Investigation of the Effects of Nanoparticle Concentration and Cutting Parameters on Surface Roughness in MQL Hard Turning Using MoS2 Nanofluid

Abstract

:1. Introduction

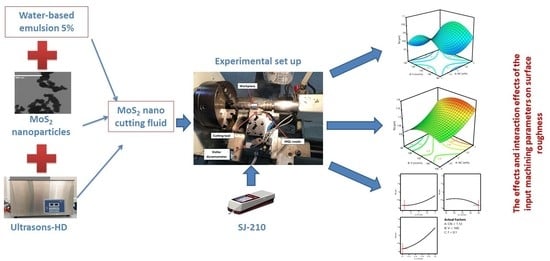

2. Materials and Methods

Experimental Set Up

3. Results and Discussions

3.1. Independent Influence of the Input Variables on Surface Roughness Ra

3.2. Interaction Effects between Input Machining Variables on the Surface Roughness

3.3. Surface Roughness Optimization

3.4. Investigation of Surface Microstructure and Topography

4. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Davim, J.P. Machining of Hard Materials; Springer: London, UK, 2011. [Google Scholar]

- Chinchanikar, S.; Choudhury, S. Hard turning using HiPIMS-coated carbide tools: Wear behavior under dry and minimum quantity lubrication (MQL). Measurement 2014, 55, 536–548. [Google Scholar] [CrossRef]

- Davim, J.P.; Sreejith, P.S.; Silva, J. Turning of Brasses Using Minimum Quantity of Lubricant (MQL) and Flooded Lubricant Conditions. Mater. Manuf. Process. 2007, 22, 45–50. [Google Scholar] [CrossRef]

- Pereira, O.; Martín-Alfonso, J.; Rodríguez, A.; Calleja-Ochoa, A.; Fernández-Valdivielso, A.; de Lacalle, L.L. Sustainability analysis of lubricant oils for minimum quantity lubrication based on their tribo-rheological performance. J. Clean. Prod. 2017, 164, 1419–1429. [Google Scholar] [CrossRef]

- Khan, M.; Mithu, M.; Dhar, N. Effects of minimum quantity lubrication on turning AISI 9310 alloy steel using vegetable oil-based cutting fluid. J. Mater. Process. Technol. 2009, 209, 5573–5583. [Google Scholar] [CrossRef]

- Pereira, O.; Celaya, A.; Urbikaín, G.; Rodríguez, A.; Fernández-Valdivielso, A.; De Lacalle, L.N.L. CO2 cryogenic milling of Inconel 718: Cutting forces and tool wear. J. Mater. Res. Technol. 2020, 9, 8459–8468. [Google Scholar] [CrossRef]

- Pereira, O.; Urbikain, G.; Rodríguez, A.; Fernández-Valdivielso, A.; Calleja, A.; Ayesta, I.; De Lacalle, L.N.L. Internal cryolubrication approach for Inconel 718 milling. Procedia Manuf. 2017, 13, 89–93. [Google Scholar] [CrossRef]

- Pereira, O.; Català, P.; Rodríguez, A.; Ostra, T.; Vivancos, J.; Rivero, A.; López-De-Lacalle, L. The Use of Hybrid CO2+MQL in Machining Operations. Procedia Eng. 2015, 132, 492–499. [Google Scholar] [CrossRef] [Green Version]

- Pereira, O.; Rodríguez, A.; Fernández-Abia, A.; Barreiro, J.; de Lacalle, L.L. Cryogenic and minimum quantity lubrication for an eco-efficiency turning of AISI 304. J. Clean. Prod. 2016, 139, 440–449. [Google Scholar] [CrossRef]

- Rodríguez, A.; Calleja, A.; López de Lacalle, L.N.; Pereira, O.; Rubio-Mateos, A.; Rodríguez, G. Drilling of CFRP-Ti6Al4V stacks using CO2-cryogenic cooling. J. Manuf. Process. 2021, 64, 58–66. [Google Scholar] [CrossRef]

- Minh, D.T.; The, L.T.; Bao, N.T. Performance of Al2O3 nanofluids in minimum quantity lubrication in hard milling of 60Si2Mn steel using cemented carbide tools. Adv. Mech. Eng. 2017, 9. [Google Scholar] [CrossRef] [Green Version]

- Sidik, N.A.C.; Samion, S.; Ghaderian, J.; Yazid, M.N.A.W.M. Recent progress on the application of nanofluids in minimum quantity lubrication machining: A review. Int. J. Heat Mass Transf. 2017, 108, 79–89. [Google Scholar] [CrossRef]

