Effects of Gaseous Ozone on Microbiological Quality of Andean Blackberries (Rubus glaucus Benth)

Abstract

:1. Introduction

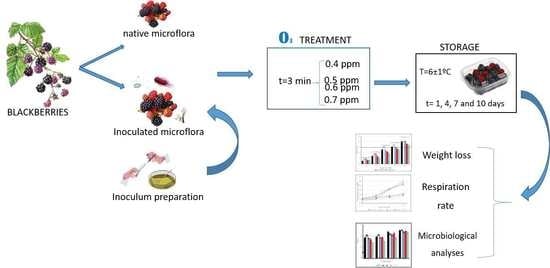

2. Materials and Methods

2.1. Plant Material

2.2. Microbial Strains

2.3. Preparation of Inoculum

2.4. Inoculation of Andean Blackberries

2.5. Ozone Treatment

2.5.1. Inoculated Blackberries

2.5.2. Non-Inoculated Blackberries

2.6. Packing and Storage

2.7. Respiration Rate

2.8. Mass Loss

2.9. Microbiological Analyses

2.9.1. Inoculated Microorganisms

2.9.2. Native Microflora: Total Aerobic Mesophiles, Psychrotrophs, and Yeasts and Molds

2.10. Statistical Analyses

3. Results and Discussion

3.1. Respiration Rate

3.2. Mass Loss

3.3. Microbiological Analyses

3.3.1. E. coli and S. enterica

3.3.2. Botrytis cinerea

3.3.3. Native Microflora: Total Aerobic Mesophiles, Psychrotrophs, and Molds and Yeasts

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Martínez, A.; Beltrán, O.; Velastegui, G.; Ayala, G.; Jácome, R.; Yánez, M.; Luciano, E. Manual del Cultivo de la Mora de Castilla; INIAP: Quito, Ecuador, 2007; pp. 9–16. (In Spanish) [Google Scholar]

- Clark, J.R.; Finn, C.E. Blackberry cultivation in the world. Rev. Bras. Frutic. 2014, 36, 46–57. [Google Scholar] [CrossRef] [Green Version]

- Gabioud Rebeaud, S.; Varone, V.; Vuong, L.; Cotter, P.Y.; Ançay, A.; Christen, D. Postharvest ozone treatment on raspberries. Acta Hortic. 2020, 1277, 449–454. [Google Scholar] [CrossRef]

- Horvitz, S.; Chanaguano, D. Microbial and sensory quality of an Andean blackberry (Rubus glaucus Benth) cultivar. Acta Hortic. 2020, 1275, 121–124. [Google Scholar] [CrossRef]

- Junqueira-Gonçalves, M.P.; Alarcón, E.; Niranjan, K. The efficacy of potassium sorbate-coated packaging to control postharvest gray mold in raspberries, blackberries and blueberries. Postharvest Biol. Technol. 2016, 11, 205–208. [Google Scholar] [CrossRef]

- Contigiani, E.V.; Jaramillo-Sánchez, G.; Castro, M.A.; Gómez, P.L.; Alzamora, S.M. Postharvest Quality of Strawberry Fruit (Fragaria × Ananassa Duch cv. Albion) as Affected by Ozone Washing: Fungal Spoilage, Mechanical Properties, and Structure. Food Bioproc. Tech. 2018, 11, 1639–1650. [Google Scholar] [CrossRef]

- Romanazzi, G.; Smilanick, J.L.; Feliziani, E.; Droby, S. Integrated management of postharvest gray mold on fruit crops. Postharvest Biol. Technol. 2016, 113, 69–76. [Google Scholar] [CrossRef]

- Vardar, C.; Ilhan, K.; Karabulut, O.A. The application of various disinfectants by fogging for decreasing postharvest diseases of strawberry. Postharvest Biol. Technol. 2012, 66, 30–34. [Google Scholar] [CrossRef]

- Murray, K.; Wu, F.; Shi, J.; Jun Xue, S.; Warriner, K. Challenges in the microbiological food safety of fresh produce: Limitations of post-harvest washing and the need for alternative interventions. Food Qual. Saf. 2017, 1, 289–301. [Google Scholar] [CrossRef] [Green Version]

