Sustainable Drying and Green Deep Eutectic Extraction of Carotenoids from Tomato Pomace

Abstract

:1. Introduction

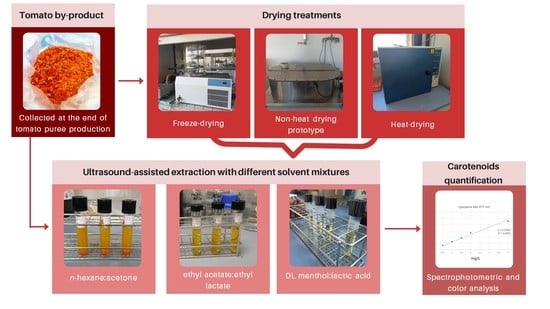

2. Materials and Methods

2.1. Water Content and Water Activity (aw)

2.2. Drying Treatments

2.3. Carotenoids Extraction Methods

2.4. Spectrophotometric Analyses

2.5. Data Processing and Statistical Analysis

3. Results and Discussion

3.1. Water Content and Water Activity (aw) in the Raw and Treated By-Products

3.2. Lycopene and β-Carotene Content in the Extracts

3.3. Color and Principal Component Analysis

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Organization for Economic Co-operation and Development (OECD). Safety Assessment of Transgenic Organism in the Environment, OECD Consensus Documents; Harmonisation of Regulatory Oversight in Biotechnology Series; OECD Publishing: Paris, France, 2017; Volume 7. [CrossRef]

- FAOSTAT. Available online: http://www.fao.org/faostat/en/#home (accessed on 25 May 2021).

- Palomo, I.; Concha-Meyer, A.; Lutz, M.; Said, M.; Saez, B.; Vasquez, A.; Fuentes, E. Chemical characterization and antiplatelet potential of bioactive extract from tomato pomace (by-product of tomato paste). Nutrients 2019, 11, 456. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Kartal, C.; Kaplan Turkoz, B.; Otles, S. Prediction, identification and evaluation of bioactive peptides from tomato seed proteins using in silico approach. J. Food Meas. Charact. 2020, 14, 1865–1883. [Google Scholar] [CrossRef]

- Silva, Y.P.A.; Borba, B.C.; Reis, M.G.; Caliari, M.; Ferreira, T.A.P. Tomato industrial waste as potential source of nutrients. In Proceedings of the X CIGR Section VI International Technical Symposium Food: In the Tree That Sustains Life, Gramado, Brasil, 24–27 October 2016. [Google Scholar]

- Vidyarthi, S.K.; Simmons, C.W. Characterization and management strategies for process discharge streams in California industrial tomato. Sci. Total Environ. 2020, 723, 137976. [Google Scholar] [CrossRef]

- Valdez-Morales, M.; Espinosa-Alonso, L.G.; Espinoza-Torres, L.C.; Delgado-Vargas, F.; Medina-Godoy, S. Phenolic content and antioxidant and antimutagenic activities in tomato peel, seeds, and by products. J. Agric. Food Chem. 2014, 62, 5281–5289. [Google Scholar] [CrossRef] [PubMed]

- Sokolov, S.; Deyneka, I.; Katanaeva, Y.; Ugrekhelidze, N.; Yatskova, E.; Kulikova, N. The effectiveness evaluation of the carotenoids extraction from the tomatoes by means of absorption spectrophotometery method. In Proceedings of the E3S Web of Conferences, Online, 29 June 2020; Volume 175, p. 01011. [Google Scholar]

- Pandya, D.; Akbari, S.; Bhatt, H.; Joshi, D.C. Standardization of solvents extraction process for lycopene extraction from tomato pomace. J. Appl. Biotechnol. Bioeng. 2017, 2, 00019. [Google Scholar] [CrossRef] [Green Version]

- Lu, Z.; Wang, J.; Gao, R.; Ye, F.; Zhao, G. Sustainable valorisation of tomato pomace: A comprehensive review. Trends Food Sci. Technol. 2019, 86, 172–187. [Google Scholar] [CrossRef]

