Influence of Waxy (High Amylopectin) and High Protein Digestibility Traits in Sorghum on Injera Sourdough-Type Flatbread Sensory Characteristics

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Milling

2.3. Preparation of Injera by the Conventional (Full-Scale) Method

2.4. Analyses

2.4.1. Chemical Composition

2.4.2. Descriptive Sensory Analysis

2.4.3. Instrumental Texture Analysis

2.4.4. Statistical Analyses

3. Results and Discussion

3.1. Chemical Composition of the Flours

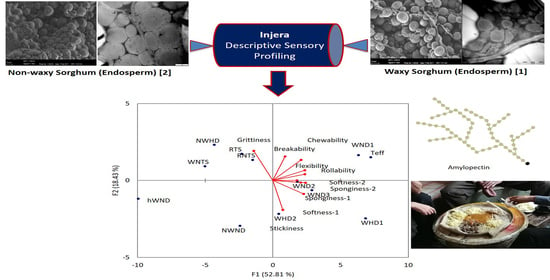

3.2. Descriptive Sensory Analysis of Injera

3.3. Instrumental Texture Analysis of Injera

4. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Neela, S.; Fanta, S.W. Injera (An ethnic, traditional staple food of Ethiopia): A review on traditional practice to scientific developments. J. Ethn. Food 2020, 7, 1–15. [Google Scholar] [CrossRef]

- Arendt, E.K.; Ryan, L.A.; Dal Bello, F. Impact of sourdough on the texture of bread. Food Microbiol. 2007, 24, 165–174. [Google Scholar] [CrossRef]

- Bultosa, G.; Taylor, J.R.N. Paste and gel properties and in vitro digestibility of tef [Eragrostis tef (Zucc.) Trotter] starch. Starch Stärke 2004, 56, 20–28. [Google Scholar] [CrossRef]

- Lobamo, T. Review paper on: Potential and constraints of teff row planting for enhancing productivity. J. Biol. Agric. Healthc. 2020, 10, 52–63. [Google Scholar]

- Akinseye, F.M.; Ajeigbea, H.A.; Traore, P.C.S.; Agelee, S.O.; Zemadim, B.; Whitbread, A. Improving sorghum productivity under changing climatic conditions: A modelling approach. Field Crops Res. 2020, 246, 1–11. [Google Scholar] [CrossRef]

- Yetneberk, S.; De Kock, H.L.; Rooney, L.W.; Taylor, J.R.N. Effects of sorghum cultivar on injera quality. Cereal Chem. 2004, 81, 314–321. [Google Scholar] [CrossRef]

- Fadda, C.; Sanguinetti, A.M.; Del Caro, A.; Collar, C.; Piga, A. Bread staling: Updating the view. Compr. Rev. Food Sci. Food Saf. 2014, 13, 473–492. [Google Scholar] [CrossRef] [Green Version]

- Hug-Iten, S.; Escher, F.; Conde-Petit, B. Staling of bread: Role of amylose and amylopectin and influence of starch-degrading enzymes. Cereal Chem. 2003, 80, 654–661. [Google Scholar] [CrossRef]

- Wang, S.; Li, C.; Copeland, L.; Niu, Q.; Wang, S. Starch retrogradation: A comprehensive review. Compr. Rev. Food Sci. Food Saf. 2015, 14, 568–585. [Google Scholar] [CrossRef]

- Sang, Y.; Bean, S.; Seib, P.A.; Pedersen, J.; Shi, Y.C. Structure and functional properties of sorghum starches differing in amylose content. J. Agric. Food Chem. 2008, 56, 6680–6685. [Google Scholar] [CrossRef]

- Lii, C.; Lai, V.M.F.; Shen, M.C. Changes in retrogradation properties of rice starches with amylose content and molecular properties. Cereal Chem. 2004, 81, 392–398. [Google Scholar] [CrossRef]

- Mouliney, M.; Lavery, B.; Sharma, R.; Jenner, C. Waxy durum and fat differ in their actions as improvers of bread quality. J. Cereal Sci. 2011, 54, 317–323. [Google Scholar] [CrossRef]

