Effect of Gamma Ray Irradiation on Friction Property of Poly(vinyl alcohol) Cast-Drying on Freeze-Thawed Hybrid Gel

Abstract

:1. Introduction

2. Results and Discussion

2.1. Swelling Property

2.2. Frictional Properties

2.2.1. Reciprocating Test at Room Temperature

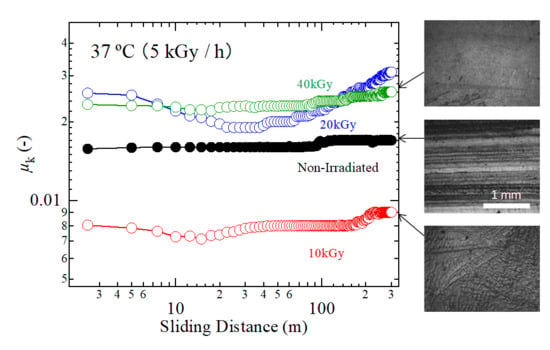

2.2.2. Reciprocating Test at 37 °C

2.3. Wear Properties

2.4. Discussion on Friction and Wear Properties

3. Conclusions

4. Materials and Methods

4.1. Sample Preparation

4.1.1. PVA CD on FT Hybrid Gel

4.1.2. Gamma Ray-Irradiation

4.2. Water Contents

4.3. Reciprocating Friction Test

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Tamura, K.; Ike, O.; Hitomi, S.; Isobe, J.; Shimizu, Y.; Nambu, M. A new hydrogel and its medical application. ASAIO J. 1986, 32, 605–608. [Google Scholar] [CrossRef]

- Otsuka, E.; Suzuki, A. A simple method to obtain a swollen PVA gel crosslinked by hydrogen bonds. J. Appl. Polym. Sci. 2009, 114, 10–16. [Google Scholar] [CrossRef]

- Otsuka, E.; Suzuki, A. Swelling properties of physically cross-linked PVA gels prepared by a cast-drying method. In Gels: Structures, Properties, and Functions; Springer: Berlin/Heidelberg, Germany, 2009; pp. 121–126. ISBN 978-3-642-00864-1. [Google Scholar]

- Suzuki, A.; Sasaki, S. Swelling and mechanical properties of physically crosslinked poly(vinyl alcohol) hydrogels. Proc. Inst. Mech. Eng. Part J J. Eng. Med. 2015, 229, 828–844. [Google Scholar] [CrossRef] [PubMed]

- Mabuchi, K.; Tsukamoto, Y.; Yamamoto, M.; Ueno, M.; Sasada, T.; Nambu, M. Lubrication property and mechanical durability of the joint prostheses containing cartilage-like polyvinyl alcohol gel. J. Soc. Orthop. Biomech. 1986, 8, 101–105. [Google Scholar]

- Sasada, T. Biomechanics and biomaterials–friction behaviour of an artificial articular cartilage. In Transactions of the 3rd World Biomaterials Congress; Kyoto International Conference Hall: Kyoto, Japan, 1988. [Google Scholar]

- Murakami, T.; Sawae, Y.; Higaki, H.; Ohtsuki, N.; Moriyama, S. The adaptive multimode lubrication in knee prostheses with artificial cartilage during walking. Tribol. Ser. 1997, 32, 371–382. [Google Scholar]

- Murakami, T.; Yarimitsu, S.; Nakashima, K.; Sawae, Y.; Sakai, N.; Araki, T.; Suzuki, A. Time-dependent frictional behaviors in hydrogel artificial cartilage materials. In Proceedings of the 6th International Biotribology Forum, Fukuoka, Japan, 5 November 2011. [Google Scholar]

- Murakami, T.; Yarimitsu, S.; Nakashima, K.; Yamaguchi, T.; Sawae, Y.; Sakai, N.; Suzuki, A. Superior lubricity in articular cartilage and artificial hydrogel cartilage. Proc. Inst. Mech. Eng. Part J J. Eng. Tribol. 2014, 228, 1099–1111. [Google Scholar] [CrossRef]

- Suzuki, A.; Sasaki, S.; Sasaki, S.; Noh, T.; Nakashima, K.; Yarimitsu, S.; Murakami, T. Elution and wear of PVA hydrogels by reciprocating friction. In Proceedings of the 5th World Tribology Congress, WTC 2013, Politecnico di Torino (DIMEAS), Torino, Italy, 8–13 September 2013. [Google Scholar]