- Sharma, P.; Sidhu, B.S.; Sharma, J. Investigation of effects of nanofluids on turning of AISI D2 steel using minimum quantity lubrication. J. Clean. Prod. 2015, 108, 72–79. [Google Scholar] [CrossRef]

- Li, X.; Zhu, H. Two-dimensional MoS2: Properties, preparation, and applications. J. Mater. 2015, 1, 33–44. [Google Scholar] [CrossRef] [Green Version]

- Vajjha, R.S.; Das, D.K. A review and analysis on influence of temperature and concentration of nanofluids on thermophysical properties, heat transfer and pumping power. Int. J. Heat Mass Transf. 2012, 55, 4063–4078. [Google Scholar] [CrossRef]

- Kalita, P.; Malshe, A.P.; Rajurkar, K.P. Study of tribo-chemical lubricant film formation during application of nanolubricants in minimum quantity lubrication (MQL) grinding. CIRP Ann. Manuf. Technol. 2012, 61, 327–330. [Google Scholar] [CrossRef]

- Kalita, P.; Malshe, A.P.; Arun Kumar, S.; Yoganath, V.G.; Gurumurthy, T. Study of specific energy and friction coefficient in minimum quantity lubrication grinding using oil-based nanolubricants. J. Manuf. Process. 2012, 14, 160–166. [Google Scholar] [CrossRef]

- Zhang, D.; Li, C.; Jia, D.; Zhang, Y.; Zhang, X. Specific grinding energy and surface roughness of nanoparticle jet minimum quantity lubrication in grinding. Chin. J. Aeronaut. 2015, 28, 570–581. [Google Scholar] [CrossRef] [Green Version]

- Wang, Y.; Li, C.; Zhang, Y.; Li, B.; Yang, M.; Zhang, X.; Guo, S.; Liu, G. Experimental evaluation of the lubrication properties of the wheel/workpiece interface in MQL grinding with different nanofluids. Tribol. Int. 2016, 99, 198–210. [Google Scholar] [CrossRef]

- Huang, W.-T.; Liu, W.-S.; Tsai, J.-T.; Chou, J.-H. Multiple Quality Characteristics of Nanofluid/Ultrasonic Atomization Minimum Quality Lubrication for Grinding Hardened Mold Steel. IEEE Trans. Autom. Sci. Eng. 2018, 15, 1065–1077. [Google Scholar] [CrossRef]

- Huang, W.-T.; Chou, F.-I.; Tsai, J.-T.; Lin, T.-W.; Chou, J.-H. Optimal Design of Parameters for the Nanofluid/Ultrasonic Atomization Minimal Quantity Lubrication in a Micro-Milling Process. IEEE Trans. Ind. Inform. 2019, 16, 5202–5212. [Google Scholar] [CrossRef]

- Hu, K.H.; Hu, X.G.; Xu, Y.F.; Huang, F.; Liu, J.S. The effect of morphology on the tribological properties of MoS2 in liquid paraffin. Tribol. Lett. 2010, 40, 155–165. [Google Scholar] [CrossRef]

- Zhang, Y.; Li, C.; Jia, D.; Zhang, D.; Zhang, X. Experimental evaluation of MoS2 nanoparticles in jet MQL grinding with different types of vegetable oil as base oil. J. Clean. Prod. 2015, 87, 930–940. [Google Scholar] [CrossRef]

- Uysal, A.; Demiren, F.; Altan, E. Applying Minimum Quantity Lubrication (MQL) Method on Milling of Martensitic Stainless Steel by Using Nano MoS2 Reinforced Vegetable Cutting Fluid. Procedia Soc. Behav. Sci. 2015, 195, 2742–2747. [Google Scholar] [CrossRef] [Green Version]

- Rahmati, B.; Sarhan, A.A.D.; Sayuti, M. Morphology of surface generated by end milling AL6061-T6 using molybdenum disulfide (MoS2) nanolubrication in end milling machining. J. Clean. Prod. 2014, 66, 685–691. [Google Scholar] [CrossRef]

- Dong, P.Q.; Duc, T.M.; Long, T.T. Performance Evaluation of MQCL Hard Milling of SKD 11 Tool Steel Using MoS2 Nanofluid. Metals 2019, 9, 658. [Google Scholar] [CrossRef]