- Purna, S.K.G.; Miller, R.A.; Seib, P.A.; Graybosch, R.A.; Shi, Y.C. Volume, texture, and molecular mechanism behind the collapse of bread made with different levels of hard waxy wheat flours. J. Cereal Sci. 2011, 54, 37–43. [Google Scholar] [CrossRef] [Green Version]

- Ma, F.; Ji, T.; Baik, B.K. Quality characteristics of northern-style Chinese steamed bread prepared from soft red winter wheat flours with waxy wheat flour substitution. J. Cereal Sci. 2017, 73, 99–107. [Google Scholar] [CrossRef] [Green Version]

- Witczak, M.; Korus, J.; Ziobro, R.; Juszczak, L. Waxy starch as dough component and anti-staling agent in gluten-free bread. LWT Food Sci. Technol. 2019, 99, 476–482. [Google Scholar] [CrossRef]

- Guo, G.; Jackson, D.S.; Graybosh, R.A.; Parkhurst, A.M. Wheat tortilla quality: Impact of amylose content adjustments using waxy wheat flour. Cereal Chem. 2003, 80, 427–436. [Google Scholar] [CrossRef]

- Jampala, B.; Rooney, W.L.; Peterson, G.C.; Bean, S.; Hays, D.B. Estimating the relative effects of the endosperm traits of waxy and high protein digestibility on yield in grain sorghum. Field Crop Res. 2012, 139, 57–62. [Google Scholar] [CrossRef]

- Elhassan, M.S.M.; Emmambux, M.N.; Hays, D.B.; Peterson, G.C.; Taylor, J.R.N. Novel biofortified sorghum lines with combined waxy (high amylopectin) starch and high protein digestibility traits: Effects on endosperm and flour properties. J. Cereal Sci. 2015, 65, 132–139. [Google Scholar] [CrossRef] [Green Version]

- Goodall, M.A.; Campanella, O.H.; Ejeta, G.; Hamaker, B.R. Grain of high digestible, high lysine (HDHL) sorghum contains kafirins, which enhance the protein network of composite dough and bread. J. Cereal Sci. 2012, 56, 352–357. [Google Scholar] [CrossRef]

- Miller, F.R.; Prihoda, K.L.; Rooney, L.W.; Rosenow, D.T.; Waniska, R.D. Registration of a food quality sorghum restorer parent, Tx2907. Crop Sci. 1996, 36, 479. [Google Scholar] [CrossRef]

- Weaver, C.A.; Hamaker, B.R.; Axtell, J.D. Discovery of grain sorghum germ plasm with high uncooked and cooked in vitro protein digestibilities. Cereal Chem. 1998, 75, 665–670. [Google Scholar] [CrossRef]

- Mezgebe, A.G.; Abegaz, K.; Taylor, J.R.N. Relationship between waxy (high amylopectin) and high protein digestibility traits in sorghum and malting. J. Cereal Sci. 2018, 79, 319–327. [Google Scholar] [CrossRef] [Green Version]

- AACC International. Moisture Content Standard Method 44-15A, Crude Protein-combustion, Standard Method 46-30, Crude Fat Content Standard Method 30-25, Ash Content Approved method 08-17. In Approved Methods of the AACC, 10th ed.; American Association of Cereal Chemists: St Paul, MN, USA, 2000. [Google Scholar]

- Einstein, M.A. Descriptive techniques and their hybridization. In Sensory Science Theory and Applications in Foods; Lawless, H.T., Klein, B., Eds.; Marcel Decker: New York, NY, USA, 1991; pp. 317–338. [Google Scholar]

- Lawless, H.T.; Heymann, H. Sensory Evaluation of Food, Principles and Practices; Aspen Publishers: Gaithersburg, MD, USA, 1999; pp. 701–737. [Google Scholar]

- Abang-Zaidel, D.N.; Chin, N.; Abdul Rahman, R.; Karim, R. Rheological characterization of gluten from extensibility measurement. J. Food Eng. 2008, 86, 549–556. [Google Scholar] [CrossRef]

