Physical and Chemical Properties, Flavor and Organoleptic Characteristics of a Walnut and Purple Rice Fermented Plant Drink

Abstract

:1. Introduction

2. Materials and Methods

2.1. Raw Materials

2.2. Strains and Growth Conditions

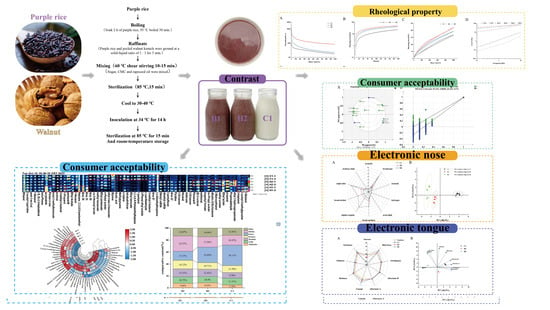

2.3. Sample Preparation

2.4. Physicochemical Analysis

2.5. Rheological Analyses

2.6. Electronic Nose and Electronic Tongue Determination

2.7. HS-GC-IMS Volatile Flavor Compound Analysis

2.8. Sensory Analysis

2.9. Data Analysis

3. Results and Discussion

3.1. Physicochemical Analysis

3.2. Rheological Measurements

3.3. Analysis of Electronic Tongue and Electronic Nose

3.3.1. Electronic Tongue Analysis

3.3.2. Electronic Nose Analysis

3.4. GC-IMS Analysis of Volatile Flavor Compounds

3.4.1. Analysis of Spectrum of Volatile Flavor Components

3.4.2. Analysis of Relative Contents of Volatile Substances

3.4.3. Principal Component Analysis of Volatile Flavor Compounds

3.5. Organoleptic Investigation

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Ingerslev, A.K.; Rasmussen, L.; Zhou, P.; Nørgaard, J.V.; Theil, P.K.; Jensen, S.K.; Lærke, H.N. Effects of dairy and plant protein on growth and growth biomarkers in a piglet model. Food Funct. 2021, 12, 11625–11640. [Google Scholar] [CrossRef] [PubMed]

- Unger, A.; Torres-Gonzalez, M.; Kraft, J. Dairy Fat Consumption and the Risk of Metabolic Syndrome: An Examination of the Saturated Fatty Acids in Dairy. Nutrients 2019, 11, 2200. [Google Scholar] [CrossRef] [PubMed]

- Montemurro, M.; Pontonio, E.; Coda, R.; Rizzello, C.J.F. Plant-Based Alternatives to Yogurt: State-of-the-Art and Perspectives of New Biotechnological Challenges. Foods 2021, 10, 316. [Google Scholar] [CrossRef] [PubMed]

- Astolfi, M.L.; Marconi, E.; Protano, C.; Canepari, S. Comparative elemental analysis of dairy milk and plant-based milk alternatives. Food Control 2020, 116, 107327. [Google Scholar] [CrossRef]

- Codex Standard 243-2003; Codex Satandard for Fermented Milk. FAO: Rome, Italy; WHO: Geneva, Switzerland, 2003.

- Vanga, S.; Raghavan, V. How well do plant based alternatives fare nutritionally compared to cow’s milk? J. Food Sci. Technol. 2018, 55, 10–20. [Google Scholar] [CrossRef]

- Craig, W.J.; Fresán, U. International Analysis of the Nutritional Content and a Review of Health Benefits of Non-Dairy Plant-Based Beverages. Nutrients 2021, 13, 842. [Google Scholar] [CrossRef]

- Zhang, Y.G.; Kan, H.; Chen, S.X.; Thakur, K.; Wang, S.; Zhang, J.G.; Shang, Y.F.; Wei, Z.J. Comparison of phenolic compounds extracted from Diaphragma juglandis fructus, walnut pellicle, and flowers of Juglans regia using methanol, ultrasonic wave, and enzyme assisted-extraction. Food Chem. 2020, 321, 126672. [Google Scholar] [CrossRef]

- Sánchez-González, C.; Ciudad, C.J.; Noé, V.; Izquierdo-Pulido, M. Health benefits of walnut polyphenols: An exploration beyond their lipid profile. Crit. Rev. Food Sci. Nutr. 2017, 57, 3373–3383. [Google Scholar] [CrossRef]

