Sustainable Feedstocks and Challenges in Biodiesel Production: An Advanced Bibliometric Analysis

Abstract

:1. Introduction

2. Materials and Methods

2.1. Data Sources

2.2. Data Analysis

3. Results and Discussion

3.1. Bibliometric Analysis

3.1.1. Publications: General Results

3.1.2. Distribution of Scientific Journals

3.1.3. Distribution by Country and Institution

3.1.4. Most Cited Articles

3.1.5. Research Areas

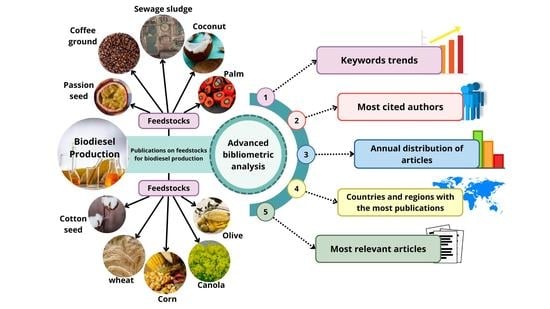

3.2. Feedstocks for Biodiesel Production

3.2.1. Classification of Feedstocks

3.2.2. Sewage Sludge

3.2.3. Microalgae

3.2.4. Waste Cooking Oil

4. Trendy Research Topics

4.1. Quantitative Analysis of Frequent Keywords

4.2. Research Areas

4.2.1. Research Fields

4.2.2. Emerging Trends

4.2.3. Two Key Insights

5. Conclusions

- One of the key raw materials highlighted in this work, sewage sludge, has received little attention in the literature, considering that the number of cited articles is still small and despite the economic and sustainability advantages cited above. This is mostly due to the fact it is still a recent research theme and that raw materials that have been explored for longer are more attractive owing to the vast knowledge repertoire.

- Waste cooking oil and microalgae are the raw materials of most significant presence in the academic outputs analyzed. These are feedstocks that have been extensively reported on in the literature, mainly due to their long-standing reputation in the area. However, there has been a noticeable reduction in the volume of cited articles over the years.

- China, Malaysia, and India are the countries with the greatest research outputs relating to feedstocks for biodiesel production. It can be concluded, therefore, that Asia shows a great interest in this area. One factor that can explain this interest may be the sheer number of people concentrated in this region, since China, India, and Malaysia account for more than 35% of the world’s total population.

- For a more specific analysis of this research, keywords collected by the CiteSpace program were used. From a systematic verification of the terms, it was possible to observe that the main research topics in this area include oleaginous yeasts, ionic liquids, process design, oil extraction, enzymatic biodiesel production, and calcium oxide.

- Two broad perspectives related to this research area have been emphasized. The first is the generalized view of the articles that engage in the topic of feedstocks for biodiesel production. It is concluded that there is a great deal of discussion regarding the economy versus sustainability dilemma, and researchers have sought practical solutions to the problems that arise from this. The second perspective concerns the recent emergence of academic interest in studying sewage sludge for biodiesel production. It is understood that this area will be further explored in the near future due to the solution that this raw material represents to the conundrum above.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- De Man, R.; German, L. Certifying the sustainability of biofuels: Promise and reality. Energy Policy 2017, 109, 871–883. [Google Scholar] [CrossRef]

- Adnan, A.I.; Ong, M.Y.; Nomanbhay, S.; Chew, K.W.; Show, P.L. Technologies for biogas upgrading to biomethane: A review. Bioengineering 2019, 6, 92. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Soleymani, M.; Rosentrater, K. Techno-economic analysis of biofuel production from macroalgae (seaweed). Bioengineering 2017, 4, 92. [Google Scholar] [CrossRef] [Green Version]

- Kang, A.; Lee, T.S. Converting sugars to biofuels: Ethanol and beyond. Bioengineering 2015, 2, 184–203. [Google Scholar] [CrossRef] [Green Version]

- Awogbemi, O.; Kallon, D.V.V. Application of tubular reactor technologies for the acceleration of biodiesel production. Bioengineering 2022, 9, 347. [Google Scholar] [CrossRef] [PubMed]

- Rai, A.K.; Al Makishah, N.H.; Wen, Z.; Gupta, G.; Pandit, S.; Prasad, R. Recent developments in lignocellulosic biofuels, a renewable source of bioenergy. Fermentation 2022, 8, 161. [Google Scholar] [CrossRef]

- Zhao, X.; Wei, L.; Cheng, S.; Julson, J. Review of heterogeneous catalysts for catalytically upgrading vegetable oils into hydrocarbon biofuels. Catalysts 2017, 7, 83. [Google Scholar] [CrossRef] [Green Version]

- Moreira, K.S.; Moura Júnior, L.S.; Monteiro, R.R.C.; de Oliveira, A.L.B.; Valle, C.P.; Freire, T.M.; Fechine, P.B.A.; de Souza, M.C.M.; Fernandez-Lorente, G.; Guisan, J.M.; et al. Optimization of the Production of Enzymatic Biodiesel from Residual Babassu Oil (Orbignya sp.) via RSM. Catalysts 2020, 10, 414. [Google Scholar] [CrossRef] [Green Version]

