Assessment of Functional Properties of Wheat–Cassava Composite Flour

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Sample Preparation

2.3. Proximate Analysis

2.4. Color Characteristics

2.5. Iodine Blue Value (IBV)

2.6. Functional Properties of Flours

2.6.1. Water Absorption Capacity (WAC, g/g)

2.6.2. The Water Solubility (WS, %) and Swelling Power (SP, %)

2.6.3. Freeze–Thaw Stability (FS)

2.6.4. Retrogradation

2.7. Functional Properties of Dough

2.7.1. Water Content

2.7.2. Sensory Evaluation

2.7.3. Wet Gluten Content

2.7.4. Farinographic Characteristics

2.7.5. Texture Analysis

2.7.6. Extension Properties

2.8. Statistics and Analysis Methods

3. Results and Discussion

3.1. Effects of CF Substitution Level on Properties of W-CF

3.1.1. Proximate Analysis of W-CF

3.1.2. Color Characteristics of W-CF

3.1.3. Iodine Blue Value (IBV) of W-CF

3.1.4. Water Absorption Capacity (WAC) of W-CF

3.1.5. Water Solubility (WS) and Swelling Power (SP) of W-CF

3.1.6. Freeze–Thaw Stability (FS) and Retrogradation of W-CF Gels

3.1.7. The Correlation between the CF Substitution Level and Properties of W-CF

3.2. Effects of CF Substitution Level on Functional Properties of Dough

3.2.1. Water Content and Sensory Evaluation

3.2.2. Wet Gluten Content of Dough

3.2.3. Farinographic Characteristics of Dough

Water Absorption

Dough Development Time

Stability Time

Softening Degree

3.2.4. Textural Properties of Dough

3.2.5. Extension Properties of Dough

3.2.6. Correlation between CF Substitution Level and Dough Properties

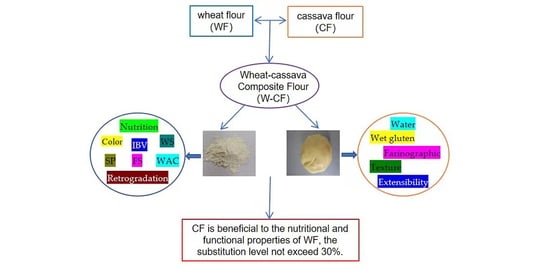

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Idris, S.; Rosnah, S.; Nor, M.Z.M.; Mokhtar, M.N.; Gani, S. Physicochemical composition of different parts of cassava (Manihot esculenta Crantz) plant. Food Res. 2020, 4 (Suppl. S1), 78–84. [Google Scholar] [CrossRef]

- Obojiofor, E.F.; Okechukwu, J.O.; Victor, E.I.; Anikwenze, R. Production, Physicochemical and organoleptic evaluation of bread made from composite wheat-cassava flour. Adv. Sci. Technol. 2021, 107, 29–36. [Google Scholar] [CrossRef]

- Yan, Y.; Zhao, S.H.; Ye, X.X.; Tian, L.; Shang, S.; Tie, W.; Hu, W. Abscisic acid signaling in the regulation of postharvest physiological deterioration of sliced cassava tuberous roots. J. Agric. Food Chem. 2022, 70, 12830–12840. [Google Scholar] [CrossRef]

- Ma, Q.X.; Xu, J.; Feng, Y.C.; Wu, X.; Lu, X.; Zhang, P. Knockdown of p-coumaroyl shikimate/quinate 3′-hydroxylase delays the occurrence of post-harvest physiological deterioration in cassava storage roots. Int. J. Mol. Sci. 2022, 23, 9231. [Google Scholar] [CrossRef]

- Onyenwoke, C.A.; Ojo, C.C.; Omodamiro, R.M. Effect of drying methods on total carotenoids content retention in pro-vitamin a high quality cassava flour. Umudike J. Eng. Technol. 2015, 1, 1–9. [Google Scholar]