- Ni, Z.J.; Zhang, Y.G.; Chen, S.X.; Thakur, K.; Wang, S.; Zhang, J.G.; Shang, Y.F.; Wei, Z.J. Exploration of walnut components and their association with health effects. Crit. Rev. Food Sci. Nutr. 2022, 62, 5113–5129. [Google Scholar] [CrossRef]

- Deng, G.F.; Xu, X.R.; Zhang, Y.; Li, D.; Gan, R.Y.; Li, H.B. Phenolic compounds and bioactivities of pigmented rice. Crit. Rev. Food Sci. Nutr. 2013, 53, 296–306. [Google Scholar] [CrossRef]

- Tyagi, A.; Lim, M.J.; Kim, N.H.; Barathikannan, K.; Vijayalakshmi, S.; Elahi, F.; Ham, H.J.; Oh, D.H. Quantification of Amino Acids, Phenolic Compounds Profiling from Nine Rice Varieties and Their Antioxidant Potential. Antioxidants 2022, 11, 839. [Google Scholar] [CrossRef] [PubMed]

- Danpreedanan, N.; Yamuangmorn, S.; Jamjod, S.; Prom, U.T.C.; Pusadee, T. Genotypic Variation of Purple Rice in Response to Shading in Yield, Anthocyanin Content, and Gene Expression. Plants 2023, 12, 2582. [Google Scholar] [CrossRef] [PubMed]

- Gu, W.; Peng, Y.; Wang, R.; Wang, R.; Wu, H.; Zhu, J.; Ni, X.; Xiong, Q. Comparison of Metabolites and Main Nutritional Components between Uncooked and Cooked Purple Rice. Metabolites 2023, 13, 1018. [Google Scholar] [CrossRef] [PubMed]

- Kasote, D.; Tiozon, R.N., Jr.; Sartagoda, K.J.D.; Itagi, H.; Roy, P.; Kohli, A.; Regina, A.; Sreenivasulu, N. Food Processing Technologies to Develop Functional Foods With Enriched Bioactive Phenolic Compounds in Cereals. Front. Plant Sci. 2021, 12, 771276. [Google Scholar] [CrossRef] [PubMed]

- Liu, W.; Pu, X.; Sun, J.; Shi, X.; Cheng, W.; Wang, B. Effect of Lactobacillus plantarum on functional characteristics and flavor profile of fermented walnut milk. LWT-Food Sci. Technol. 2022, 160, 113254. [Google Scholar] [CrossRef]

- Henchion, M.; Hayes, M.; Mullen, A.M.; Fenelon, M.; Tiwari, B. Future Protein Supply and Demand: Strategies and Factors Influencing a Sustainable Equilibrium. Foods 2017, 6, 53. [Google Scholar] [CrossRef]

- Khezerlou, A.; Zolfaghari, H.; Forghani, S.; Abedi-Firoozjah, R.; Alizadeh Sani, M.; Negahdari, B.; Jalalvand, M.; Ehsani, A.; McClements, D. Combining Non-Thermal Processing Techniques with Edible Coating Materials: An Innovative Approach to Food Preservation. Coatings 2023, 13, 830. [Google Scholar] [CrossRef]

- Berbert; Queiroz, D.M.; Melo, E.C. Official Methods of Analysis of AOAC International, 18th ed.; AOAC: Rockville, MD, USA, 2005. [Google Scholar]

- Turek, K.; Wszołek, M. Effect of walnut oil on the fatty acid content of probiotic kefir produced either with kefir grains or kefir starter cultures. Int. Dairy J. 2022, 127, 105290. [Google Scholar] [CrossRef]

- Ge, Z.; Yin, D.; Li, Z.; Chen, X.; Dong, M. Effects of Commercial Polysaccharides Stabilizers with Different Charges on Textural, Rheological, and Microstructural Characteristics of Set Yoghurts. Foods 2022, 11, 1764. [Google Scholar] [CrossRef]