- Wu, X.; Jampala, B.; Robbins, A.; Hays, D.; Yan, S.; Xu, E.; Rooney, W.; Peterson, G.; Shi, Y.C.; Wang, D. Ethanol fermentation performance of grain sorghums (Sorghum bicolor) with modified endosperm matrices. J. Agric. Food Chem. 2010, 58, 9556–9562. [Google Scholar] [CrossRef]

- Maphalla, T.G.; Emmambux, M.N. Functionality of maize, wheat, teff and cassava starches with stearic acid and xanthan gum. Carbohydr. Polym. 2016, 136, 970–978. [Google Scholar] [CrossRef] [Green Version]

- Kobue-Lekalake, R.I.; Taylor, J.R.N.; De Kock, H.L. Application of the dual attribute time-intensity (DATI) sensory method to the temporal measurement of bitterness and astringency in sorghum. Int. J. Food Sci. Technol. 2012, 47, 459–466. [Google Scholar] [CrossRef] [Green Version]

- Fox, G.; Nugusu, Y.; Nida, H.; Tedessa, T.; McLean, G.; Jordan, D. Evaluation of variation in Ethiopian sorghum injera quality with new imaging techniques. Cereal Chem. 2019, 97, 362–372. [Google Scholar] [CrossRef]

- Purhagen, J.K.; Sjöö, M.E.; Eliasson, A.C. The use of normal and heat-treated barley flour and waxy barley starch as anti-staling agents in laboratory and industrial baking processes. J. Food Eng. 2011, 104, 414–421. [Google Scholar] [CrossRef]

- Yang, S.; Cheng, P.; Wang, L.; Lin, S.; Yang, C.; Wang, T. Bread quality improvement by means of selected pregelatinized waxy rice flour (PWRF). Emir. J. Food Agric. 2017, 29, 664–673. [Google Scholar] [CrossRef] [Green Version]

- Park, C.S.; Baik, B.K. Characteristics of French bread baked from wheat flours of reduced starch amylose content. Cereal Chem. 2007, 84, 437–442. [Google Scholar] [CrossRef]

- Belton, P.S.; Delgadillo, I.; Halford, N.G.; Shewry, P.R. Kafirin structure and functionality. J. Cereal Sci. 2006, 44, 272–286. [Google Scholar] [CrossRef] [Green Version]

- Qin, P.; Ma, C.-X.; Wu, R.-L.; Kong, Z.-Y.; Zhang, B.-Q. Effect of waxy wheat flour blends on the quality of fresh and stale bread. Agric. Sci. China 2009, 8, 401–409. [Google Scholar] [CrossRef]

- Di Monaco, R.; Cavella, S.; Torrieri, E.; Masi, P. Consumer acceptability of vegetable soups. J. Sens. Stud. 2007, 22, 81–98. [Google Scholar] [CrossRef]

| Sensory Category | Attributes | Definition/Reference | Scale Anchors (0, 10) |

|---|---|---|---|

| Aroma | Fermented | Intensity of aroma associated with beer | No fermented aroma, intense fermented aroma |

| Sorghum | Intensity of aroma associated with sorghum porridge | No sorghum aroma, intense sorghum aroma | |

| Musty | Intensity of aroma associated with moldy smell | No musty aroma, intense musty aroma | |

| Overall aroma | Overall intensity of aroma of injera | No aroma, intense overall aroma | |

| Appearance | Shininess * | The property of having a smooth shiny/glossy/lustrous surface | Not shiny surface, very shiny surface |

| Eye # size * | The size of pores formed on surface | Very large, very small | |

| Eye evenness and distribution * | The distribution and evenness of the pores | Not evenly distributed, very evenly distributed | |

| Texture (assessed by hand) | Softness-1 * | The measure of resistance to deformation | Not soft, very soft |

| Flexibility | The property of bending easily without breaking | Not flexible, very flexible | |

| Rollability * | The ease to roll the injera | Not rollable, very rollable | |

| Stickiness * | Degree to which a product tends to be glutinous | Not sticky, very sticky | |

| Sponginess-1 | Property resembling a sponge; light, porous and compressible | Not spongy, Very spongy | |