- Vega, O.; Carvajal, L.M.; Rodriguez, F.; Marin, M.C.; Ramirez, C.; Simpson, R.; Valdenegro, M. Effect of thermal pretreatments and cooking characteristics on physicochemical, rheological, and sensorial properties of food products based on cassava (Manihot esculenta Crantz). J. Food Process Eng. 2018, 41, e12612. [Google Scholar] [CrossRef]

- Oliveira, V.A.; Costa, G.F.; Sousa, S. Chemical and microbial evaluation of bread and biscuits made from wheat flour substituted with cassava flour. Nutr. Food Sci. 2021, 51, 792–807. [Google Scholar] [CrossRef]

- Chisenga, S.M.; Workneh, T.S.; Bultosa, G.; Alimi, B.A.; Siwela, M. Dough rheology and loaf quality of wheat-cassava bread using difffferent cassava varieties and wheat substitution levels. Food Biosci. 2020, 34, 100529. [Google Scholar] [CrossRef]

- Wangtueai, S.; Phimolsiripol, Y.; Vichasilp, C.; Regenstein, J.M.; Schoenlechner, R. Optimization of gluten-free functional noodles formulation enriched with fish gelatin hydrolysates. LWT-Food Sci. Technol. 2020, 133, 109977. [Google Scholar] [CrossRef]

- Okafor, E.N.; Erukainure, O.L.; Ozumba, A.U.; Adewale, C.O.; Kayode, F.O.; Asieba, G.O.; Elemo, G.N. Cassava Flour substitution modulates glycemic responses and glycemic index of wheat breads in apparent healthy volunteers. J. Diet. Suppl. 2017, 14, 446–452. [Google Scholar] [CrossRef]

- Aryeetey, E.; Wireko-Manu, F.D.; Asante, J.O.; Laryea, D.; Ellis, W.O.; Oduro, I.; Ngadi, M. Recipe standardization of bread using cassava-wheat composite flour. J. Culin. Sci. Technol. 2019, 17, 232–255. [Google Scholar] [CrossRef]

- AOAC. Official Methods of Analysis of AOAC International, 16th ed.; AOAC International: Arlington, VA, USA, 2005. [Google Scholar]

- Kaur, M.; Kaushal, P.; Sandhu, K.S. Studies on physicochemical and pasting properties of Taro (Colocasia esculenta L.) flour in comparison with a cereal, tuber and legume flour. J. Food Sci. Technol. 2011, 50, 94–100. [Google Scholar] [CrossRef] [PubMed]

- Wu, T.Y.; Chang, C.R.; Chang, T.J.; Chang, Y.J.; Liew, Y.; Chau, C.F. Changes in physicochemical properties of corn starch upon modifications by atmospheric pressure plasma jet. Food Chem. 2019, 283, 46–51. [Google Scholar] [CrossRef] [PubMed]

- AACC. AACC International, Approved Methods of the American Association of Cereal Chemists, 10th ed.; AACC International: St. Paul, MN, USA, 2011. [Google Scholar]

- Zhang, Q.; Yu, J.; Li, K.; Bai, L.; Zhang, X.; Lu, Y.; Sun, X.; Li, W. The rheological performance and structure of wheat/acorn composite dough and the quality and in vitro digestibility of its noodles. Foods 2021, 10, 2727. [Google Scholar] [CrossRef] [PubMed]

- Lagnika, C.; Houssou, P.A.F.; Dansou, V.; Hotegni, A.B.; Amoussa, A.M.O.; Kpotouhedo, F.Y.; Doko, S.A.; Lagnika, L. Physico-functional and sensory properties of flour and bread made from composite wheat-cassava. Pak. J. Nutr. 2019, 18, 538–547. [Google Scholar] [CrossRef]

- Skibsted, L.H.; Kidmose, U.; Thybo, A.K.; Jensen, S. Addition of cassava flours in bread-making: Sensory and textural evaluation. LWT-Food Sci. Technol. 2015, 60, 292–299. [Google Scholar] [CrossRef]