- Jia, S.; Zhao, H.; Tao, H.; Yu, B.; Liu, P.; Cui, B. Influence of corn resistant starches type III on the rheology, structure, and viable counts of set yogurt. Int. J. Biol. Macromol. 2022, 203, 10–18. [Google Scholar] [CrossRef]

- Szołtysik, M.; Kucharska, A.Z.; Dąbrowska, A.; Zięba, T.; Bobak, Ł.; Chrzanowska, J. Effect of Two Combined Functional Additives on Yoghurt Properties. Foods 2021, 10, 1159. [Google Scholar] [CrossRef] [PubMed]

- Ale, E.C.; Perezlindo, M.J.; Pavón, Y.; Peralta, G.H.; Costa, S.; Sabbag, N.; Bergamini, C.; Reinheimer, J.A.; Binetti, A.G. Technological, rheological and sensory characterizations of a yogurt containing an exopolysaccharide extract from Lactobacillus fermentum Lf2, a new food additive. Food Res. Int. 2016, 90, 259–267. [Google Scholar] [CrossRef] [PubMed]

- Aryana, K.J.; Olson, D.W. A 100-Year Review: Yogurt and other cultured dairy products. J. Dairy Sci. 2017, 100, 9987–10013. [Google Scholar] [CrossRef] [PubMed]

- Glibowski, P.; Karwowska, M.; Latoch, A.; Nosowska, K.; Udeh, K.O. Effect of different tea extracts on the physicochemical and sensory parameters of stirred probiotic yoghurts. Acta Sci. Pol. Technol. Aliment. 2019, 18, 185–193. [Google Scholar] [CrossRef] [PubMed]

- Schlörmann, W.; Lamberty, J.; Ludwig, D.; Lorkowski, S.; Glei, M. In vitro-fermented raw and roasted walnuts induce expression of CAT and GSTT2 genes, growth inhibition, and apoptosis in LT97 colon adenoma cells. Nutr. Res. 2017, 47, 72–80. [Google Scholar] [CrossRef]

- Lee, W.J.; Lucey, J.A. Formation and Physical Properties of Yogurt. Asian-Australas. J. Anim. Sci. 2010, 23, 1127–1136. [Google Scholar] [CrossRef]

- Bao, H.; You, S.G.; Cao, L.; Zhou, R.; Wang, Q.; Cui, S.W. Chemical and rheological properties of polysaccharides from fruit body of Auricularia auricular-judae. Food Hydrocoll. 2016, 57, 30–37. [Google Scholar] [CrossRef]

- Wang, X.; Kristo, E.; LaPointe, G. Adding apple pomace as a functional ingredient in stirred-type yogurt and yogurt drinks—ScienceDirect. Food Hydrocoll. 2019, 100, 105453. [Google Scholar] [CrossRef]

- Chavhan, G.B.; Kanawjia, S.K.; Khetra, Y.; Puri, R. Effect of potassium-based emulsifying salts on sensory, textural, and functional attributes of low-sodium processed Mozzarella cheese. Dairy Sci. Technol. 2014, 95, 265–278. [Google Scholar] [CrossRef]

- Chronakis, I.S. On the molecular characteristics, compositional properties, and structural-functional mechanisms of maltodextrins: A review. Crit. Rev. Food Sci. Nutr. 1998, 38, 599–637. [Google Scholar] [CrossRef]

- Huang, T.; Tu, Z.; Shangguan, X.; Wang, H.; Zhang, L.; Bansal, N. Characteristics of fish gelatin-anionic polysaccharide complexes and their applications in yoghurt: Rheology and tribology. Food Chem. 2021, 343, 128413. [Google Scholar] [CrossRef] [PubMed]

- Nguyen, P.T.M.; Kravchuk, O.; Bhandari, B.; Prakash, S. Effect of different hydrocolloids on texture, rheology, tribology and sensory perception of texture and mouthfeel of low-fat pot-set yoghurt. Food Hydrocoll. 2017, 72, 90–104. [Google Scholar] [CrossRef]

- Gupta, M.K.; Torrico, D.D.; Ong, L.; Gras, S.L.; Dunshea, F.R.; Cottrell, J. Plant and Dairy-Based Yogurts: A Comparison of Consumer Sensory Acceptability Linked to Textural Analysis. Foods 2022, 11, 463. [Google Scholar] [CrossRef] [PubMed]

