Towards Less Plastic in Food Contact Materials: An In-Depth Overview of the Belgian Market

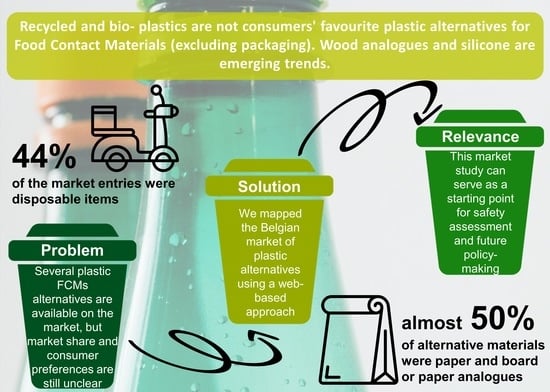

Abstract

:1. Introduction

2. Materials and Methods

2.1. Study Design

2.2. Data Sources

2.3. Data Mining and Data Cleaning

- Removing duplicates: e.g., an identical product from different retailers, the same product in various sizes, and the same product in different versions (like knife, fork, or spoon).

- Handling missing values, like the material description.

- Deleting nonavailable items (assumed as nonavailable on the market).

- Data standardisation: ensuring harmonised material and usage categories through the dataset.

3. Results and Discussion

4. Research Limitations and Perspectives

5. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Sonego, E.; Di Filippo, P.; Riccardi, C.; Pomata, D.; Bannò, A.; Simonetti, G.; Buiarelli, F. Occurrence and migration study of chemicals from baking paper and aluminium foil. Food Chem. 2023, 409, 135260. [Google Scholar] [CrossRef]

- European Commission. A European Strategy for Plastics in a Circular Economy. In Communication from the Commission to the European Parliament, the Council, the European Economic and Social Committee and the Committee of the Regions; European Commission: Brussels, Belgium, 2018. [Google Scholar]

- Ali, A.; Bahadar, A.; Khan, A.; Sanaullah, K. 8-Role of agricultural waste in recycled plastic biocomposites. In Recycled Plastic Biocomposites; Rahman, M.R., Bakri, M.K.B., Eds.; Woodhead Publishing Series in Composites Science and Engineering; Woodhead Publishing: Cambridge, UK, 2022; pp. 165–194. ISBN 978-0-323-88653-6. [Google Scholar]

- Plastics Europe. Plastics—The Facts 2022; Plastics Europe: Bruxelles, Belgium, 2022. [Google Scholar]

- Kan, M.; Miller, S.A. Environmental impacts of plastic packaging of food products. Resour. Conserv. Recycl. 2022, 180, 106156. [Google Scholar] [CrossRef]

- European Commission. The European Green Deal. In Communication from the Commission to the European Parliament, the European Council, the Council, the European Economic and Social Committee and the Committee of the Regions; European Commission: Brussels, Belgium, 2019. [Google Scholar]

- The European Parliament; The Council of the European Union. Directive (EU) 2019/904 of the European Parliament and of the Council of 5 June 2019 on the Reduction of the Impact of Certain Plastic Products on the Environment. Off. J. Eur. Union 2019, 155, 1–19. [Google Scholar]

- European Commission. A New Circular Economy Action Plan For a Cleaner and More Competitive Europe. In Communication from the Commission to the European Parliament, the Council, the European Economic and Social Committee and the Committee of the Regions; European Commission: Brussels, Belgium, 2020. [Google Scholar]

- Groth, C.; Wegmann, C.; Meyerding, S.G.H. Perception of product sustainability: The case of processed—A qualitative study in Germany. J. Retail. Consum. Serv. 2023, 71, 103214. [Google Scholar] [CrossRef]

- Heidbreder, L.M.; Tröger, J.; Schmitt, M. Exploring the psychological antecedents of private and public sphere behaviours to reduce household plastic consumption. Environ. Dev. Sustain. 2023, 25, 3405–3428. [Google Scholar] [CrossRef]

- Markevičiūtė, Z.; Varžinskas, V. Plant-Origin Feedstock Applications in Fully Green Food Packaging: The Potential for Tree-Free Paper and Plant-Origin Bio-Plastics in the Baltic Sea Region. Sustainability 2022, 14, 7393. [Google Scholar] [CrossRef]

- Mahalik, N.P.; Nambiar, A.N. Trends in food packaging and manufacturing systems and technology. Trends Food Sci. Technol. 2010, 21, 117–128. [Google Scholar] [CrossRef]

- Rhim, J.-W.; Park, H.-M.; Ha, C.-S. Bio-nanocomposites for food packaging applications. Prog. Polym. Sci. 2013, 38, 1629–1652. [Google Scholar] [CrossRef]

