Quality Characteristics of Healthy Dry Fermented Sausages Formulated with a Mixture of Olive and Chia Oil Structured in Oleogel or Emulsion Gel as Animal Fat Replacer

Abstract

:1. Introduction

2. Materials and Methods

2.1. Oleogel and Emulsion Gel Preparation

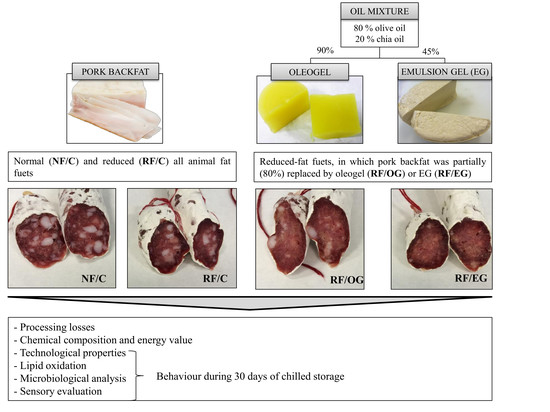

2.2. Fuet Design and Preparation

2.3. Processing Losses

2.4. Chemical Composition and Energy Value of Fuets

2.5. Technological Properties

2.6. Lipid Oxidation

2.7. Microbiological Analysis

2.8. Sensory Analysis

2.9. Statistical Analysis

3. Results and Discussion

3.1. Processing Losses

3.2. Chemical Composition and Energy Value

3.3. Nutritional and Health Claims

3.4. Technological Properties

3.5. Lipid Oxidation

3.6. Microbiological Analysis

3.7. Sensory Analysis

4. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Bou, R.; Cofrades, S.; Jiménez-Colmenero, F. Fermented meat sausages. In Fermented foods in health and disease prevention; Frias, J., Martínez-Villaluenga, C., Penas, E., Eds.; Elsevier Science LTD: London, UK, 2017; pp. 203–235. [Google Scholar]

- Jiménez-Colmenero, F. Healthier lipid formulation approaches in meat-based functional foods. Technological options for replacement of meat fats by non-meat fats. Trends Food Sci. Tech. 2007, 18, 567–578. [Google Scholar] [CrossRef] [Green Version]

- Jiménez-Colmenero, F.; Salcedo-Sandoval, L.; Bou, R.; Cofrades, S.; Herrero, A.M.; Ruiz-Capillas, C. Novel applications of oil-structuring methods as a strategy to improve the fat content of meat products. Trends Food Sci. Tech. 2015, 44, 177–188. [Google Scholar] [CrossRef] [Green Version]

- Barbut, S.; Wood, J.; Marangoni, A. Potential use of organogels to replace animal fat in comminuted meat products. Meat Sci. 2016, 122, 155–162. [Google Scholar] [CrossRef]

- Fayaz, G.; Goli, S.A.H.; Kadivar, M. A novel propolis wax-based organogel: Effect of oil type on its formation, crystal structure and thermal properties. J. Am. Oil Chem. Soc. 2017, 94, 47–55. [Google Scholar] [CrossRef]

- Gómez-Estaca, J.; Herrero, A.M.; Herranz, B.; Alvarez, M.D.; Jiménez-Colmenero, F.; Cofrades, S. Characterization of ethyl cellulose and beeswax oleogels and their suitability as fat replacers in healthier lipid pates development. Food Hydrocolloid 2019, 87, 960–969. [Google Scholar] [CrossRef]

- Pintado, T.; Ruiz-Capillas, C.; Jiménez-Colmenero, F.; Carmona, P.; Herrero, A.M. Oil-in-water emulsion gels stabilized with chia (Salvia hispanica L.) and cold gelling agents: Technological and infrared spectroscopic characterization. Food Chem. 2015, 185, 470–478. [Google Scholar] [CrossRef] [PubMed]