- de Oliveira, A.L.B.; Cavalcante, F.T.T.; da Silva Moreira, K.; de Castro Monteiro, R.R.; Rocha, T.G.; da Silva Souza, J.E.; da Fonseca, A.M.; Lopes, A.A.S.; Guimarões, A.P.; de Lima, R.K.C.; et al. Lipases immobilized onto nanomaterials as biocatalysts in biodiesel production: Scientific context, challenges, and opportunities. Rev. Virtual Química 2021, 13, 875–891. [Google Scholar] [CrossRef]

- Monteiro, R.R.C.; Arana-Peña, S.; da Rocha, T.N.; Miranda, L.P.; Berenguer-Murcia, Á.; Tardioli, P.W.; dos Santos, J.C.S.; Fernandez-Lafuente, R. Liquid lipase preparations designed for industrial production of biodiesel. Is it really an optimal solution? Renew. Energy 2021, 164, 1566–1587. [Google Scholar] [CrossRef]

- Cavalcante, F.T.T.; Neto, F.S.; Rafael de Aguiar Falcão, I.; Erick da Silva Souza, J.; de Moura Junior, L.S.; da Silva Sousa, P.; Rocha, T.G.; de Sousa, I.G.; de Lima Gomes, P.H.; de Souza, M.C.M.; et al. Opportunities for improving biodiesel production via lipase catalysis. Fuel 2021, 288, 119577. [Google Scholar] [CrossRef]

- Rocha, T.G.; de L Gomes, P.H.; de Souza, M.C.M.; Monteiro, R.R.C.; dos Santos, J.C.S. Lipase cocktail for optimized biodiesel production of free fatty acids from residual chicken oil. Catal. Lett. 2021, 151, 1155–1166. [Google Scholar] [CrossRef]

- Mota, G.F.; de Sousa, I.G.; de Oliveira, A.L.B.; Cavalcante, A.L.G.; da Silva Moreira, K.; Cavalcante, F.T.T.; da Silva Souza, J.E.; de Aguiar Falcão, Í.R.; Rocha, T.G.; Valério, R.B.R.; et al. Biodiesel production from microalgae using lipase-based catalysts: Current challenges and prospects. Algal Res. 2022, 62, 102616. [Google Scholar] [CrossRef]

- Athar, M.; Zaidi, S. A review of the feedstocks, catalysts, and intensification techniques for sustainable biodiesel production. J. Environ. Chem. Eng. 2020, 8, 104523. [Google Scholar] [CrossRef]

- Ma, X.; Gao, M.; Gao, Z.; Wang, J.; Zhang, M.; Ma, Y.; Wang, Q. Past, current, and future research on microalga-derived biodiesel: A critical review and bibliometric analysis. Environ. Sci. Pollut. Res. 2018, 25, 10596–10610. [Google Scholar] [CrossRef]

- Jiang, W.; Aishan, T.; Halik, Ü.; Wei, Z.; Wumaier, M. A Bibliometric and Visualized Analysis of Research Progress and Trends on Decay and Cavity Trees in Forest Ecosystem over 20 Years: An Application of the CiteSpace Software. Forests 2022, 13, 1437. [Google Scholar] [CrossRef]

- Li, N.; Han, R.; Lu, X. Bibliometric analysis of research trends on solid waste reuse and recycling during 1992–2016. Resour. Conserv. Recycl. 2018, 130, 109–117. [Google Scholar] [CrossRef]

- Donthu, N.; Kumar, S.; Mukherjee, D.; Pandey, N.; Lim, W.M. How to conduct a bibliometric analysis: An overview and guidelines. J. Bus. Res. 2021, 133, 285–296. [Google Scholar] [CrossRef]

- Kargbo, D.M. Biodiesel production from municipal sewage sludges. Energy Fuels 2010, 24, 2791–2794. [Google Scholar] [CrossRef]

- Callegari, A.; Hlavinek, P.; Capodaglio, A.G. Production of energy (biodiesel) and recovery of materials (biochar) from pyrolysis of urban waste sludge. Rev. Ambiente Água 2018, 13, 1. [Google Scholar] [CrossRef]

- Tamala, J.K.; Maramag, E.I.; Simeon, K.A.; Ignacio, J.J. A bibliometric analysis of sustainable oil and gas production research using VOSviewer. Clean. Eng. Technol. 2022, 7, 100437. [Google Scholar] [CrossRef]

- Sweileh, W.M.; Al-Jabi, S.W.; AbuTaha, A.S.; Zyoud, S.H.; Anayah, F.M.A.; Sawalha, A.F. Bibliometric analysis of worldwide scientific literature in mobile—Health: 2006–2016. BMC Med. Inform. Decis. Mak. 2017, 17, 72. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Chen, C. CiteSpace II: Detecting and visualizing emerging trends and transient patterns in scientific literature. J. Am. Soc. Inf. Sci. Technol. 2006, 57, 359–377. [Google Scholar] [CrossRef] [Green Version]

- Veillette, M.; Chamoumi, M.; Nikiema, J.; Faucheux, N.; Heitz, M. Production of biodiesel from microalgae. In Advances in Chemical Engineering; InTech: Rijeka, Croatia, 2012. [Google Scholar]

