Muffin-Type Bakery Product Based on Mexican Mesquite (Prosopis spp.) Flour: Texture Profile, Acceptability, and Physicochemical Properties

Abstract

:1. Introduction

2. Materials and Methods

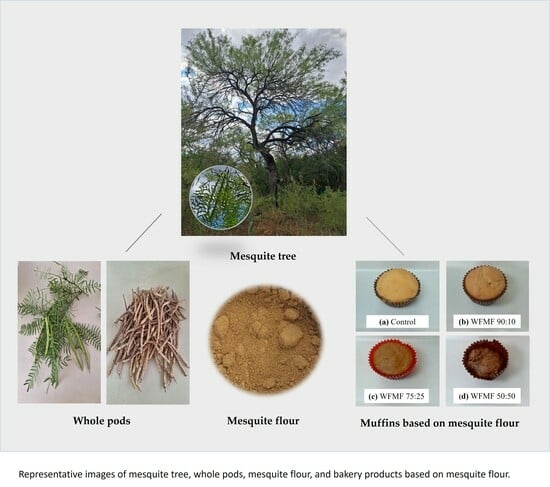

2.1. Preparation of Bakery Products Based on Mesquite Flour

2.2. Preliminary Preference Test

2.3. Water Activity, Color Analysis, and Texture Profile Analysis of Bakery Products

2.3.1. Water Activity (Aw)

2.3.2. Color Measurements

2.3.3. Texture Profile Analysis (TPA)

2.3.4. Bromatological Analysis

2.4. Statistical Analysis

3. Results and Discussion

3.1. Preliminary Preference Test of Bakery Products

3.2. Aw, Color Properties, and Texture Profile of Bakery Products

3.3. Bromatological Analysis

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Rosa, C.S.; Tessele, K.; Prestes, R.C.; Silveira, M.; Franco, F. Effect of substituting of cocoa powder for carob flour in cakes made with soy and banana flours. Int. Food Res. J. 2015, 22, 2111–2118. [Google Scholar]

- Aydın, S.; Özdemir, Y. Development and characterization of carob flour based functional spread for increasing use as nutritious snack for children. J. Food Qual. 2017, 2017, 5028150. [Google Scholar] [CrossRef]

- Goranova, Z.; Petrova, T.; Baeva, M.; Stefanov, S. Effect of natural sugar substitutes—Mesquite (Prosopis alba) flour and coconut (Cocos nucifera L.) sugar on the quality properties of sponge cakes. Ukr. Food J. 2020, 9, 561–575. [Google Scholar] [CrossRef]

- Bigne, F.; Ferrero, C.; Puppo, M.C. Effect of freezing and frozen storage on mesquite–wheat dough for panettone-like breads. J. Food Meas. Charact. 2019, 13, 2853–2861. [Google Scholar] [CrossRef]

- Pawłowska, K.; Kuligowski, M.; Jasińska-Kuligowska, I.; Kidoń, M.; Siger, A.; Rudzińska, M.; Nowak, J. Effect of replacing cocoa powder by carob powder in the muffins on sensory and physicochemical properties. Plant Foods Hum. Nutr. 2018, 73, 196–202. [Google Scholar] [CrossRef] [PubMed]

- Korus, J.; Witczak, M.; Korus, A.; Juszczak, L. Mesquite (Prosopis L.) as a functional ingredient in gluten-free dough and bread. LWT 2022, 168, 113957. [Google Scholar] [CrossRef]

- Gonzalez-Montemayor, A.M.; Solanilla-Duque, J.F.; Flores-Gallegos, A.C.; Lopez-Badillo, C.M.; Ascacio-Valdes, J.A.; Rodríguez-Herrera, R. Green bean, pea and mesquite whole pod flours nutritional and functional properties and their effect on sourdough bread. Foods 2021, 10, 2227. [Google Scholar] [CrossRef]

- Díaz-Batalla, L.; Hernández-Uribe, J.P.; Gutiérrez-Dorado, R.; Téllez-Jurado, A.; Castro-Rosas, J.; Pérez-Cadena, R.; Gómez-Aldapa, C.A. Nutritional characterization of Prosopis laevigata legume tree (mesquite) seed flour and the effect of extrusion cooking on its bioactive components. Foods 2018, 7, 124. [Google Scholar] [CrossRef]

- Afifi, H.A.S.; Al-rub, I.A. Prosopis cineraria as an unconventional legumes, nutrition and health benefits. In Legume Seed Nutraceutical Research; Jimenez-Lopez, J.C., Clemente, A., Eds.; Intech Open: London, UK, 2019; pp. 1–18. [Google Scholar] [CrossRef]