- Pintado, T.; Herrero, A.M.; Jiménez-Colmenero, F.; Ruiz-Capillas, C. Emulsion gels as potential fat replacers delivering beta-glucan and healthy lipid content for food applications. J. Food Sci. Tech. Mys. 2016, 53, 4336–4347. [Google Scholar] [CrossRef] [Green Version]

- EFSA (European Food Safety Agency). Scientific opinion on dietary reference values for fats, including saturated fatty acids, polyunsaturated fatty acids, monounsaturated fatty acids, trans fatty acids, and cholesterol. EFSA J. 2010, 8, 1461–1568. [Google Scholar]

- WHO. Diet, Nutrition and the Prevention of chronic diseases; World Health Organization Technical Report Series; WHO: Geneve, Switzerland, 2003. [Google Scholar]

- Borges, T.H.; Pereira, J.A.; Cabrera-Vique, C.; Lara, L.; Oliveira, A.F.; Seiquer, I. Characterization of Arbequina virgin olive oils produced in different regions of Brazil and Spain: Physicochemical properties, oxidative stability and fatty acid profile. Food Chem. 2017, 215, 454–462. [Google Scholar] [CrossRef]

- Ayerza, R. Oil content and fatty-acid composition of chia (Salvia hispanica L.) from 5 Northwestern locations in Argentina. J. Am. Oil Chem. Soc. 1995, 72, 1079–1081. [Google Scholar] [CrossRef]

- Agregan, R.; Barba, F.J.; Gavahian, M.; Franco, D.; Khaneghah, A.M.; Carballo, J.; Ferreira, I.C.F.R.; Barretto, A.C.D.; Lorenzo, J.M. Fucus vesiculosus extracts as natural antioxidants for improvement of physicochemical properties and shelf life of pork patties formulated with oleogels. J. Sci. Foof. Agr. 2019, 99, 4561–4570. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Alejandre, M.; Passarini, D.; Astiasaran, I.; Ansorena, D. The effect of low-fat beef patties formulated with a low-energy fat analogue enriched in long-chain polyunsaturated fatty acids on lipid oxidation and sensory attributes. Meat Sci. 2017, 134, 7–13. [Google Scholar] [CrossRef] [PubMed]

- Barbut, S.; Marangoni, A.G.; Thode, U.; Tiensa, B.E. Using canola oil organogels as fat replacement in liver pate. J. Food Sci. 2019, 84, 2646–2651. [Google Scholar] [CrossRef] [PubMed]

- Franco, D.; Martins, A.J.; López-Pedrouso, M.; Purrinos, L.; Cerqueira, M.A.; Vicente, A.A.; Pastrana, L.M.; Zapata, C.; Lorenzo, J.M. Strategy towards replacingp backfat with a linseed oleogel in frankfurter sausages and its evaluation on physicochemical, nutritional, and sensory characteristics. Foods 2019, 8, 366. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Freire, M.; Cofrades, S.; Serrano-Casas, V.; Pintado, T.; Jiménez, M.J.; Jiménez-Colmenero, F. Gelled double emulsions as delivery systems for hydroxytyrosol and n-3 fatty acids in healthy pork patties. J. Food Sci. Tech. Mys. 2017, 54, 3959–3968. [Google Scholar] [CrossRef]

- Gómez-Estaca, J.; Pintado, T.; Jiménez-Colmenero, F.; Cofrades, S. Assessment of a healthy oil combination structured in ethyl cellulose and beeswax oleogels as animal fat replacers in low-fat, PUFA-enriched pork burgers. Food Bioprocess Tech. 2019, 12, 1068–1081. [Google Scholar] [CrossRef] [Green Version]

- Pintado, T.; Herrero, A.M.; Jiménez-Colmenero, F.; Pasqualin-Cavalheiro, C.; Ruiz-Capillas, C. Chia and oat emulsion gels as new animal fat replacers and healthy bioactive sources in fresh sausage formulation. Meat Sci. 2018, 135, 6–13. [Google Scholar] [CrossRef]