- Shah, S.H. Sustainable biodiesel production. In Encyclopedia of Renewable and Sustainable Materials; Elsevier: Amsterdam, The Netherlands, 2020; pp. 347–355. [Google Scholar]

- Muthukumaran, C.; Sharmila, G.; Manojkumar, N.; Gnanaprakasam, A.; Sivakumar, V.M. Optimization and kinetic modeling of biodiesel production. In Encyclopedia of Renewable and Sustainable Materials; Elsevier: Amsterdam, The Netherlands, 2020; pp. 193–201. [Google Scholar]

- Mata, T.M.; Martins, A.A.; Caetano, N.S. Microalgae for biodiesel production and other applications: A review. Renew. Sustain. Energy Rev. 2010, 14, 217–232. [Google Scholar] [CrossRef] [Green Version]

- Aslam, M.M.; Khan, A.A.; Cheema, H.M.N.; Hanif, M.A.; Azeem, M.W.; Azmat, M.A. Novel mutant camelina and jatropha as valuable feedstocks for biodiesel production. Sci. Rep. 2020, 10, 21868. [Google Scholar] [CrossRef]

- Ghani, N.; Iqbal, J.; Sadaf, S.; Nawaz Bhatti, H.; Asgher, M. Comparison of photo-esterification capability of bismuth vanadate with reduced graphene oxide bismuth vanadate (RGO/BiVO4) composite for biodiesel production from high free fatty acid containing non-edible oil. ChemistrySelect 2020, 5, 9245–9253. [Google Scholar] [CrossRef]

- Mureed, K.; Kanwal, S.; Hussain, A.; Noureen, S.; Hussain, S.; Ahmad, S.; Ahmad, M.; Waqas, R. Biodiesel production from algae grown on food industry wastewater. Environ. Monit. Assess. 2018, 190, 271. [Google Scholar] [CrossRef]

- da Silva Dutra, L.; Costa Cerqueira Pinto, M.; Cipolatti, E.P.; Aguieiras, E.C.G.; Manoel, E.A.; Greco-Duarte, J.; Guimarães Freire, D.M.; Pinto, J.C. How the biodiesel from immobilized enzymes production is going on: An advanced bibliometric evaluation of global research. Renew. Sustain. Energy Rev. 2022, 153, 111765. [Google Scholar] [CrossRef]

- Mahlia, T.M.I.; Syazmi, Z.A.H.S.; Mofijur, M.; Abas, A.E.P.; Bilad, M.R.; Ong, H.C.; Silitonga, A.S. Patent landscape review on biodiesel production: Technology updates. Renew. Sustain. Energy Rev. 2020, 118, 109526. [Google Scholar] [CrossRef]

- Atabani, A.E.; Silitonga, A.S.; Ong, H.C.; Mahlia, T.M.I.; Masjuki, H.H.; Badruddin, I.A.; Fayaz, H. Non-edible vegetable oils: A critical evaluation of oil extraction, fatty acid compositions, biodiesel production, characteristics, engine performance and emissions production. Renew. Sustain. Energy Rev. 2013, 18, 211–245. [Google Scholar] [CrossRef]

- Ahmad, A.L.; Yasin, N.H.M.; Derek, C.J.C.; Lim, J.K. Microalgae as a sustainable energy source for biodiesel production: A review. Renew. Sustain. Energy Rev. 2011, 15, 584–593. [Google Scholar] [CrossRef]

- Halim, R.; Danquah, M.K.; Webley, P.A. Extraction of oil from microalgae for biodiesel production: A review. Biotechnol. Adv. 2012, 30, 709–732. [Google Scholar] [CrossRef] [PubMed]

- Tan, T.; Lu, J.; Nie, K.; Deng, L.; Wang, F. Biodiesel production with immobilized lipase: A review. Biotechnol. Adv. 2010, 28, 628–634. [Google Scholar] [CrossRef] [PubMed]

- Karmakar, A.; Karmakar, S.; Mukherjee, S. Properties of various plants and animals feedstocks for biodiesel production. Bioresour. Technol. 2010, 101, 7201–7210. [Google Scholar] [CrossRef] [PubMed]

- Aransiola, E.F.; Ojumu, T.V.; Oyekola, O.O.; Madzimbamuto, T.F.; Ikhu-Omoregbe, D.I.O. A review of current technology for biodiesel production: State of the art. Biomass Bioenergy 2014, 61, 276–297. [Google Scholar] [CrossRef]

- Koh, M.Y.; Ghazi, T.I.M. A review of biodiesel production from Jatropha curcas L. oil. Renew. Sustain. Energy Rev. 2011, 15, 2240–2251. [Google Scholar] [CrossRef]

- Wahlen, B.D.; Willis, R.M.; Seefeldt, L.C. Biodiesel production by simultaneous extraction and conversion of total lipids from microalgae, cyanobacteria, and wild mixed-cultures. Bioresour. Technol. 2011, 102, 2724–2730. [Google Scholar] [CrossRef]

- Atadashi, I.M.; Aroua, M.K.; Abdul Aziz, A.R.; Sulaiman, N.M.N. The effects of catalysts in biodiesel production: A review. J. Ind. Eng. Chem. 2013, 19, 14–26. [Google Scholar] [CrossRef]

