Micrometric Growth Defects of DLC Thin Films

Abstract

:1. Introduction

2. Materials and Methods

2.1. Material and Coating

2.2. Electrochemical Set-Up

2.3. Digital Microscope Set-Up for In Situ Observations

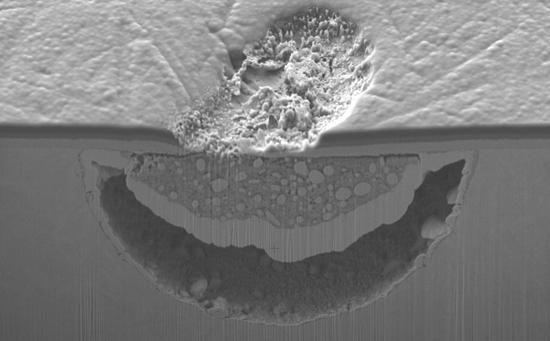

2.4. SEM-FIB Apparatus

3. Results and Discussion

3.1. Classic Polarization Experiment

3.2. Observation of the Coated Surface

3.3. Enhancing the Defects’ Detection and Tracking with a Specific Electrochemical Test

3.3.1. Evolution of a Coated Surface Containing Defects during Static −1.2 V and +0.4 V Polarization

3.3.2. Evolution of a Coated Surface Containing One Single Defect during Static −1.2 V and +0.4 V Polarization

3.3.3. Alternative Static +0.4 V and −1.2 V Polarization Sequence

4. Discussion

- an incomplete/inadequate surface preparation (cleaning, polishing, etching) of the substrate,

- workshop environment before deposition,

- flaking from previous coating on reactor walls or heaters during the outgasing step,

- flaking from rotation of support fixtures during deposition,

- microdroplets from evaporators or arcing from targets during deposition.

5. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Donnet, C.; Erdemir, A. Tribology of Diamond-Like Carbon Films; Springer: Boston, MA, USA, 2008; pp. 1–673. [Google Scholar]

- Vetter, J. 60 years of DLC coatings: Historical highlights and technical review of cathodic arc processes to synthesize various DLC types, and their evolution for industrial applications. Surf. Coat. Technol. 2014, 257, 213–240. [Google Scholar] [CrossRef]

- Grill, A. Diamond-like carbon: State of the art. Diam. Relat. Mater. 1999, 8, 428–434. [Google Scholar] [CrossRef]

- BEwilogua, K.; Hofmann, D. History of diamond-like carbon films—From first experiments to worldwide applications. Surf. Coat. Technol. 2014, 242, 214–225. [Google Scholar] [CrossRef]

- Robertson, J. Diamond-like amorphous carbon. Mater. Sci. Eng. 2002, 37, 129–281. [Google Scholar] [CrossRef]

- Hadinata, S.-S.; Lee, M.-T.; Pan, S.-J.; Tsai, W.-T.; Tai, C.-Y.; Shih, C.-F. TElectrochemical performances of diamond-like carbon coatings on carbon steel, stainless steel, and brass. Thin Solid Films 2013, 529, 412–416. [Google Scholar] [CrossRef]

- Sharma, R.; Barhai, P.K.; Kumari, N. Corrosion resistant behaviour of DLC films. Thin Solid Films 2008, 516, 5397–5403. [Google Scholar] [CrossRef]

- Azzi, M.; Amirault, P.; Paquette, M.; Klemberg-Sapieha, J.E.; Martinu, L. Corrosion performance and mechanical stability of 316L/DLC coating system: Role of interlayers. Surf. Coat. Technol. 2010, 204, 3986–3994. [Google Scholar] [CrossRef]

- Miya, H.; Wang, J. Corrosion Protect DLC Coating on Steel and Hastelloy. Mater. Trans. 2006, 49, 1333–1337. [Google Scholar] [CrossRef]

- Nery, R.P.O.S.; Bonelli, R.S.; Camargo, S.S. Evaluation of corrosion resistance of diamond-like carbon films deposited onto AISI 4340 steel. J. Mater. Sci. 2010, 45, 5472–5477. [Google Scholar] [CrossRef]

- Dorner, A.; Wielage, B.; Schürer, C. Improvement of the corrosion resistance of C/Al-composites by diamond-like carbon coatings. Thin Solid Films 1999, 355, 214–218. [Google Scholar] [CrossRef]