- Pintado, T.; Herrero, A.M.; Ruiz-Capillas, C.; Triki, M.; Carmona, P.; Jiménez-Colmenero, F. Effects of emulsion gels containing bioactive compounds on sensorial, technological, and structural properties of frankfurters. Food Sci. Technol. Int. 2015, 22, 132–145. [Google Scholar] [CrossRef] [Green Version]

- Poyato, C.; Astiasaran, I.; Barriuso, B.; Ansorena, D. A new polyunsaturated gelled emulsion as replacer of pork back-fat in burger patties: Effect on lipid composition, oxidative stability and sensory acceptability. LWT 2015, 62, 1069–1075. [Google Scholar] [CrossRef] [Green Version]

- Serdaroglu, M.; Nacak, B.; Karabiyikoglu, M. Effects of beef fat replacement with gelled emulsion prepared with olive oil on quality parameters of chicken patties. Korean J. Food Sci. An. 2017, 37, 376–384. [Google Scholar]

- Wolfer, T.L.; Acevedo, N.C.; Prusa, K.J.; Sebranek, J.G.; Tarte, R. Replacement of pork fat in frankfurter-type sausages by soybean oil oleogels structured with rice bran wax. Meat Sci. 2018, 145, 352–362. [Google Scholar] [CrossRef] [PubMed]

- Alejandre, M.; Poyato, C.; Ansorena, D.; Astiasarán, I. Linseed oil gelled emulsion: A successful fat replacer in dry fermented sausages. Meat Sci. 2016, 121, 107–113. [Google Scholar] [CrossRef] [PubMed]

- Glisic, M.; Baltic, M.; Glisic, M.; Trbovic, D.; Jokanovic, M.; Parunovic, N.; Dimitrijevic , M.; Suvajdzic, S.; Boskovic , M.; Vasilev, D.; et al. Inulin-based emulsion-filled gel as a fat replacer in prebiotic- and PUFA-enriched dry fermented sausages. Int. J. Food Sci. Tech. 2019, 54, 787–797. [Google Scholar] [CrossRef]

- Franco, D.; Martins, A.J.; López-Pedrouso, M.; Cerqueira, M.A.; Purrinos, L.; Pastrana, L.M.; Vicente , A.A.; Zapata, C.; Lorenzo, J.M. Evaluation of linseed oil oleogels to partially replace pork backfat in fermented sausages. J. Sci. Food Agr. 2020, 100, 218–224. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Delgado-Pando, G.; Cofrades, S.; Ruiz-Capillas, C.; Solas, M.T.; Jiménez-Colmenero, F. Healthier lipid combination oil-in-water emulsions prepared with various protein systems: an approach for development of functional meat products. Eur. J. Lipid Sci. Tech. 2010, 112, 791–801. [Google Scholar] [CrossRef]

- Mora-Gallego, H.; Guardia, M.D.; Serra, X.; Gou, P.; Arnau, J. Sensory characterisation and consumer acceptability of potassium chloride and sunflower oil addition in small-caliber non-acid fermented sausages with a reduced content of sodium chloride and fat. Meat Sci. 2016, 112, 9–15. [Google Scholar] [CrossRef] [PubMed]

- AOAC. Official Methods of Analysis, 18th ed.; AOAC International: Gaithersburg, MD, USA, 2005. [Google Scholar]

- Bligh, E.G.; Dyer, W.J. A rapid method of total lipid extraction and purification. Can J. Biochem. Phys. 1959, 37, 911–917. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Lee, M.R.F.; Tweed, J.K.S.; Kim, E.J.; Scollan, N.D. Beef, chicken and lamb fatty acid analysis -a symplified direct bimethylation procedureusing freeze-dried material. Meat Sci. 2012, 92, 863–866. [Google Scholar] [CrossRef]