- Haros, M.; Rosell, C.M.; Collar, C. Assessment of hydrocolloid effects on the thermo-mechanical properties of wheat using the mixolab. Food Hydrocoll. 2007, 21, 452–462. [Google Scholar] [CrossRef]

- Goldstein, A.; Ashrafi, L.; Seetharaman, K. Effects of cellulosic fibre on physical and rheological properties of starch, gluten and wheat flour. Int. J. Food Sci. Technol. 2010, 45, 1641–1646. [Google Scholar] [CrossRef]

- Putseys, J.A.; Lamberts, L.; Delcour, J.A. Amylose-lipid complexes: Formation, identity and physicochemical properties. J. Cereal Sci. 2010, 51, 238–247. [Google Scholar] [CrossRef]

- Oyeyinka, S.A.; Singh, S.; Venter, S.L.; Amonsou, E.O. Effect of lipid types on complexation and some physicochemical properties of bambara groundnut starch. Starch-Stärke 2017, 69, 1600158. [Google Scholar] [CrossRef]

- Lin, L.M.; Li, K.M.; Xu, H.; Jian, C.P.; Zhang, Z.W. Comparative analysis of processing characteristics of whole cassava flour and cassava flour. J. Trop. Biol. 2016, 7, 58–63. (In Chinese) [Google Scholar] [CrossRef]

- Vandeputte, G.E.; Vermeylen, R.; Geeroms, J.; Delcour, J.A. Rice starches III. structural aspects provide insight in amylopectin retrogradation properties and gel texture. J. Cereal Sci. 2003, 38, 61–68. [Google Scholar] [CrossRef]

- Hu, X.H.; Cheng, L.; Hong, Y.; Li, Z.F.; Li, C.M.; Gu, Z.B. An extensive review: How starch and gluten impact dough machinability and resultant bread qualities. Crit. Rev. Food Sci. Nutr. 2023, 63, 1930–1941. [Google Scholar] [CrossRef]

- Naqash, F.; Gani, A.; Gani, A.; Masoodi, F.A. Gluten-free baking: Combating the challenges-A review. Trends Food Sci. Technol. 2017, 66, 98–107. [Google Scholar] [CrossRef]

- Oladunmoye, O.O.; Aworh, O.C.; Maziya-Dixon, B.; Erukainure, O.L.; Elemo, G.N. Chemical and functional properties of cassava starch, durum wheat semolina flour and their blends. Food Sci. Nutr. 2014, 2, 132–138. [Google Scholar] [CrossRef]

- Jia, C.L.; Huang, W.N.; Abdel-Shamie, M.A.; Huang, G.X.; Huang, G.W. Dough rheological, mixolab mixing, and nutritional characteristics of almond cookies with and without xylanase. J. Food Eng. 2011, 105, 227–232. [Google Scholar] [CrossRef]

- Li, M.F.; Liu, C.; Zheng, X.L.; Hong, J.; Bian, K.; Li, L. Interaction between A-type/B-type starch granules and gluten in dough during mixing. Food Chem. 2021, 358, 129870. [Google Scholar] [CrossRef] [PubMed]

- Liu, R.; Sun, W.S.; Zhang, Y.J.; Huang, Z.Q.; Hu, H.Y.; Zhao, M.Y.; Li, W.H. Development of a novel model dough based on mechanically activated cassava starch and gluten protein: Application in bread. Food Chem. 2019, 300, 125196. [Google Scholar] [CrossRef]

- Sudha, M.L.; Vetrimani, R.; Leelavathi, K. Influence of fiber from different cereals on the rheological characteristics of wheat flour dough and on biscuit quality. Food Chem. 2007, 100, 1365–1370. [Google Scholar] [CrossRef]

- Khoshgozaran-Abras, S.; Azizi, M.H.; Bagheripoor-Fallah, N.; Khodamoradi, A. Effect of brown rice flour fortification on the quality of wheat-based dough and flat bread. J. Food Sci. Technol. 2014, 51, 2821–2826. [Google Scholar] [CrossRef]

