Computer Vision Method in Beer Quality Evaluation—A Review

Abstract

:1. Introduction

2. Computer Vision and Image Analysis-Basics

2.1. Illumination

- maximizing the contrast of the features that must be inspected or measured

- minimizing the contrast of the features of no interest

- getting rid of unwanted variations caused by ambient light and differences between items that are non-relevant to the inspection task.

- daylight illuminants lamps (illuminants that represent daylight conditions): C lamp, D50 lamp and D65 lamp

- incandescent/tungsten lamps: A lamp

- fluorescent lamps: F2 lamp (cool white fluorescent), F7 lamp, and F11 lamp

- special light sources.

- reflected and/or

- transmitted and/or

- absorbed and/or

- strayed.

- direct incident light (front light)

- ○

- vertical illumination from above,

- ○

- ring illumination,

- ○

- angular illumination;

- incident lighting with a diffuser

- ○

- flat,

- ○

- coaxial,

- ○

- dome-shaped;

- lateral light at angles—at angles from one side or all around;

- shallowly—illumination at a shallow angle from all sides: dark field illumination (usually uses a low angle ring light that is mounted very close to the object where the light rays from the light source are not reflected into the camera lens, but only a proportion of light that is scattered by an uneven surface);

- backlighting—transmitted light from the opposite side of the object (backlit image);

2.2. Image Acquisition Devices

- Field of View (FOV)—visible object area photographed;

- Working Distance (WD)—the distance between the lens front and the inspected object;

- Resolution—number of pixels or number of minimal parts of the object that can be distinguished by digital imaging;

- Depth of Field (DOF)—the maximum depth tenable in acceptable focus;

- Sensor Size—the active area size of the camera sensor;

- Camera.

2.3. Hardware and Supplied Software

3. Digital Image Analysis

4. Perception and Measuring of Beer Color

5. Bubble Size Distribution and Nucleation in Beer

- Image (photographic) analysis methods—analysis of the captured images of bubbles;

- Optical probe methods—analysis of the bubble penetration length in the area of intensive bubbles migration;

- Electrical conductivity (resistivity) probe methods—analysis of the bubble volume with ultrasound/isokinetic sampling probes.

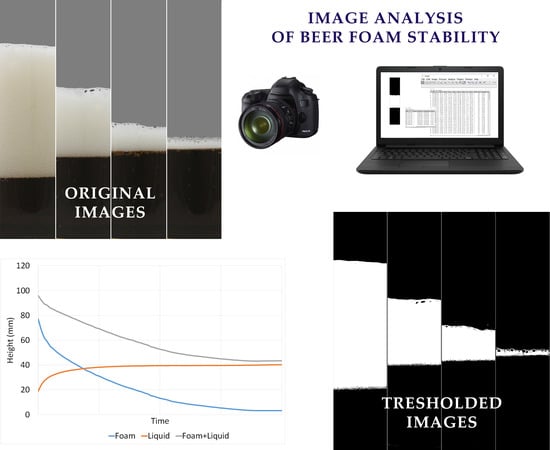

6. Foam Stability (Head Retention)

7. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Mastanjević, K.; Krstanović, V.; Lukinac, J.; Jukić, M.; Lučan, M.; Mastanjević, K. Craft brewing—Is it really about the sensory revolution? Kvas. Prum. 2019, 65, 13–16. [Google Scholar] [CrossRef]

- Gonzalez-Viejo, C.; Fuentes, S.; Li, G.J.; Collmann, R.; Conde, B.; Torrico, D. Development of a robotic pourer constructed with ubiquitous materials, open hardware and sensors to assess beer foam quality using computer vision and pattern recognition algorithms: RoboBEER. Food Res. Int. 2016, 89, 504–513. [Google Scholar] [CrossRef] [PubMed]

- Baert, J.J.; De Clippeleer, J.; Hughes, P.S.; De Cooman, L.; Aerts, G. On the origin of free and bound staling aldehydes in beer. J. Agric. Food Chem. 2012, 60, 11449–11472. [Google Scholar] [CrossRef] [PubMed]

- Cooper, D.J.; Husband, F.A.; Mills, E.N.C.; Wilde, P.J. Role of beer lipid-binding proteins in preventing lipid destabilization of foam. J. Agric. Food Chem. 2002, 50, 7645–7650. [Google Scholar] [CrossRef] [PubMed]

- Ebienfa, P.; Grudanov, V.; Ermakov, A.; Pozdniakov, V. Improving the process of roasting malt with intensive stirring machine. Ukr. Food J. 2015, 4, 95–108. [Google Scholar]

