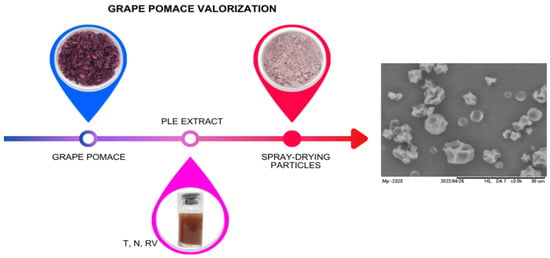

Grape Pomace Rich-Phenolics and Anthocyanins Extract: Production by Pressurized Liquid Extraction in Intermittent Process and Encapsulation by Spray-Drying

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Pigment Extraction by PLE in an Intermittent Process

2.3. Production and Characterization of Grape Pomace Extract

2.3.1. Determination of Total Phenolic Content (TPC)

2.3.2. Determination of Total Anthocyanins (TA)

2.3.3. Determination of Antioxidant Capacity by FRAP

2.4. Microencapsulation by Spray-Drying

2.5. Microparticles Characterization

2.5.1. Phytochemicals and Antioxidant Activity

2.5.2. Particle Size, Distribution, and Morphology

2.5.3. Fourier-Transformed Infrared Spectroscopy (FTIR)

3. Results and Discussion

3.1. Preliminary Tests to Choose the Extraction Solvent

3.2. PLE Extraction Conditions Using Grape Pomace

3.3. Powders Characterization

3.3.1. Mean Diameter Size and Distribution, Morphology of the Particles and Phenolic Compounds

3.3.2. Chemical Characterization by FTIR

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- García-Lomillo, J.; González-SanJosé, M.L. Applications of Wine Pomace in the Food Industry: Approaches and Functions. Compr. Rev. Food Sci. Food Saf. 2017, 16, 3–22. [Google Scholar] [CrossRef]

- Castellanos-Gallo, L.; Ballinas-Casarrubias, L.; Espinoza-Hicks, J.C.; Hernández-Ochoa, L.R.; Muñoz-Castellanos, L.N.; Zermeño-Ortega, M.R.; Borrego-Loya, A.; Salas, E. Grape Pomace Valorization by Extraction of Phenolic Polymeric Pigments: A Review. Processes 2022, 10, 469. [Google Scholar] [CrossRef]

- Richter, B.E.; Jones, B.A.; Ezzell, J.L.; Porter, N.L.; Avdalovic, N.; Pohl, C. Accelerated solvent extraction: A technique for sample preparation. Anal. Chem. 1996, 68, 1033–1039. [Google Scholar] [CrossRef]

- Cornelio-Santiago, H.P.; Bodini, R.B.; Mazalli, M.R.; Gonçalves, C.B.; Rodrigues, C.E.C.; Lopes de Oliveira, A. Oil extraction from pequi (Caryocar brasiliensis Camb.) and sacha inchi (Plukenetia huayllabambana sp. Nov.) almonds by pressurized liquid with intermittent purge: The effects of variables on oil yield and composition. J. Supercrit. Fluids 2022, 182, 105527. [Google Scholar] [CrossRef]

- Castro-Puyana, M.; Herrero, M.; Urreta, I.; Mendiola, J.A.; Cifuentes, A.; Ibáñez, E.; Suárez-Alvarez, S. Optimization of clean extraction methods to isolate carotenoids from the microalga Neochloris oleoabundans and subsequent chemical characterization using liquid chromatography tandem mass spectrometry. Anal. Bioanal. Chem. 2013, 405, 4607–4616. [Google Scholar] [CrossRef] [PubMed]

- Colivet, J.; Oliveira, A.L.; Carvalho, R.A. Influence of the bed height on the kinetics of watermelon seed oil extraction with pressurized ethanol. Sep. Purif. Technol. 2016, 169, 187–195. [Google Scholar] [CrossRef]

- Cornelio-Santiago, H.P.; Gonçalves, C.B.; de Oliveira, N.A.; de Oliveira, A.L. Supercritical CO2 extraction of oil from green coffee beans: Solubility, triacylglycerol composition, thermophysical properties and thermodynamic modelling. J. Supercrit. Fluids 2017, 128, 386–394. [Google Scholar] [CrossRef]