- Tao, H.; Zhu, X.F.; Nan, B.X.; Jiangm, R.Z.; Wang, H.L. Effect of extruded starches on the structure, farinograph characteristics and baking behavior of wheat dough. Food Chem. 2021, 348, 129017. [Google Scholar] [CrossRef] [PubMed]

- Pang, H.M.; Chen, Y.; Zhao, S.M.; Li, J.K.; Xiong, S.B. Investigations on the rheological properties and thermal properties of wheat-mung bean blend. J. Chin. Cereals Oils Assoc. 2015, 30, 36–38. (In Chinese) [Google Scholar]

- Wang, C.X. Study on potato instant noodle test. Yangling Northwest Agric. For. Univ. 2005, 28, 31–32. (In Chinese) [Google Scholar]

- Wu, N.N.; Yang, T.; Tan, B.; Liu, M.; Liu, Y.X. The properties of dough prepared from mixtures of extruded brown rice flour and wheat flour. J. Chin. Cereals Oils Assoc. 2017, 32, 1–7. (In Chinese) [Google Scholar]

- Ortolan, F.; Steel, C.J. Protein characteristics that affect the quality of vital wheat gluten to be used in baking: A review. Compr. Rev. Food Sci. Food Saf. 2017, 16, 369–381. [Google Scholar] [CrossRef]

- Cao, X.L.; Zhou, S.M.; Yi, C.P.; Wang, L.; Qian, H.F.; Zhang, H.; Qi, X.G. Effect of whole flour on the quality, texture profile, and oxidation stability of instant fried noodles. J. Texture Stud. 2017, 48, 607–615. [Google Scholar] [CrossRef]

- Tao, C.S.; Wang, K.J.; Liu, X.J.; Gou, E.T. Effects of potato starch on the properties of wheat dough and the quality of fresh noodles. CyTA—J. Food 2020, 18, 427–434. [Google Scholar] [CrossRef]

| CF Substitution Level (%) | Moisture (%) | Protein (%) | Fat (%) | Crude Fiber (%) | Ash (%) | Starch (%) |

|---|---|---|---|---|---|---|

| 0 | 12.53 ± 0.24 a | 8.49 ± 0.10 a | 1.72 ± 0.11 a | 0.45 ± 0.07 g | 0.73 ± 0.08 e | 70.27 ± 1.53 d |

| 10 | 12.19 ± 0.17 b | 7.92 ± 0.11 b | 1.63 ± 0.11 ab | 0.58 ± 0.02 f | 0.83 ± 0.06 de | 70.71 ± 1.02 cd |

| 20 | 11.83 ± 0.14 c | 7.30 ± 0.07 c | 1.54 ± 0.15 abc | 0.77 ± 0.04 e | 0.95 ± 0.05 d | 71.41 ± 1.02 bcd |

| 30 | 11.63 ± 0.12 c | 6.68 ± 0.11 d | 1.48 ± 0.11 bc | 0.88 ± 0.05 d | 1.10 ± 0.07 c | 71.97 ± 0.46 bcd |

| 40 | 11.29 ± 0.17 d | 6.03 ± 0.08 e | 1.38 ± 0.01 cd | 1.05 ± 0.03 c | 1.20 ± 0.04 bc | 72.40 ± 0.38 bc |

| 50 | 11.07 ± 0.03 d | 5.35 ± 0.13 f | 1.26 ± 0.16 d | 1.18 ± 0.08 b | 1.32 ± 0.11 b | 72.95 ± 1.27 b |

| 100 | 9.58 ± 0.15 e | 2.21 ± 0.15 g | 1.02 ± 0.09 e | 1.89 ± 0.09 a | 1.90 ± 0.07 a | 75.01 ± 0.78 a |