- Deshwal, G.K.; Panjagari, N.R.; Alam, T. An overview of paper and paper based food packaging materials: Health safety and environmental concerns. J. Food Sci. Technol. 2019, 56, 4391–4403. [Google Scholar] [CrossRef]

- Chen, X.; Chen, F.; Yang, Q.; Gong, W.; Wang, J.; Li, Y.; Wang, G. An environmental food packaging material part I: A case study of life-cycle assessment (LCA) for bamboo fiber environmental tableware. Ind. Crops Prod. 2023, 194, 116279. [Google Scholar] [CrossRef]

- Petkoska, A.T.; Daniloski, D.; D’Cunha, N.M.; Naumovski, N.; Broach, A.T. Edible packaging: Sustainable solutions and novel trends in food packaging. Food Res. Int. 2021, 140, 109981. [Google Scholar] [CrossRef]

- Janjarasskul, T.; Krochta, J.M. Edible Packaging Materials. Annu. Rev. Food Sci. Technol. 2010, 1, 415–448. [Google Scholar] [CrossRef] [PubMed]

- Statista. Packaging Market Shares Worldwide 2019, by Material. 2022. Available online: https://www.statista.com/statistics/271601/packaging-materials-in-the-global-packaging-market-since-2003/ (accessed on 24 March 2023).

- Future Business Insights. The Global Food Packaging Market Is Projected to Grow from $338.34 Billion in 2021 to $478.18 Billion in 2028 at a Cagr of 5.1% in Forecast Period, 2021–2028 Period. 2021. Available online: https://www.fortunebusinessinsights.com/industry-reports/food-packaging-market-101941 (accessed on 24 March 2023).

- Precedence Research. Food Packaging Market (By Material: Plastics, Paper & Paper-based, Glass, Metal, and Others; By Type: Semi-rigid, Rigid, and Flexible; By Application: Dairy Products, Bakery & Confectionary, Fruits & Vegetables, Sauces & Dressings, Meat, Poultry, & Seafood, and Others)—Global Market Size, Trends Analysis, Segment Forecasts, Regional Outlook 2020–2027. Food Packag. Mark. 2020. Available online: https://www.precedenceresearch.com/food-packaging-market (accessed on 16 March 2023).

- Yi, Z. Chapter Two—Market Research. In Marketing Services and Resources in Information Organizations; Yi, Z., Ed.; Chandos Information Professional Series; Chandos Publishing: Witney, UK, 2018; pp. 19–27. ISBN 978-0-08-100798-3. [Google Scholar]

- Diouf, R.; Sarr, E.N.; Sall, O.; Birregah, B.; Bousso, M.; Mbaye, S.N. Web Scraping: State-of-the-Art and Areas of Application. In Proceedings of the 2019 IEEE International Conference on Big Data (Big Data), Los Angeles, CA, USA, 9–12 December 2019; pp. 6040–6042. [Google Scholar]

- Nigam, H.; Biswas, P. Web Scraping: From Tools to Related Legislation and Implementation Using Python. In Proceedings of the Innovative Data Communication Technologies and Application; Raj, J.S., Iliyasu, A.M., Bestak, R., Baig, Z.A., Eds.; Springer: Singapore, 2021; pp. 149–164. [Google Scholar]

- Chazelas, E.; Deschasaux, M.; Srour, B.; Kesse-Guyot, E.; Julia, C.; Alles, B.; Druesne-Pecollo, N.; Galan, P.; Hercberg, S.; Latino-Martel, P.; et al. Food additives: Distribution and co-occurrence in 126,000 food products of the French market. Sci. Rep. 2020, 10, 3980. [Google Scholar] [CrossRef] [Green Version]

- Chu, X.; Ilyas, I.F.; Krishnan, S.; Wang, J. Data Cleaning: Overview and Emerging Challenges. In Proceedings of the 2016 International Conference on Management of Data; Association for Computing Machinery: New York, NY, USA, 2016; pp. 2201–2206. [Google Scholar]

- Beldi, G.; Senaldi, C.; Robouch, P.; Hoekstra, E. Testing Conditions for Kitchenware Articles in Contact with Foodstuffs: Plastics, Metals, Silicone & Rubber; European Union: Maastricht, The Netherlands, 2021. [Google Scholar]

- Steenburgh, T.J.; Wittink, D.R. Market Research. In International Encyclopedia of the Social & Behavioral Sciences; Smelser, N.J., Baltes, P.B., Eds.; Pergamon: Oxford, UK, 2001; pp. 9207–9211. ISBN 978-0-08-043076-8. [Google Scholar]

- East, R. Online Grocery Sales after the Pandemic. Int. J. Mark. Res. 2022, 64, 13–18. [Google Scholar] [CrossRef]