- Huang, W.-T.; Chou, F.-I.; Tsai, J.-T.; Chou, J.-H. Application of Graphene Nanofluid/Ultrasonic Atomization MQL System in Micromilling and Development of Optimal Predictive Model for SKH-9 High-Speed Steel Using Fuzzy-Logic-Based Multi-objective Design. Int. J. Fuzzy Syst. 2020, 22, 2101–2118. [Google Scholar] [CrossRef]

- Duc, T.M.; Long, T.T.; Chien, T.Q. Performance Evaluation of MQL Parameters Using Al2O3 and MoS2 Nanofluids in Hard Turning 90CrSi Steel. Lubricants 2019, 7, 40. [Google Scholar] [CrossRef] [Green Version]

- Duc, T.M.; Long, T.T.; Tuan, N.M. Performance Investigation of MQL Parameters Using Nano Cutting Fluids in Hard Milling. Fluids 2021, 6, 248. [Google Scholar] [CrossRef]

- Park, K.-H.; Olortegui-Yume, J.A.; Joshi, S.; Kwon, P.; Yoon, M.-C.; Lee, G.-B.; Park, S.-B. Measurement of Droplet Size and Distribution for Minimum Quantity Lubrication (MQL). In Proceedings of the International Conference on Smart Manufacturing Application, Goyangi, Korea, 9–11 April 2008; pp. 447–454. [Google Scholar] [CrossRef]

- Plata, S. A note on Fisher’s correlation coefficient. Appl. Math. Lett. 2006, 19, 499–502. [Google Scholar] [CrossRef] [Green Version]

- Elbestawi, M.A.; Chen, L.; Becze, C.E.; El-Wardany, T.I. High-Speed Milling of Dies and Molds in Their Hardened State. CIRP Ann. 1997, 46, 57–62. [Google Scholar] [CrossRef]

- Benga, G.C.; Abrao, A.M. Turning of hardened 100Cr6 bearing steel with ceramic and PCBN cutting tools. J. Mater. Process. Technol. 2003, 143–144, 237–241. [Google Scholar] [CrossRef]

- Duc, T.M.; Long, T.T.; Tuan, N.M. Novel Uses of Al2O3/Mos2 Hybrid Nanofluid in MQCL Hard Milling of Hardox 500 Steel. Lubricants 2021, 9, 45. [Google Scholar] [CrossRef]

- Abdullah, A.B.; Chia, L.Y.; Samad, Z. The Effect of Feed Rate and Cutting Speed to Surface Roughness. Asian J. Sci. Res. 2008, 1, 12–21. [Google Scholar] [CrossRef]

| Element | C | Si | Mn | Ni | S | P | Cr | Mo | W | V | Ti | Cu |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Weight (%) | 0.85 ÷ 0.95 | 1.20 ÷ 1.60 | 0.30 ÷ 0.60 | Max 0.40 | Max 0.03 | Max 0.03 | 0.95 ÷ 1.25 | Max 0.20 | Max 0.20 | Max 0.15 | Max 0.03 | Max 0.3 |

| Tensile Strength (MPa) | Yield Stress (MPa) | Young’s Modulus (MPa) |

|---|---|---|

| 790 | 445 | 1.9 |

| Input Machining Variables | Symbol | Level | Response Variable | ||

|---|---|---|---|---|---|

| Low | Medium | High | |||

| Nanoparticle concentration (NC), wt% | A | 1.0 | 2.0 | 3.0 | Surface roughness Ra |