- Horvitz, S.; Chanaguano, D.; Arozarena, I. Andean blackberries (Rubus glaucus Benth) quality as affected by harvest maturity and storage conditions. Sci. Hortic. 2017, 226, 293–301. [Google Scholar] [CrossRef]

- Torlak, E. Use of gaseous ozone for reduction of ochratoxin A and fungal populations on sultanas. Aust. J. Grape Wine Res. 2019, 25, 25–29. [Google Scholar] [CrossRef] [Green Version]

- Pandiselvam, R.; Sunoj, S.; Manikantan, M.R.; Kothakota, A.; Hebbar, K.B. Application and Kinetics of Ozone in Food Preservation. Ozone Sci Eng. 2017, 39, 115–126. [Google Scholar] [CrossRef]

- United States Food and Drug Administration. Rules and Regulations. Part 173-Secondary Direct Food Additives Permitted in Food for Human Consumption (21 CFR Part 173 Authority: 21 USC. 321, 342, 348); Federal Register; United States Food and Drug Administration: Silver Spring, MD, USA, 2001; Volume 66, p. 123. [Google Scholar]

- Zainuri, J.; Sauqi, A.; Sjah, T.; Desiana, R.Y. Combination of ozone and packaging treatments maintained the quality and improved the shelf life of tomato fruit. IOP Conf. Ser. Earth Environ. Sci. 2018, 102, 012027. [Google Scholar] [CrossRef]

- Tzortzakis, N.; Chrysargyris, A. Postharvest ozone application for the preservation of fruits and vegetables. Food Rev Int. 2017, 33, 270–315. [Google Scholar] [CrossRef]

- Glowacz, M.; Rees, D. The practicality of using ozone with fruit and vegetables. J. Sci. Food Agric. 2016, 96, 4637–4643. [Google Scholar] [CrossRef]

- Pinto, L.; Caputo, L.; Quintieri, L.; de Candia, S.; Baruzzi, F. Efficacy of gaseous ozone to counteract postharvest table grape sour rot. Food Microbiol. 2017, 66, 190–198. [Google Scholar] [CrossRef] [PubMed]

- Ozkan, R.; Smilanick, J.L.; Karabulut, O.A. Toxicity of ozone gas to conidia of Penicillium digitatum, Penicillium italicum, and Botrytis cinerea and control of gray mold on table grapes. Postharvest Biol. Technol. 2011, 60, 47–51. [Google Scholar] [CrossRef]

- Lopes-Morais, M.; Alvinhäo, J.E.O.; Vilela-Franco, D.; Silva, E.d.B.; Dessimoni-Pinto, N.A.V. Application of ozone aiming to keep the quality of strawberries using a low cost reactor. Rev Bras Frutic. 2015, 37, 559–567. [Google Scholar] [CrossRef] [Green Version]

- Pinto, L.; Palma, A.; Cefola, M.; Pace, B.; D’Aquino, S.; Carboni, C.; Baruzzi, F. Effect of modified atmosphere packaging (MAP) and gaseous ozone pre-packaging treatment on the physico-chemical, microbiological and sensory quality of small berry fruit. Food Packag. Shelf Life 2020, 26, 100573. [Google Scholar] [CrossRef]

- Onopiuk, A.; Półtorak, A.; Moczkowska, M.; Szpicer, A.; Wierzbicka, A. The impact of ozone on health-promoting, microbiological, and colour properties of Rubus ideaus raspberries. CyTA-J. Food 2017, 15, 563–573. [Google Scholar] [CrossRef] [Green Version]

- Piechowiak, T.; Antos, P.; Kosowski, P.; Skrobacz, K.; Józefczyk, R.; Balawejder, M. Impact of ozonation process on the microbiological and antioxidant status of raspberries (Rubus ideaeus L.) during storage at room temperature. Agric Food Sci. 2019, 28, 35–44. [Google Scholar] [CrossRef]

- Han, Q.; Gao, H.; Chen, H.; Fang, X.; Wu, W. Precooling and ozone treatments affects postharvest quality of black mulberry (Morus nigra) fruits. Food Chem. 2017, 221, 1947–1953. [Google Scholar] [CrossRef] [PubMed]