- Bourne, M.C. Texture profile analysis. Food Tech. 1978, 32, 62. [Google Scholar]

- Domínguez, R.; Pateiro, M.; Gagaoua, M.; Barba, F.J.; Zhang, W.; Lorenzo, J.M. A comprehensive review on lipid oxidation in meat and meat products. Antioxidants 2019, 8, 429. [Google Scholar] [CrossRef] [Green Version]

- Delgado-Pando, G.; Cofrades, S.; Ruiz-Capillas, C.; Triki, M.; Jiménez-Colmenero, F. Enriched n-3 PUFA/konjac gel low-fat pork liver pate: Lipid oxidation, microbiological properties and biogenic amine formation during chilling storage. Meat Sci. 2012, 92, 762–767. [Google Scholar] [CrossRef] [PubMed]

- Campagnol, P.C.B.; dos Santos, B.A.; Wagner, R.; Terra, N.N.; Pollonio, M.A.R. Amorphous cellulose gel as a fat substitute in fermented sausages. Meat Sci. 2012, 90, 36–42. [Google Scholar] [CrossRef] [PubMed]

- Muguerza, E.; Fista, G.; Ansorena, D.; Astiasaran, I.; Bloukas, J.G. Effect of fat level and partial replacement of pork backfat with olive oil on processing and quality characteristics of fermented sausages. Meat Sci. 2002, 61, 397–404. [Google Scholar] [CrossRef]

- Ruiz-Capillas, C.; Triki, M.; Herrero, A.M.; Rodríguez-Salas, L.; Jiménez-Colmenero, F. Konjac gel as pork backfat replacer in dry fermented sausages: Processing and quality characteristics. Meat Sci. 2012, 92, 144–150. [Google Scholar] [CrossRef] [PubMed]

- Wood, J.D.; Enser, M.; Fisher, A.V.; Nute, G.R.; Sheard, P.R.; Richardson, R.I.; Hughes, S.I.; Whittington, F.M. Fat deposition, fatty acid composition and meat quality: A review. Meat Sci. 2008, 78, 343–358. [Google Scholar] [CrossRef]

- Angiolillo, L.; Conte, A.; Del Nobile, M.A. Technological strategies to produce functional meat burgers. Lwt 2015, 62, 697–703. [Google Scholar] [CrossRef]

- Barros, J.C.; Munekata, P.E.; Pires, M.A.; Rodrigues, I.; Andaloussi, O.S.; Rodrigues, C.E.C.; Trindade, M.A. Omega-3-and fibre-enriched chicken nuggets by replacement of chicken skin with chia (Salvia hispanica L.) flour. Lwt 2018, 90, 283–289. [Google Scholar] [CrossRef]

- Pintado, T.; Herrero, A.M.; Jiménez-Colmenero, F.; Ruiz-Capillas, C. Strategies for incorporation of chia (Salvia hispanica L.) in frankfurters as a health-promoting ingredient. Meat Sci. 2016, 114, 75–84. [Google Scholar] [CrossRef]

- Salcedo-Sandoval, L.; Cofrades, S.; Ruiz-Capillas, C.; Jiménez-Colmenero, F. Effect of cooking method on the fatty acid content of reduced-fat and PUFA-enriched pork patties formulated with a konjac-based oil bulking system. Meat Sci. 2014, 98, 795–803. [Google Scholar] [CrossRef] [Green Version]

- Simopoulos, A.P. The importance of the omega-6/omega-3 fatty acid ratio in cardiovascular disease and other chronic diseases. Exp. Biol. Med. 2008, 233, 674–688. [Google Scholar] [CrossRef]

- European Commission. Regulation (EC) No 1924/2006 of the European Parliament and of the Council of 20 December 2006 on nutrition and health claims made on foods. OJEU 2006, L 404, 3–18. [Google Scholar]

- European Commission. Regulation (EU) No 432/2012 of the European Parliament and of the Council of 16 may 2012 establishing a list of permited health claims made on foods other than those referring to the reduction of disease risk and to children’s development and health. OJEU 2012, L 136, 1–408. [Google Scholar]

- IARC (International Agency for Research on Cancer). IARC monographs evaluate consumption of red meat and processed meat. Available online: https://www.iarc.fr/wp-content/uploads/2018/07/pr240_E.pdf (accessed on 5 May 2020).

