Effects of Different Freezing Treatments during the Winemaking of a Varietal White Wine with Regard to Its Phenolic Components

Abstract

:1. Introduction

2. Materials and Methods

2.1. Grape Variety and Winemaking Procedures

- Reference batch treatment (R): the grape bunches were destemmed and traditionally milled, and no freezing process was used;

- Crushed-grape freezing (M): the bunches were destemmed, the grapes were crushed, and the must was frozen in a chamber at −18 °C;

- Whole-bunch freezing (B): the bunches of grapes, without any further processing, were frozen in a chamber at −18 °C.

2.2. Characterization of the Wines

2.3. Determining Total and Individual Phenolic Compounds

2.4. Susceptibility to Oxidation

2.5. Statistical Analyses

3. Results

3.1. Effects of Freezing on the Wines That Did Not Undergo Pre-Fermentative Maceration

3.1.1. General Characterization of the Musts and Wines That Did Not Undergo Pre-Fermentative Maceration

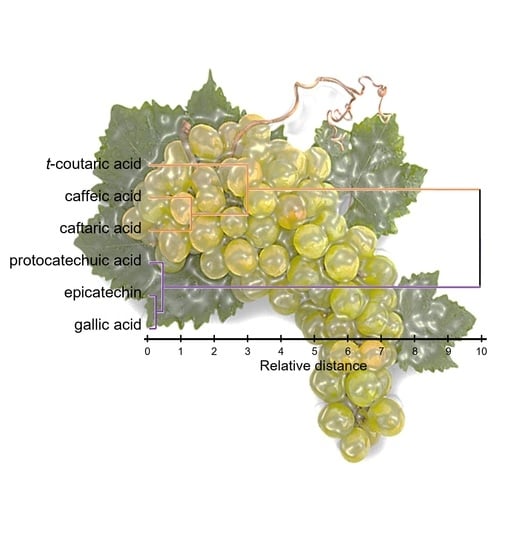

3.1.2. Characterization of Individual Phenolic Compounds in Wines without Pre-Fermentative Maceration

3.2. Effects of Freezing on the Wines Produced through Pre-Fermentative Maceration

3.2.1. Evolution of Phenolic Compounds during the Pre-Fermentative Maceration of the Wines

3.2.2. Characterization of the Musts and Wines after Pre-Fermentative Maceration

3.2.3. Characterization of Individual Phenolic Compounds in the Wines Subjected to Pre-Fermentative Maceration

3.3. Evaluation of Stability against Oxidation

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Hidalgo Torres, J. La Calidad del Vino Desde el Viñedo; Ediciones Mundi-Prensa: Madrid, Spain, 2006. [Google Scholar]

- Hidalgo Torres, J. Tratado de Enología: Tomo I (2a. ed.) (Capítulo XII), 2nd ed.; Mundi-Prensa: Madrid, Spain, 2011. [Google Scholar]

- Aleixandre-Tudo, J.L.; du Toit, W. Cold maceration application in red wine production and its effects on phenolic compounds: A review. LWT 2018, 95, 200–208. [Google Scholar] [CrossRef]

- Jagatić Korenika, A.M.; Maslov, L.; Jakobović, S.; Palčić, I.; Jeromel, A. Comparative study of aromatic and polyphenolic profiles of Croatian white wines produced by cold maceration. Czech J. Food Sci. 2018, 36, 459–469. [Google Scholar] [CrossRef]

- Korenika, A.-M.J. Influence of Cold Maceration Treatment on Aromatic and Sensory Properties of Vugava Wine (Vitis vinifera L.). J. Microbiol. Biotechnol. Food Sci. 2020, 10, 49–53. [Google Scholar] [CrossRef]

- Luan, Y.; Zhang, B.Q.; Duan, C.Q.; Yan, G.L. Effects of different pre-fermentation cold maceration time on aroma compounds of Saccharomyces cerevisiae co-fermentation with Hanseniaspora opuntiae or Pichia kudriavzevii. LWT 2018, 92, 177–186. [Google Scholar] [CrossRef]

- Ruiz-Rodríguez, A.; Palma, M.; Barroso, C.G. Influence of temperature during pre-fermentative maceration and alcoholic fermentation on the phenolic composition of ‘cabernet sauvignon’ wines. Foods 2021, 10, 1053. [Google Scholar] [CrossRef]