- Ngoh, C.; Groening, C. The effect of COVID-19 on consumers’ channel shopping behaviors: A segmentation study. J. Retail. Consum. Serv. 2022, 68, 103065. [Google Scholar] [CrossRef]

- Ibrahim, N.I.; Shahar, F.S.; Sultan, M.T.H.; Shah, A.U.M.; Safri, S.N.A.; Mat Yazik, M.H. Overview of Bioplastic Introduction and Its Applications in Product Packaging. Coatings 2021, 11, 1423. [Google Scholar] [CrossRef]

- The European Parliament; The Council of the European Union. Regulation (EC) No 1935/2004 of the European Parliament and of the Council of 27 October 2004 on Materials and Articles Intended to Come into Contact with Food and Repealing Directives 80/590/EEC and 89/109/EEC 2004. Off. J. Eur. Union 2004, 45, 247–260. [Google Scholar]

- The European Parliament; The Council of the European Union. Regulation (EC) No 178/2002 of the European Parliament and of the Council of 28 January 2002 laying down the general principles and requirements of food law, establishing the European Food Safety Authority and laying down procedures in matters of food safety 2002. Off. J. Eur. Union 2002, 6, 463–482. [Google Scholar]

- European Commission. Commission Regulation (EU) No 10/2011 of 14 January 2011 on plastic materials and articles intended to come into contact with food 2011. Off. J. Eur. Union 2011, 45, 42–130. [Google Scholar]

- European Commission. Commission Regulation (EU) 2022/1616 of 15 September 2022 on recycled plastic materials and articles intended to come into contact with foods, and repealing Regulation (EC) No 282/2008 2022. Off. J. Eur. Union 2022, 20, 3–46. [Google Scholar]

- Bayer, F.L.; Jetten, J. Chapter 15—Safety assessment of refillable and recycled plastics packaging for food use. In Present Knowledge in Food Safety; Knowles, M.E., Anelich, L.E., Boobis, A.R., Popping, B., Eds.; Academic Press: Cambridge, MA, USA, 2023; pp. 240–259. ISBN 978-0-12-819470-6. [Google Scholar]

- Rudin, A.; Choi, P. Chapter 13—Biopolymers. In The Elements of Polymer Science & Engineering, 3rd ed.; Rudin, A., Choi, P., Eds.; Academic Press: Boston, MA, USA, 2013; pp. 521–535. ISBN 978-0-12-382178-2. [Google Scholar]

- Nguyen, A.T.; Parker, L.; Brennan, L.; Lockrey, S. A consumer definition of eco-friendly packaging. J. Clean. Prod. 2020, 252, 119792. [Google Scholar] [CrossRef]

- Orzan, G.; Cruceru, A.F.; Bălăceanu, C.T.; Chivu, R.-G. Consumers’ Behavior Concerning Sustainable Packaging: An Exploratory Study on Romanian Consumers. Sustainability 2018, 10, 1787. [Google Scholar] [CrossRef]

- Riley, A. 10—Paper and paperboard packaging. In Packaging Technology; Emblem, A., Emblem, H., Eds.; Woodhead Publishing: Cambridge, UK, 2012; pp. 178–239. ISBN 978-1-84569-665-8. [Google Scholar]

- Mertens, B.; Bossuyt, M.V.; Fraselle, S.; Blaude, M.N.; Vanhaecke, T.; Rogiers, V.; Verschaeve, L.; Hoeck, E.V. Coatings in food contact materials: Potential source of genotoxic contaminants? Food Chem. Toxicol. 2017, 106, 496–505. [Google Scholar] [CrossRef]

- Bouma, K.; Wijk, D.K.K.; Sijm, D.T.H.M. Migration of formaldehyde from ‘biobased’ bamboo/melamine cups: A Dutch retail survey. Chemosphere 2022, 292, 133439. [Google Scholar] [CrossRef]

- Testa, F.; Iorio, V.D.; Cerri, J.; Pretner, G. Five shades of plastic in food: Which potentially circular packaging solutions are Italian consumers more sensitive to. Resour. Conserv. Recycl. 2021, 173, 105726. [Google Scholar] [CrossRef]

- Galbiati, E.; Tietz, T.; Zellmer, S.; Merkel, S. Risk Assessment of Food Contact Materials II. EFSA J. 2022, 20, 408. [Google Scholar] [CrossRef] [PubMed]

- Sevi, T.; Jati, I.R.A.; Tristanto, N.A.; Ristiarini, S. Consumer perceptions of edible packaging made of gelatin as chili powder packaging. E3S Web Conf 2022, 344, 04002. [Google Scholar] [CrossRef]

- Poon, W.C.; Tung, S.E.H. The rise of online food delivery culture during the COVID-19 pandemic: An analysis of intention and its associated risk. Eur. J. Manag. Bus. Econ. 2022. ahead-of-print. [Google Scholar] [CrossRef]