- Cornelio-Santiago, H.P.; Mazalli, M.R.; Rodrigues, C.E.C.; de Oliveira, A.L. Extraction of Brazil nut kernel oil using green solvents: Effects of the process variables in the oil yield and composition. J. Food Process Eng. 2019, 42, e13271. [Google Scholar] [CrossRef]

- de Oliveira, N.A.; Cornelio-Santiago, H.P.; Fukumasu, H.; de Oliveira, A.L. Green coffee extracts rich in diterpenes—Process optimization of pressurized liquid extraction using ethanol as solvent. J. Food Eng. 2018, 224, 148–155. [Google Scholar] [CrossRef]

- da Cunha Rodrigues, L.; Bodini, R.B.; de Caneppele, F.L.; Dacanal, G.C.; Crevelin, E.J.; de Moraes, L.A.B.; de Oliveira, A.L. Pressurized Liquid Extraction (PLE) in an Intermittent Process as an Alternative for Obtaining Passion Fruit (Passiflora edulis) Leaf Hydroalcoholic Extract (Tincture). Processes 2023, 11, 2308. [Google Scholar] [CrossRef]

- Otero-Pareja, M.J.; Casas, L.; Fernández-Ponce, M.T.; Mantell, C.; De La Ossa, E.J.M. Green extraction of antioxidants from different varieties of red grape pomace. Molecules 2015, 20, 9686–9702. [Google Scholar] [CrossRef]

- Perra, M.; Leyva-Jiménez, F.J.; Manca, M.L.; Manconi, M.; Rajha, H.N.; Borrás-Linares, I.; Segura-Carretero, A.; Lozano-Sánchez, J. Application of pressurized liquid extraction to grape by-products as a circular economy model to provide phenolic compounds enriched ingredient. J. Clean. Prod. 2023, 402. [Google Scholar] [CrossRef]

- Tonon, R.V.; Brabet, C.; Hubinger, M.D. Influence of process conditions on the physicochemical properties of açai (Euterpe oleraceae Mart.) powder produced by spray drying. J. Food Eng. 2008, 88, 411–418. [Google Scholar] [CrossRef]

- De Souza, V.B.; Fujita, A.; Thomazini, M.; Da Silva, E.R.; Lucon, J.F.; Genovese, M.I.; Favaro-Trindade, C.S. Functional properties and stability of spray-dried pigments from Bordo grape (Vitis labrusca) winemaking pomace. Food Chem. 2014, 164, 380–386. [Google Scholar] [CrossRef]

- De Souza, V.B.; Thomazini, M.; Balieiro, J.C.D.C.; Fávaro-Trindade, C.S. Effect of spray drying on the physicochemical properties and color stability of the powdered pigment obtained from vinification byproducts of the Bordo grape (Vitis labrusca). Food Bioprod. Process. 2015, 93, 39–50. [Google Scholar] [CrossRef]

- Moser, P.; Telis, V.R.N.; de Andrade Neves, N.; García-Romero, E.; Gómez-Alonso, S.; Hermosín-Gutiérrez, I. Storage stability of phenolic compounds in powdered BRS Violeta grape juice microencapsulated with protein and maltodextrin blends. Food Chem. 2017, 214, 308–318. [Google Scholar] [CrossRef]

- Rubio, F.T.V.; Haminiuk, C.W.I.; Martelli-Tosi, M.; da Silva, M.P.; Makimori, G.Y.F.; Favaro-Trindade, C.S. Utilization of grape pomaces and brewery waste Saccharomyces cerevisiae for the production of bio-based microencapsulated pigments. Food Res. Int. 2020, 136, 109470. [Google Scholar] [CrossRef]

- de Tavares, I.M.C.; Sumere, B.R.; Gómez-Alonso, S.; Gomes, E.; Hermosín-Gutiérrez, I.; Da-Silva, R.; Lago-Vanzela, E.S. Storage stability of the phenolic compounds, color and antioxidant activity of jambolan juice powder obtained by foam mat drying. Food Res. Int. 2020, 128, 108750. [Google Scholar] [CrossRef]