- Aragón-García, F.; Ruíz-Rodríguez, A.; Palma, M. Changes in the Aromatic Compounds Content in the Muscat Wines as a Result of the Application of Ultrasound during Pre-Fermentative Maceration. Foods 2021, 10, 1462. [Google Scholar] [CrossRef]

- Hidalgo Fernández-Cano, L.; Hidalgo Torres, J. Tratado de Viticultura, 5th ed.; Ediciones Mundi-Prensa: Madrid, Spain, 2011. [Google Scholar]

- Baiano, A.; Mentana, A.; Varva, G.; Quinto, M. Effects of different vinification procedures and aging containers on phenolic and volatile composition of Greco white wines. Eur. Food Res. Technol. 2017, 243, 1667–1680. [Google Scholar] [CrossRef]

- Baiano, A.; Varva, G.; De Gianni, A.; Terracone, C.; Viggiani, I.; Del Nobile, M.A. Effects of different vinification technologies on physico-chemical properties and antioxidant activity of “Falanghina” and “Bombino bianco” wines. Eur. Food Res. Technol. 2013, 237, 831–842. [Google Scholar] [CrossRef]

- Olejar, K.J.; Fedrizzi, B.; Kilmartin, P.A. Influence of harvesting technique and maceration process on aroma and phenolic attributes of Sauvignon blanc wine. Food Chem. 2015, 183, 181–189. [Google Scholar] [CrossRef]

- Ruiz-Rodríguez, A.; Durán-Guerrero, E.; Natera, R.; Palma, M.; Barroso, C.G. Influence of two different cryoextraction procedures on the quality of wine produced from muscat grapes. Foods 2020, 9, 1529. [Google Scholar] [CrossRef]

- Roldán, A.M.; Sánchez-García, F.; Pérez-Rodríguez, L.; Palacios, V.M. Influence of different vinification techniques on volatile compounds and the aromatic profile of palomino fino wines. Foods 2021, 10, 453. [Google Scholar] [CrossRef]

- Pedrosa-López, M.C.; Aragón-García, F.; Ruíz-Rodríguez, A.; Piñeiro, Z.; Durán-Guerrero, E.; Palma, M. Effects from the Freezing of Either Whole or Crushed Grapes on the Volatile Compounds Contents in Muscat Wines. Foods 2022, 11, 1782. [Google Scholar] [CrossRef]

- OIV. Compendium of International Methods of Wine and Must Analysis International Organisation of Vine and Wine; OIV: Paris, France, 2021; Volume 2, ISBN 9782850380167. [Google Scholar]

- González de Peredo, A.V.; Vázquez-Espinosa, M.; Piñeiro, Z.; Espada-Bellido, E.; Ferreiro-González, M.F.; Barbero, G.; Palma, M. Development of a rapid and accurate UHPLC-PDA-FL method for the quantification of phenolic compounds in grapes. Food Chem. 2021, 334, 127569. [Google Scholar] [CrossRef]

- Marín-SanRomán, S.; Rubio-Bretón, P.; Pérez-Álvarez, E.P.; Garde-Cerdán, T. Advancement in analytical techniques for the extraction of grape and wine volatile compounds. Food Res. Int. 2020, 137, 109712. [Google Scholar] [CrossRef]

- Ferreiro-González, M.; Carrera, C.; Ruiz-Rodríguez, A.; Barbero, G.; Ayuso, J.; Palma, M.; Barroso, C. A New Solid Phase Extraction for the Determination of Anthocyanins in Grapes. Molecules 2014, 19, 21398–21410. [Google Scholar] [CrossRef]

- Ortega-Heras, M.; Pérez-Magariño, S.; González-Sanjosé, M.L. Comparative study of the use of maceration enzymes and cold pre-fermentative maceration on phenolic and anthocyanic composition and colour of a Mencía red wine. LWT—Food Sci. Technol. 2012, 48, 1–8. [Google Scholar] [CrossRef]

- De Matos, A.D.; Longo, E.; Chiotti, D.; Pedri, U.; Eisenstecken, D.; Sanoll, C.; Robatscher, P.; Boselli, E. Pinot blanc: Impact of the winemaking variables on the evolution of the phenolic, volatile and sensory profiles. Foods 2020, 9, 499. [Google Scholar] [CrossRef]

- Casassa, L.F.; Sari, S.E. Sensory and chemical effects of two alternatives of prefermentative cold soak in Malbec wines during winemaking and bottle ageing. Int. J. Food Sci. Technol. 2015, 50, 1044–1055. [Google Scholar] [CrossRef]