| Texture (assessed in mouth) | Chewiness | A measure of the ease to masticate or chew the injera | Not chewy, very chewy |

| Softness-2 * | The measure of resistance to deformation | Not soft, very soft | |

| Sponginess-2 | Property resembling a sponge; light, porous and compressible | Not spongy, very spongy | |

| Breakability | The measure of resistance to breaking | Not breakable, very breakable | |

| Grittiness * | Degree to which small particles were noticed during mastication. | Not gritty, very gritty | |

| Dry mouthfeel | Degree to which the injera feels dry while chewing and absorbs saliva | No dry mouthfeel, intense dry mouthfeel | |

| Flavour | Sourness * | Fundamental taste sensation elicited by acids | No sour taste, intense sour taste |

| Bitterness * | Fundamental taste sensation elicited by caffeine | No bitter taste, intense bitter taste | |

| Starchy | Flavour associated with carbohydrate-rich products (bread and pasta) | No starchy flavour, intense starchy flavour | |

| Sweetness * | Fundamental taste sensation elicited by sugar | No sweet taste, intense sweet taste | |

| Overall flavour | Overall intensity of flavor of injera | No flavour, intense overall flavour | |

| Aftertaste | Sourness * | Intensity of the sour taste remaining in the mouth after swallowing the injera | No sour aftertaste, intense sour aftertaste |

| Bitterness * | Intensity of the bitter taste remaining in the mouth after swallowing the injera | No bitter aftertaste, intense bitter aftertaste | |

| Dry mouthfeel | Degree to which mouth feels dry after swallowing the injera | No dry mouthfeel, intense dry mouthfeel | |

| Fine particles | Degree to which small particles remained in the mouth after swallowing. | No fine particles, many fine particles | |

| Astringent | Chemical sensation associated with puckering of tongue caused by substances such as tannins perceived after swallowing the injera | No astringent taste, intense astringent taste | |

| Lingering | Length of time which the aftertaste lasts after swallowing | No lingering aftertaste, intense lingering aftertaste |

| Sorghum Line | Starch Amylopectin (%) * | Starch | Protein | Fat | Ash |

|---|---|---|---|---|---|

| NWND | 79.9 a ± 1.1 | 80.3 a ± 1.2 | 12.8 cd ± 0.5 | 2.7 a ± 0.0 | 1.7 ab ± 0.2 |

| NWHD | 81.1 ab ± 1.0 | 78.0 a ± 2.8 | 12.9 cd ± 0.0 | 4.1 bcd ± 0.7 | 1.7 ab ± 0.0 |

| hWND | 85.4 bc ± 0.1 | 76.9 a ± 3.0 | 13.1 cd ± 0.0 | 3.7 abcd ± 0.2 | 1.4 a ± 0.1 |

| WHD1 | 87.9 c ± 0.7 | 80.0 a ± 3.8 | 11.7 a ± 0.1 | 4.1 bcd ± 0.2 | 1.5 a ± 0.0 |

| WND1 | 88.7 cd ± 0.9 | 76.6 a ± 2.5 | 13.5 d ± 0.0 | 4.6 d ± 0.4 | 1.8 ab ± 0.1 |

| WND2 | 89.1 cde ± 2.5 | 79.3 a ± 4.0 | 13.2 cd ± 0.3 | 3.0 ab ± 0.1 | 1.6 ab ± 0.1 |

| WHD2 | 93.6 de ± 2.0 | 80.0 a ± 1.3 | 12.8 cd ± 0.0 | 2.6 a ± 0.0 | 2.2 b ± 0.2 |

| WND3 | 94.1 e ± 0.4 | 80.7 a ± 1.4 | 11.9 ab ± 0.1 | 3.1 ab ± 0.0 | 1.3 a ± 0.0 |

| wNTS | 75.6 a ± 1.3 | 81.2 a ± 1.1 | 11.4 a ± 0.2 | 3.5 abcd ± 0.1 | 1.3 a ± 0.0 |

| RNTS | 77.2 a ± 0.8 | 79.0 a ± 1.2 | 12.7 bc ± 0.1 | 4.3 cd ± 0.4 | 1.6 ab ± 0.4 |

