4 | 0.97 |

| Samples | L | a | b | ΔΕ |

|---|---|---|---|---|

| Ch | 91.76 ± 0.11 a | −1.13 ± 0.07 b | 5.27 ± 0.30 c | 6.89 ± 0.25 c |

| 25DES | 77.04 ± 1.09 b | −0.79 ± 0.41 b | 38.00 ± 1.15 c | 41.65 ± 1.52 b |

| 50DES | 76.43 ± 0.98 b | 1.52 ± 0.73 a | 44.76 ± 1.00 c | 47.93 ± 1.35 a |

| 25DES0 | 91.63 ± 0.24 a | −1.04 ± 0.37 b | 4.70 ± 1.46 b | 6.82 ± 0.86 c |

| 50DES0 | 92.64 ± 0.64 a | −1.11 ± 0.23 b | 4.98 ± 1.07 a | 6.03 ± 1.04 c |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kyriakidou, A.; Makris, D.P.; Lazaridou, A.; Biliaderis, C.G.; Mourtzinos, I. Physical Properties of Chitosan Films Containing Pomegranate Peel Extracts Obtained by Deep Eutectic Solvents. Foods 2021, 10, 1262. https://doi.org/10.3390/foods10061262

Kyriakidou A, Makris DP, Lazaridou A, Biliaderis CG, Mourtzinos I. Physical Properties of Chitosan Films Containing Pomegranate Peel Extracts Obtained by Deep Eutectic Solvents. Foods. 2021; 10(6):1262. https://doi.org/10.3390/foods10061262

Chicago/Turabian StyleKyriakidou, Aikaterini, Dimitris P. Makris, Athina Lazaridou, Costas G. Biliaderis, and Ioannis Mourtzinos. 2021. "Physical Properties of Chitosan Films Containing Pomegranate Peel Extracts Obtained by Deep Eutectic Solvents" Foods 10, no. 6: 1262. https://doi.org/10.3390/foods10061262

APA StyleKyriakidou, A., Makris, D. P., Lazaridou, A., Biliaderis, C. G., & Mourtzinos, I. (2021). Physical Properties of Chitosan Films Containing Pomegranate Peel Extracts Obtained by Deep Eutectic Solvents. Foods, 10(6), 1262. https://doi.org/10.3390/foods10061262