- Hou, X.; Chen, S.; Pu, Y.; Wang, T.; Xu, H.; Li, H.; Ma, P.; Hou, X. Effect of Winemaking on Phenolic Compounds and Antioxidant Activities of Msalais Wine. Molecules 2023, 28, 1250. [Google Scholar] [CrossRef]

- Dumitriu, G.-D.; Teodosiu, C.; Gabur, I.; Cotea, V.V.; Peinado, R.A.; de Lerma, N.L. Alternative winemaking techniques to improve the content of phenolic and aromatic compounds in wines. Agriculture 2021, 11, 233. [Google Scholar] [CrossRef]

- Gambacorta, G.; Antonacci, D.; Pati, S.; la Gatta, M.; Faccia, M.; Coletta, A.; La Notte, E. Influence of winemaking technologies on phenolic composition of Italian red wines. Eur. Food Res. Technol. 2011, 233, 1057–1066. [Google Scholar] [CrossRef]

- Aleixandre-Tudo, J.L.; du Toit, W. Understanding cold maceration in red winemaking: A batch processing and multi-block data analysis approach. LWT 2019, 111, 147–157. [Google Scholar] [CrossRef]

- Gil Cortiella, M.; Úbeda, C.; del Barrio-Galán, R.; Peña-Neira, A. Impact of berry size at harvest on red wine composition: A winemaker’s approach. J. Sci. Food Agric. 2020, 100, 836–845. [Google Scholar] [CrossRef] [PubMed]

- Nenadis, N.; Paraskevopoulou, A. Browning susceptibility of commercial monovarietal white wines under accelerated oxidation conditions: Correlation with compositional data and effect on total phenol content and radical scavenging activity. Eur. Food Res. Technol. 2016, 242, 1821–1828. [Google Scholar] [CrossRef]

- Kallithraka, S.; Salacha, M.I.; Tzourou, I. Changes in phenolic composition and antioxidant activity of white wine during bottle storage: Accelerated browning test versus bottle storage. Food Chem. 2009, 113, 500–505. [Google Scholar] [CrossRef]

- Boido, E.; García-Marino, M.; Dellacassa, E.; Carrau, F.; Rivas-Gonzalo, J.C.; Escribano-Bailón, M.T. Characterisation and evolution of grape polyphenol profiles of Vitis vinifera L. cv. Tannat during ripening and vinification. Aust. J. Grape Wine Res. 2011, 17, 383–393. [Google Scholar] [CrossRef]

- Soto, M.L.; Conde, E.; González-López, N.; Conde, M.J.; Moure, A.; Sineiro, J.; Falqué, E.; Domínguez, H.; Núñez, M.J.; Parajó, J.C. Recovery and concentration of antioxidants from winery wastes. Molecules 2012, 17, 3008–3024. [Google Scholar] [CrossRef]

- Alvarez-Casas, M.; Pajaro, M.; Lores, M.; Garcia-Jares, C. Polyphenolic Composition and Antioxidant Activity of Galician Monovarietal Wines from Native and Experimental Non-Native White Grape Varieties. Int. J. Food Prop. 2016, 19, 2307–2321. [Google Scholar] [CrossRef]

| Must Batch | Description |

|---|---|

| R0 | Regular winemaking process. Destemming of the bunches and crushing of the grapes, followed by immediate pressing and racking |

| M0 | Frozen must with crushed grapes, i.e., destemming and crushing of the grapes followed by the freezing of their pulp and skins. After thawing, the grapes were pressed and racked. |

| B0 | Freezing of whole bunches of grapes. After thawing, the grapes were destemmed and crushed, followed by their immediate pressing and racking. |

| RC | Destemming and crushing of the grapes, followed by cold pre-fermentative maceration of the paste for 4 h at 10 °C. Pressing and racking were performed after the cold maceration. |

| MC | Destemming and crushing of the grapes, followed by freezing of the grapes’ pulp. After thawing, cold pre-fermentative maceration was performed for 4 h at 10 °C. Pressing and racking were performed after the cold maceration. |

| BC | Freezing whole bunches of grapes. After thawing, the grapes were destemmed and crushed and then cold macerated for 4 h at 10 °C. After their maceration, the grapes were pressed and racked. |