- Brueckner-Guehmann, M.; Banovic, M.; Drusch, S. Towards an increased plant protein intake: Rheological properties, sensory perception and consumer acceptability of lactic acid fermented, oat-based gels. Food Hydrocoll. 2019, 96, 201–208. [Google Scholar] [CrossRef]

- Dong, W.; Hu, R.; Long, Y.; Li, H.; Zhang, Y.; Zhu, K.; Chu, Z. Comparative evaluation of the volatile profiles and taste properties of roasted coffee beans as affected by drying method and detected by electronic nose, electronic tongue, and HS-SPME-GC-MS. Food Chem. 2019, 272, 723–731. [Google Scholar] [CrossRef] [PubMed]

- Zhang, J.; Cao, J.; Pei, Z.; Wei, P.; Xiang, D.; Cao, X.; Shen, X.; Li, C. Volatile flavour components and the mechanisms underlying their production in golden pompano (Trachinotus blochii) fillets subjected to different drying methods: A comparative study using an electronic nose, an electronic tongue and SDE-GC-MS. Food Res. Int. 2019, 123, 217–225. [Google Scholar] [CrossRef]

- Lu, L.; Hu, Z.; Hu, X.; Li, D.; Tian, S. Electronic tongue and electronic nose for food quality and safety. Food Res. Int. 2022, 162, 112214. [Google Scholar] [CrossRef] [PubMed]

- Tiggemann, L.; Ballen, S.C.; Bocalon, C.M.; Graboski, A.M.; Manzoli, A.; Steffens, J.; Valduga, E.; Steffens, C. Electronic nose system based on polyaniline films sensor array with different dopants for discrimination of artificial aromas. Innov. Food Sci. Emerg. Technol. 2017, 43, 112–116. [Google Scholar] [CrossRef]

- Yakubu, H.G.; Kovacs, Z.; Toth, T.; Bazar, G. Trends in artificial aroma sensing by means of electronic nose technologies to advance dairy production—A review. Crit. Rev. Food Sci. Nutr. 2023, 63, 234–248. [Google Scholar] [CrossRef]

- Arroyo-Manzanares, N.; Martín-Gómez, A.; Jurado-Campos, N.; Garrido-Delgado, R.; Arce, C.; Arce, L. Target vs spectral fingerprint data analysis of Iberian ham samples for avoiding labelling fraud using headspace—Gas chromatography-ion mobility spectrometry. Food Chem. 2018, 246, 65–73. [Google Scholar] [CrossRef]

- Ge, S.; Chen, Y.; Ding, S.; Zhou, H.; Jiang, L.; Yi, Y.; Deng, F.; Wang, R. Changes in volatile flavor compounds of peppers during hot air drying process based on headspace-gas chromatography-ion mobility spectrometry (HS-GC-IMS). J. Sci. Food Agric. 2020, 100, 3087–3098. [Google Scholar] [CrossRef] [PubMed]

- Wei, X.; Handoko, D.D.; Pather, L.; Methven, L.; Elmore, J.S. Evaluation of 2-acetyl-1-pyrroline in foods, with an emphasis on rice flavour. Food Chem. 2017, 232, 531–544. [Google Scholar] [CrossRef] [PubMed]

- Cao, M.; Fonseca, L.M.; Schoenfuss, T.C.; Rankin, S.A. Homogenization and lipase treatment of milk and resulting methyl ketone generation in blue cheese. J. Agric. Food Chem. 2014, 62, 5726–5733. [Google Scholar] [CrossRef] [PubMed]

- Licón, C.C.; Mendoza, J.H.D.; Maggi, L.; Berruga, M.I.; Aranda, R.M.M.; Carmona, M. Optimization of headspace sorptive extraction for the analysis of volatiles in pressed ewes’ milk cheese. Int. Dairy J. 2012, 23, 53–61. [Google Scholar] [CrossRef]

- Li, M.; Yang, R.; Zhang, H.; Wang, S.; Chen, D.; Lin, S. Development of a flavor fingerprint by HS-GC-IMS with PCA for volatile compounds of Tricholoma matsutake Singer. Food Chem. 2019, 290, 32–39. [Google Scholar] [CrossRef] [PubMed]