- Bellido-Milla, D.; Moreno-Perez, J.M.; Hernández-Artiga, M.P. Differentiation and classification of beers with flame atomic spectrometry and molecular absorption spectrometry and sample preparation assisted by microwaves. Spectrochim. Acta Part B 2000, 55, 855–864. [Google Scholar] [CrossRef]

- Duarte, I.F.; Barros, A.; Almeida, C.; Spraul, M.; Gil, A.M. Multivariate analysis of NMR and FTIR data as a potential tool for the quality control of beer. J. Agric. Food Chem. 2004, 52, 1031–1038. [Google Scholar] [CrossRef]

- Lachenmeier, D.W.; Frank, W.; Humpfer, E.; Schäfer, H.; Keller, S.; Mörtter, M. Quality control of beer using high-resolution nuclear magnetic resonance spectroscopy and multivariate analysis. Eur. Food Res. Technol. 2005, 220, 215–221. [Google Scholar] [CrossRef]

- Lachenmeier, D.W. Rapid quality control of spirit drinks and beer using multivariate data analysis of Fourier transform infrared spectra. Food Chem. 2007, 101, 825–832. [Google Scholar] [CrossRef]

- Patel, K.K.; Kar, A.; Jha, S.N.; Khan, M.A. Machine vision system: A tool for quality inspection of food and agricultural products. J. Food Sci. Technol. 2012, 49, 123–141. [Google Scholar] [CrossRef]

- Lukinac, J.; Jukić, M.; Mastanjević, K.; Lučan, M. Application of computer vision and image analysis method in cheese-quality evaluation: A review. Ukr. Food J. 2018, 7, 192–214. [Google Scholar] [CrossRef]

- Wu, D.; Sun, D.W. Food colour measurement using computer vision. In Instrumental Assessment of Food Sensory Quality, 1st ed.; Kilcast, D., Ed.; Woodhead Publishing Ltd.: Cambridge, UK, 2013; pp. 165–189. [Google Scholar]

- Abdullah, M.Z. Image Acquisition System. In Computer Vision Technology for Food Quality Evaluation, 2nd ed.; Sun, D.-W., Ed.; Academic Press: San Diego, CA, USA, 2016; pp. 3–43. [Google Scholar]

- Brosnan, T.; Sun, D.-W. Improving quality inspection of food products by computer vision—A review. J. Food Eng. 2004, 61, 3–16. [Google Scholar] [CrossRef]

- Sun, D.-W. Computer Vision Technology for Food Quality Evaluation, 1st ed.; Sun, D.-W., Ed.; Academic Press: San Diego, CA, USA, 2008. [Google Scholar]

- Davies, E.R. Computer and Machine Vision, Theory, Algorithms, Practicalities, 4th ed.; Mirmehdi, M., Ed.; Academic Press: Oxford, UK, 2012. [Google Scholar]

- Wang, H.-H.; Sun, D.-W. Correlation between cheese meltability determined with a computer vision method and with Arnott and Schreiber. J. Food Sci. 2002, 67, 745–749. [Google Scholar] [CrossRef]

- Moeslund, T.B. Image acquisition. In Introduction to Video and Image Processing. Building Real Systems and Applications, 1st ed.; Moeslund, T.B., Ed.; Springer London Ltd.: London, UK, 2012; pp. 7–24. [Google Scholar]

- Gunasekaran, S. Computer vision technology for food quality assurance. Trends Food Sci. Technol. 1996, 7, 245–256. [Google Scholar] [CrossRef]

- Batchelor, B.G. Machine Vision Handbook, 1st ed.; Batchelor, B.G., Ed.; Springer London Ltd.: London, UK, 2012. [Google Scholar]

- Pedreschi, F.; Leon, J.; Mery, D.; Moyano, P. Development of a computer vision system to measure the color of potato chips. Food Res. Int. 2006, 39, 1092–1098. [Google Scholar] [CrossRef]

- Zuech, N. Machine Vision and Lighting. Machine Vision on Line. 2004. Available online: https://www.visiononline.org/vision-resources-details.cfm/vision-resources/Machine-Vision-and-Lighting/content_id/1269 (accessed on 25 January 2019).