- Martín, C.; Moure, A.; Martín, G.; Carrillo, E.; Domínguez, H.; Parajó, J.C. Fractional characterisation of jatropha, neem, moringa, trisperma, castor and candlenut seeds as potential feedstocks for biodiesel production in Cuba. Biomass Bioenergy 2010, 34, 533–538. [Google Scholar] [CrossRef]

- Srivastava, N.; Srivastava, M.; Gupta, V.K.; Manikanta, A.; Mishra, K.; Singh, S.; Singh, S.; Ramteke, P.W.; Mishra, P.K. Recent development on sustainable biodiesel production using sewage sludge. 3 Biotech 2018, 8, 245. [Google Scholar] [CrossRef]

- Mohiddin, M.N.B.; Tan, Y.H.; Seow, Y.X.; Kansedo, J.; Mubarak, N.M.; Abdullah, M.O.; Chan, Y.S.; Khalid, M. Evaluation on feedstock, technologies, catalyst and reactor for sustainable biodiesel production: A review. J. Ind. Eng. Chem. 2021, 98, 60–81. [Google Scholar] [CrossRef]

- Banković-Ilić, I.B.; Stamenković, O.S.; Veljković, V.B. Biodiesel production from non-edible plant oils. Renew. Sustain. Energy Rev. 2012, 16, 3621–3647. [Google Scholar] [CrossRef]

- Gardy, J.; Osatiashtiani, A.; Céspedes, O.; Hassanpour, A.; Lai, X.; Lee, A.F.; Wilson, K.; Rehan, M. A magnetically separable SO4/Fe-Al-TiO2 solid acid catalyst for biodiesel production from waste cooking oil. Appl. Catal. B Environ. 2018, 234, 268–278. [Google Scholar] [CrossRef] [Green Version]

- Kwon, E.E.; Kim, S.; Jeon, Y.J.; Yi, H. Biodiesel production from sewage sludge: New paradigm for mining energy from municipal hazardous material. Environ. Sci. Technol. 2012, 46, 10222–10228. [Google Scholar] [CrossRef] [PubMed]

- Olkiewicz, M.; Plechkova, N.V.; Fabregat, A.; Stüber, F.; Fortuny, A.; Font, J.; Bengoa, C. Efficient extraction of lipids from primary sewage sludge using ionic liquids for biodiesel production. Sep. Purif. Technol. 2015, 153, 118–125. [Google Scholar] [CrossRef]

- Liu, X.; Zhu, F.; Zhang, R.; Zhao, L.; Qi, J. Recent progress on biodiesel production from municipal sewage sludge. Renew. Sustain. Energy Rev. 2021, 135, 110260. [Google Scholar] [CrossRef]

- Chang, Z.; Long, G.; Zhou, J.L.; Ma, C. Valorization of sewage sludge in the fabrication of construction and building materials: A review. Resour. Conserv. Recycl. 2020, 154, 104606. [Google Scholar] [CrossRef]

- Kumar, M.; Ghosh, P.; Khosla, K.; Thakur, I.S. Biodiesel production from municipal secondary sludge. Bioresour. Technol. 2016, 216, 165–171. [Google Scholar] [CrossRef]

- Kacprzak, M.; Neczaj, E.; Fijałkowski, K.; Grobelak, A.; Grosser, A.; Worwag, M.; Rorat, A.; Brattebo, H.; Almås, Å.; Singh, B.R. Sewage sludge disposal strategies for sustainable development. Environ. Res. 2017, 156, 39–46. [Google Scholar] [CrossRef]

- Arazo, R.O.; de Luna, M.D.G.; Capareda, S.C. Assessing biodiesel production from sewage sludge-derived bio-oil. Biocatal. Agric. Biotechnol. 2017, 10, 189–196. [Google Scholar] [CrossRef]

- Balasubramanian, S.; Tyagi, R.D. Value-added bio-products from sewage sludge. In Current Developments in Biotechnology and Bioengineering; Elsevier: Amsterdam, The Netherlands, 2017; pp. 27–42. [Google Scholar]

- Wu, X.; Zhu, F.; Qi, J.; Zhao, L. Biodiesel production from sewage sludge by using alkali catalyst catalyze. Procedia Environ. Sci. 2016, 31, 26–30. [Google Scholar] [CrossRef] [Green Version]

- Navia, R.; Mittelbach, M. Could sewage sludge be considered a source of waste lipids for biodiesel production? Waste Manag. Res. 2012, 30, 873–874. [Google Scholar] [CrossRef] [PubMed]

- Branco-Vieira, M.; Mata, T.M.; Martins, A.A.; Freitas, M.A.V.; Caetano, N.S. Economic analysis of microalgae biodiesel production in a small-scale facility. Energy Rep. 2020, 6, 325–332. [Google Scholar] [CrossRef]

- Reza Talaghat, M.; Mokhtari, S.; Saadat, M. Modeling and optimization of biodiesel production from microalgae in a batch reactor. Fuel 2020, 280, 118578. [Google Scholar] [CrossRef]

- Mubarak, M.; Shaija, A.; Suchithra, T. Flocculation: An effective way to harvest microalgae for biodiesel production. J. Environ. Chem. Eng. 2019, 7, 103221. [Google Scholar] [CrossRef]