- Piechowiak, T.; Antos, P.; Józefczyk, R.; Kosowski, P.; Skrobacz, K.; Balawejder, M. Impact of Ozonation Process on the Microbiological Contamination and Antioxidant Capacity of Highbush Blueberry (Vaccinum corymbosum L.) Fruit during Cold Storage. Ozone Sci. Eng. 2019, 41, 376–385. [Google Scholar] [CrossRef]

- Barth, M.M.; Zhou, C.; Mercier, J.; Payne, F.A. Ozone storage effects on anthocyanin content and fungal growth in blackberries. J. Food Sci. 1995, 60, 1286–1288. [Google Scholar] [CrossRef]

- Pérez, A.G.; Sanz, C.; Ríos, J.J.; Olías, R.; Olías, J.M. Effects of ozone treatment on postharvest strawberry quality. J. Agric. Food Chem. 1999, 47, 1652–1656. [Google Scholar] [CrossRef]

- Tabakoglu, N.; Karaca, H. Effects of ozone-enriched storage atmosphere on postharvest quality of black mulberry fruits (Morus nigra L.). LWT 2018, 92, 276–281. [Google Scholar] [CrossRef]

- Concha-Meyer, A.; Eifert, J.D.; Williams, R.C.; Marcy, J.E.; Welbaum, G.E. Shelf Life Determination of Fresh Blueberries (Vaccinium corymbosum) Stored under Controlled Atmosphere and Ozone. Int. J. Food Sci. 2015, 2015, 164143. [Google Scholar] [CrossRef] [Green Version]

- Sharpe, D.; Fan, L.; McRae, K.; Walker, B.; MaCKay, R.; Doucette, C. Effects of ozone treatment on Botrytis cinerea and Sclerotinia sclerotiorum in relation to horticultural product quality. J. Food Sci. 2009, 74, M250–M257. [Google Scholar] [CrossRef]

- Chilosi, G.; Tagliavento, V.; Simonelli, R. Application of ozone gas at low doses in the cold storage of fruit and vegetables. Acta Hortic. 2015, 1071, 681–686. [Google Scholar] [CrossRef]

- Instituto Ecuatoriano de Normalización. INEN 2427:2010: Frutas Frescas. Mora. Requisitos; Instituto Ecuatoriano de Normalización: Quito, Ecuador, 2010. (In Spanish) [Google Scholar]

- Brodowska, A.J.; Nowak, A.; Kondratiuk-Janyska, A.; Piątkowski, M.; Śmigielski, K. Modelling the Ozone-Based Treatments for Inactivation of Microorganisms. Int. J. Environ. Res. Public Health 2017, 14, 1196. [Google Scholar] [CrossRef] [Green Version]

- Pérez-Gallardo, A.; García-Almendárez, B.; Barbosa-Cánovas, G.; Pimentel-González, D.; Reyes-González, L.R.; Regalado, C. Effect of starch-beeswax coatings on quality parameters of blackberries (Rubus spp.). J. Food Sci. Technol. 2015, 52, 5601–5610. [Google Scholar] [CrossRef] [Green Version]

- Chen, C.; Zhang, H.; Zhang, X.; Dong, C.; Xue, W.; Xu, W. The effect of different doses of ozone treatments on the postharvest quality and biodiversity of cantaloupes. Postharvest Biol. Technol. 2020, 163, 111124. [Google Scholar] [CrossRef]

- Allende, A.; Marín, A.; Buendía, B.; Tomás-Barberán, F.; Gil, M.I. Impact of combined postharvest treatments (UV-C light, gaseous O3, superatmospheric O2 and high CO2) on health promoting compounds and shelf-life of strawberries. Postharvest Biol. Technol. 2007, 46, 201–211. [Google Scholar] [CrossRef]

- Forney, C.F.; Song, J.; Fan, L.; Hildebrand, P.D.; Jordan, M.A. Ozone and 1-MCP alter the postharvest quality of broccoli. J. Amer. Soc. Hort. Sci. 2003, 128, 403–408. [Google Scholar] [CrossRef] [Green Version]