- Gonzales-Barron, U.; Dijkshoorn, R.; Maloncy, M.; Finimundy, T.; Carocho, M.; Ferreira, C.F.R.; Cadavez, V. Nutritional quality and staling of wheat bread partially replaced with Peruvian mesquite (Prosopis pallida) flour. Food Res. Int. 2020, 137, 109621. [Google Scholar] [CrossRef]

- Korus, J.; Witczak, M.; Korus, A.; Juszczak, L. Influence of Wheat-Mesquite (Prosopis L.) Composite flour on dough rheology and quality of bread. Acta Univ. Cibiniensis Ser. E Food Technol. 2022, 26, 225–236. [Google Scholar] [CrossRef]

- Bigne, F.; Puppo, M.C.; Ferrero, C. Mesquite (Prosopis alba) flour as a novel ingredient for obtaining a “panettone-like” bread. Applicability of part-baking technology. LWT 2018, 89, 666–673. [Google Scholar] [CrossRef]

- Gonzales-Barron, U.; Dijkshoorn, R.; Maloncy, M.; Finimundy, T.; Calhelha, R.C.; Pereira, C.; Cadavez, V. Nutritive and bioactive properties of mesquite (Prosopis pallida) flour and its technological performance in breadmaking. Foods 2020, 9, 597. [Google Scholar] [CrossRef] [PubMed]

- Torrelio-Martos, A.G.; López, E.P. Chemical composition, percent of dietary reference intake, and acceptability of gluten-free bread made from Prosopis nigra flour, added with hydrocolloids. Food Sci. Technol. 2018, 38, 619–624. [Google Scholar] [CrossRef]

- Zhong, J.; Lu, P.; Wu, H.; Liu, Z.; Sharifi-Rad, J.; Setzer, W.N.; Suleria, H.A.R. Current insights into phytochemistry, nutritional, and pharmacological properties of Prosopis plants. Evid. Based Complement. Altern. Med. 2022, 2022, 2218029. [Google Scholar] [CrossRef] [PubMed]

- Różyło, R.; Dziki, D.; Gawlik-Dziki, U.; Biernacka, B.; Wójcik, M.; Ziemichód, A. Physical and antioxidant properties of gluten-free bread enriched with carob fibre. Int. Agrophys. 2017, 31, 411–418. [Google Scholar] [CrossRef]

- Bigne, F.; Puppo, M.C.; Ferrero, C. Rheological and microstructure characterization of composite dough with wheat and mesquite (Prosopis spp) flours. Int. J. Food Prop. 2016, 19, 243–256. [Google Scholar] [CrossRef]

- Bigne, F.; Romero, A.; Ferrero, C.; Puppo, M.; Guerrero, A. Rheological and microstructural study of wheat doughs partially replaced with mesquite flour (Prosopis alba) and added with transglutaminase. Food Bioprocess Technol. 2017, 10, 819–830. [Google Scholar] [CrossRef]

- Treviño-Garza, M.Z.; Correa-Cerón, R.C.; Ortiz-Lechuga, E.G.; Solís-Arévalo, K.K.; Castillo-Hernández, S.L.; Gallardo-Rivera, C.T.; Arévalo-Niño, K. Effect of linseed (Linum usitatissimum) mucilage and chitosan edible coatings on quality and shelf-life of fresh-cut cantaloupe (Cucumis melo). Coatings 2019, 9, 368. [Google Scholar] [CrossRef]

- Jamanca-Gonzales, N.C.; Ocrospoma-Dueñas, R.W.; Quintana-Salazar, N.B.; Siche, R.; Silva-Paz, R.J. Influence of preferments on the physicochemical and sensory quality of traditional panettone. Foods 2022, 11, 2566. [Google Scholar] [CrossRef]

- AOAC. Official Methods of Analysis of the AOAC, 17th ed.; American Official Analytical Chemists: Washington, DC, USA, 2000. [Google Scholar]

- Barba de la Rosa, A.P.; Frias-Hernández, J.T.; Olalde-Portugal, V.; González-Castañeda, J. Processing, nutritional evaluation, and utilization of whole mesquite flour (Prosopis laevigata). J. Food Sci. 2006, 71, S315–S320. [Google Scholar] [CrossRef]

- Hleap, J.I.; Velasco, V.A. Analysis of the properties of texture during the storage of sausage made from red tilapia (Oreochromis sp.). Biotecnol. Sect. Agropecu. Agroindustrial 2010, 8, 46–56. Available online: http://www.scielo.org.co/pdf/bsaa/v8n2/v8n2a07.pdf (accessed on 1 June 2023).