- Abdullah, M.Z.; Abdul-Aziz, S.; Dos-Mohamed, A.M. Quality inspection of bakery products using colour-based machine vision system. J. Food Qual. 2000, 23, 39–50. [Google Scholar] [CrossRef]

- Choudhury, A.K.R. Colour measurement instruments. In Principles of Colour and Appearance Volume 1: Object Appearance, Colour Perception and Instrumental Measurement, 1st ed.; Choudhury, A.K.R., Ed.; Woodhead Publishing: Cambridge, UK, 2014; pp. 221–269. [Google Scholar]

- Sliwinska, M.; Wisniewska, P.; Dymerski, T.; Namiesnik, J.; Wardenki, W. Food analysis using artificial senses. J. Agric. Food Chem. 2014, 62, 1423–1448. [Google Scholar] [CrossRef] [PubMed]

- Waltham, N. CCD and CMOS sensors. In Observing Photons in Space. A Guide to Experimental Space Astronomy, 2nd ed.; Huber, M.C.E., Pauluhn, A., Culhane, J.L., Timothy, J.G., Wilhelm, K., Zehnder, A., Eds.; Springer: New York, NY, USA, 2013; pp. 443–453. [Google Scholar]

- Zhang, B.; Huang, W.; Li, J.; Zhao, C.; Fan, S.; Wu, J.; Liu, C. Principles, developments and applications of computer vision for external quality inspection of fruits and vegetables, A review. Food Res. Int. 2014, 62, 326–343. [Google Scholar] [CrossRef]

- Sun, D.W. Inspecting pizza topping percentage and distribution by a computer vision method. J. Food Eng. 2000, 44, 245–249. [Google Scholar] [CrossRef]

- Sun, D.-W. Computer vision-an objective, rapid and non-contact quality evaluation tool for the food industry. J. Food Eng. 2004, 61, 1–2. [Google Scholar] [CrossRef]

- Ying, Y.; Jing, H.; Tao, Y.; Zhang, N. Detecting stem and shape of pears using fourier transformation and an artificial neural network. Trans. ASAE 2003, 46, 157–162. [Google Scholar] [CrossRef]

- Hughes, P.S.; Baxter, E.D. Beer: Quality, Safety and Nutritional Aspects; Righelato, R., Ed.; Royal Society of Chemistry: Cambridge, UK, 2001. [Google Scholar]

- De Schutter, D.P.; Saison, D.; Delvaux, F.; Derdelinckx, G.; Delvaux, F.R. The chemistry of aging beer. In Beer in Health and Disease Prevention, 1st ed.; Preedy, V.R., Ed.; Academic Press Inc.: New York, NY, USA, 2008; pp. 375–388. [Google Scholar]

- Lewis, M.J.; Bamforth, C.W. Essays in Brewing Science, 1st ed.; Lewis, M.J., Bamforth, C.W., Eds.; Springer: New York, NY, USA, 2006; pp. 20–27. [Google Scholar]

- Pozdrik, R.; Roddick, F.A.; Rogers, P.J.; Nguyen, T. Spectrophotometric method for exploring 3-methyl-2-butene-1-thiol (MBT) Formation in Lager. J. Agric. Food Chem. 2006, 5, 6123–6129. [Google Scholar] [CrossRef]

- Nursten, H.E. The Maillard Reaction, Chemistry, Biochemistry and Implication, 1st ed.; Baynes, J.W., Ed.; The Royal Society of Chemistry: Cambridge, UK, 2005. [Google Scholar]

- Park, C.W.; Kang, K.O.; Kim, W.J. Effects of reaction conditions for improvement of caramelization rate. Korean J. Food Sci. Technol. 1998, 30, 983–987. [Google Scholar]

- Committee of the EBC. Analytica EBC; Schweizer Brauerei-Rundschau: Zurich, Switzerland, 1975. [Google Scholar]

- Smedley, S.M. Colour determination of beer using tristimulus values. J. Inst. Brew. 1992, 98, 497–504. [Google Scholar] [CrossRef]

- De Lange, A.J. Color. In Brewing Materials and Processes. A Practical Approach to Beer Excellence, 1st ed.; Bamforth, C.W., Ed.; Academic Press Elsevier: London, UK, 2016; pp. 199–249. [Google Scholar]

- De Lange, A.J. The standard reference method of beer color specification as the basis for a new method of beer color reporting. J. Am. Soc. Brew. Chem. 2008, 66, 143–150. [Google Scholar]

- Davies, N.L. Perception of color and flavor in malt. MBAA Tech. Q. 2010, 474, 12–16. [Google Scholar] [CrossRef]

- Yagiz, Y.; Balaban, M.O.; Kristinsson, H.G.; Welt, B.A.; Marshall, M.R. Comparison of Minolta colorimeter and machine vision system in measuring colour of irradiated Atlantic salmon. J. Sci. Food Agric. 2009, 89, 728–730. [Google Scholar] [CrossRef]