- El Hadi, M.A.; Zhang, F.J.; Wu, F.F.; Zhou, C.H.; Tao, J. Advances in fruit aroma volatile research. Molecules 2013, 18, 8200–8229. [Google Scholar] [CrossRef] [PubMed]

- Lee, S.M.; Lim, H.J.; Chang, J.W.; Hurh, B.S.; Kim, Y.S. Investigation on the formations of volatile compounds, fatty acids, and γ-lactones in white and brown rice during fermentation. Food Chem. 2018, 269, 347–354. [Google Scholar] [CrossRef] [PubMed]

- Liu, H.; Xu, Y.; Wu, J.; Wen, J.; Yu, Y.; An, K.; Zou, B. GC-IMS and olfactometry analysis on the tea aroma of Yingde black teas harvested in different seasons. Food Res. Int. 2021, 150, 110784. [Google Scholar] [CrossRef]

- Powers, R.; Worley, B. Multivariate Analysis in Metabolomics. Curr. Metabol. 2013, 1, 92–107. [Google Scholar] [CrossRef]

- Oh, Y.J.; Kim, T.S.; Moon, H.W.; Lee, S.Y.; Lee, S.Y.; Ji, G.E.; Hwang, K.T. Lactobacillus plantarum PMO 08 as a Probiotic Starter Culture for Plant-Based Fermented Beverages. Molecules 2020, 25, 5056. [Google Scholar] [CrossRef]

| QDA | Description | Definition |

|---|---|---|

| Flavor | Green grass flavor | Odors associated with newly cut grass |

| Nuts flavor | Odors associated with nuts | |

| Cereal flavor | Odors associated with cereals | |

| Fermented flavor | Acid substances produced by fermentation of dairy products, with an occasionally sour smell | |

| Taste | Sweetness | Taste related to sucrose |

| Sour taste | Taste associated with citric acid | |

| Bitter taste | Taste associated with caffeine | |

| Salty taste | Taste related to sodium chloride | |

| Astringent taste | The sample is placed on the tongue to make the tongue feel convergent | |

| Taste | Dispersion | The extent of the sample in the mouth without chewing |

| Thickness | The force, fluidity, and thinness of the tongue to suck the sample in the spoon into the mouth or expand the sample | |

| Adhesion | Mechanical texture characteristics related to the force required to move the adhesive object, stickiness | |

| Granular feeling | The number and size of particles that can be perceived in the sample | |

| Overall | Acceptance | Acceptance of the sample |

| H1 | H2 | C1 | |

|---|---|---|---|

| Protein (%) | 3.02 ± 0.04 a | 2.99 ± 0.04 b | 2.86 ± 0.02 c |

| Fat (%) | 6.67 ± 0.08 a | 6.02 ± 0.07 b | 2.93 ± 0.04 c |

| Titration acidity | 48.93 ± 1.70 b | 4.07 ± 0.68 c | 78.72 ± 1.41 a |

| pH | 4.45 ± 0.01 c | 6.38 ± 0.06 a | 4.54 ± 0.03 b |

| Total solids (%) | 29.09 ± 0.03 a | 28.74 ± 0.04 b | 20.55 ± 0.03 c |

| Compound | Relative Retention Index | Relative Amount | Odor Description | ||

|---|---|---|---|---|---|

| H1 | H2 | C1 | |||

| Aldehydes | |||||

| (−)-Perillaldehyde | 1153.4 | 0.58 ± 0.01% b | 0.49 ± 0.03% b | 1.39 ± 0.04% a | Perilla incense |

| (E, E)-2,4-heptadienal | 1009.5 | 0.56 ± 0.06% a | 0.53 ± 0.031% a | 0.33 ± 0.03% a | Melon and fruit fragrance |

| 3-Methyl-2-butenal | 762.6 | 2.94 ± 0.05% a | 1.52 ± 0.06% b | 1.83 ± 0.03% b | Almond, roasted |

| Hexanal | 1071.2 | 1.24 ± 0.01% b | 2.51 ± 0.08% a | 0.40 ± 0.03% c | Apple, fat, fresh, green, oil |