| CF Substitution Level (%) | Colorimetric Value of W-CF | ||

|---|---|---|---|

| L* | a* | b* | |

| 0 | 98.04 ± 0.22 d | 0.24 ± 0.04 d | 4.52 ± 0.15 a |

| 10 | 98.48 ± 0.15 c | 0.34 ± 0.03 c | 4.42 ± 0.08 a |

| 20 | 98.54 ± 0.14 c | 0.39 ± 0.02 b | 4.26 ± 0.06 b |

| 30 | 98.73 ± 0.10 b | 0.42 ± 0.03 b | 4.06 ± 0.08 c |

| 40 | 98.95 ± 0.08 a | 0.46 ± 0.03 a | 3.84 ± 0.14 d |

| 50 | 99.08 ± 0.10 a | 0.49 ± 0.02 a | 3.72 ± 0.05 d |

| Indexes | CF Substitution Level | Moisture | Protein | Fat | Fiber | Ash | Starch | L* | a* | b* | IBV | WAC | WS | SP | FS | Retrogradation |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Moisture | −1.00 ** | 1 | ||||||||||||||

| Protein | −1.00 ** | 0.99 ** | 1 | |||||||||||||

| Fat | −1.00 ** | 0.99 ** | 1.00 ** | 1 | ||||||||||||

| Fiber | 1.00 ** | −1.00 ** | −1.00 ** | −0.99 ** | 1 | |||||||||||

| Ash | 1.00 ** | −0.99 ** | −1.00 ** | −0.99 ** | 1.00 ** | 1 | ||||||||||

| Starch | 1.00 ** | −1.00 ** | −1.00 ** | −0.99 ** | 1.00 ** | 1.00 ** | 1 | |||||||||

| L* | 0.98 ** | −0.98 ** | −0.97 ** | −0.97 ** | 0.97 ** | 0.97 ** | 0.97 ** | 1 | ||||||||

| a* | 0.97 ** | −0.98 ** | −0.96 ** | −0.96 ** | 0.97 ** | 0.96 ** | 0.97 ** | 0.99 ** | 1 | |||||||

| b* | −0.99 ** | 0.99 ** | 1.00 ** | 0.99 ** | −0.99 ** | −1.00 ** | −0.99 ** | −0.96 ** | −0.95 ** | 1 | ||||||

| IBV | 0.99 ** | −0.98 ** | −1.00 ** | −0.99 ** | 0.99 ** | 0.99 ** | 0.99 ** | 0.96 ** | 0.94 ** | −0.99 ** | 1 | |||||

| WAC | 0.65 | −0.67 | −0.63 | −0.59 | 0.65 | 0.66 | 0.68 | 0.66 | 0.72 | −0.63 | 0.58 | 1 | ||||

| WS | −1.00 ** | 0.99 ** | 1.00 ** | 0.99 ** | −0.99 ** | −1.00 ** | −0.99 ** | −0.97 ** | −0.95 ** | 1.00 ** | −1.00 ** | −0.6 | 1 | |||

| SP | 0.98 ** | −0.96 ** | −0.98 ** | −0.98 ** | 0.97 ** | 0.98 ** | 0.97 ** | 0.92 ** | 0.90 ** | −0.99 ** | 0.99 ** | 0.54 | −0.99 ** | 1 | ||

| FS | 0.99 ** | −0.98 ** | −0.99 ** | −0.98 ** | 0.99 ** | 0.99 ** | 0.99 ** | 0.95 ** | 0.94 ** | −1.00 ** | 0.99 ** | 0.63 | −1.00 ** | 0.99 ** | 1 | |

| Retrogradation | 0.80 * | −0.81 * | −0.80 * | −0.81 * | 0.81 * | 0.78 * | 0.77 * | 0.80 * | 0.76 * | −0.83 * | 0.81 * | 0.29 | −0.82 * | 0.80 * | 0.82 * | 1 |

| CF Substitution Level (%) | Water Content (%) | Description of Dough Properties |

|---|---|---|

| 0 | 44.48 ± 0.61 a | Too soft, good extensibility and plasticity, very good elasticity, easy to sheet and mold. |