- Sharma, S.; Katoch, V.; Kumar, S.; Chatterjee, S. Functional relationship of vegetable colors and bioactive compounds: Implications in human health. J. Nutr. Biochem. 2021, 92, 108615. [Google Scholar] [CrossRef]

- Ali, M.Y.; Sina, A.A.I.; Khandker, S.S.; Neesa, L.; Tanvir, E.M.; Kabir, A.; Khalil, M.I.; Gan, S.H. Nutritional composition and bioactive compounds in tomatoes and their impact on human health and disease: A review. Foods 2021, 10, 45. [Google Scholar] [CrossRef]

- Mai, Z.; Ngan, R.; Ng, W.; Yuen, K.; Ip, D.; Chan, Y.; Lee, A.; Ho, S.; Lung, M.; Lam, T. Dietary fiber intake from fresh and preserved food and risk of nasopharyngeal carcinoma: Observational evidence from a Chinese population. Nutr. J. 2021, 20, 110. [Google Scholar] [CrossRef]

- Li, N.; Wu, X.; Zhuang, W.; Xia, L.; Chen, Y.; Wu, C.; Rao, Z.; Du, L.; Zhao, R.; Yi, M.; et al. Tomato and lycopene and multiple health outcomes: Umbrealla review. Food Chem. 2021, 343, 128396. [Google Scholar] [CrossRef]

- Correddu, F.; Lunesu, M.; Buffa, G.; Atzori, A.; Nudda, A.; Battacone, G.; Pulina, G. Can agro-industrial by-products rich in polyphenols be advantageously used in the feeding and nutrition of dairy small ruminants? Animals 2020, 10, 131. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Hassan, S.S.; Williams, G.A.; Jaiswal, A.K. Lignocellulosic biorefineries in Europe: Current state and prospects. Trends Biotechnol. 2019, 37, 231–234. [Google Scholar] [CrossRef] [Green Version]

- Moreno, A.D.; Duque, A.; Gonzalez, A.; Ballesteros, I.; Negro, M.J. Valorization of greenhouse horticulture waste from a biorefinery perspective. Foods 2021, 10, 114. [Google Scholar] [CrossRef] [PubMed]

- Wathoni, N.; Haerani, A.; Yuniarsih, N.; Haryanti, R. A review on herbal cosmetic in Indonesia. Int. J. App. Pharm. 2018, 10, 13–16. [Google Scholar] [CrossRef]

- Naviglio, D.; Sapio, L.; Langella, C.; Ragone, A.; Illiano, M.; Naviglio, S.; Gallo, M. Beneficial effects and perspective strategies for lycopene food enrichment: A systematic review. Syst. Rev. Pharm. 2019, 10, 383–392. [Google Scholar]

- Dominguez, R.; Gullòn, P.; Pateiro, M.; Minekata, P.; Zhang, W.; Lorenzo, J. Tomato as potential source of natural additives for meat industry. A review. Antioxidants 2020, 9, 73. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Kumar, P.; Chatli, M.; Mehta, N.; Malav, O.; Verma, A.; Kumar, D.; Rathour, M. Antioxidant and antimicrobial efficacy of sapota powder in pork patties stored under different packaging conditions. Korean J. Food Sci. Anim. Resour. 2018, 38, 593–605. [Google Scholar]

- Awad, A.M.; Kumar, P.; Ismail-Fitry, M.R.; Josuoh, S.; Ab Aziz, M.F.; Sazili, A.Q. Green extractions of bioactive compounds from plant biomass and their application in meat as natural antioxidant. Antioxidants 2021, 10, 1465. [Google Scholar] [CrossRef]

- Carocho, M.; Morales, P.; Ferreira, I.C.F.R. Natural food additives: Quo vadis? Trends Food Sci. Technol. 2015, 45, 284–295. [Google Scholar] [CrossRef] [Green Version]