- Dev Sarkar, R.; Singh, H.B.; Chandra Kalita, M. Enhanced lipid accumulation in microalgae through nanoparticle-mediated approach, for biodiesel production: A mini-review. Heliyon 2021, 7, e08057. [Google Scholar] [CrossRef] [PubMed]

- Enwereuzoh, U.; Harding, K.; Low, M. Microalgae cultivation using nutrients in fish farm effluent for biodiesel production. S. Afr. J. Chem. Eng. 2021, 37, 46–52. [Google Scholar] [CrossRef]

- Amenaghawon, A.N.; Obahiagbon, K.; Isesele, V.; Usman, F. Optimized biodiesel production from waste cooking oil using a functionalized bio-based heterogeneous catalyst. Clean. Eng. Technol. 2022, 8, 100501. [Google Scholar] [CrossRef]

- Suzihaque, M.U.H.; Syazwina, N.; Alwi, H.; Ibrahim, U.K.; Abdullah, S.; Haron, N. A sustainability study of the processing of kitchen waste as a potential source of biofuel: Biodiesel production from waste cooking oil (WCO). Mater. Today Proc. 2022, 63, S484–S489. [Google Scholar] [CrossRef]

- Falowo, O.A.; Oladipo, B.; Taiwo, A.E.; Olaiya, A.T.; Oyekola, O.O.; Betiku, E. Green heterogeneous base catalyst from ripe and unripe plantain peels mixture for the transesterification of waste cooking oil. Chem. Eng. J. Adv. 2022, 10, 100293. [Google Scholar] [CrossRef]

- Cordero-Ravelo, V.; Schallenberg-Rodriguez, J. Biodiesel production as a solution to waste cooking oil (WCO) disposal. Will any type of WCO do for a transesterification process? A quality assessment. J. Environ. Manag. 2018, 228, 117–129. [Google Scholar] [CrossRef] [PubMed]

- Chen, C.; Chitose, A.; Kusadokoro, M.; Nie, H.; Xu, W.; Yang, F.; Yang, S. Sustainability and challenges in biodiesel production from waste cooking oil: An advanced bibliometric analysis. Energy Rep. 2021, 7, 4022–4034. [Google Scholar] [CrossRef]

- Aghbashlo, M.; Tabatabaei, M.; Amid, S.; Hosseinzadeh-Bandbafha, H.; Khoshnevisan, B.; Kianian, G. Life cycle assessment analysis of an ultrasound-assisted system converting waste cooking oil into biodiesel. Renew. Energy 2020, 151, 1352–1364. [Google Scholar] [CrossRef]

- Gouran, A.; Aghel, B.; Nasirmanesh, F. Biodiesel production from waste cooking oil using wheat bran ash as a sustainable biomass. Fuel 2021, 295, 120542. [Google Scholar] [CrossRef]

- Rezania, S.; Oryani, B.; Park, J.; Hashemi, B.; Yadav, K.K.; Kwon, E.E.; Hur, J.; Cho, J. Review on transesterification of non-edible sources for biodiesel production with a focus on economic aspects, fuel properties and by-product applications. Energy Convers. Manag. 2019, 201, 112155. [Google Scholar] [CrossRef]

- Ferrero, G.O.; Sánchez Faba, E.M.; Rickert, A.A.; Eimer, G.A. Alternatives to rethink tomorrow: Biodiesel production from residual and non-edible oils using biocatalyst technology. Renew. Energy 2020, 150, 128–135. [Google Scholar] [CrossRef]

- Patel, N.K.; Shah, S.N. Biodiesel from plant oils. In Food, Energy, and Water; Elsevier: Amsterdam, The Netherlands, 2015; pp. 277–307. [Google Scholar]

- Wang, H.; Zhang, W.; Zhang, Y.; Xu, J. A bibliometric review on stability and reinforcement of special soil subgrade based on CiteSpace. J. Traffic Transp. Eng. Engl. Ed. 2022, 9, 223–243. [Google Scholar] [CrossRef]

- Wilks, D.S. Cluster Analysis. In International Geophysics; Elsevier: Amsterdam, The Netherlands, 2011; Volume 100, pp. 603–616. [Google Scholar] [CrossRef]

- Chattopadhyay, A.; Mitra, M.; Maiti, M.K. Recent advances in lipid metabolic engineering of oleaginous yeasts. Biotechnol. Adv. 2021, 53, 107722. [Google Scholar] [CrossRef]

- Chtourou, H.; Dahmen, I.; Jebali, A.; Karray, F.; Hassairi, I.; Abdelkafi, S.; Ayadi, H.; Sayadi, S.; Dhouib, A. Characterization of Amphora sp., a newly isolated diatom wild strain, potentially usable for biodiesel production. Bioprocess Biosyst. Eng. 2015, 38, 1381–1392. [Google Scholar] [CrossRef]

- El-Sheekh, M.; Abomohra, A.E.-F.; Eladel, H.; Battah, M.; Mohammed, S. Screening of different species of scenedesmus isolated from Egyptian freshwater habitats for biodiesel production. Renew. Energy 2018, 129, 114–120. [Google Scholar] [CrossRef]