- Herrero, A.M.; Ordonez, J.A.; de Avila, R.; Herranz, B.; de la Hoz, L.; Cambero, M.I. Breaking strength of dry fermented sausages and their correlation with texture profile analysis (TPA) and physico-chemical characteristics. Meat Sci. 2007, 77, 331–338. [Google Scholar] [CrossRef] [PubMed]

- Triki, M.; Herrero, A.M.; Rodríguez-Salas, L.; Jiménez-Colmenero, F.; Ruiz-Capillas, C. Chilled storage characteristics of low-fat, n-3 PUFA-enriched dry fermented sausage reformulated with a healthy oil combination stabilized in a konjac matrix. Food Control 2013, 31, 158–165. [Google Scholar] [CrossRef]

- Munekata, P.E.S.; Domínguez, R.; Franco, D.; Bermúdez, R.; Trindade, M.A.; Lorenzo, J.M. Effect of natural antioxidants in Spanish salchichón elaborated with encapsulated n-3 long chain fatty acids in konjac glucomannan matrix. Meat Sci. 2017, 124, 54–60. [Google Scholar] [CrossRef] [PubMed]

- Komprda, T.; Neznalova, J.; Standara, S.; Bover-Cid, S. Effect of starter culture and storage temperature on the content of biogenic amines in dry fermented sausage polican. Meat Sci. 2001, 59, 267–276. [Google Scholar] [CrossRef]

- Fonseca, S.; Gómez, M.; Domínguez, R.; Lorenzo, J.M. Physicochemical and sensory properties of Celta dry-ripened “salchichón” as affected by fat content. Grasas Aceites 2015, 66, 59. [Google Scholar]

- Lorenzo, J.M.; Franco, D. Fat effect on physico-chemical, microbial and textural changes through the manufactured of dry-cured foal sausage: Lipolysis, proteolysis and sensory properties. Meat Sci. 2012, 92, 704–714. [Google Scholar] [CrossRef]

- Gómez, M.; Lorenzo, J.M. Effect of fat level on physicochemical, volatile compounds and sensory characteristics of dry-ripened “chorizo” from Celta pig breed. Meat Sci. 2013, 95, 658–666. [Google Scholar]

- Jiménez-Colmenero, F.; Triki, M.; Herrero, A.M.; Rodríguez-Salas, L.; Ruiz-Capillas, C. Healthy oil combination stabilized in a konjac matrix as pork fat replacement in low-fat, PUFA-enriched, dry fermented sausages. LWT 2013, 51, 158–163. [Google Scholar] [CrossRef] [Green Version]

- Bloukas, J.G.; Paneras, E.D.; Fournitzis, G.C. Effect of replacing pork backfat with olive oil on processing and quality characteristics of fermented sausages. Meat Sci. 1997, 45, 133–144. [Google Scholar] [CrossRef]

- Josquin, N.M.; Linssen, J.P.H.; Houben, J.H. Quality characteristics of Dutch-style fermented sausages manufactured with partial replacement of pork back-fat with pure, pre-emulsified or encapsulated fish oil. Meat Sci. 2012, 90, 81–86. [Google Scholar] [CrossRef] [PubMed]

- Ansorena, D.; Astiasarán, I. The use of linseed oil improves nutritional quality of the lipid fraction of dry-fermented sausages. Food Chem. 2004, 87, 69–74. [Google Scholar] [CrossRef] [Green Version]