| Pentanal-D | 978.2 | 0.21 ± 0.00% b | 0.41 ± 0.01% a | 0.17 ± 0.00% c | Grass smell |

| (E)-2-octenal | 1070.2 | 0.61 ± 0.01% b | 0.70 ± 0.01% a | 0.18 ± 0.01% c | Fat, fruit, grass, spice |

| Methional | 906.1 | 0.82 ± 0.01% b | 1.53 ± 0.06% a | 0.38 ± 0.02% c | Savory |

| Propionaldehyde | 819 | 0.44 ± 0.01% b | 0.59 ± 0.02% a | 0.11 ± 0.00% c | Floral, pungent, solvent |

| Pentanal-M | 977 | 0.30 ± 0.01% ab | 0.25 ± 0.01% b | 0.39 ± 0.02% a | Grass smell |

| Ketone | |||||

| Pentan-2-one | 980 | 0.19 ± 0.03% a | 0.15 ± 0.01% c | 0.15 ± 0.06% b | Flowers, fruit fragrance |

| Dihydro-2(3h)-furanone | 908.7 | 0.51 ± 0.02% b | 0.82 ± 0.03% a | 0.26 ± 0.01% c | - |

| Acetone | 812.8 | 9.28 ± 0.02% a | 6.06 ± 0.10% b | 10.11 ± 0.12% a | Pungent |

| 2-Octanone | 1304.7 | 3.42 ± 0.03% a | 2.97 ± 0.12% b | 0.78 ± 0.04% c | Fat, fragrant, mold |

| 3-Octanone | 979.1 | 0.72 ± 0.02% a | 0.72 ± 0.06% a | 0.28 ± 0.02% b | Butter, herbs, mold |

| Pent-1-en-3-ol | 1156.3 | 1.39 ± 0.06% a | 1.40 ± 0.06% a | 1.05 ± 0.07% b | Fruit fragrance, vegetable fragrance |

| 1-Butanol | 1116 | 0.36 ± 0.02% a | 0.37 ± 0.02% a | 0.35 ± 0.01% a | Fruit |

| 1-Propanol | 1023.9 | 0.99 ± 0.02% a | 0.69 ± 0.02% b | 0.41 ± 0.02% c | Alcohol, candy, pungent |

| 1-Hexanol | 873.6 | 0.23 ± 0.16% a | 0.63 ± 0.12% a | 0.33 ± 0.09% a | Banana, flower, grass, herb |

| Ethanol | 948.2 | 7.29 ± 0.01% a | 6.92 ± 0.03% a | 4.98 ± 0.02% b | Alcohol, sweet |

| 1-Pentanol | 1242.4 | 0.35 ± 0.02% b | 0.29 ± 0.02% b | 0.89 ± 0.04% a | Balsamic, fruit, pungent, yeast |

| 2-Butanol | 1008.8 | 0.64 ± 0.01% a | 0.10 ± 0.01% b | 0.15 ± 0.01% b | Wine |

| 3-Methyl-3-butenol | 1245 | 0.72 ± 0.04% a | 0.78 ± 0.02% a | 0.62 ± 0.04% a | - |

| 2-Butoxyethanol | 906.2 | 0.95 ± 0.12% a | 0.92 ± 0.04% a | 0.45 ± 0.03% b | - |

| 3-Heptanol | 1304.1 | 0.40 ± 0.02% a | 0.33 ± 0.02% a | 0.15 ± 0.00% b | Herbs |

| Esters | |||||

| 2-Phenyl ethyl acetate | 1240.9 | 1.27 ± 0.06% a | 1.17 ± 0.05% a | 4.90 ± 0.43% b | Fruit |

| Ethyl benzoate | 1155.4 | 1.80 ± 0.03% b | 1.29 ± 0.05% c | 3.64 ± 0.00% a | Bitterness |

| Butyl-2-methylbutanoate | 1041.3 | 0.40 ± 0.09% b | 0.70 ± 0.01% a | 0.83 ± 0.10% a | Fruit fragrance |