- Lopez, C.J.; Caleja, C.; Prieto, M.A.; Barreiro, M.F.; Barros, L.; Ferreira, I.C.F.R. Optimization and comparison of heat and ultrasound assisted extraction techniques to obtain anthocyanin compounds from Arbutus unedo L. Fruits. Food Chem. 2018, 264, 81–91. [Google Scholar] [CrossRef] [Green Version]

- Neri-Numa, I.A.; Pessoa, M.G.; Paulino, B.N.; Pastore, G.M. Genipin: A natural blue pigment for food and health purposes. Trends Foods Sci. Technol. 2017, 67, 271–279. [Google Scholar] [CrossRef]

- Caseiro, M.; Ascenso, A.; Costa, A.; Creagh-Flynn, J.; Johnson, M.; Simones, S. Lycopene in human health. LWT Food Sci. Technol. 2020, 127, 109323. [Google Scholar] [CrossRef]

- Manzoor, M.; Singh, J.; Gani, A.; Noor, N. Valorization of natural colors as health-promoting bioactive compounds: Phytochemical profile, extraction techniques, and pharmacological perspectives. Food Chem. 2021, 362, 130141. [Google Scholar] [CrossRef] [PubMed]

- Gosh, S.; Sarkar, T.; Das, A.; Chakraborty, R. Natural colorants from plant pigments and their encapsulation: An emerging window for the food industry. LWT Food Sci. Technol. 2022, 153, 112527. [Google Scholar] [CrossRef]

- Ghosh, S.; Sarkar, T.; Das, A.; Chakraborty, R. Micro and nanoencapsulation of natural colors: A holistic view. Appl. Biochem. Biotechnol. 2021, 193, 3787–3811. [Google Scholar] [CrossRef]

- Vieira, D.; Caliari, M.; de Souza, E.; Soares Junior, M. Methods for a pigments extraction and determination of color in tomato for processing cultivars. Food Sci. Technol. 2020, 40, 11–17. [Google Scholar] [CrossRef] [Green Version]

- FAOSTAT. Food and Agriculture Organization of the United Nations. Available online: https://www.fao.org/faostat/en/#data/QC/visualize (accessed on 25 May 2021).

- Deng, Y.; Zhao, S.; Yang, X.; Hou, F.; Fan, L.; Wang, W.; Xu, E.; Cheng, H.; Guo, M.; Liu, D. Evaluation of extraction technologies of lycopene: Hindrance of extraction, effects on isomerization and comparative analysis—A review. Trends Food Sci. Technol. 2021, 115, 285–296. [Google Scholar] [CrossRef]

- BBC Research. Neutraceuticals: Global Markets to 2026. Available online: https://www.bccresearch.com/market-research/food-and-beverage/nutraceuticals-global-markets.html (accessed on 3 December 2021).

- BBC Research. The Global Market for Carotenoids. Available online: https://www.bccresearch.com/market-research/food-and-beverage/the-global-market-for-carotenoids.html (accessed on 3 December 2021).

- Saini, R.K.; Moon, S.H.; Keum, Y. An updated review on use of tomato pomace and crustacean processing waste to recover commercially vital carotenoids. Food Res. Int. 2018, 108, 516–529. [Google Scholar] [CrossRef]

- Junior, S.S.; Casagrande, J.G.; Toledo, C.A.L.; Ponce, F.S.; Ferreira, F.S.; Zanuzo, M.R.; Diamante, M.S.; Lima, G.P.P. Selection of thermotolerant Italian tomato cultivars with high fruit yield and nutritional quality for the consumer taste grown under protected cultivation. Sci. Hortic. 2022, 291, 19. [Google Scholar] [CrossRef]

- Jalali-Jivan, M.; Fathi-Achachlouei, B.; Ahmadi-Gavlighi, H.; Jafari, S. Improving the extraction efficiency and stability of β-carotene from carrot by enzyme-assisted green nanoemulsification. Innov. Food Sci. Emerg. Technol. 2021, 74, 18. [Google Scholar] [CrossRef]