- Stone, H.; Sidel, J.L. Sensory evaluation practices, 3rd ed.; Elsevier: Redwood City, CA, USA, 2004. [Google Scholar]

| Meat | Pork Back Fat | Oleogel | Emulsion Gel | Water | |

|---|---|---|---|---|---|

| NF/C | 74.0 | 20.0 | 0.5 | ||

| RF/C | 74.0 | 9.0 | 11.5 | ||

| RF/OG | 74.0 | 4.0 | 7.5 | 9.0 | |

| RF/EG | 74.0 | 4.0 | 15.0 | 1.5 |

| Parameters | Samples | |||

|---|---|---|---|---|

| NF/C | RF/C | RF/OG | RF/EG | |

| Composition (%) | ||||

| Moisture | 32.63 ± 0.87 a | 36.07 ± 0.47 b | 37.45 ± 0.70 b | 36.84 ± 0.76 b |

| Ash | 4.72 ± 0.04 a | 6.13 ± 0.03 c | 4.90 ± 0.01 ab | 5.07 ± 0.15 b |

| Protein | 31.17 ± 0.07 a | 37.74 ± 0.74 c | 31.92 ± 0.96 a | 35.12 ± 0.24 b |

| Fat | 29.73 ± 2.42 b | 19.78 ± 1.86 a | 22.30 ± 2.13 a | 22.01 ± 0.61 a |

| Fatty acid profile (g/100 g of fuet) | ||||

| Myristic C14:0 | 0.50 ± 0.01 c | 0.37 ± 0.04 b | 0.17 ± 0.00 a | 0.16 ± 0.01 a |

| Palmitic C16:0 | 7.85 ± 0.24 c | 5.82 ± 0.57 b | 3.92 ± 0.06 a | 3.76 ± 0.12 a |

| Stearic C18:0 | 3.54 ± 0.17 c | 2.63 ± 0.28 b | 1.56 ± 0.03 a | 1.55 ± 0.06 a |

| ∑ SFA | 12.11 ± 0.42 c | 8.99 ± 0.90 b | 5.79 ± 0.09 a | 5.61 ± 0.19 a |

| Vaccenic C18:1n7 | 1.19 ± 0.03 c | 0.91 ± 0.08 b | 0.63 ± 0.01 a | 0.62 ± 0.02 a |

| Oleic C18:1n9 | 13.60 ± 0.33 c | 10.30 ± 0.93 a | 12.29 ± 0.20 b | 11.94 ± 0.18 b |

| ∑ MUFA | 16.12 ± 0.38 c | 12.20 ± 1.10 a | 13.51 ± 0.22 b | 13.10 ± 0.21 b |

| Linoleic C18:2n6 | 2.31 ± 0.04 b | 1.81 ± 0.14 a | 1.81 ± 0.02 c | 1.77 ± 0.03 c |

| Linolenic C18:3n3 | 0.12 ± 0.00 a | 0.09 ± 0.01 a | 1.68 ± 0.03 b | 1.61 ± 0.03 b |

| ∑ PUFA | 2.83 ± 0.05 b | 2.25 ± 0.17 a | 3.81 ± 0.04 d | 3.60 ± 0.04 c |

| Nutritional significance ratios | ||||

| PUFA/SFA | 0.23 ± 0.01 a | 0.25 ± 0.01 a | 0.66 ± 0.01 b | 0.64 ± 0.02 b |

| n-6/n-3 | 14.0 ± 0.22 b | 15.04 ± 0.47 b | 1.12 ± 0.01 a | 1.19 ± 0.02 a |

| Claims | Conditions Applying to Them | Fuet Samples | |||

|---|---|---|---|---|---|

| NF/C | RF/C | RF/OG | RF/EG | ||

| “high protein” Proteins contribute to a growth in muscle mass and the maintenance of muscle mass and normal bones. Protein is needed for normal growth and development of bone in children. | May only be made where at least 20% of the energy value of the food is provided by protein | X | X | X | X |