| Cutting speed (V), m/min | B | 80 | 120 | 160 | |

| Feed rate (f), mm/rev | C | 0.1 | 0.15 | 0.2 | |

| Std | Run | NC (wt%) | V (m/min) | f (mm/rev) | Ra (µm) |

|---|---|---|---|---|---|

| 1 | 27 | 1 | 80 | 0.15 | 0.766 |

| 2 | 14 | 3 | 80 | 0.15 | 0.730 |

| 3 | 5 | 1 | 160 | 0.15 | 0.600 |

| 4 | 9 | 3 | 160 | 0.15 | 0.686 |

| 5 | 15 | 1 | 120 | 0.1 | 0.504 |

| 6 | 26 | 3 | 120 | 0.1 | 1.157 |

| 7 | 24 | 1 | 120 | 0.2 | 1.767 |

| 8 | 18 | 3 | 120 | 0.2 | 1.111 |

| 9 | 23 | 2 | 80 | 0.1 | 0.614 |

| 10 | 3 | 2 | 160 | 0.1 | 0.432 |

| 11 | 29 | 2 | 80 | 0.2 | 0.948 |

| 12 | 4 | 2 | 160 | 0.2 | 1.397 |

| 13 | 16 | 2 | 120 | 0.15 | 0.805 |

| 14 | 8 | 2 | 120 | 0.15 | 0.912 |

| 15 | 19 | 2 | 120 | 0.15 | 0.452 |

| 16 | 6 | 1 | 80 | 0.15 | 0.843 |

| 17 | 1 | 3 | 80 | 0.15 | 0.858 |

| 18 | 12 | 1 | 160 | 0.15 | 0.573 |

| 19 | 2 | 3 | 160 | 0.15 | 0.654 |

| 20 | 28 | 1 | 120 | 0.1 | 0.548 |

| 21 | 22 | 3 | 120 | 0.1 | 1.050 |

| 22 | 10 | 1 | 120 | 0.2 | 1.599 |

| 23 | 21 | 3 | 120 | 0.2 | 1.432 |

| 24 | 13 | 2 | 80 | 0.1 | 0.589 |

| 25 | 25 | 2 | 160 | 0.1 | 0.381 |

| 26 | 17 | 2 | 80 | 0.2 | 0.820 |

| 27 | 30 | 2 | 160 | 0.2 | 1.037 |

| 28 | 20 | 2 | 120 | 0.15 | 0.535 |

| 29 | 7 | 2 | 120 | 0.15 | 0.939 |

| 30 | 11 | 2 | 120 | 0.15 | 0.821 |

| Source | Sum of | df | Mean | F-Value | p-Value | |

|---|---|---|---|---|---|---|

| Model | 3.078313 | 9 | 0.342035 | 15.65286 | <<0.0001 | Significant |

| NC | 0.01428 | 1 | 0.01428 | 0.653521 | 0.428369 | |

| V | 0.010404 | 1 | 0.010404 | 0.476128 | 0.498111 | |

| f | 1.461681 | 1 | 1.461681 | 66.89229 | <<0.0001 | |

| NC∗V | 0.004418 | 1 | 0.004418 | 0.202185 | 0.657798 | |

| NC∗f | 0.489061 | 1 | 0.489061 | 22.38134 | 0.000128 | |

| V∗f | 0.139392 | 1 | 0.139392 | 6.379128 | 0.020098 | |

| NC2 | 0.211536 | 1 | 0.211536 | 9.680743 | 0.005501 | |

| V2 | 0.29391 | 1 | 0.29391 | 13.45046 | 0.001529 | |

| f2 | 0.400044 | 1 | 0.400044 | 18.30757 | 0.000367 | |

| Residual | 0.437025 | 20 | 0.021851 | |||

| Lack of Fit | 0.073218 | 3 | 0.024406 | 1.140449 | 0.361035 | Not significant |

| Pure Error | 0.363807 | 17 | 0.0214 | |||

| Cor Total | 3.515338 | 29 |

| Fit Statistics | Value |

|---|---|

| R2 | 0.87568 |

| Adjusted R2 | 0.819737 |

| Predicted R2 | 0.747006 |

| Adeq Precision | 15.7962 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Tuan, N.M.; Ngoc, T.B.; Thu, T.L.; Long, T.T. Investigation of the Effects of Nanoparticle Concentration and Cutting Parameters on Surface Roughness in MQL Hard Turning Using MoS2 Nanofluid. Fluids 2021, 6, 398. https://doi.org/10.3390/fluids6110398

Tuan NM, Ngoc TB, Thu TL, Long TT. Investigation of the Effects of Nanoparticle Concentration and Cutting Parameters on Surface Roughness in MQL Hard Turning Using MoS2 Nanofluid. Fluids. 2021; 6(11):398. https://doi.org/10.3390/fluids6110398

Chicago/Turabian StyleTuan, Ngo Minh, Tran Bao Ngoc, Tran Le Thu, and Tran The Long. 2021. "Investigation of the Effects of Nanoparticle Concentration and Cutting Parameters on Surface Roughness in MQL Hard Turning Using MoS2 Nanofluid" Fluids 6, no. 11: 398. https://doi.org/10.3390/fluids6110398

APA StyleTuan, N. M., Ngoc, T. B., Thu, T. L., & Long, T. T. (2021). Investigation of the Effects of Nanoparticle Concentration and Cutting Parameters on Surface Roughness in MQL Hard Turning Using MoS2 Nanofluid. Fluids, 6(11), 398. https://doi.org/10.3390/fluids6110398