- Kumar, P.; Sethi, S.; Sharma, R.R.; Srivastav, M.; Varghese, E. Effect of chitosan coating on postharvest life and quality of plum during storage at low temperature. Sci. Hortic. 2017, 226, 104–109. [Google Scholar] [CrossRef]

- Joo, M.; Lewandowski, N.; Auras, R.; Harte, J.; Almenar, E. Comparative shelf life study of blackberry fruit in bio-based and petroleum-based containers under retail storage conditions. Food Chem. 2011, 126, 1734–1740. [Google Scholar] [CrossRef]

- Nayak, S.L.; Sethi, S.; Sharma, R.R.; Sharma, R.M.; Singh, S.; Singh, D. Aqueous ozone controls decay and maintains quality attributes of strawberry (Fragaria × ananassa Duch.). J. Food Sci. Technol. 2020, 57, 319–326. [Google Scholar] [CrossRef]

- Li, H.; Xiong, Z.; Gui, D.; Li, X. Effect of aqueous ozone on quality and shelf life of Chinese winter jujube. J. Food Process. Preserv. 2019, 43, e14244. [Google Scholar] [CrossRef]

- Wieczynska, J.; Lovino, R.; Lamaj, F.; De Cillis, M.F.; Baser, N.; Ismaili, K.; Verrastro, V.; Tarricone, L.; Simeone, V. Effect of O3 and high CO2 application during cold storage on quality of organic table grape (Vitis vinifera L. ‘Italia’). Acta Hortic. 2015, 1071, 575–581. [Google Scholar] [CrossRef]

- Horvitz, S.; Cantalejo, M.J. The Effects of Gaseous Ozone and Chlorine on Quality and Shelf-life of Minimally Processed Red Pepper. Acta Hortic. 2010, 877, 583–589. [Google Scholar] [CrossRef]

- Niveditha, A.; Pandiselvam, R.; Prasath, V.A.; Singh, S.K.; Gul, K.; Kothakota, A. Application of cold plasma and ozone technology for decontamination of Escherichia coli in foods—A review. Food Control 2021, 130, 108338. [Google Scholar] [CrossRef]

- Ali, A.; Yeoh, W.K.; Forney, C.; Siddiqui, M.W. Advances in postharvest technologies to extend the storage life of minimally processed fruits and vegetables. Crit. Rev. Food Sci. Nutr. 2018, 58, 2632–2649. [Google Scholar] [CrossRef]

- Emer, Z.; Akbas, M.Y.; Ozdemir, M. Bactericidal activity of ozone against E. coli in whole and ground black peppers. J. Food Prot. 2008, 71, 914–917. [Google Scholar] [CrossRef]

- Bialka, K.L.; Demirci, A. Utilization of gaseous ozone for the decontamination of Escherichia coli O157:H7 and Salmonella on raspberries and strawberries. J. Food Prot. 2007, 70, 1093–1098. [Google Scholar] [CrossRef]

- Akata, I.; Torlak, E.; Erci, F. Efficacy of gaseous ozone for reducing microflora and foodborne pathogens on button mushroom. Postharvest Biol. Technol. 2015, 109, 40–44. [Google Scholar] [CrossRef]

- Daş, E.; Candan-Gürakan, G.; Bayındırlı, A. Effect of controlled atmosphere storage, modified atmosphere packaging and gaseous ozone treatment on the survival of Salmonella enteritidis on cherry tomatoes. Food Microbiol. 2006, 23, 430–438. [Google Scholar] [CrossRef]

- Gibson, K.E.; Almeida, G.; Jones, S.L.; Wright, K.; Lee, J.A. Inactivation of bacteria on fresh produce by batch wash ozone sanitation. Food Control 2019, 106, 106747. [Google Scholar] [CrossRef]

- Jacques, A.C.; Zambiazi, R.C.; Ávila-Gandra, E.; Krumreich, F.; Rickies da Luz, S.; Ribeiro Galvão Machado, M. Sanitization by Chlorine compounds and Ozone: Effect on Bioactive Compounds in Blackberry (Rubus fruticosus) cv. Tupy. Rev. Ceres 2015, 62, 507–515. [Google Scholar] [CrossRef] [Green Version]