| “reduced fat” | May only be made where the reduction in content is at least 30% compared to a similar product | X | |||

| “high unsaturated fat” Replacing saturated fats with unsaturated fats in the diet contributes to the maintenance of normal blood cholesterol levels. | May only be made where at least 70% of fatty acids present in the product derive from unsaturated fat under the condition that unsaturated fat provides more than 20% of the energy of the product. | X | X | ||

| “high omega-3 fatty acids” Alpha-linolenic acid (ALA) contributes to the maintenance of normal blood cholesterol levels. Information shall be given to the consumer that the beneficial effect is obtained with a daily intake of 2 g of ALA. | May only be made where the product contains at least 0.6 g ALA / 100 g of product and per 100 kcal. | X | X | ||

| Samples | Days of Storage (5 °C) | |||

|---|---|---|---|---|

| 0 | 15 | 30 | ||

| Aw | NF/C | 0.87 ± 0.02 a1 | 0.89 ± 0.01 c1 | 0.88 ± 0.00 a1 |

| RF/C | 0.88 ± 0.01 a2 | 0.84 ± 0.00 a1 | 0.87 ± 0.00 a2 | |

| RF/OG | 0.91 ± 0.01 b1 | 0.90 ± 0.00 c1 | 0.90 ± 0.00 b1 | |

| RF/EG | 0.90 ± 0.01 b2 | 0.88 ± 0.01 b1 | 0.92 ± 0.00 b3 | |

| pH | NF/C | 5.41 ± 0.01 b1 | 5.74 ± 0.11 b2 | 6.34 ± 0.04 a3 |

| RF/C | 5.50 ± 0.01 b1 | 5.87 ± 0.07 c2 | 6.5 ± 0.04 b3 | |

| RF/OG | 5.27 ± 0.01 a1 | 5.60 ± 0.04 a2 | 6.64 ± 0.03 c3 | |

| RF/EG | 5.20 ± 0.01 a1 | 5.77 ± 0.12 bc2 | 6.62 ± 0.02 c3 | |

| Colour parameters | ||||

| L* | NF/C | 41.45 ± 2.85 a12 | 42.74 ± 2.99 a2 | 38.76 ± 1.59ab1 |

| RF/C | 45.68 ± 2.79 b2 | 41.02 ± 1.63 a1 | 39.60 ± 3.99 b1 | |

| RF/OG | 41.69 ± 2.47 a1 | 41.69 ± 1.92 a1 | 40.76 ± 2.39 b1 | |

| RF/EG | 42.12 ± 1.86 ab2 | 39.85 ± 2.52 a2 | 35.31 ± 3.50 a1 | |

| a* | NF/C | 14.11 ± 0.99 ab2 | 11.60 ± 2.99 a1 | 17.75 ± 1.73 b3 |

| RF/C | 12.79 ± 1.87 a1 | 16.82 ± 1.17 b2 | 16.72 ± 1.70 ab2 | |

| RF/OG | 15.58 ± 1.38 b1 | 16.75 ± 0.88 b1 | 16.74 ± 2.04 ab1 | |

| RF/EG | 14.25 ± 1.29 ab1 | 16.52 ± 1.01 b2 | 15.33 ± 0.95 a12 | |

| b* | NF/C | 6.07 ± 0.82 a1 | 4.66 ± 1.39 a1 | 7.77 ± 1.36 a2 |

| RF/C | 8.23 ± 2.40 b1 | 7.01 ± 1.19 b1 | 7.66 ± 0.83 a1 | |

| RF/OG | 7.91 ± 0.98 b1 | 10.19 ± 1.08 c2 | 10.43 ± 1.10 b2 | |

| RF/EG | 8.95 ± 0.78 b1 | 9.70 ± 0.74 c1 | 9.32 ± 0.82 ab1 | |

| Texture profile analysis | ||||