| RTS | 79.1 a ± 1.2 | 78.5 a ± 3.8 | 11.2 a ± 0.2 | 3.3 abc ± 0.1 | 1.3 a ± 0.1 |

| Teff | 77.6 ** | 76.3 a ± 0.8 | 13.4 cd ± 0.0 | 2.9 a ± 0.1 | 3.3 c ± 0.2 |

| Flour Type | Storage Time | Panellist | Flour Type × Storage Time | ||

|---|---|---|---|---|---|

| Aroma | Fermented aroma | ns | *** | *** | ns |

| Sorghum aroma | * | *** | *** | ns | |

| Musty/stale aroma | *** | * | *** | ns | |

| Overall aroma | *** | *** | *** | ns | |

| Appearance | Shininess of top * | *** | ns | *** | * |

| Shininess of bottom * | *** | ns | *** | ns | |

| Eye size * | *** | ns | *** | ns | |

| Eye evenness * | *** | * | *** | ** | |

| Texture (assessed by hand) | Softness-1 * | *** | *** | *** | *** |

| Sponginess-1 | *** | *** | *** | ns | |

| Flexibility | *** | *** | *** | * | |

| Rollability * | *** | *** | *** | ** | |

| Stickiness * | *** | *** | *** | * | |

| Texture (assessed in mouth) | Chewiness | ** | *** | *** | ns |

| Softness-2 * | *** | *** | *** | ns | |

| Sponginess-2 | *** | *** | *** | ns | |

| Breakability | ns | ** | *** | ns | |

| Grittiness * | * | ns | *** | ns | |

| Dry mouthfeel | ns | ns | *** | ns | |

| Flavour | Sourness * | *** | ns | *** | ns |

| Bitterness * | ** | *** | *** | ns | |

| Starchy | ns | ** | *** | ns | |

| Sweetness * | ns | *** | *** | ns | |

| Overall flavor | *** | *** | *** | ns | |

| Aftertaste | Sourness * | *** | *** | *** | ns |

| Bitterness * | ns | *** | *** | ns | |

| Dry mouthfeel | ns | ns | *** | ns | |

| Fine particles | *** | * | *** | ns | |

| Astringent | ** | * | *** | ns | |

| Lingering | ** | *** | *** | ns |

| Sorghum Line | Stress (kPa) at Maximum Elastic Extension | Strain (%) at Maximum Elastic Extension | ||||

|---|---|---|---|---|---|---|

| Storage Days (5 °C) | Storage Days (5 °C) | |||||

| 0 | 2 | 4 | 0 | 2 | 4 | |

| NWND | 159 f ± 14 | 217 fg ± 12 | 351 h ± 20 | 34.2 bc ± 2.2 | 10.1 a ± 0.6 | 5.6 bc ± 0.6 |

| NWHD | 153 def ± 10 | 226 g ± 16 | 386 i ± 20 | 33.5 bc ± 2.1 | 11.6 ab ± 1.1 | 4.7 ab ± 0.5 |

| hWND | 150 def ± 5 | 188 cde ± 8 | 296 efg ± 18 | 35.8 cd ± 2.2 | 11.0 a ± 1.0 | 5.3 ab ± 0.5 |

| WHD1 | 152 def ± 11 | 202 ef ± 16 | 303 fg ± 10 | 39.9 de ± 2.6 | 14.9 cd ± 1.2 | 7.2 d ± 0.8 |

| WND1 | 137 bc ± 9 | 178 bcd ± 10 | 247 cd ± 19 | 42.3 e ± 1.2 | 14.4 c ± 1.0 | 6.8 d ± 0.5 |

| WND2 | 130 bc ± 10 | 157 b ± 13 | 266 de ± 10 | 40.7 e ± 1.7 | 16.8 de ± 1.2 | 6.9 d ± 0.7 |

| WHD2 | 126 ab ± 7 | 161 b ± 6 | 215 bc ± 15 | 39.3 de ± 2.4 | 17.7 e ± 0.7 | 7.8 d ± 0.5 |