- Junker-Frohn, L.; Luck, M.; Schmittgen, S.; Wensing, J.; Carraresi, L.; Thiele, B.; Groher, T.; Reimer, J.; Broring, S.; Noga, G.; et al. Tomato’s green gold: Bioeconomy potential of residual leaf biomass as a novel source for the secondary metabolite rutin. ACS Omega 2019, 4, 19071–19080. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Almeida, P.V.; Rodrigues, R.P.; Garspar, M.C.; Braga, M.E.M.; Quina, M.J. Integrated management of residues from tomato production: Recovery of value-added compounds and biogas production in the biorefinery context. J. Environ. Manag. 2021, 299, 111. [Google Scholar] [CrossRef] [PubMed]

- Bhattacharjee, C.; Saxena, V.K.; Dutta, S. Insights into effectiveness of tight ultrafiltration and frozen storage in bioactive compound retention in watermelon juice concentrate. J. Food Process Eng. 2020, 43, 117. [Google Scholar] [CrossRef]

- Deng, Q.; Zinoviadou, K.G.; Galanakis, C.M.; Orlien, V.; Vorobiev, E.; Lebovka, N.; Barba, F.J. The effects of conventional and non-conventional processing on glucosinolates and its derived forms, isothiocynates: Extraction, degradation and applications. Food Eng. Rev. 2015, 7, 357–381. [Google Scholar] [CrossRef]

- Wen, L.; Zhang, Z.; Sun, D.; Sivagnanam, S.P.; Tiwari, B.K. Combination of emerging technologies for the extraction of bioactive compounds. Crit. Rev. Food Sci. Nutr. 2020, 60, 1826–1841. [Google Scholar] [CrossRef]

- Koteswararao, P.R.; Tulasi, S.L.; Pavani, Y. Impact of solvents on environmental pollution. National Seminar on Impact of Toxic Metals, Minerals and Solvents leading to Environmental lution. J. Chem. Pharm. Sci. 2014, 3, 132–135. [Google Scholar]

- Naviglio, D.; Pizzolongo, F.; Ferrara, L.; Aragòn, A.; Santini, A. Extraction of pure lycopene from industrial tomato by-products in water using a new high-pressure process. J. Sci. Food Agric. 2008, 88, 2414–2420. [Google Scholar] [CrossRef]

- Joshi, D.; Adhikari, N. An overview on common organic solvents and their toxicity. J. Pharm. Res. Int. 2019, 28, 118. [Google Scholar] [CrossRef]

- Płotka-Wasylka, J.; Rutkowska, M.; Owczarek, K.; Tobiszewski, M.; Namieśnik, J. Extraction with environmentally friendly solvents. TrAC Trends Anal. Chem. 2017, 91, 12–25. [Google Scholar] [CrossRef]

- Torres-Valenzuela, L.S.; Ballesteros-Gomez, A.; Rubio, S. Green solvents for the extraction of high added-value compounds from agri-food waste. Food Eng. Rev. 2020, 12, 83–100. [Google Scholar] [CrossRef]

- Sekharan, T.R.; Chandira, R.M.; Tamilvanan, S.; Rajesh, S.C.; Venkateswarlu, B.S. Deep eutectic solvents as an alternative to other harmful solvents. Biointerface Res. Appl. Chem. 2022, 12, 847–860. [Google Scholar]

- Khandelwal, S.; Tailor, Y.; Kumar, M. Deep eutectic solvents (DESs) as eco-friendly and sustainable solvent/catalyst system in organic trasformations. J. Mol. Liq. 2016, 215, 345–386. [Google Scholar] [CrossRef]

- Silva, Y.P.A.; Ferreira, T.A.P.C.; Jiao, G.; Brooks, M.S. Sustainable approach for lycopene extraction from tomato processing by-product using hydrophobic eutectic solvents. J. Food Sci. Technol. 2019, 56, 1649–1654. [Google Scholar] [CrossRef] [PubMed]

- Aniceto, J.; Rodrigues, V.; Portugal, I.; Silva, C. Valorization of tomato residues by supercritical fluid extraction. Processes 2021, 10, 125. [Google Scholar] [CrossRef]