- Carra, J.B.; de Matos, R.L.N.; Novelli, A.P.; do Couto, R.O.; Yamashita, F.; Ribeiro, M.A.d.S.; Meurer, E.C.; Verri, W.A.; Casagrande, R.; Georgetti, S.R.; et al. Spray-drying of casein/pectin bioconjugate microcapsules containing grape (Vitis labrusca) by-product extract. Food Chem. 2022, 368, 130817. [Google Scholar] [CrossRef]

- Pan, L.H.; Chen, L.P.; Wu, C.L.; Wang, J.F.; Luo, S.Z.; Luo, J.P.; Zheng, Z. Microencapsulation of blueberry anthocyanins by spray drying with soy protein isolates/high methyl pectin combination: Physicochemical properties, release behavior in vitro and storage stability. Food Chem. 2022, 395, 133626. [Google Scholar] [CrossRef]

- Almeida, R.F.; Gomes, M.H.G.; Kurozawa, L.E. Rice bran protein increases the retention of anthocyanins by acting as an encapsulating agent in the spray drying of grape juice. Food Res. Int. 2023, 172, 113237. [Google Scholar] [CrossRef] [PubMed]

- Singleton, V.L.; Rossi, J.A., Jr. Colorimetry of Total Phenolics with Phosphomolybdic-Phosphotungstic Acid Reagents. Am. J. Enol. Vitic. 1965, 16, 144–158. [Google Scholar] [CrossRef]

- Lee, J.; Durst, R.W.; Wrolstad, R.E. Determination of total monomeric anthocyanin pigment content of fruit juices, beverages, natural colorants, and wines by the pH differential method: Collaborative study. J. AOAC Int. 2005, 88, 1269–1278. [Google Scholar] [CrossRef] [PubMed]

- Pulido, R.; Bravo, L.; Saura-Calixto, F. Antioxidant activity of dietary polyphenols as determined by a modified ferric reducing/antioxidant power assay. J. Agric. Food Chem. 2000, 48, 3396–3402. [Google Scholar] [CrossRef] [PubMed]

- Dammak, I.; Lourenço, R.V.; Sobral, P.J.d.A. Active gelatin films incorporated with Pickering emulsions encapsulating hesperidin: Preparation and physicochemical characterization. J. Food Eng. 2019, 240, 9–20. [Google Scholar] [CrossRef]

- Kavela, E.T.A.; Szalóki-Dorkó, L.; Máté, M. The Efficiency of Selected Green Solvents and Parameters for Polyphenol Extraction from Chokeberry (Aronia melanocarpa (Michx)) Pomace. Foods 2023, 12, 3639. [Google Scholar] [CrossRef]

- Oancea, S. A review of the current knowledge of thermal stability of anthocyanins and approaches to their stabilization to heat. Antioxidants 2021, 10, 1337. [Google Scholar] [CrossRef] [PubMed]

- Ju, Z.Y.; Howard, L.R. Effects of solvent and temperature on pressurized liquid extraction of anthocyanins and total phenolics from dried red grape skin. J. Agric. Food Chem. 2003, 51, 5207–5213. [Google Scholar] [CrossRef]

- Ferreira, S.; Piovanni, G.M.O.; Malacrida, C.R.; Nicoletti, V.R. Influence of emulsification methods and spray drying parameters on the microencapsulation of turmeric oleoresin. Emirates J. Food Agric. 2019, 31, 491–500. [Google Scholar] [CrossRef]

- Moreno, T.; de Paz, E.; Navarro, I.; Rodríguez-Rojo, S.; Matías, A.; Duarte, C.; Sanz-Buenhombre, M.; Cocero, M.J. Spray Drying Formulation of Polyphenols-Rich Grape Marc Extract: Evaluation of Operating Conditions and Different Natural Carriers. Food Bioprocess Technol. 2016, 9, 2046–2058. [Google Scholar] [CrossRef]