- Zeng, A.; Liu, E.; Annergren, I.F.; Tan, S.N.; Zhang, S.; Hing, P.; Gao, J. EIS capacitance diagnosis of nanoporosity effect on the corrosion protection of DLC films. Diam. Relat. Mater. 2002, 11, 160–168. [Google Scholar] [CrossRef]

- Lillard, R.S.; Butt, D.P.; Taylor, T.N.; Walter, K.C.; Nastasi, M. The breakdown mechanism of diamond-like carbon coated nickel in chloride solution. Corrosion Sci. 2003, 39, 1605–1624. [Google Scholar] [CrossRef]

- Kim, H.G.; Ahn, S.H.; Kim, J.G.; Park, S.J.; Lee, K.R. Corrosion performance of diamond-like carbon (DLC)-coated Ti alloy in the simulated body fluid environment. Diam. Relat. Mater. 2008, 14, 35–41. [Google Scholar] [CrossRef]

- Liu, E.; Kwek, H.W. Electrochemical performance of diamond-like carbon thin films. Thin Solid Films 2008, 516, 5201–5205. [Google Scholar] [CrossRef]

- Fenker, M.; Balzer, M.; Kappl, H. Corrosion protection with hard coatings on steel: Past approaches and current research efforts. Surf. Coat. Technol. 2014, 205, 182–205. [Google Scholar] [CrossRef]

- Panjan, P.; Gselman, P.; Kek-Merl, D.; Čekada, M.; Panjan, M.; Dražić, G.; Bončina, T.; Zupanič, F. Growth defect density in PVD hard coatings prepared by different deposition techniques. Surf. Coat. Technol. 2013, 237, 349–356. [Google Scholar] [CrossRef]

- Panjan, P.; Čekada, M.; Panjan, M.; Kek-Merl, D. Growth defects in PVD hard coatings. Vaccum 2009, 84, 209–214. [Google Scholar] [CrossRef]

- Bard, A.J.; Faulkner, L.R. Electrochemical Methods, Fundamentals and Applications, 2nd ed.; John Wiley & Sons: Burlington, NJ, USA, 2001. [Google Scholar]

- Mattox, D.M. Handbook of Physical Vapor Deposition (PVD) Processing, 2nd ed.; Elsevier: Burlington, MA, USA, 2010; pp. 357–359. [Google Scholar]

- Balzer, M. Identification of the growth defects responsible for pitting corrosion on sputter-coated steel samples by Large Area High Resolution mapping. Thin Solid Films 2015, 581, 99–106. [Google Scholar] [CrossRef]

- Maerten, T.; Oltra, R.; Jaoul, C.; Le Niniven, C.; Tristant, P.; Meunier, F.; Jarry, O. Investigation of diamond-like carbon coated steel corrosion: Enhancing the optical detection of defects by a controlled electrochemical activation. Surf. Coat. Technol. 2019, 363, 344–351. [Google Scholar] [CrossRef]

| Diamond-Like Carbon Coating | |

|---|---|

| DLC top layer | ∼1.2 μm |

| Sublayers | Ti layer (∼0.4 μm)/Si-based layer (∼0.8 μm) |

| Total thickness | ∼2.3 μm |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Maerten, T.; Jaoul, C.; Oltra, R.; Duport, P.; Le Niniven, C.; Tristant, P.; Meunier, F.; Jarry, O. Micrometric Growth Defects of DLC Thin Films. C 2019, 5, 73. https://doi.org/10.3390/c5040073

Maerten T, Jaoul C, Oltra R, Duport P, Le Niniven C, Tristant P, Meunier F, Jarry O. Micrometric Growth Defects of DLC Thin Films. C. 2019; 5(4):73. https://doi.org/10.3390/c5040073

Chicago/Turabian StyleMaerten, Thibault, Cédric Jaoul, Roland Oltra, Patrice Duport, Christophe Le Niniven, Pascal Tristant, Frédéric Meunier, and Olivier Jarry. 2019. "Micrometric Growth Defects of DLC Thin Films" C 5, no. 4: 73. https://doi.org/10.3390/c5040073

APA StyleMaerten, T., Jaoul, C., Oltra, R., Duport, P., Le Niniven, C., Tristant, P., Meunier, F., & Jarry, O. (2019). Micrometric Growth Defects of DLC Thin Films. C, 5(4), 73. https://doi.org/10.3390/c5040073