- Abomohra, A.E.-F.; El-Naggar, A.H.; Baeshen, A.A. Potential of macroalgae for biodiesel production: Screening and evaluation studies. J. Biosci. Bioeng. 2018, 125, 231–237. [Google Scholar] [CrossRef] [PubMed]

- Kosiński, S.; Rykowska, I.; Gonsior, M.; Krzyżanowski, P. Ionic liquids as antistatic additives for polymer composites—A review. Polym. Test. 2022, 112, 107649. [Google Scholar] [CrossRef]

- Mansir, N.; Teo, S.H.; Rashid, U.; Saiman, M.I.; Tan, Y.P.; Alsultan, G.A.; Taufiq-Yap, Y.H. Modified waste egg shell derived bifunctional catalyst for biodiesel production from high FFA waste cooking oil. A review. Renew. Sustain. Energy Rev. 2018, 82, 3645–3655. [Google Scholar] [CrossRef]

- Zhang, J.; Chen, S.; Yang, R.; Yan, Y. Biodiesel production from vegetable oil using heterogenous acid and alkali catalyst. Fuel 2010, 89, 2939–2944. [Google Scholar] [CrossRef]

- Petchsoongsakul, N.; Ngaosuwan, K.; Kiatkittipong, W.; Aiouache, F.; Assabumrungrat, S. Process design of biodiesel production: Hybridization of ester-and transesterification in a single reactive distillation. Energy Convers. Manag. 2017, 153, 493–503. [Google Scholar] [CrossRef]

- Zeng, D.; Li, R.; Wang, B.; Xu, J.; Fang, T. A review of transesterification from low-grade feedstocks for biodiesel production with supercritical methanol. Russ. J. Appl. Chem. 2014, 87, 1176–1183. [Google Scholar] [CrossRef]

- Soares, D.; Pinto, A.F.; Gonçalves, A.G.; Mitchell, D.A.; Krieger, N. Biodiesel production from soybean soapstock acid oil by hydrolysis in subcritical water followed by lipase-catalyzed esterification using a fermented solid in a packed-bed reactor. Biochem. Eng. J. 2013, 81, 15–23. [Google Scholar] [CrossRef]

- Jain, S.; Sharma, M.P. Biodiesel Production from Jatropha curcas Oil. Renew. Sustain. Energy Rev. 2010, 14, 3140–3147. [Google Scholar] [CrossRef]

- Gonfa Keneni, Y.; Mario Marchetti, J. Oil extraction from plant seeds for biodiesel production. AIMS Energy 2017, 5, 316–340. [Google Scholar] [CrossRef]

- Silitonga, A.S.; Masjuki, H.H.; Ong, H.C.; Yusaf, T.; Kusumo, F.; Mahlia, T.M.I. Synthesis and optimization of hevea brasiliensis and ricinus communis as feedstock for biodiesel production: A comparative study. Ind. Crops Prod. 2016, 85, 274–286. [Google Scholar] [CrossRef]

- Atabani, A.E.; César, A.d.S. Calophyllum inophyllum L.—A prospective non-edible biodiesel feedstock. Study of biodiesel production, properties, fatty acid composition, blending and engine performance. Renew. Sustain. Energy Rev. 2014, 37, 644–655. [Google Scholar] [CrossRef]

- Adachi, D.; Koda, R.; Hama, S.; Yamada, R.; Nakashima, K.; Ogino, C.; Kondo, A. An integrative process model of enzymatic biodiesel production through ethanol fermentation of brown rice followed by lipase-catalyzed ethanolysis in a water-containing system. Enzym. Microb. Technol. 2013, 52, 118–122. [Google Scholar] [CrossRef]

- Lokman, I.M.; Rashid, U.; Yunus, R.; Taufiq-Yap, Y.H. Carbohydrate-derived solid acid catalysts for biodiesel production from low-cost feedstocks: A review. Catal. Rev. 2014, 56, 187–219. [Google Scholar] [CrossRef]

- Zul, N.A.; Ganesan, S.; Hamidon, T.S.; Oh, W.-D.; Hussin, M.H. A review on the utilization of calcium oxide as a base catalyst in biodiesel production. J. Environ. Chem. Eng. 2021, 9, 105741. [Google Scholar] [CrossRef]

- Mazaheri, H.; Ong, H.C.; Amini, Z.; Masjuki, H.H.; Mofijur, M.; Su, C.H.; Anjum Badruddin, I.; Khan, T.M.Y. An overview of biodiesel production via calcium oxide based catalysts: Current state and perspective. Energies 2021, 14, 3950. [Google Scholar] [CrossRef]

- Peñarrubia Fernandez, I.A.; Liu, D.-H.; Zhao, J. LCA studies comparing alkaline and immobilized enzyme catalyst processes for biodiesel production under brazilian conditions. Resour. Conserv. Recycl. 2017, 119, 117–127. [Google Scholar] [CrossRef]

- Moser, B.R.; Vaughn, S.F. Efficacy of fatty acid profile as a tool for screening feedstocks for biodiesel production. Biomass Bioenergy 2012, 37, 31–41. [Google Scholar] [CrossRef]