- Ahmed, G.H.G.; Fernández-González, A.; García, M.E.D. Nano-encapsulation of grape and apple pomace phenolic extract in chitosan and soy protein via nanoemulsification. Food Hydrocoll. 2020, 108, 105806. [Google Scholar] [CrossRef]

- Mesquita, M.S.; Santos, P.D.F.; Holkem, A.T.; Thomazini, M.; Favaro-trindade, C.S. Encapsulation of Formosa Papaya (Carica papaya L.) Seed Extract: Physicochemical Characteristics of Particles, and Study of Stability and Release of Encapsulated Phenolic Compounds. Processes 2023, 11, 27. [Google Scholar] [CrossRef]

| Independent Variable\Coded Values → | −1.68 | −1 | 0 | 1 | 1.68 |

|---|---|---|---|---|---|

| T (X1) (°C) | 26 | 50 | 85 | 120 | 144 |

| N (X2) (n) | 2 | 3 | 4 | 5 | 6 |

| RV (X3) (%) | 40 | 60 | 90 | 120 | 140 |

| Sample | T (°C) | N | RV (%) | TPC (mg GAE/g, d.b.) | Anthocyanins (mg/g, d.b.) | FRAP (μmol FeSO4/g, d.b.) |

|---|---|---|---|---|---|---|

| 1 | 50 (−1) | 3 (−1.0) | 60 (−1) | 16.4 ± 0.2 | 3.4 ± 0.09 | 2.81 ± 0.22 |

| 2 | 120 (+1) | 3 (−1.0) | 60 (−1) | 48.9 ± 0.2 | 1.65 ± 0.04 | 6.40 ± 0.43 |

| 3 | 50 (−1) | 5 (+1.0) | 60 (−1) | 21.5 ± 2.1 | 3.66 ± 0.09 | 3.04 ± 0.22 |

| 4 | 120 (+1) | 5 (+1.0) | 60 (−1) | 51.5 ± 1.3 | 1.59 ± 0.01 | 6.01 ± 0.97 |

| 5 | 50 (−1) | 3 (−1.0) | 120 (+1) | 15.7 ± 0.1 | 3.21 ± 0.10 | 2.58 ± 0.04 |

| 6 | 120 (+1) | 3 (−1.0) | 120 (+1) | 55.6 ± 0.3 | 1.87 ± 0.04 | 5.46 ± 0.41 |

| 7 | 50 (−1) | 5 (+1.0) | 120 (+1) | 22.2 ± 0.1 | 3.38 ± 0.15 | 3.89 ± 0.76 |

| 8 | 120 (+1) | 5 (+1.0) | 120 (+1) | 72.1 ± 1.5 | 0.26 ± 0.08 | 7.39 ± 0.41 |

| 9 | 26 (−1.68) | 4 (0) | 90 (0) | 20.5 ± 0.2 | 3.44 ± 0.04 | 3.64 ± 0.16 |

| 10 | 144 (+1.68) | 4 (0) | 90 (0) | 97.4 ± 1.1 | 1.06 ± 0.58 | 7.14 ± 0.46 |

| 11 | 85 (0) | 2 (−1.68) | 90 (0) | 21.9 ± 0.4 | 2.61 ± 0.13 | 4.74 ± 0.57 |

| 12 | 85 (0) | 6 (+1.68) | 90 (0) | 41.7 ± 0.2 | 3.99 ± 0.07 | 6.43 ± 0.12 |

| 13 | 85 (0) | 4 (0) | 40 (−1.68) | 38.1 ± 0.4 | 3.38 ± 0.06 | 5.73 ± 0.53 |

| 14 | 85 (0) | 4 (0) | 140 (+1.68) | 35.8 ± 1.3 | 3.44 ± 0.15 | 9.95 ± 1.57 |

| 15 | 85 (0) | 4 (0) | 90 (0) | 54.6 ± 0.7 | 2.28 ± 0.01 | 4.29 ± 0.75 |

| 16 | 85 (0) | 4 (0) | 90 (0) | 23.4 ± 0.5 | 2.21 ± 0.06 | 3.66 ± 0.12 |

| 17 | 85 (0) | 4 (0) | 90 (0) | 32.1 ± 0.2 | 1.70 ± 0.50 | 7.80 ± 0.50 |

| TPC (mg GAE/g, d.b.) (Y1) | Anthocyanins (mg/g, d.b.) (Y2) | Antioxidant Activity (FRAP, μmol FeSO4/g, d.b.) (Y3) | |