- Leon, K.; Mery, D.; Pedreschi, F.; Leon, J. Color measurement in L*a*b* units from RGB digital images. Food Res. Int. 2006, 39, 1084–1091. [Google Scholar] [CrossRef]

- Silva, T.C.O.; Godinho, M.S.; De Oliveira, A.E. Identification of pale lager beers via image analysis. Lat. Am. Appl. Res. 2011, 41, 141–145. [Google Scholar]

- Nikolova, K.T.; Gabrova, R.; Boyadzhiev, D.; Pisanova, E.S.; Ruseva, J.; Yanakiev, D. Classification of different types of beer according to their colour characteristics. J. Phys. Conf. Ser. 2017, 794, 1742–6596. [Google Scholar] [CrossRef]

- Mastanjević, K.; Krstanović, V.; Lukinac, J.; Jukić, M.; Vulin, Z.; Mastanjević, K. Beer–The Importance of colloidal stability (non-biological haze). Fermentation 2018, 4, 91. [Google Scholar] [CrossRef]

- Bamforth, C.W. The relative significance of physics and chemistry for beer foam excellence: Theory and practice. J. Inst. Brew. 2004, 110, 259–266. [Google Scholar] [CrossRef]

- Bamforth, C.W. The foaming properties of beer. J. Inst. Brew. 1985, 91, 370–383. [Google Scholar] [CrossRef]

- Saxena, S.C.; Patel, D.; Smith, D.N.; Ruether, J.A. An assessment of experimental techniques for the measurement of bubble size in a bubble slurry reactor as applied to indirect coal liquefaction. Chem. Eng. Commun. 1988, 63, 87–127. [Google Scholar] [CrossRef]

- Shafer, N.E.; Zare, R.N. Through a beer glass darkly. Phys. Today 1991, 44, 48–52. [Google Scholar] [CrossRef]

- Lubetkin, S.; Blackwell, B. The nucleation of bubbles in supersaturated solutions. J. Colliods Interface Sci. 1988, 26, 610–615. [Google Scholar] [CrossRef]

- Liger-Belair, G.; Marchal, R.; Robillard, B.; Vignes-Adler, M.; Maujean, A.; Jeandet, P. Study of effervescence in a glass of champagne: Frequencies of bubble formation, growth rates, and velocities of rising bubbles. Am. J. Enol. Vitic. 1999, 50, 317–323. [Google Scholar]

- Hepworth, N.J.; Hammond, J.R.M.; Varley, J. Novel application of computer vision to determine bubble size distributions in beer. J. Food Eng. 2004, 61, 119–124. [Google Scholar] [CrossRef]

- Hepworth, N.J.; Boyd, J.W.R.; Hammond, J.R.M.; Varley, J. Modelling the effect of liquid motion on bubble nucleation during beer dispense. Chem. Eng. Sci. 2003, 58, 4071–4084. [Google Scholar] [CrossRef]

- Hepworth, N.J.; Varley, J.; Hind, A. Characterizing gas bubble dispersions in beer. Food Bioprod. Process. 2001, 79, 13–20. [Google Scholar] [CrossRef]

- Zabulis, X.; Papara, M.; Chatziargyriou, A.; Karapantsios, T.D. Detection of densely dispersed spherical bubbles in digital images based on a template matching technique—Application to wet foams. Colloids Surf. A Physicochem. Eng. Asp. 2007, 309, 96–106. [Google Scholar] [CrossRef]

- Evans, D.E.; Bamforth, C.W. Beer foam: Achieving a suitable head. In Beer: A Quality Perspective, 1st ed.; Bamforth, C.W., Ed.; Academic Press: Burlington, NJ, USA, 2009; pp. 1–60. [Google Scholar]

- Asano, K.; Hashimoto, N. Isolation and characterization of foaming proteins of beer. J. Am. Soc. Brew. Chem. 1980, 38, 129–137. [Google Scholar] [CrossRef]

- Evans, D.E.; Sheehan, M.C. Do not be fobbed off, the substance of beer foam, a review. J. Am. Soc. Brew. Chem. 2002, 60, 47–57. [Google Scholar]

- Kunimune, T. Foam Enhancing Properties of Hop Bitter Acids and Propylene Glycol Alginate. Master’s Thesis, Oregon State University, Corvallis, OR, USA, 14 January 2007. [Google Scholar]

- Hao, J.L.Q.; Dong, J.; Yu, J.; Fan, W.; Chen, J. Identification of the major proteins in beer foam by mass spectometry following sodium dodecyl sulphatepolyacrylamide gel electrophoresis. J. Am. Soc. Brew. Chem. 2006, 64, 166–174. [Google Scholar]