| WND3 | 124 ab ± 8 | 166 bc ± 12 | 201 ab ± 9 | 39.9 de ± 3.5 | 17.1 e ± 1.4 | 7.6 d ± 0.8 |

| wNTS | 157 ef ± 10 | 204 efg ± 11 | 294 ef ± 20 | 32.0 abc ± 2.7 | 13.3 bc ± 1.0 | 4.3 a ± 0.5 |

| RNTS | 146 cdef ± 6 | 207 efg ± 8 | 330 gh ± 26 | 30.6 ab ± 2.0 | 11.4 ab ± 1.0 | 5.5 b ± 0.8 |

| RTS | 140 bcde ± 8 | 197 def ± 18 | 278 def ± 23 | 28.4 a ± 1.9 | 14.3 c ± 1.2 | 5.3 ab ± 0.6 |

| Teff | 111 a ± 6 | 120 a ± 8 | 169 a ± 12 | 42.5 e ± 2.7 | 21.5 f ± 1.5 | 10.6 e ± 0.5 |

| Soft-1 | Flexibility | Rollability | Stickiness | Spongy-1 | Chewiness | Soft-2 | Breakability | Grittiness | Dry MF | Stress | Strain | |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Fresh injera | ||||||||||||

| Flexibility | 0.600 * | |||||||||||

| Rollability | 0.584 * | 0.961 ** | ||||||||||

| Stickiness | 0.555 ns | 0.106 ns | 0.103 ns | |||||||||

| Spongy-1 | 0.650 * | 0.579 * | 0.535 ns | 0.001 ns | ||||||||

| Chewiness | 0.479 ns | 0.805 ** | 0.893 ** | −0.070 ns | 0.437 ns | |||||||

| 1 Soft-2 | 0.940 ** | 0.675 * | 0.670 * | 0.347 ns | 0.688 * | 0.640 * | ||||||

| Breakability | 0.454 ns | 0.305 ns | 0.396 ns | −0.034 ns | 0.562 ns | 0.445 ns | 0.599 * | |||||

| Grittiness | −0.605 * | −0.479 ns | −0.412 ns | −0.629 * | −0.335 ns | −0.158 ns | −0.386 ns | 0.192 ns | ||||

| Dry MF | −0.691 * | −0.608 * | −0.509 ns | −0.282 ns | −0.800 ** | −0.317 ns | −0.680 * | −0.336 ns | 0.365 ns | |||

| Stress | −0.729 ** | −0.373 ns | −0.445 ns | −0.505 ns | −0.071 ns | −0.400 ns | −0.690 * | −0.270 ns | 0.411 ns | 0.121 ns | ||

| Strain | 0.725 ** | 0.618 * | 0.633 * | 0.456 ns | 0.404 ns | 0.460 ns | 0.714 ** | 0.141 ns | −0.590 * | −0.417 ns | −0.750 * | |

| Spongy-2 | 0.501 ns | 0.523 ns | 0.494 ns | −0.153 ns | 0.895 ** | 0.405 ns | 0.592 * | 0.701 * | −0.223 ns | −0.576 * | −0.026 ns | 0.273 ns |

| Two-days stored | ||||||||||||

| Flexibility | 0.791 ** | |||||||||||

| Rollability | 0.741 ** | 0.987 ** | ||||||||||

| Stickiness | −0.010 ns | −0.374 ns | −0.376 ns | |||||||||

| Sponginess | 0.935 ** | 0.886 ** | 0.867 ** | −0.230 ns | ||||||||

| Chewiness | 0.154 ns | 0.302 ns | 0.344 ns | −0.482 ns | 0.362 ns | |||||||

| Soft-2 | 0.946 ** | 0.813 ** | 0.770 ** | −0.164 | 0.957 ** | 0.383 ns | ||||||

| Breakability | −0.613 * | −0.647 * | −0.690 * | 0.070 ns | −0.648 * | −0.091 ns | −0.494 ns | |||||

| Grittiness | −0.723 ** | −0.639 * | −0.619 * | 0.208 ns | −0.699 * | −0.311 ns | −0.706 * | 0.663 * | ||||