| Hardness (N) | NF/C | 5.81 ± 0.91 b1 | 4.54 ± 1.40 a1 | 12.30 ± 1.66 b2 |

| RF/C | 9.51 ± 0.18 c1 | 12.36 ± 2.06 c1 | 16.79 ± 3.34 c2 | |

| RF/OG | 3.75 ± 0.49 a1 | 3.78 ± 0.65 a1 | 5.36 ± 0.52 a2 | |

| RF/EG | 5.84 ± 0.50 b1 | 7.71 ± 1.08 b2 | 7.97 ± 0.73 a2 | |

| Compound | Samples | |||

|---|---|---|---|---|

| NF/C | RF/C | RF/OG | RF/EG | |

| TBARs | ||||

| day 0 | 0.103 ± 0.025 a1 | 0.085 ± 0.010 a1 | 0.404 ± 0.028 b1 | 0.404 ± 0.028 b1 |

| day 30 | 0.107 ± 0.016 a1 | 0.091 ± 0.010 a1 | 0.384 ± 0.040 b1 | 0.365 ± 0.041b1 |

| Hexanal | ||||

| day 0 | 156.0 ± 0.4 a1 | 152.3 ± 20.8 a1 | 239.8 ± 26.2 b2 | 367.0 ± 15.2 c2 |

| day 30 | 119.4 ± 18.4 a1 | 121.3 ± 9.9 a1 | 153.1 ± 0.5 a1 | 279.4 ± 26.2 b1 |

| Heptanal | ||||

| day 0 | 17.5 ± 3.1 a2 | 30.8 ± 4.8 a2 | 65.3 ± 36.8 b2 | 60.1 ± 3.8 b2 |

| day 30 | 11.9 ± 1.3 a1 | 12.3 ± 5.6 a1 | 35.6 ± 1.1 b1 | 48.0 ± 1.2 c1 |

| Octanal | ||||

| day 0 | 74.2 ± 4.0 a1 | 55.4 ± 1.9 a1 | 473.3 ± 188.5 b2 | 462.2 ± 139.3 b2 |

| day 30 | 51.4 ± 3.4 a1 | 51.0 ± 6.1 a1 | 96.5 ± 0.5 b1 | 137.9 ± 11.5 c1 |

| Nonanal | ||||

| day 0 | 366.9 ± 20.7 a1 | 352.6 ± 39.4 a1 | 971.8 ± 164.4 b1 | 809.2 ± 1.1 b1 |

| day 30 | 324.9 ± 18.1 a1 | 387.8 ± 66.2 a1 | 762.2 ± 22.3 b1 | 882.5 ± 20.9 b1 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Pintado, T.; Cofrades, S. Quality Characteristics of Healthy Dry Fermented Sausages Formulated with a Mixture of Olive and Chia Oil Structured in Oleogel or Emulsion Gel as Animal Fat Replacer. Foods 2020, 9, 830. https://doi.org/10.3390/foods9060830

Pintado T, Cofrades S. Quality Characteristics of Healthy Dry Fermented Sausages Formulated with a Mixture of Olive and Chia Oil Structured in Oleogel or Emulsion Gel as Animal Fat Replacer. Foods. 2020; 9(6):830. https://doi.org/10.3390/foods9060830

Chicago/Turabian StylePintado, Tatiana, and Susana Cofrades. 2020. "Quality Characteristics of Healthy Dry Fermented Sausages Formulated with a Mixture of Olive and Chia Oil Structured in Oleogel or Emulsion Gel as Animal Fat Replacer" Foods 9, no. 6: 830. https://doi.org/10.3390/foods9060830

APA StylePintado, T., & Cofrades, S. (2020). Quality Characteristics of Healthy Dry Fermented Sausages Formulated with a Mixture of Olive and Chia Oil Structured in Oleogel or Emulsion Gel as Animal Fat Replacer. Foods, 9(6), 830. https://doi.org/10.3390/foods9060830