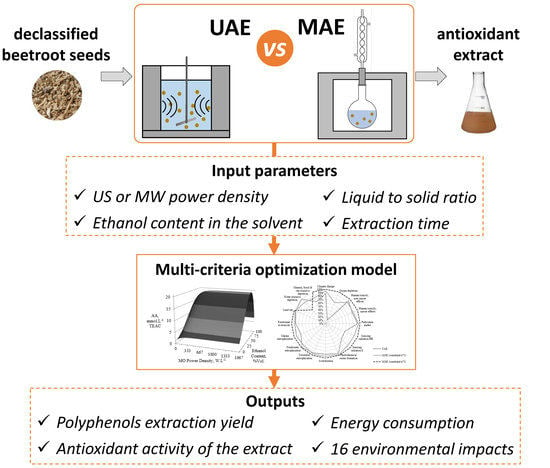

Multi-Criteria Optimization including Environmental Impacts of a Microwave-Assisted Extraction of Polyphenols and Comparison with an Ultrasound-Assisted Extraction Process

Abstract

:1. Introduction

2. Materials and Methods

2.1. Origin and Pretreatments of Beet Seeds By-Product

2.2. Analytical Methods

2.3. Study of Beet Seed Pretreatment Effect on the Extraction of Antioxidant Polyphenols

2.4. Optimization of MAE of Antioxidant Polyphenols: Data Collection and Modelling

2.4.1. Data Collection

2.4.2. Modelling of Energy Consumption Output

2.4.3. Modelling of Polyphenols concentration and Antioxidant Activity of the Extracts

2.4.4. Modelling of Environmental Impact Outputs Using LCA Methodology

- Goal and Scope Definition

- Inventory

- Life Cycle Impact Assessment

3. Results and Discussion

3.1. Effect of Beet Seed Pretreatment on Polyphenols Extraction

3.2. Modelling of TP, AA, EC and EI Outputs for the Studied MAE Process

3.3. Multi-Criteria Optimization of MAE

3.3.1. Maximization of Polyphenols Extraction and Antioxidant Activity of the Extracts

3.3.2. Multi-Criteria Optimization under Different Constraints

- -

- Minimize energy consumption (EC);

- -

- Minimize duration (t);

- -

- Minimize the EI category “climate change” (CC);

- -

- Minimize ethanol content in solvent (X1);

- -

- Minimize MW power density applied (X3).

3.4. Comparaison between MAE and UAE

- -

- Consume less electricity as possible (constraint n°1);

- -

- Apply the same power density, ratio and ethanol content as UAE scenario with MAE, i.e., respectively 667 W.L−1, 5 mL.g−1 and 65%Vol. (constraint n°2).

- -

- Ozone depletion (up to 82% lower than MAE scenarios);

- -

- Ionizing radiation human health (up to 35% lower than MAE scenarios);

- -

- Climate change (up to 12% lower than MAE scenarios).

4. Conclusions

- -

- The improvement of extraction at the cost of a small increase in EC by US assistance;

- -

- The significant decrease in extraction duration due to MW assistance.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Carciochi, R.A.; Galván D’Alessandro, L.; Vauchel, P.; Rodriguez, M.M.; Nolasco, S.M.; Dimitrov, K. Valorization of agri-food by-products by extracting valuable bioactive compounds using green processes. In Handbook of Food Bioengineering, Volume 4: Ingredients Extraction by Physicochemical Methods in Food, 1st ed.; Grumezescu, A., Holban, A.M., Eds.; Academic Press: London, UK, 2017; pp. 191–228. [Google Scholar]

- Casazza, A.A.; Pettinato, M.; Perego, P. Polyphenols from apple skins: A study on microwave-assisted extraction optimization and exhausted solid characterization. Sep. Purif. Technol. 2020, 240, 116640. [Google Scholar] [CrossRef]

- Chemat, F.; Abert-Vian, M.; Fabiano-Tixier, A.-S.; Strube, J.; Uhlenbrock, L.; Gunjevic, V.; Cravotto, G. Green extraction of natural products. Origins, current status, and future challenges. TrAC 2019, 118, 248–263. [Google Scholar] [CrossRef]