- Chen, C. CiteSpace: A Practical Guide for Mapping Scientific Literature; Nova Science: New York, NY, USA, 2016. [Google Scholar]

- Maheshwari, P.; Haider, M.B.; Yusuf, M.; Klemeš, J.J.; Bokhari, A.; Beg, M.; Al-Othman, A.; Kumar, R.; Jaiswal, A.K. A review on latest trends in cleaner biodiesel production: Role of feedstock, production methods, and catalysts. J. Clean. Prod. 2022, 355, 131588. [Google Scholar] [CrossRef]

- Ambat, I.; Srivastava, V.; Sillanpää, M. Recent advancement in biodiesel production methodologies using various feedstock: A review. Renew. Sustain. Energy Rev. 2018, 90, 356–369. [Google Scholar] [CrossRef]

- Bergmann, J.; Tupinambá, D.; Costa, O.Y.; Almeida, J.R.; Barreto, C.; Quirino, B. Biodiesel production in brazil and alternative biomass feedstocks. Renew. Sustain. Energy Rev. 2013, 21, 411–420. [Google Scholar] [CrossRef]

| Rank | Journal | C | IF | NP | NC | AC | P |

|---|---|---|---|---|---|---|---|

| 1 | Renewable & sustainable energy reviews | USA | 14.982 | 33 | 8250 | 250 | 9.9% |

| 2 | Bioresource technology | NL | 9.642 | 16 | 1785 | 111.5 | 4.8% |

| 3 | Energy conversion and management | EN | 9.709 | 13 | 789 | 61.4 | 3.9% |

| 4 | Biomass & bioenergy | EN | 5.061 | 6 | 750 | 125 | 1.8% |

| 5 | Fuel | EN | 6.609 | 18 | 729 | 40.5 | 5.4% |

| 6 | Biofuels, bioproducts & biorefining—Biofpr | EN | 4.102 | 5 | 151 | 30.2 | 1.5% |

| 7 | Journal of environmental chemical engineering | EN | 5.909 | 4 | 63 | 15.7 | 1.2% |

| 8 | Catalysts | CH | 4.146 | 6 | 59 | 9.8 | 1.8% |

| 9 | Biofuels-UK | EN | 2.956 | 4 | 57 | 14.2 | 1.2% |

| 10 | Environmental chemistry letters | GER | 9.027 | 4 | 53 | 13.2 | 1.2% |

| Rank | Country | NP | NC | AC | Total Link Strength | AC |

|---|---|---|---|---|---|---|

| 1 | China | 53 | 2555 | 48.2 | 169 | 250 |

| 2 | Malaysia | 48 | 3715 | 77.4 | 353 | 111.5 |

| 3 | India | 48 | 2190 | 45.6 | 252 | 61.4 |

| 4 | United States of America | 33 | 2030 | 61.5 | 116 | 125 |

| 5 | Thailand | 17 | 164 | 9.6 | 55 | 40.5 |

| 6 | Indonesia | 16 | 1309 | 81.8 | 134 | 30.2 |

| 7 | Brazil | 15 | 531 | 35.4 | 51 | 15.7 |

| 8 | Italy | 13 | 164 | 12.6 | 42 | 9.8 |

| 9 | Serbia | 12 | 920 | 76.6 | 82 | 14.2 |

| 10 | Saudi Arabia | 12 | 492 | 41.0 | 100 | 13.2 |

| Rank | Article Title | Authors | Year Published | Citations |

|---|---|---|---|---|

| 1 | Microalgae for biodiesel production and other applications: A review [27]. | Mata, Teresa M.; Martins, Antonio A.; Caetano, Nidia. S. | 2010 | 3162 |

| 2 | Non-edible vegetable oils: A critical evaluation of oil extraction, fatty acid compositions, biodiesel production, characteristics, engine performance, and emissions production [33]. | Atabani, A. E.; Silitonga, A. S.; Ong, H. C.; Mahlia, T. M. I.; Masjuki, H. H.; Badruddin, Irfan Anjum; Fayaz, H. | 2013 | 645 |

| 3 | Microalgae as a sustainable energy source for biodiesel production: A review [34]. | Ahmad, A. L.; Yasin, N. H. Mat; Derek, C. J. C.; Lim, J. K. | 2011 | 590 |

| 4 | Extraction of oil from microalgae for biodiesel production: A review [35]. | Halim, Ronald; Danquah, Michael K.; Webley, Paul A. | 2012 | 586 |

| 5 | Biodiesel production with immobilized lipase: A review [36]. | Tan, Tianwei; Lu, Jike; Nie, Kaili; Deng, Li; Wang, Fang | 2010 | 457 |

| 6 | Properties of various plants and animal feedstocks for biodiesel production [37]. | Karmakar, Aninidita; Karmakar, Subrata; Mukherjee, Souti | 2010 | 421 |

| 7 | A review of current technology for biodiesel production: State of the art [38]. | Aransiola, E. F.; Ojumu, T. V.; Oyekola, O. O.; Madzimbamuto, T. F.; Ikhu-Omoregbe, D. I. O. | 2014 | 368 |

| 8 | A review of biodiesel production from jatropha curcas L. oil [39]. | Koh, May Ying; Ghazi, Tinia Idaty Mohd | 2011 | 365 |