- Chakori, S.; Aziz, A.A.; Smith, C.; Dargusch, P. Untangling the underlying drivers of the use of single-use food packaging. Ecol. Econ. 2021, 185, 107063. [Google Scholar] [CrossRef]

- Singh, A.K.; Itkor, P.; Lee, M.; Shin, J.; Lee, Y.S. Promoting sustainable packaging applications in the circular economy by exploring and advancing molded pulp materials for food products: A review. Crit. Rev. Food Sci. Nutr. 2022. ahead of print. [Google Scholar] [CrossRef] [PubMed]

- Tyagi, P.; Salem, K.S.; Hubbe, M.A.; Pal, L. Advances in barrier coatings and film technologies for achieving sustainable packaging of food products—A review. Trends Food Sci. Technol. 2021, 115, 461–485. [Google Scholar] [CrossRef]

- Weligama Thuppahige, V.T.; Karim, M.A. A comprehensive review on the properties and functionalities of biodegradable and semibiodegradable food packaging materials. Compr. Rev. Food Sci. Food Saf. 2022, 21, 689–718. [Google Scholar] [CrossRef] [PubMed]

- Moos, P. Towards Safe and Sustainable Food Packaging; The European Consumer Organisation (BEUC): Bruxelles, Belgium, 2021. [Google Scholar]

- Morashti, J.A.; An, Y.; Jang, H. A Systematic Literature Review of Sustainable Packaging in Supply Chain Management. Sustainability 2022, 14, 4921. [Google Scholar] [CrossRef]

- Moshood, T.D.; Nawanir, G.; Mahmud, F.; Mohamad, F.; Ahmad, M.H.; AbdulGhani, A. Sustainability of biodegradable plastics: New problem or solution to solve the global plastic pollution? Curr. Res. Green Sustain. Chem. 2022, 5, 100273. [Google Scholar] [CrossRef]

- Versino, F.; Ortega, F.; Monroy, Y.; Rivero, S.; López, O.V.; García, M.A. Sustainable and Bio-Based Food Packaging: A Review on Past and Current Design Innovations. Foods 2023, 12, 1057. [Google Scholar] [CrossRef] [PubMed]

- Bonwick, G.; Bradley, E.; Lock, I.; Romero, R. Bio-Based Materials for Use in Food Contact Applications; FERA: London, UK, 2019. [Google Scholar]

- Muhamedbegović, B.; Ahmetović, N.; Suljagić, J.; Bajrić, B. Chemical migration from food contact materials into food—Gaps in Eu legislation and safety assessment. In Proceedings of the 13 International Scientific Conference on Manufacturing Engineering Development and Modernization Of The Manufacturing, Sarajevo, Bosnia and Herzegovina, 29 September–1 October 2021. [Google Scholar]

| Info | Description |

|---|---|

| ID code | A unique identifier code. |

| Material | Information on the material as described in the data source. |

| Main material classification | According to a harmonised material classification. |

| Material subcategory | If needed (e.g., bagasse, bamboo, coconut, etc.). |

| Coating | Presence of a coating, only for paper and board, and according to the information described in the data source. |

| Secondary material | In case different materials are used/declared. |

| Additional information | |

| Main usage category | Based on EURL kitchenware guidelines [26]. |

| Usage subcategory | Based on EURL kitchenware guidelines [26]. |

| Usage detail | If needed (e.g., disposable, etc.). |

| Description | Description of the FCM as available in the data source. |

| Brand | Brand of the item (according to data source). |

| Retailer | Name of the shop. |

| Source | Link to the website. |

| Remarks |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ciano, S.; Di Mario, M.; Goscinny, S.; Van Hoeck, E. Towards Less Plastic in Food Contact Materials: An In-Depth Overview of the Belgian Market. Foods 2023, 12, 2737. https://doi.org/10.3390/foods12142737

Ciano S, Di Mario M, Goscinny S, Van Hoeck E. Towards Less Plastic in Food Contact Materials: An In-Depth Overview of the Belgian Market. Foods. 2023; 12(14):2737. https://doi.org/10.3390/foods12142737

Chicago/Turabian StyleCiano, Salvatore, Mélanie Di Mario, Séverine Goscinny, and Els Van Hoeck. 2023. "Towards Less Plastic in Food Contact Materials: An In-Depth Overview of the Belgian Market" Foods 12, no. 14: 2737. https://doi.org/10.3390/foods12142737

APA StyleCiano, S., Di Mario, M., Goscinny, S., & Van Hoeck, E. (2023). Towards Less Plastic in Food Contact Materials: An In-Depth Overview of the Belgian Market. Foods, 12(14), 2737. https://doi.org/10.3390/foods12142737