| 10 | 43.91 ± 0.19 ab | Very soft, very good extensibility, malleability, and elasticity, does not stick to hand, easier to sheet and mold. |

| 20 | 43.10 ± 0.10 bc | Soft, good extensibility, malleability, and elasticity, does not stick to hand, easier to sheet and mold. |

| 30 | 42.57 ± 0.64 c | Softer, good extensibility, elasticity, and plasticity, easy to sheet and mold. |

| 40 | 41.34 ± 0.69 d | Poor softness, poor extensibility and plasticity, general elasticity, sticky, not easy to sheet or mold. |

| 50 | 39.64 ± 0.51 e | Hard, poor extensibility and plasticity, basically inelastic, very sticky, difficult to sheet and mold. |

| CF Substitution Level (%) | Farinographic Characteristics of Dough | |||

|---|---|---|---|---|

| Water Absorption (%) | Development Time (min) | Stability Time (min) | Degree of Softening (mN·m) | |

| 0 | 57.80 ± 0.00 f | 1.63 ± 0.06 a | 1.97 ± 0.06 a | 44.67 ± 1.15 c |

| 10 | 59.50 ± 0.00 e | 0.97 ± 0.06 c | 1.70 ± 0.06 b | 45.67 ± 2.08 c |

| 20 | 60.80 ± 0.00 d | 0.80 ± 0.00 d | 0.93 ± 0.06 c | 54.00 ± 0.00 a |

| 30 | 62.00 ± 0.20 c | 0.83 ± 0.06 cd | 0.67 ± 0.06 d | 52.67 ± 2.52 ab |

| 40 | 63.77 ± 0.25 b | 0.90 ± 0.10 cd | 0.67 ± 0.06 d | 52.67 ± 2.31 ab |

| 50 | 64.40 ± 0.17 a | 1.13 ± 0.12 b | 0.90 ± 0.06 c | 50.00 ± 1.00 b |

| CF Substitution Level (%) | Texture Properties of Dough | |||

|---|---|---|---|---|

| Hardness (g) | Chewiness (mJ) | Elasticity (mm) | Cohesiveness | |

| 0 | 2320.33 ± 140.68 f | 22.27 ± 2.84 f | 1.34 ± 0.11 c | 0.63 ± 0.04 b |

| 10 | 2731.67 ± 230.82 e | 27.07 ± 4.51 e | 1.46 ± 0.10 b | 0.66 ± 0.04 b |

| 20 | 3214.67 ± 433.18 d | 33.77 ± 3.09 d | 1.63 ± 0.06 a | 0.71 ± 0.05 a |

| 30 | 3588.17 ± 372.41 c | 39.82 ± 2.37 c | 1.27 ± 0.08 cd | 0.61 ± 0.03 b |

| 40 | 4683.83 ± 268.69 b | 45.73 ± 2.64 b | 1.17 ± 0.08 d | 0.46 ± 0.04 c |

| 50 | 5376.33 ± 263.94 a | 60.22 ± 3.52 a | 0.99 ± 0.09 e | 0.43 ± 0.04 c |

| CF Substitution Level (%) | Extension Properties of Dough | |||

|---|---|---|---|---|

| Resistance to Extension (g) | Extensibility (mm) | Extended Area (g·m) | Extension Ratio (g/mm) | |