| 9 | Biodiesel production by simultaneous extraction and conversion of total lipids from microalgae, cyanobacteria, and wild mixed-cultures [40]. | Wahlen, Bradley D.; Willis, Robert M.; Seefeldt, Lance C. | 2011 | 319 |

| 10 | The effects of catalysts in biodiesel production: A review [41]. | Atadashi, I. M.; Aroua, M. K.; Aziz, A. R. Abdul; Sulaiman, N. M. N. | 2013 | 308 |

| Rank | Keyword | Frequency | TLS | Rank | Keyword | Frequency | TLS |

|---|---|---|---|---|---|---|---|

| 1 | biodiesel | 225 | 978 | 13 | performance | 31 | 170 |

| 2 | transesterification | 145 | 714 | 14 | fuel production | 31 | 183 |

| 3 | waste cooking oil | 91 | 475 | 15 | lipase | 27 | 136 |

| 4 | optimization | 62 | 323 | 16 | Jatropha curcas | 26 | 130 |

| 5 | feedstocks | 61 | 285 | 17 | heterogeneous catalyst | 26 | 137 |

| 6 | soybean oil | 60 | 336 | 18 | free fatty acids | 25 | 158 |

| 7 | esterification | 50 | 272 | 19 | seed oil | 24 | 133 |

| 8 | vegetable oil | 47 | 252 | 20 | extraction | 22 | 100 |

| 9 | oil | 40 | 149 | 21 | in situ transesterification | 20 | 104 |

| 10 | microalgae | 40 | 189 | 22 | rapeseed oil | 20 | 111 |

| 11 | palm oil | 35 | 205 | 23 | vegetable oil | 20 | 111 |

| 12 | fuel | 31 | 159 | 24 | kinetics | 20 | 127 |

| CID | Label | NS | Mean | Top Five Terms | Representative Articles |

|---|---|---|---|---|---|

| #0 | oleaginous yeast | 70 | 2015 | oleaginous yeast; lipid extraction; wild strain; Egyptian freshwater habitat; different species. | (CHTOUROU, 2015) and (EL-SHEEKH, 2018) |

| #1 | ionic liquid | 63 | 2014 | ionic liquid; ultrasound-assisted transesterification; using calcium oxide catalyst; economic variable; acyl acceptor. | (ZHANG, 2010) and (MANSIR, 2018) |

| #2 | process design | 54 | 2013 | process design; heterogeneous catalyst; subcritical water; packed bed reactor; soybean soap stock acid oil. | (ZENG, 2014) and (SOARES, 2013) |

| #3 | oil extraction | 47 | 2014 | oil extraction; plant seed; Ricinus communis; Hevea brasiliensis; Calophyllum inophyllum L. | (KENENI, 2017) and (SILITONGA, 2016) |

| #4 | enzymatic biodiesel production | 42 | 2013 | enzymatic biodiesel production; low-cost feedstock; carbohydrate-derived solid acid catalyst; brown rice; ethanol fermentation. | (ADACHI, 2016) and (LOKMAN, 2014) |

| #5 | calcium oxide | 27 | 2016 | calcium oxide; current state; technological progress; different type; LCA studies. | (MAZAHERI, 2021) and (FERNANDEZ, PENARRUBIA, 2017) |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Sales, M.B.; Borges, P.T.; Ribeiro Filho, M.N.; Miranda da Silva, L.R.; Castro, A.P.; Sanders Lopes, A.A.; Chaves de Lima, R.K.; de Sousa Rios, M.A.; Santos, J.C.S.d. Sustainable Feedstocks and Challenges in Biodiesel Production: An Advanced Bibliometric Analysis. Bioengineering 2022, 9, 539. https://doi.org/10.3390/bioengineering9100539

Sales MB, Borges PT, Ribeiro Filho MN, Miranda da Silva LR, Castro AP, Sanders Lopes AA, Chaves de Lima RK, de Sousa Rios MA, Santos JCSd. Sustainable Feedstocks and Challenges in Biodiesel Production: An Advanced Bibliometric Analysis. Bioengineering. 2022; 9(10):539. https://doi.org/10.3390/bioengineering9100539

Chicago/Turabian StyleSales, Misael B., Pedro T. Borges, Manoel Nazareno Ribeiro Filho, Lizandra Régia Miranda da Silva, Alyne P. Castro, Ada Amelia Sanders Lopes, Rita Karolinny Chaves de Lima, Maria Alexsandra de Sousa Rios, and José C. S. dos Santos. 2022. "Sustainable Feedstocks and Challenges in Biodiesel Production: An Advanced Bibliometric Analysis" Bioengineering 9, no. 10: 539. https://doi.org/10.3390/bioengineering9100539

APA StyleSales, M. B., Borges, P. T., Ribeiro Filho, M. N., Miranda da Silva, L. R., Castro, A. P., Sanders Lopes, A. A., Chaves de Lima, R. K., de Sousa Rios, M. A., & Santos, J. C. S. d. (2022). Sustainable Feedstocks and Challenges in Biodiesel Production: An Advanced Bibliometric Analysis. Bioengineering, 9(10), 539. https://doi.org/10.3390/bioengineering9100539