- González, A.; Alvis, A.; Arrazola, G. Effect of edible coating on the properties of sweet potato slices (Ipomoea Batatas Lam) cooked by deep-fat frying. Part 1: Texture. Inf. Tecnol. 2015, 26, 95–102. [Google Scholar] [CrossRef]

- Dhal, S.; Anis, A.; Shaikh, H.M.; Alhamidi, A.; Pal, K. Effect of mixing time on properties of whole wheat flour-based cookie doughs and cookies. Foods 2023, 12, 941. [Google Scholar] [CrossRef]

| Composition | Value (%) |

|---|---|

| Moisture | 5.83 ± 0.11 |

| Dry matter | 94.17 ± 0.11 |

| Ash | 4.61 ± 0.01 |

| Protein | 17.71 ± 0.12 |

| Fat | 9.57 ± 0.04 |

| Crude fiber | 7.88 ± 0.12 |

| Carbohydrates | 54.09 ± 0.16 |

| Formulation | Water (%) | Oil (%) | Egg (%) | Wheat Based Flour (%) | Mesquite Flour (%) |

|---|---|---|---|---|---|

| Control | 22.36 | 3.31 | 18.44 | 55.89 | - |

| WFMF 90:10 | 22.36 | 3.31 | 18.44 | 50.30 | 5.59 |

| WFMF 75:25 | 22.36 | 3.31 | 18.44 | 41.92 | 13.97 |

| WFMF 50:50 | 22.36 | 3.31 | 18.44 | 27.95 | 27.95 |

| Physicochemical Analysis | Control | WFMF 90:10 | WFMF 75:25 | WFMF 50:50 |

|---|---|---|---|---|

| Moisture | 28.86 ± 0.00 b | 32.03 ± 0.01 d | 29.41 ± 0.08 c | 27.16 ± 0.10 a |

| dry matter | 71.15 ± 0.02 c | 67.94 ± 0.06 a | 70.59 ± 0.08 b | 72.84 ± 0.10 d |

| Ash | 1.83 ± 0.02 a | 1.75 ± 0.04 a | 2.24 ± 0.02 b | 2.69 ± 0.04 c |

| Protein | 6.07 ± 0.02 a | 6.33 ± 0.01 b | 8.86 ± 0.05 c | 11.28 ± 0.04 d |

| Fat | 10.89 ± 0.09 d | 9.90 ± 0.05 c | 8.45 ± 0.07 b | 7.70 ± 0.03 a |

| Crude fiber | 0.57 ± 0.00 a | 2.04 ± 0.01 b | 2.28 ± 0.06 c | 4.04 ± 0.13 d |

| Carbohydrates | 51.80 ± 0.11 b | 47.96 ± 0.01 a | 48.75 ± 0.11 a | 47.13 ± 0.08 a |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Alemán-Huerta, M.E.; Castillo-Cázares, B.A.; Márquez-Reyes, J.M.; Báez-González, J.G.; Quintero-Zapata, I.; Gandarilla-Pacheco, F.L.; de Luna-Santillana, E.d.J.; Treviño-Garza, M.Z. Muffin-Type Bakery Product Based on Mexican Mesquite (Prosopis spp.) Flour: Texture Profile, Acceptability, and Physicochemical Properties. Foods 2023, 12, 3587. https://doi.org/10.3390/foods12193587

Alemán-Huerta ME, Castillo-Cázares BA, Márquez-Reyes JM, Báez-González JG, Quintero-Zapata I, Gandarilla-Pacheco FL, de Luna-Santillana EdJ, Treviño-Garza MZ. Muffin-Type Bakery Product Based on Mexican Mesquite (Prosopis spp.) Flour: Texture Profile, Acceptability, and Physicochemical Properties. Foods. 2023; 12(19):3587. https://doi.org/10.3390/foods12193587

Chicago/Turabian StyleAlemán-Huerta, María Elizabeth, Brenda A. Castillo-Cázares, Julia Mariana Márquez-Reyes, Juan G. Báez-González, Isela Quintero-Zapata, Fátima Lizeth Gandarilla-Pacheco, Erick de Jesús de Luna-Santillana, and Mayra Z. Treviño-Garza. 2023. "Muffin-Type Bakery Product Based on Mexican Mesquite (Prosopis spp.) Flour: Texture Profile, Acceptability, and Physicochemical Properties" Foods 12, no. 19: 3587. https://doi.org/10.3390/foods12193587

APA StyleAlemán-Huerta, M. E., Castillo-Cázares, B. A., Márquez-Reyes, J. M., Báez-González, J. G., Quintero-Zapata, I., Gandarilla-Pacheco, F. L., de Luna-Santillana, E. d. J., & Treviño-Garza, M. Z. (2023). Muffin-Type Bakery Product Based on Mexican Mesquite (Prosopis spp.) Flour: Texture Profile, Acceptability, and Physicochemical Properties. Foods, 12(19), 3587. https://doi.org/10.3390/foods12193587