- Getachew, A.; Jacobsen, C.; Holdt, S. Emerging technologies for the extraction of marine phenolics: Opportunities and challenges. Mar. Drugs 2020, 18, 122. [Google Scholar] [CrossRef] [PubMed]

- Clausen, I.C.; Ustad, T.S.; Strommen, I.; Walde, P.M. Atmospheric freeze drying: A review. Dry. Technol. 2010, 25, 947–957. [Google Scholar] [CrossRef]

- Ratti, C. Hot and freeze-drying of high-value foods: A review. J. Food Eng. 2001, 49, 311–319. [Google Scholar] [CrossRef]

- Rybak, K.; Parniakov, O.; Samborska, K.; Wiktor, A.; Witrowa-Rajchert, D.; Nowacka, M. Energy and quality aspects of freeze-drying preceded by traditional and novel pre-treatment methods as exemplified by red bell pepper. Sustainability 2021, 13, 116. [Google Scholar] [CrossRef]

- Singh, A.P.; Mandal, R.; Shojaei, M.; Singh, A.; Kowalczewski, P.L.; Ligaj, M.; Pawlicz, J.; Jarzebski, M. Novel drying methods for sustainable upcycling of brewers’ spent grains as a plant protein source. Sustainability 2020, 12, 3660. [Google Scholar] [CrossRef]

- Gheonea, I.; Aprodu, I.; Enachi, E.; Horincar, G.; Bolea, C.A.; Bahrim, G.E.; Rapeanu, G.; Stanciuc, N. Investigations on thermostability of carotenoids from tomato peels in oils using a kinetic approach. J. Food Process. Preserv. 2020, 44, 19. [Google Scholar]

- Silva, Y.P.A.; Ferreira, T.A.P.C.; Celli, G.B.; Brooks, M.S. Optimization of lycopene extraction from tomato processing waste using an eco-friendly ethyl lactate-ethyl acetate solvent: A green valorization approach. Waste Biomass Valorization 2019, 10, 2851–2861. [Google Scholar] [CrossRef]

- Sperber, W.H. Influence of water activity on foodborne bacteria: A review. J. Food Prot. 1983, 46, 142–150. [Google Scholar] [CrossRef] [PubMed]

- Kiranoudis, C.T.; Maroulis, Z.B.; Tsami, E.; Marinos-Kouris, D. Equilibrium moisture content and heat of desorption of some vegetables. J. Food Eng. 1993, 20, 55–74. [Google Scholar] [CrossRef]

- MacHmudah, S.; Winardi, S.; Sasaki, M.; Goto, M.; Kusumoto, N.; Hayakawa, K. Lycopene extraction from tomato peel by-product containing tomato seed using supercritical carbon dioxide. J. Food Eng. 2012, 108, 290–296. [Google Scholar] [CrossRef]

- Henry, L.; Catignani, G.; Schwartz, S. Oxidative degradation kinetics of lycopene, lutein, and 9-cis and all trans β-carotene. JAOCS 1998, 75, 823–829. [Google Scholar] [CrossRef]

- Morales-Soriano, E.; Panozzo, A.; Ugás, R.; Grauwet, T.; Van Loey, T.; Hendrickx, M. Carotenoid profile basic structural indicators of native Peruvian chili peppers. Eur. Food Res. Technol. 2019, 245, 717–732. [Google Scholar] [CrossRef]