- Evans, E.D.; Surrel, A.; Sheehly, M.; Stewart, D.C.; Robinson, L.H. Comparison of foam quality and the influence of hop alpha-acids and proteins using five foam analysis methods. J. Am. Soc. Brew. Chem. 2008, 66, 1–10. [Google Scholar]

- Constant, M. A practical method for characterizing poured beer foam. J. Am. Soc. Brew. Chem. 1992, 50, 37–47. [Google Scholar] [CrossRef]

- Yasui, K.; Yakoi, S.; Shigyo, T.; Tamaki, T.; Shinotsuka, K.A. Customer-orientated approach to the development of a visual and statistical foam analysis. J. Am. Soc. Brew. Chem. 1998, 56, 152–158. [Google Scholar]

- Wallin, C.E.; Di Pietro, M.B.; Schwarz, R.W.; Bamforth, C.W. A comparison of three methods for the assessment of foam stability of beer. J. Inst. Brew. 1992, 116, 78–80. [Google Scholar] [CrossRef]

- Kruss Application Report: Comparison of The Foam Behaviour of Different Types of Beer Independently of CO2 Content. (Kruss, AR275). Available online: https://www.kruss-scientific.com/fileadmin/user_upload/website/literature/kruss-ar275-en.pdf (accessed on 25 January 2019).

- Sauerbrei, S.; Haß, E.C.; Plath, P.J. The Apollonian decay of beer foam bubble size distribution and the lattices of young diagrams and their correlated mixing functions. Discret. Dyn. Nat. Soc. 2006, 2006, 79717. [Google Scholar] [CrossRef]

- Cimini, A.; Pallottino, F.; Menesatti, P.; Moresi, M. A low-cost image analysis system to upgrade the rudin beer foam head retention meter. Food Bioprocess. Technol. 2016, 9, 1587–1597. [Google Scholar] [CrossRef]

- Rudin, A.D. Measurement of the foam stability of beers. J. Inst. Brew. 1957, 63, 506–509. [Google Scholar] [CrossRef]

| Cameras Categorization | Application | Features | ||

|---|---|---|---|---|

| Cameras Type According to the Image Processing Demands | Network cameras (Internet Protocol camera, IP) | Surveillance | Record a video Day/night modes Special infrared filters Compressed captured photos Simultaneously connected to a large number of users via the Internet | |

| Industrial cameras (Machine vision) | Area scan cameras | Application in different purposes and industries (packaging system management; traffic control system) | Record video or photo Raw photo (no loosing data by compression) | |

| Line scan cameras | ||||

| Color | Color cameras | intelligent traffic systems | Color image | |

| Monochrome cameras | Black and white image | |||

| Sensor Types | CMOS sensor | apply in cases where high speed is required | strong value for the performance high frame rates high resolution low power consumption | |

| CCD sensor | Those sensors are light sensitive, provide image of high quality, and applied in cases where in no need of high speed | high frame rates without deterioration in image quality | ||

| Shutter Technique | Global shutter | Capturing fast moving object | allow the light to strike the entire sensor surface all at once | |

| Rolling shutter | Capturing a stationary object | exposes the image line-by-line | ||

| Frame Rate (fps) | Slow sensor | For slow moving or stationary object which require low frame rates (medicine—microscopic inspection) | Small frame rate | |

| Quick sensor | For fast moving application which require high frame rates (inspection of printed images or labels) | High frame rate | ||

| Resolution | Camera with high resolution | For capturing precision image with large number of details | ||

| Camera with low resolution | For capturing image where details are not the main focus (moving object) | |||

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Lukinac, J.; Mastanjević, K.; Mastanjević, K.; Nakov, G.; Jukić, M. Computer Vision Method in Beer Quality Evaluation—A Review. Beverages 2019, 5, 38. https://doi.org/10.3390/beverages5020038

Lukinac J, Mastanjević K, Mastanjević K, Nakov G, Jukić M. Computer Vision Method in Beer Quality Evaluation—A Review. Beverages. 2019; 5(2):38. https://doi.org/10.3390/beverages5020038

Chicago/Turabian StyleLukinac, Jasmina, Kristina Mastanjević, Krešimir Mastanjević, Gjore Nakov, and Marko Jukić. 2019. "Computer Vision Method in Beer Quality Evaluation—A Review" Beverages 5, no. 2: 38. https://doi.org/10.3390/beverages5020038

APA StyleLukinac, J., Mastanjević, K., Mastanjević, K., Nakov, G., & Jukić, M. (2019). Computer Vision Method in Beer Quality Evaluation—A Review. Beverages, 5(2), 38. https://doi.org/10.3390/beverages5020038