- Chemat, F.; Abert Vian, M.; Fabiano-Tixier, A.-S.; Nutrizio, M.; Režek Jambrak, A.; Munekata, P.E.S.; Lorenzo, J.M.; Barba, F.J.; Binello, A.; Cravotto, G. A review of sustainable and intensified techniques for extraction of food and natural products. Green Chem. 2020, 22, 2325–2353. [Google Scholar] [CrossRef]

- Panzella, L.; Moccia, F.; Nasti, R.; Marzorati, S.; Verotta, L.; Napolitano, A. Bioactive Phenolic Compounds from Agri-Food Wastes: An Update on Green and Sustainable Extraction Methodologies. Front. Nutr. 2020, 7, 60. [Google Scholar] [CrossRef]

- Vu, H.T.; Scarlett, C.J.; Vuong, Q.V. Maximising recovery of phenolic compounds and antioxidant properties from banana peel using microwave assisted extraction and water. J. Food Sci. Technol. 2019, 56, 1360–1370. [Google Scholar] [CrossRef]

- Trujillo-Malor, I.; Céspedes-Acuña, C.; Silva, F.L.; Alarcón-Enos, J. Improvement of the polyphenol extraction from avocado peel by assisted ultrasound and microwaves. J. Food Proc. Eng. 2019, 42, 13197. [Google Scholar]

- Plazzotta, S.; Ibarz, R.; Manzocco, L.; Martín-Belloso, O. Optimizing the antioxidant biocompound recovery from peach waste extraction assisted by ultrasounds or microwaves. Ultrason. Sonochem. 2020, 63, 104954. [Google Scholar] [CrossRef] [PubMed]

- Pettinato, M.; Casazza, A.A.; Ferrari, P.F.; Palombo, D.; Perego, P. Eco-sustainable recovery of antioxidants from spent coffee grounds by microwave-assisted extraction: Process optimization, kinetic modeling and biological validation. Food Bioprod. Proc. 2019, 114, 31–42. [Google Scholar] [CrossRef]

- Mellinas, A.C.; Jiménez, A.; Garrigós, M.C. Optimization of microwave-assisted extraction of cocoa bean shell waste and evaluation of its antioxidant, physicochemical and functional properties. LWT-Food Sci. Technol. 2020, 127, 109361. [Google Scholar] [CrossRef]

- ISO 14040:2006; Environmental Management—Life Cycle Assessment—Principles and Framework. International Standard Organisation: Geneva, Switzerland, 2006.

- ISO 14044:2006; Environmental Management—Life Cycle Assessment—Requirements and Guidelines. International Standard Organisation: Geneva, Switzerland, 2006; Volume 5, p. 46.

- Vauchel, P.; Colli, C.; Pradal, D.; Philippot, M.; Decossin, S.; Dhulster, P.; Dimitrov, K. Comparative LCA of ultrasound-assisted extraction of polyphenols from chicory grounds under different operational conditions. J. Clean. Prod. 2018, 196, 1116–1123. [Google Scholar] [CrossRef]

- Carciochi, R.A.; Dieu, V.; Vauchel, P.; Pradal, D.; Dimitrov, K. Reduction of environmental impacts of caffeine extraction from guarana by using ultrasound assistance. Food Bioprod. Proc. 2021, 127, 266–275. [Google Scholar] [CrossRef]

- Croxatto Vega, G.; Sohn, J.; Voogt, J.; Birkved, M.; Irving Olsen, S.; Ekman Nilsson, A. Insights from combining techno-economic and life cycle assessment—A case study of polyphenol extraction from red wine pomace. Resour. Cons. Rec. 2021, 167, 105318. [Google Scholar] [CrossRef]

- Santiago, B.; Calvo, A.A.; Gullón, B.; Feijoo, G.; Moreira, M.T.; González-García, S. Production of flavonol quercetin and fructooligosaccharides from onion (Allium cepa L.) waste: An environmental life cycle approach. Chem. Eng. J. 2020, 392, 123772. [Google Scholar] [CrossRef]

- Garcia-Garcia, G.; Rahimifard, S.; Singh Matharu, A.; Dugmore, T. Life-Cycle Assessment of Microwave Assisted Pectin Extraction at Pilot-scale. ACS Sustain. Chem. Eng. 2019, 7, 5167–5175. [Google Scholar] [CrossRef]