- Vlassi, E.; Vlachos, P.; Kornaros, M. Effect of ozonation on table grapes preservation in cold storage. J. Food Sci. Technol. 2018, 55, 2031–2038. [Google Scholar] [CrossRef]

- Smilanick, J.L.; Margosan, D.M.; Mlikota, F. Impact of ozonated water on the quality and shelf-life of fresh citrus fruit, stone fruit and table grapes. Ozone Sci. Eng. 2002, 24, 343–356. [Google Scholar] [CrossRef]

- Brodowska, A.J.; Śmigielski, K.; Nowak, A.; Czyżowska, A.; Otlewska, A. The Impact of Ozone Treatment in Dynamic Bed Parameters on Changes in Biologically Active Substances of Juniper Berries. PLoS ONE 2015, 10, e0144855. [Google Scholar] [CrossRef]

- Karakosta, E.S.; Karabagias, I.K.; Riganakos, K.A. Shelf Life Extension of Greenhouse Tomatoes Using Ozonation in Combination with Packaging under Refrigeration. Ozone Sci. Eng. 2019, 41, 389–397. [Google Scholar] [CrossRef]

- Alves, H.; Alencar, E.R.; Ferreira, W.F.S.; Silva, C.R.; Ribeiro, J.L. Microbiological and physical-chemical aspects of strawberry exposed to ozone gas at different concentrations during storage. Braz. J. Food Technol. 2019, 22, e2018002. [Google Scholar] [CrossRef]

- Liu, Z.; Li, W.; Zhai, X.; Li, X. Combination of precooling with ozone fumigation or low fluctuation of temperature for the quality modifications of postharvest sweet cherries. J. Food Process. Preserv. 2021, 45, e15504. [Google Scholar] [CrossRef]

- Artés-Hernández, F.; Aguayo, E.; Artés, F. Alternative atmosphere treatments for keeping quality of ‘Autumn seedless’ table grapes during long-term cold storage. Postharvest Biol. Technol. 2004, 31, 59–67. [Google Scholar] [CrossRef]

- Horvitz, S.; Cantalejo, M.J. Application of ozone for the postharvest treatment of fruits and vegetables. Crit. Rev. Food Sci. Nutr. 2014, 54, 312–339. [Google Scholar] [CrossRef] [PubMed]

| Microorganism | Day | O3 Concentration (ppm) | ||||

|---|---|---|---|---|---|---|

| 0.0 | 0.4 | 0.5 | 0.6 | 0.7 | ||

| E. coli | 1 | 4.71 ± 0.02 Dd | 4.45 ± 0.02 Cd | 4.36 ± 0.05 BCd | 4.27 ± 0.06 ABc | 4.23 ± 0.13 Ac |

| 4 | 4.39 ± 0.05 Cc | 4.30 ± 0.02 Bc | 4.20 ± 0.08 BAc | 4.19 ± 0.04 BAc | 4.29 ± 0.04 Bc | |

| 7 | 4.00 ± 0.02 Bb | 3.99 ± 0.01 Bb | 3.95 ± 0.03 BBb | 3.92 ± 0.06 BBb | 3.65 ± 0.09 Ab | |

| 10 | 3.49 ± 0.06 Ba | 3.39 ± 0.08 Ba | 3.51 ± 0.08 BBa | 3.05 ± 0.09 BAa | 2.96 ± 0.11 Aa | |

| S. enterica | 1 | 4.47 ± 0.03 Ed | 4.29 ± 0.09 Dd | 3.96 ± 0.08 BCd | 3.75 ± 0.10 BBd | 3.38 ± 0.02 Ad |

| 4 | 4.00 ± 0.08 Cc | 3.90 ± 0.03 Bc | 3.87 ± 0.03 BBc | 2.97 ± 0.10 BAc | 2.98 ± 0.01 Ac | |

| 7 | 3.25 ± 0.05 Eb | 2.99 ± 0.19 Db | 2.15 ± 0.05 BCb | 1.04 ± 0.07 BBb | 0.80 ± 0.06 Ab | |

| 10 | 1.58 ± 0.14 Da | 0.95 ± 0.16 Ca | 0.50 ± 0.00 BBa | 0.00 ± 0.00 BAa | 0.00 ± 0.00 Aa | |