| Ethyl acetate | 871.5 | 0.38 ± 0.05% a | 0.43 ± 0.01% a | 0.31 ± 0.02% a | Aromatic, brandy, grape |

| Methyl hexanoate | 932.6 | 0.47 ± 0.09% a | 0.82 ± 0.08% a | 0.84 ± 0.22% a | Pineapple |

| Ethyl pentanoate | 902 | 3.03 ± 1.85% a | 6.61 ± 0.87% a | 3.92 ± 0.80% a | Apple |

| n-Pentyl acetate | 913.3 | 0.14 ± 0.06% a | 0.39 ± 0.06% a | 0.33 ± 0.10% a | Pineapple, apple |

| Isopentyl formate | 796.6 | 0.09 ± 0.00% b | 0.13 ± 0.01% a | 0.07 ± 0.00% b | Apple |

| Iso-Propyl acetate | 857.2 | 0.32 ± 0.02% a | 0.36 ± 0.02% a | 0.12 ± 0.00% b | Banana |

| Methyl acetate | 801.4 | 0.48 ± 0.01% b | 0.79 ± 0.02% a | 0.22 ± 0.02% c | Mint, cool |

| Ethyl lactate | 794.1 | 0.29 ± 0.01% b | 0.34 ± 0.00% a | 0.09 ± 0.00% c | Cheese, floral, fruit, pungent |

| Ethyl 2-hydroxypropanoate | 807.8 | 0.07 ± 0.00% b | 0.21 ± 0.00% a | 0.03 ± 0.00% c | Rum, fruit, and creamy aroma |

| Ethyl trans-2-hexenoate | 1045 | 6.42 ± 1.80% b | 12.46 ± 1.02% ab | 18.81 ± 3.49% a | Fruit |

| Acids | |||||

| Acetic acid | 1432 | 9.01 ± 0.55% a | 7.97 ± 0.03% ab | 6.71 ± 0.03% b | Acid, fruit, pungent, sour |

| Cis-3-hexenyl lactate | 1234.7 | 1.74 ± 0.19% c | 2.43 ± 0.03% b | 4.60 ± 0.35% a | Green |

| Ethers | |||||

| Dibutyl sulfide | 1069 | 2.61 ± 0.02% b | 3.68 ± 0.01% a | 0.45 ± 0.02% c | Green |

| Dimethyl sulfide | 770.2 | 2.11 ± 0.03% b | 3.78 ± 0.04% a | 0.90 ± 0.01% c | Seafood flavor |

| Enolefins | |||||

| Undecane | 1079.1 | 0.48 ± 0.01% a | 0.47 ± 0.01% b | 0.25 ± 0.02% b | - |

| 2,2,4,6,6-Pentamethylheptane | 977.7 | 0.65 ± 0.01% b | 0.37 ± 0.03% c | 1.41 ± 0.05% a | - |

| 2,2,4,6,6-Pentamethylheptane-M | 994 | 7.68 ± 0.06% a | 5.04 ± 0.25% b | 4.21 ± 0.02% c | - |

| Beta-pinene | 977 | 1.02 ± 0.01% ab | 1.15 ± 0.00% a | 0.88 ± 0.02% b | Pine, polish, wood |

| o-Xylene | 888.3 | 0.52 ± 0.16% a | 0.21 ± 0.03% a | 0.75 ± 0.12% a | Fragrance |

| Acrylonitrile | 1001.6 | 2.21 ± 0.01% a | 0.90 ± 0.01% b | 1.87 ± 0.01% b | Peach kernel flavor |

| 2-Acetyl-1-pyrroline | 926.8 | 12.94 ± 0.31% a | 9.01 ± 0.35% b | 6.81 ± 0.33% b | Savory |

| Styrene | 866 | 0.08 ± 0.01% a | 0.09 ± 0.01% a | 0.14 ± 0.03% a | Special aroma |

| Heterocyclic | |||||

| Tetrahydrofuran | 887.2 | 0.61 ± 0.12% a | 0.50 ± 0.04% a | 1.06 ± 0.21% a | Ethyl ether flavor |

| Methylpyrazine | 1244.7 | 3.37 ± 0.03% b | 2.93 ± 0.05% b | 8.02 ± 0.00% a | Nuts |