| Dry MF | −0.132 ns | −0.204 ns | −0.263 ns | 0.183 ns | −0.172 ns | −0.356 ns | −0.053 ns | 0.661 * | 0.426 ns | |||

| Stress | −0.718 ** | −0.571 ns | −0.483 ns | −0.007 ns | −0.552 ns | 0.188 ns | −0.616 * | 0.478 ns | 0.744 ** | 0.020 ns | ||

| Strain | 0.948 ** | 0.827 ** | 0.773 ** | −0.123 ns | 0.870 ** | 0.205 ns | 0.900 ** | −0.570 ns | −0.787 ** | −0.168 ns | −0.779 ** | |

| Spongy-2 | 0.583 * | 0.655 * | 0.705 * | −0.035 ns | 0.636 * | 0.367 ns | 0.669 * | −0.505 ns | −0.402 ns | −0.157 ns | −0.300 ns | 0.579 * |

| Four-days stored | ||||||||||||

| Flexibility | 0.402 ns | |||||||||||

| Rollability | 0.348 ns | 0.961 ** | ||||||||||

| Stickiness | −0.262 ns | −0.612 * | −0.548 ns | |||||||||

| Sponginess | 0.911 ** | 0.526 ns | 0.514 ns | −0.484 ns | ||||||||

| Chewiness | 0.604 * | 0.748 ** | 0.692 * | −0.726 ** | 0.660 * | |||||||

| Soft-2 | 0.950 ** | 0.386 ns | 0.367 ns | −0.282 ns | 0.854 ** | 0.669 * | ||||||

| Breakability | −0.146 ns | 0.112 ns | −0.043 ns | 0.107 ns | −0.274 ns | −0.047 ns | −0.236 ns | |||||

| Grittiness | −0.732 ** | −0.395 ns | −0.354 ns | 0.328 ns | −0.721 ** | −0.283 ns | −0.604 * | 0.144 ns | ||||

| Dry MF | −0.289 ns | 0.340 ns | 0.299 ns | −0.357 ns | −0.108 ns | 0.148 ns | −0.289 ns | 0.531 ns | 0.175 ns | |||

| Stress | −0.733 ** | −0.445 ns | −0.518 ns | −0.015 ns | −0.640 * | −0.392 ns | −0.742 ** | 0.253 ns | 0.633 * | 0.443 ns | ||

| Strain | 0.735 ** | 0.694 * | 0.697 * | −0.401 ns | 0.694 * | 0.820 ** | 0.793 ** | 0.023 ns | −0.423 ns | 0.110 ns | −0.694 * | |

| Spongy-2 | 0.274 ns | 0.256 ns | 0.263 ns | −0.162 ns | 0.295 ns | 0.334 ns | 0.376 | −0.171 ns | −0.128 ns | 0.399 ns | −0.124 | 0.452 ns |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Mezgebe, A.G.; Taylor, J.R.N.; de Kock, H.L. Influence of Waxy (High Amylopectin) and High Protein Digestibility Traits in Sorghum on Injera Sourdough-Type Flatbread Sensory Characteristics. Foods 2020, 9, 1749. https://doi.org/10.3390/foods9121749

Mezgebe AG, Taylor JRN, de Kock HL. Influence of Waxy (High Amylopectin) and High Protein Digestibility Traits in Sorghum on Injera Sourdough-Type Flatbread Sensory Characteristics. Foods. 2020; 9(12):1749. https://doi.org/10.3390/foods9121749

Chicago/Turabian StyleMezgebe, Abadi G., John R. N. Taylor, and Henriëtte L. de Kock. 2020. "Influence of Waxy (High Amylopectin) and High Protein Digestibility Traits in Sorghum on Injera Sourdough-Type Flatbread Sensory Characteristics" Foods 9, no. 12: 1749. https://doi.org/10.3390/foods9121749

APA StyleMezgebe, A. G., Taylor, J. R. N., & de Kock, H. L. (2020). Influence of Waxy (High Amylopectin) and High Protein Digestibility Traits in Sorghum on Injera Sourdough-Type Flatbread Sensory Characteristics. Foods, 9(12), 1749. https://doi.org/10.3390/foods9121749