| Compound Name | Regression Equation | Squared Regression Coefficient (R2) | LOD (mg L−1) | LOQ (mg L−1) |

|---|---|---|---|---|

| Gallic acid | y = 30,593x + 1463 | 0.9999 | 0.14 | 0.43 |

| Protocatechuic acid | y = 34,822x + 9115 | 0.9992 | 0.10 | 0.34 |

| p-Coumaric acid | y = 123,270x + 38,070 | 0.9994 | 0.11 | 0.35 |

| Caffeic acid | y = 40,016x + 19,027 | 0.9985 | 0.21 | 0.71 |

| Epicatechin | y = 660,659x + 283,654 | 0.9997 | 0.13 | 0.41 |

| Total Phenolic Compounds (mg L−1 of Gallic Acid) | ||

|---|---|---|

| Musts | Wines | |

| R0 | 215.2 ± 7.5 | 219.5 ± 7.1 |

| M0 | 293.4 ± 14.9 * | 245.1 ± 3.1 * |

| B0 | 198.3 ± 6.1 | 204.8 ± 5.6 |

| R0 | M0 | B0 | |

|---|---|---|---|

| Gallic acid | 0.45 ± 0.01 a | 0.67 ± 0.07 b | 0.93 ± 0.12 c |

| Protocatechuic acid | 0.41 ± 0.04 a | 1.24 ± 0.04 b | 0.61 ± 0.03 c |

| Caftaric acid | Traces 2 | 9.85 ± 0.07 a | Traces 2 |

| t-Coutaric acid | 3.86 ± 0.06 a | 14.25 ± 0.05 b | 0.38 ± 0.02 c |

| Caffeic acid | 2.00 ± 0.02 a | 9.25 ± 0.03 b | 0.79 ± 0.08 c |

| Epicatechin | 0.59 ± 0.10 a | 0.92 ± 0.14 b | 0.69 ± 0.02 a |

| Total Phenolic Compounds (mg L−1 of Gallic Acid) | ||

|---|---|---|

| Musts | Wines | |

| RC | 293.0 ± 6.4 a | 213.9 ± 7.4 a |

| MC | 330.6 ± 10.8 a | 245.4 ± 4.9 b |

| BC | 436.0 ± 12.1 b | 223.5 ± 5.8 a |

| RC | MC | BC | |

|---|---|---|---|

| Gallic acid | 0.83 ± 0.09 a | 0.61 ± 0.06 b | 0.94 ± 0.03 c |

| Protocatechuic acid | Traces 2 | 1.17 ± 0.04 | Traces 2 |

| Caftaric acid | Traces 2 | 8.81 ± 0.08 | Traces 2 |

| t-Coutaric acid | 2.67 ± 0.09 a | 9.95 ± 0.06 b | Traces 2 |

| Caffeic acid | 1.44 ± 0.01 a | 9.13 ± 0.03 b | 1.60 ± 0.01 c |

| Epicatechin | 0.66 ± 0.02 a | 0.44 ± 0.12 b | 0.76 ± 0.04 c |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Vilar-Bustillo, J.; Ruiz-Rodríguez, A.; Carrera, C.A.; Piñeiro, Z.; Palma, M. Effects of Different Freezing Treatments during the Winemaking of a Varietal White Wine with Regard to Its Phenolic Components. Foods 2023, 12, 1963. https://doi.org/10.3390/foods12101963

Vilar-Bustillo J, Ruiz-Rodríguez A, Carrera CA, Piñeiro Z, Palma M. Effects of Different Freezing Treatments during the Winemaking of a Varietal White Wine with Regard to Its Phenolic Components. Foods. 2023; 12(10):1963. https://doi.org/10.3390/foods12101963

Chicago/Turabian StyleVilar-Bustillo, Juan, Ana Ruiz-Rodríguez, Ceferino A. Carrera, Zulema Piñeiro, and Miguel Palma. 2023. "Effects of Different Freezing Treatments during the Winemaking of a Varietal White Wine with Regard to Its Phenolic Components" Foods 12, no. 10: 1963. https://doi.org/10.3390/foods12101963

APA StyleVilar-Bustillo, J., Ruiz-Rodríguez, A., Carrera, C. A., Piñeiro, Z., & Palma, M. (2023). Effects of Different Freezing Treatments during the Winemaking of a Varietal White Wine with Regard to Its Phenolic Components. Foods, 12(10), 1963. https://doi.org/10.3390/foods12101963