- Bouchez, A.; Vauchel, P.; D’Alessandro, L.G.; Dimitrov, K. Multi-objective optimization tool for ultrasound-assisted extraction including environmental impacts. Chem. Eng. Res. Des. 2020, 164, 324–337. [Google Scholar] [CrossRef]

- Singleton, V.L.; Orthofer, R.; Lamuela-Raventós, R.M. Analysis of total phenols and other oxidation substrates and antioxidants by means of folin-ciocalteu reagent. In Methods in Enzymology; Elsevier: Amsterdam, The Netherlands, 1999; pp. 152–178. [Google Scholar]

- Brand-Williams, W.; Cuvelier, M.E.; Berset, C. Use of a free radical method to evaluate antioxidant activity. LWT-Food Sci. Technol. 1995, 28, 25–30. [Google Scholar] [CrossRef]

- Patricelli, A.; Assogna, A.; Casalaina, A.; Emmi, E.; Sodini, G. Fattori che influenzano l’estrazione dei lipidi da semi decorticate di girasole. Riv. Ital. Sostanze Gr. 1979, 56, 136–142. [Google Scholar]

- Wernet, G.; Bauer, C.; Steubing, B.; Reinhard, J.; Moreno-Ruiz, E.; Weidema, B. The ecoinvent database version 3 (part I): Overview and methodology. Int. J. Life Cycle Assess. 2016, 21, 1218–1230. [Google Scholar] [CrossRef]

- Wolf, M.; Chomkhamsri, K.; Brandao, M.; Pant, R.; Ardente, F.; Pennington, D.; Manfredi, S.; De Camillis, C.; Goralczyk, M. ILCD Handbook-General Guide for Life Cycle Assessment-Detailed Guidance; Joint Research Centre: Brussels, Belgium, 2010. [Google Scholar]

- Vinatoru, M.; Mason, T.J.; Calinescu, I. Ultrasonically assisted extraction (UAE) and microwave assisted extraction (MAE) of functional compounds from plant materials. TrAC 2017, 97, 159–178. [Google Scholar] [CrossRef]

- Périno, S.; Pierson, J.T.; Ruiz, K.; Cravotto, G.; Chemat, F. Laboratory to pilot scale: Microwave extraction for polyphenols lettuce. Food Chem. 2016, 204, 108–114. [Google Scholar] [CrossRef]

- Périno-Issartier, S.; Zill-e-Huma; Abert-Vian, M.; Chemat, F. Solvent free microwave-assisted extraction of antioxidants from Sea Buckthorn (Hippophae rhamnoides) food by-products. Food Bioprocess Technol. 2011, 4, 1020–1028. [Google Scholar] [CrossRef]

- EC-JRC. Life Cycle Impact Assessment Guide: Characterisation Factors of the ILCD-Recommended Life Cycle Impact Assessment Methods-Database and Supporting Information; Publication Office of the European Union: Luxembourg, 2012; p. 31. Available online: http://lct.jrc.ec.europa.eu (accessed on 28 March 2023).

- Jolliet, O.; Saade-Sbeih, M.; Shaked, S.; Jolliet, A.; Crettaz, P. Environmental Life Cycle Assessment; CRC Press: Boca Raton, FL, USA, 2015. [Google Scholar]

| Output Modelled | MAE Model (Present Work) | UAE Model (Previous Work [18]) |

|---|---|---|

| tb breaking time (min) (time when ultrasound generation switch from continuous to the discontinuous mode) | Not applicable | where V is the solvent volume, ρw and ρe are water and ethanol densities, respectively, Cpw and Cpe are water and ethanol calorific capacities, respectively, and y is the efficiency of heat transmission to the solvent |

| TP or AA TP is the total polyphenol concentration (g.L−1 GAE) and AA is the antioxidant activity (mM TEAC): one equation of the same type was used for TP and for AA | where t is the extraction time; A, B, K1 and K2 are coefficients expressed as second order polynomial functions of input parameters (solvent composition X1, liquid/solid ratio X2 and MW power density X3) | with where t is the extraction time; tb is the breaking time; A, B, C, K1, K2 and K3 are coefficients expressed as second order polynomial functions of input parameters (solvent composition X1, liquid/solid ratio X2 and US power density X3) |