| Microbial Group | Day | O3 Concentration (ppm) | ||||

|---|---|---|---|---|---|---|

| 0.0 | 0.4 | 0.5 | 0.6 | 0.7 | ||

| Aerobic mesophiles | 1 | 2.93 ± 0.03 Ea | 2.66 ± 0.10 Da | 2.25 ± 0.06 Ca | 1.30 ± 0.19 Ba | 1.08 ± 0.12 Aa |

| 4 | 3.23 ± 0.10 Cb | 2.75 ± 0.16 Ba | 2.54 ± 0.21 Bb | 2.18 ± 0.03 Ab | 2.08 ± 0.08 Ab | |

| 7 | 4.00 ± 0.06 Dc | 3.17 ± 0.02 Cb | 2.58 ± 0.11 Bb | 2.26 ± 0.12 Ab | 2.29 ± 0.06 Ac | |

| 10 | 4.00 ± 0.10 Ec | 3.88 ± 0.02 Dc | 3.66 ± 0.04 Cc | 3.15 ± 0.07 Bc | 2.73 ± 0.02 Ad | |

| Psychrotrophs | 1 | 4.44 ± 0.15 Ca | 3.95 ± 0.12 Ba | 2.70 ± 0.01 Aa | 2.58 ± 0.02 Aa | 2.55 ± 0.04 Aa |

| 4 | 4.54 ± 0.06 Da | 4.07 ± 0.04 Cb | 3.72 ± 0.02 Bb | 4.15 ± 0.12 Cb | 3.46 ± 0.25 Ab | |

| 7 | 5.10 ± 0.03 Db | 4.84 ± 0.00 Cc | 4.29 ± 0.01 Bc | 4.32 ± 0.23 Bb | 4.01 ± 0.01 Ac | |

| 10 | 6.18 ± 0.05 Ec | 5.32 ± 0.07 Dd | 4.89 ± 0.05 Cd | 4.78 ± 0.03 Bc | 4.11 ± 0.03 Ac | |

| Molds and yeasts | 1 | 5.25 ± 0.09 Ea | 4.88 ± 0.05 Da | 4.21 ± 0.03 Ca | 3.22 ± 0.08 Ba | 3.01 ± 0.17 Aa |

| 4 | 6.18 ± 0.12 Eb | 5.30 ± 0.02 Db | 5.04 ± 0.02 Cb | 4.61 ± 0.03 Bb | 4.36 ± 0.03 Ab | |

| 7 | 6.81 ± 0.10 Ec | 6.16 ± 0.01 Dc | 5.60 ± 0.04 Cc | 5.43 ± 0.02 Bc | 5.31 ± 0.01 Ac | |

| 10 | 7.07 ± 0.04 Dd | 6.22 ± 0.00 Cd | 6.20 ± 0.03 Cd | 6.13 ± 0.02 Bd | 5.79 ± 0.02 Ad | |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Horvitz, S.; Arancibia, M.; Arroqui, C.; Chonata, E.; Vírseda, P. Effects of Gaseous Ozone on Microbiological Quality of Andean Blackberries (Rubus glaucus Benth). Foods 2021, 10, 2039. https://doi.org/10.3390/foods10092039

Horvitz S, Arancibia M, Arroqui C, Chonata E, Vírseda P. Effects of Gaseous Ozone on Microbiological Quality of Andean Blackberries (Rubus glaucus Benth). Foods. 2021; 10(9):2039. https://doi.org/10.3390/foods10092039

Chicago/Turabian StyleHorvitz, Sandra, Mirari Arancibia, Cristina Arroqui, Erika Chonata, and Paloma Vírseda. 2021. "Effects of Gaseous Ozone on Microbiological Quality of Andean Blackberries (Rubus glaucus Benth)" Foods 10, no. 9: 2039. https://doi.org/10.3390/foods10092039

APA StyleHorvitz, S., Arancibia, M., Arroqui, C., Chonata, E., & Vírseda, P. (2021). Effects of Gaseous Ozone on Microbiological Quality of Andean Blackberries (Rubus glaucus Benth). Foods, 10(9), 2039. https://doi.org/10.3390/foods10092039