| 2-Pentylfuran | 1214.9 | 2.04 ± 0.07% a | 2.09 ± 0.09% a | 0.47 ± 0.04% b | Butter, floral, fruit |

| Pyridine | 1174.7 | 1.21 ± 0.07% a | 0.77 ± 0.01% b | 0.47 ± 0.00% c | Odor |

| 2-Acetyl-3-methylpyrazine | 1074.1 | 0.30 ± 0.01% a | 0.18 ± 0.00% b | 0.11 ± 0.00% c | Wood fragrance |

| 2,5-Dimethylthiophene | 1168.6 | 0.61 ± 0.02% a | 0.50 ± 0.01% b | 0.43 ± 0.00% b | - |

| C1 | H1 | H2 | ||

| Flavor | Green grass flavor | 1.25 ± 0.62 c | 3.42 ± 0.67 b | 4.50 ± 1.00 a |

| Nuts flavor | 0.00 ± 0.00 c | 4.17 ± 0.72 b | 5.00 ± 0.74 a | |

| Grainy flavor | 0.00 ± 0.00 c | 2.17 ± 0.58 b | 3.33 ± 0.65 a | |

| Fermented flavor | 6.50 ± 0.80 b | 7.17 ± 0.58 a | 0.00 ± 0.00 c | |

| Taste | Sweetness | 5.83 ± 0.58 b | 4.83 ± 0.72 c | 7.25 ± 0.45 a |

| Sour taste | 5.83 ± 0.94 a | 5.92 ± 0.67 a | 0.00 ± 0.00 c | |

| Bitter taste | 0.33 ± 0.49 c | 1.92 ± 0.51 b | 3.17 ± 0.58 a | |

| Salty taste | 0.42 ± 0.51 b | 0.83 ± 0.39 a | 0.67 ± 0.49 ab | |

| Astringent taste | 0.25 ± 0.45 c | 1.75 ± 0.45 b | 3.75 ± 0.62 a | |

| Textural attributes | Dispersion | 7.25 ± 0.45 a | 4.50 ± 0.52 b | 3.67 ± 0.78 c |

| Thickness | 6.92 ± 0.51 a | 3.67 ± 0.49 b | 4.08 ± 0.67 b | |

| Adhesion | 4.08 ± 0.51 c | 6.50 ± 0.67 a | 5.50 ± 0.52 b | |

| Granular feeling | 0.00 ± 0.00 c | 4.00 ± 0.60 b | 4.83 ± 0.72 a | |

| Overall | Acceptance | 7.17 ± 0.58 a | 6.92 ± 0.51 a | 6.08 ± 0.67 b |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Mu, H.; Dai, T.; Huang, S.; Wu, K.; Wang, M.; Tan, C.; Zhang, F.; Sheng, J.; Zhao, C. Physical and Chemical Properties, Flavor and Organoleptic Characteristics of a Walnut and Purple Rice Fermented Plant Drink. Foods 2024, 13, 400. https://doi.org/10.3390/foods13030400

Mu H, Dai T, Huang S, Wu K, Wang M, Tan C, Zhang F, Sheng J, Zhao C. Physical and Chemical Properties, Flavor and Organoleptic Characteristics of a Walnut and Purple Rice Fermented Plant Drink. Foods. 2024; 13(3):400. https://doi.org/10.3390/foods13030400

Chicago/Turabian StyleMu, Hongyu, Tianyi Dai, Si Huang, Kuan Wu, Mingming Wang, Chunlei Tan, Feng Zhang, Jun Sheng, and Cunchao Zhao. 2024. "Physical and Chemical Properties, Flavor and Organoleptic Characteristics of a Walnut and Purple Rice Fermented Plant Drink" Foods 13, no. 3: 400. https://doi.org/10.3390/foods13030400

APA StyleMu, H., Dai, T., Huang, S., Wu, K., Wang, M., Tan, C., Zhang, F., Sheng, J., & Zhao, C. (2024). Physical and Chemical Properties, Flavor and Organoleptic Characteristics of a Walnut and Purple Rice Fermented Plant Drink. Foods, 13(3), 400. https://doi.org/10.3390/foods13030400