| Sample | Mean Moisture Content% ± SD | Mean aw |

|---|---|---|

| Raw (P) | 63.4 ± 1.7 | 0.99 |

| Freeze-dried (L) | 3.5 ± 0.1 | 0.30 |

| Air-dried (E) | 9.9 ± 0.2 | 0.67 |

| Heat-dried (S) | 20.3 ± 0.2 | 0.69 |

| Extract | Lycopene Content (µg/g) ± SD | β-Carotene Content (µg/g) ± SD |

|---|---|---|

| T | 34.11 a;B ± 1.11 | 2117.64 a;B ± 100.46 |

| G | 27.44 b;C ± 2.50 | 1510.19 b;B ± 79.51 |

| ML | 12.32 c;C ± 1.78 | 492.46 c;B ± 87.88 |

| TL | 96.55 a;A ± 10.39 | 5717.46 a;A ± 710.70 |

| GL | 56.28 b;B ± 6.07 | 3000.45 b;B,C ± 26.58 |

| MLL | 48.89 b;B ± 1.89 | 2273.87 b;A ± 92.58 |

| TE | 81.20 a;A ± 4.20 | 4777.59 a;A ± 256.04 |

| GE | 75.86 a;A ± 10.94 | 3950.08 a,b;A ± 597.49 |

| MLE | 82.86 a;A ± 11.18 | 2923.02 b;A± 583.24 |

| TS | 15.87 a;B ± 0.21 | 507.29 a;C ± 48.56 |

| GS | 1.80 c;D ± 0.83 | ND |

| MLS | 11.22 b;C ± 0.45 | 78.27 b;B ± 21.61 |

| Solvent mixture | <0.0001 | <0.0001 |

| Drying method (treatment) | <0.0001 | <0.0001 |

| Solvent mixture * Drying method (treatment) | <0.0001 | <0.0001 |

| Sample | a* | b* | L* |

|---|---|---|---|

| T | −6.01 b;C | 22.28 a;A | 95.31 b;A |

| TL | −4.85 b;B,C | 25.85 a;A | 91.82 b;B |

| TE | −4.32 b;B | 22.48 a;A | 93.43 a;B |

| TS | −2.22 a;A | 7.91 a;B | 96.20 a;A |

| G | −5.17 a,b;C | 18.74 a;A | 95.23 b;A |

| GL | −2.32 a;A,B | 7.72 b;B,C | 95.27 a;A |

| GE | −3.17 a;B | 9.73 b;B | 95.14 a;A |

| GS | −1.34 a;A | 3.10 b;C | 95.51 a;A |

| ML | −4.16 a;C | 10.42 b;A | 96.23 a;A |

| MLL | −3.00 a;B | 9.17 b;A | 95.66 a;B |

| MLE | −3.15 a;B | 9.71 b;A | 95.35 a;B |

| MLS | −1.38 a;A | 3.86 b;B | 96.44 a;A |

| Solvent mixture | <0.0001 | <0.0001 | <0.0001 |

| Drying method (treatment) | <0.0001 | <0.0001 | <0.0001 |

| Solvent mixture * Drying method (treatment) | <0.0001 | 0.005 | 0.010 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Lazzarini, C.; Casadei, E.; Valli, E.; Tura, M.; Ragni, L.; Bendini, A.; Gallina Toschi, T. Sustainable Drying and Green Deep Eutectic Extraction of Carotenoids from Tomato Pomace. Foods 2022, 11, 405. https://doi.org/10.3390/foods11030405

Lazzarini C, Casadei E, Valli E, Tura M, Ragni L, Bendini A, Gallina Toschi T. Sustainable Drying and Green Deep Eutectic Extraction of Carotenoids from Tomato Pomace. Foods. 2022; 11(3):405. https://doi.org/10.3390/foods11030405

Chicago/Turabian StyleLazzarini, Celeste, Enrico Casadei, Enrico Valli, Matilde Tura, Luigi Ragni, Alessandra Bendini, and Tullia Gallina Toschi. 2022. "Sustainable Drying and Green Deep Eutectic Extraction of Carotenoids from Tomato Pomace" Foods 11, no. 3: 405. https://doi.org/10.3390/foods11030405

APA StyleLazzarini, C., Casadei, E., Valli, E., Tura, M., Ragni, L., Bendini, A., & Gallina Toschi, T. (2022). Sustainable Drying and Green Deep Eutectic Extraction of Carotenoids from Tomato Pomace. Foods, 11(3), 405. https://doi.org/10.3390/foods11030405