| 0 | 32.50 ± 2.59 a | 43.80 ± 2.64 a | 1419.37 ± 82.58 a | 0.75 ± 0.10 a |

| 10 | 28.17 ± 1.17 b | 39.32 ± 1.87 b | 1107.21 ± 64.26 b | 0.72 ± 0.05 a |

| 20 | 23.83 ± 1.47 c | 30.58 ± 2.07 c | 726.53 ± 23.26 c | 0.78 ± 0.10 a |

| 30 | 17.33 ± 1.21 d | 23.99 ± 3.13 d | 413.51 ± 36.70 d | 0.74 ± 0.13 a |

| 40 | 13.83 ± 1.17 e | 20.00 ± 1.49 e | 276.97 ± 34.09 e | 0.69 ± 0.07 a |

| 50 | 10.33 ± 0.82 f | 15.34 ± 1.09 f | 158.94 ± 21.58 f | 0.67 ± 0.05 a |

| Indexes | Water Content | Wet Gluten | Water Absorption | Development time | Stability Time | Degree of Softening | Hardness | Chewiness | Elasticity | Cohesiveness | Resistance to Extension | Extensibility | Extended Area | Extension Ratio |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| CF Substitution level | −0.98 ** | −0.98 ** | 0.99 ** | −0.46 | −0.84 * | 0.63 | 0.98 ** | 0.98 ** | −0.71 | −0.81 * | −1.00 ** | −0.99 ** | −0.98 ** | −0.7 |

| Water content | 1 | 0.99 ** | −0.96 ** | 0.3 | 0.71 | −0.49 | −0.99 ** | −1.00 ** | 0.77 * | 0.86 * | 0.96 ** | 0.95 ** | 0.91 ** | 0.76 * |

| Wet gluten | 1 | −0.98 ** | 0.59 | 0.89 ** | −0.75 | −0.99 ** | −0.99 ** | 0.6 | 0.78 * | 0.98 ** | 0.97 ** | 0.95 ** | 0.55 | |

| Water absorption | 1 | −0.52 | −0.86 * | 0.66 | 0.97 ** | 0.96 ** | −0.67 | −0.79 * | −0.99 ** | −0.99 ** | −0.98 ** | −0.69 | ||

| Development time | 1 | 0.75 | −0.77 * | −0.33 | −0.33 | −0.2 | −0.06 | 0.48 | 0.5 | 0.6 | −0.02 | |||

| Stability time | 1 | −0.93 ** | −0.74 | −0.74 | 0.33 | 0.44 | 0.86 * | 0.89 ** | 0.93 ** | 0.26 | ||||

| Degree of softening | 1 | 0.52 | 0.52 | 0 | −0.15 | −0.65 | −0.71 | −0.76 * | 0.07 | |||||

| Hardness | 1 | 0.98 ** | −0.77 * | −0.88 ** | −0.97 ** | −0.96 ** | −0.93 ** | −0.78 * | ||||||

| Chewiness | 1 | −0.77 * | −0.83 * | −0.97 ** | −0.96 ** | −0.93 ** | −0.74 | |||||||

| Elasticity | 1 | 0.94 ** | 0.72 | 0.67 | 0.6 | 0.88 ** | ||||||||

| Cohesiveness | 1 | 0.80 * | 0.76 * | 0.7 | 0.92 ** | |||||||||

| Resistance to extension | 1 | 1.00 ** | 0.99 ** | 0.68 | ||||||||||

| Extensibility | 1 | 0.99 ** | 0.62 | |||||||||||

| Extended area | 1 | 0.57 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Li, M.; Zhang, Y.; You, X.; Wang, Y.; Zhou, K.; Wei, P.; Wei, L. Assessment of Functional Properties of Wheat–Cassava Composite Flour. Foods 2023, 12, 3585. https://doi.org/10.3390/foods12193585

Li M, Zhang Y, You X, Wang Y, Zhou K, Wei P, Wei L. Assessment of Functional Properties of Wheat–Cassava Composite Flour. Foods. 2023; 12(19):3585. https://doi.org/10.3390/foods12193585

Chicago/Turabian StyleLi, Mingjuan, Yayuan Zhang, Xiangrong You, Ying Wang, Kui Zhou, Ping Wei, and Linyan Wei. 2023. "Assessment of Functional Properties of Wheat–Cassava Composite Flour" Foods 12, no. 19: 3585. https://doi.org/10.3390/foods12193585

APA StyleLi, M., Zhang, Y., You, X., Wang, Y., Zhou, K., Wei, P., & Wei, L. (2023). Assessment of Functional Properties of Wheat–Cassava Composite Flour. Foods, 12(19), 3585. https://doi.org/10.3390/foods12193585