- Murakami, T.; Sakai, N.; Yamaguchi, T.; Yarimitsu, S.; Nakashima, K.; Sawae, Y.; Suzuki, A. Evaluation of a superior lubrication mechanism with biphasic hydrogels for artificial cartilage. Tribol. Int. 2015, 89, 19–26. [Google Scholar] [CrossRef]

- Murakami, T.; Yarimitsu, S.; Nakashima, K.; Sakai, N.; Yamaguchi, T.; Sawae, Y.; Suzuki, A. Synergistic Lubricating Function with Different Modes for Artificial Hydrogel Cartilage. In Proceedings of the 8th International Biotribology Forum and the 36th Biotribology Symposium, Yokohama Japan, 21–22 September 2015. [Google Scholar]

- Sasaki, S.; Murakami, T.; Suzuki, A. Frictional properties of physically cross-linked PVA hydrogels as artificial cartilage. Biosurf. Biotribol. 2016, 2, 11–17. [Google Scholar] [CrossRef]

- Tohfafarosh, M.; Baykal, D.; Kiel, J.W.; Mansmann, K.; Kurtz, S.M. Effects of gamma and e-beam sterilization on the chemical, mechanical and tribological properties of a novel hydrogel. J. Mech. Behav. Biomed. Mater. 2016, 53, 250–256. [Google Scholar] [CrossRef] [PubMed]

- Kanjickal, D.; Lopina, S.; Evancho-Chapman, M.M.; Schmidt, S.; Donovan, D. Effects of sterilization on poly (ethylene glycol) hydrogels. J. Biomed. Mater. Res. Part A 2008, 87, 608–617. [Google Scholar] [CrossRef] [PubMed]

- Wang, B.; Kodama, M.; Mukataka, S.; Kokufuta, E. On the intermolecular crosslinking of PVA chains in an aqueous solution by γ-ray irradiation. Polym. Gels Netw. 1998, 6, 71–81. [Google Scholar] [CrossRef]

- Rosiak, J.M.; Yoshii, F. Hydrogels and their medical applications. Nucl. Instrum. Methods Phys. Res. B 1999, 151, 56–64. [Google Scholar] [CrossRef]

- Bhat, N.V.; Nate, M.M.; Kurup, M.B.; Bambole, V.A.; Sabharwal, S. Effect of γ-radiation on the structure and morphology of polyvinyl alcohol films. Nucl. Instrum. Methods Phys. Res. B 2005, 237, 585–592. [Google Scholar] [CrossRef]

- Schulz, R.M.; Bader, A. Cartilage tissue engineering and bioreactor systems for the cultivation and stimulation of chondrocytes. Eur. Biophys. J. 2007, 36, 539–568. [Google Scholar] [CrossRef] [PubMed]

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Sasaki, S.; Omata, S.; Murakami, T.; Nagasawa, N.; Taguchi, M.; Suzuki, A. Effect of Gamma Ray Irradiation on Friction Property of Poly(vinyl alcohol) Cast-Drying on Freeze-Thawed Hybrid Gel. Gels 2018, 4, 30. https://doi.org/10.3390/gels4020030

Sasaki S, Omata S, Murakami T, Nagasawa N, Taguchi M, Suzuki A. Effect of Gamma Ray Irradiation on Friction Property of Poly(vinyl alcohol) Cast-Drying on Freeze-Thawed Hybrid Gel. Gels. 2018; 4(2):30. https://doi.org/10.3390/gels4020030

Chicago/Turabian StyleSasaki, Saori, Seiji Omata, Teruo Murakami, Naotsugu Nagasawa, Mitsumasa Taguchi, and Atsushi Suzuki. 2018. "Effect of Gamma Ray Irradiation on Friction Property of Poly(vinyl alcohol) Cast-Drying on Freeze-Thawed Hybrid Gel" Gels 4, no. 2: 30. https://doi.org/10.3390/gels4020030

APA StyleSasaki, S., Omata, S., Murakami, T., Nagasawa, N., Taguchi, M., & Suzuki, A. (2018). Effect of Gamma Ray Irradiation on Friction Property of Poly(vinyl alcohol) Cast-Drying on Freeze-Thawed Hybrid Gel. Gels, 4(2), 30. https://doi.org/10.3390/gels4020030