|---|---|---|---|

| First-order model | |||

| β0 | 34.9 * | 2.29 * | 4.85 * |

| Linear Coefficient | |||

| β1 | 19.0 * | −1.04 * | 1.62 * |

| β2 | 3.83 | −0.155 | 0.38 |

| β3 | 3.42 | −0.199 | 0.13 |

| Interaction | |||

| β12 | 0.947 | −0.261 | 0.001 |

| β13 | 3.41 | −0.081 | −0.022 |

| β23 | 1.91 | −0.205 | 0.423 |

| R2 | 0.91 | 0.94 | 0.69 |

| Fcalculated | 6.33 | 10.0 | 1.46 |

| Ftabulated | 6.16 | 6.16 | 6.16 |

| p | 0.048 | 0.022 | 0.373 |

| Second-order model | |||

| β0 | 27.1 * | 2.11 * | |

| Linear Coefficient | |||

| β1 | 20.6 * | −0.902 * | |

| β2 | 4.69 * | −0.079 | |

| β3 | 1.71 | −0.110 | |

| Quadratic Coef. | |||

| β11 | 10.2 * | −0.083 | |

| β22 | 0.556 | 0.288 | |

| β33 | 2.38 | 0.327 | |

| Interaction | |||

| β12 | 0.947 | −0.261 | |

| β13 | 3.41 | −0.081 | |

| β23 | 1.91 | −0.205 | |

| R2 | 0.96 | 0.81 | |

| Fcalculated | 59.8 | 24.0 | |

| Ftabulated1 (p = 0.05) | 6.94 | 4.54 | |

| Flack of fit | 7.56 | 5.15 | |

| Ftabulated2 (p = 0.05) | 4.67 | 19.41 | |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Silva, J.T.d.P.; Borges, M.H.; de Souza, C.A.C.; Fávaro-Trindade, C.S.; Sobral, P.J.d.A.; de Oliveira, A.L.; Martelli-Tosi, M. Grape Pomace Rich-Phenolics and Anthocyanins Extract: Production by Pressurized Liquid Extraction in Intermittent Process and Encapsulation by Spray-Drying. Foods 2024, 13, 279. https://doi.org/10.3390/foods13020279

Silva JTdP, Borges MH, de Souza CAC, Fávaro-Trindade CS, Sobral PJdA, de Oliveira AL, Martelli-Tosi M. Grape Pomace Rich-Phenolics and Anthocyanins Extract: Production by Pressurized Liquid Extraction in Intermittent Process and Encapsulation by Spray-Drying. Foods. 2024; 13(2):279. https://doi.org/10.3390/foods13020279

Chicago/Turabian StyleSilva, Jessica Thaís do Prado, Millene Henrique Borges, Carlos Antonio Cardoso de Souza, Carmen Sílvia Fávaro-Trindade, Paulo José do Amaral Sobral, Alessandra Lopes de Oliveira, and Milena Martelli-Tosi. 2024. "Grape Pomace Rich-Phenolics and Anthocyanins Extract: Production by Pressurized Liquid Extraction in Intermittent Process and Encapsulation by Spray-Drying" Foods 13, no. 2: 279. https://doi.org/10.3390/foods13020279

APA StyleSilva, J. T. d. P., Borges, M. H., de Souza, C. A. C., Fávaro-Trindade, C. S., Sobral, P. J. d. A., de Oliveira, A. L., & Martelli-Tosi, M. (2024). Grape Pomace Rich-Phenolics and Anthocyanins Extract: Production by Pressurized Liquid Extraction in Intermittent Process and Encapsulation by Spray-Drying. Foods, 13(2), 279. https://doi.org/10.3390/foods13020279