| EC Energy consumption (kWh) | wherePs is the electric power consumed by the stirrer; t is the extraction time; Ps is the electric power consumed by the water chiller; Pmw is the power consumed for MW generation; Ecentr is the energy consumed for centrifugation | where Ecentr is the energy consumed for centrifugation; Ps is the electric power consumed by the stirrer; t is the extraction time; tb is the breaking time; Pus is the power consumed for US generation in the continuous mode and the average power consumed for US generation in the discontinuous mode |

| EI 16 environmental impact categories with respective unit as defined in the ILCD Handbook, 2010 [23]: one equation of the same type was used for each of the 16 categories of impact | where t is the extraction time; X1 and X2 are the coded values for the solvent composition and the liquid/solid ratio, respectively; Aeq, Beq, At, Bt, Arm, Brm, Aex, Bex, Aeof are coefficients associated to each life cycle stage (equipment, transports, raw materials, extraction, end of life) | |

| Output | Maximum Output Value | Ethanol Content, %Vol. | Ratio L/S, mL.g−1 | MW Power Density, W.L−1 | Extraction Time, min | Energy Consumption, kWh |

|---|---|---|---|---|---|---|

| TP, g.L−1 GAE | 3.7 | 65 | 5.0 | 1162 | 120 | 5.51 |

| AA, mmol.L−1 TEAC | 20.5 | 66 | 5.0 | 1198 | 120 | 5.59 |

| Constraint | Minimize EC | Minimize Time | Minimize Climate Change EI | Minimize Ethanol Content | Minimize MW Power Density | |

|---|---|---|---|---|---|---|

| Input and Output Parameters | ||||||

| Extraction time (t), min | 19 | 17 | 20 | 120 | 120 | |

| Ethanol content (X1), %vol. | 66 | 66 | 56 | 42 | 66 | |

| Ratio L/S (X2), mL.g−1 | 5 | 5 | 5 | 5 | 5 | |

| MW power density (X3), W.L−1 | 1300 | 1667 | 1663 | 1667 | 140 | |

| Energy consumption (EC), kWh | 1.08 | 1.11 | 1.25 | 6.70 | 3.10 | |

| Process Input and Output Parameters | UAE | MAE (Constraint n°1) | MAE (Constraint n°2) |

|---|---|---|---|

| Extraction duration, min | 120 | 19 | 30 |

| Ethanol content, %vol. | 65 | 66 | 65 |

| Ratio L/S, mL.g−1 | 5 | 5 | 5 |

| US power density, W.L−1 | 667 | NA | NA |

| MW power density, W.L−1 | NA | 1300 | 667 |

| Energy consumption, kWh | 0.34 | 1.08 | 1.23 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Bouchez, A.; Vauchel, P.; Périno, S.; Dimitrov, K. Multi-Criteria Optimization including Environmental Impacts of a Microwave-Assisted Extraction of Polyphenols and Comparison with an Ultrasound-Assisted Extraction Process. Foods 2023, 12, 1750. https://doi.org/10.3390/foods12091750

Bouchez A, Vauchel P, Périno S, Dimitrov K. Multi-Criteria Optimization including Environmental Impacts of a Microwave-Assisted Extraction of Polyphenols and Comparison with an Ultrasound-Assisted Extraction Process. Foods. 2023; 12(9):1750. https://doi.org/10.3390/foods12091750

Chicago/Turabian StyleBouchez, Alice, Peggy Vauchel, Sandrine Périno, and Krasimir Dimitrov. 2023. "Multi-Criteria Optimization including Environmental Impacts of a Microwave-Assisted Extraction of Polyphenols and Comparison with an Ultrasound-Assisted Extraction Process" Foods 12, no. 9: 1750. https://doi.org/10.3390/foods12091750

APA StyleBouchez, A., Vauchel, P., Périno, S., & Dimitrov, K. (2023). Multi-Criteria Optimization including Environmental Impacts of a Microwave-Assisted Extraction of Polyphenols and Comparison with an Ultrasound-Assisted Extraction Process. Foods, 12(9), 1750. https://doi.org/10.3390/foods12091750