1. Introduction

Polymeric materials derived from renewable resources have lately garnered more attention as environmentally friendly and sustainable chemistry, demonstrating the variety obtained through synthesis and semi-synthesis [

1,

2,

3]. The principal source of greenhouse gas emissions is the use of fossil fuels in various industrial operations. Concerns about the increasing carbon footprint of major manufacturing facilities have prompted the industry to switch from biosources to polymers, bringing the possibility of the phasing out of traditional polymers closer to reality. In 1840, Hancock and Rudersdorf developed the first artificial polymers by blending natural rubber with sulfur to create a strong and flexible material [

4]. Major advancements in polymer chemistry facilitate the development of purely synthetic or complex polymer materials. The two key advantages of bio-based polymers, according to scientists, have yet to be acknowledged politically. The first advantage is the replacement of fossil carbon in the process of production with renewable carbon from biomass, which is vital for a sustainable and climate-friendly plastics industry. The second benefit is that biodegradable bio-based polymers account for approximately a quarter of all bio-based polymers (depending on the environment). Corn, sugar cane, vegetable oils, soybeans, and cellulose can all be used to produce this polymer. Plant-derived bio-based polymers, also known as the next-generation polymers which have been used to reduce fossil fuel usage and may be a solution for the issue of plastics uncollected and unprocessed in an environment, and such polymers biodegrade without leaving microplastics behind [

5,

6]. Furthermore, owing to the extensive use of live and controllable polymerization techniques, biocompatible synthetic materials have been reported as one of the most relevant and fruitful disciplines of polymer chemistry in recent decades. Biosynthetic polymers are a kind of material that is utilized in numerous applications, including new biomolecular stabilizers, biosensors, therapeutic agents, biomedical adhesives, drug delivery, biomimetic scaffolds, and vehicle antifouling materials [

7]. Bio-based polymer branches are dynamic and versatile, and they are in many stages of development, ranging from research to preliminary market acceptance to application in long-term high-performance polymers such as cellulose and nylon, which indicates market growth.

National policy, technology, raw material costs, competition (fossil fuels and biomass), consumer acceptance, crude oil prices, and accessibility to clear and reliable market data are all factors that influence the rate of expansion of bio-based polymer branches. This article examines a variety of bio-based polymers, focusing on their characteristics, production processes, and commercial uses. The review highlighted the composition and usage of bio-based polymers including polylactic acid, polyhydroxyalkanoate, biopolyethylene, and polysuccinic acid succinate. Furthermore, the process economics of conventional petroleum-based polymers were compared, as well as the process economics of monomer and polymer synthesis. Researchers working on the synthesis of conventionalpetroleum-derived raw material-based and bio-based polymers may find this paper useful [

8]. For example, we described:

- (1)

Structural dynamics of polymer assemblies,

- (2)

Architecture control of synthetic components, and

- (3)

Biostabilization (storage, release, and biotolerance) of therapeutic contents [

9].

The authors also point out that the outcome of this review is quite beneficial for researchers. As a result, the research focuses on the benefits of simple formulations for the development of highly functional biosynthetic polymers, as well as current trends, breakthroughs, and potential applications. The merits of simple synthetic polymer formulations include the potential challenges of using bio-based materials in a variety of applications, as well as the solutions and key industry players that may help bring these materials to market. The conclusion offers a predicted position on future growth in the area, which is contingent on the ability to surpass sustainability limitations [

10]. The review investigated market conditions, growth rates, market share, market momentum, challenges and opportunities, risk and entry barriers, sales channels, distributors, and future trends. In this context, our creative efforts to go beyond what nature has mastered are showcased.

4. Degradation vs. Biodegradation

Each polymer degrades with time, resulting in a loss of strength, quality, and molecular weight. It is well known that most polymers require 100–1000 years to completely degrade. By-products of BDPs include carbon dioxide, methane, water, and inorganic chemicals, as well as biomass that may be readily scavenged by microbes. They degrade extremely quickly in comparison to non-BDPs [

31]. Many pro-oxidants (ferromanganese and cobalt salts) are formulated for use in composting, garbage, and soil treatment polymers. According to scientific recommendations and studies, these additives may regulate the life of plastic films and goods when combined with conventional polymers in the right proportions, enabling plastic waste to be destroyed without having to be collected and disposed of. This oxidized molecular fragment is biodegradable and hydrophilic, according to the study, and the molar mass value is reduced by more than a tenth. It has been reported that polymers containing the above additives are fragmented into smaller parts that are invisible to the naked eye, but it is unclear whether these parts are truly biodegradable; that is, whether they are accessible to microflora (bacteria, fungi, etc.) to convert and assimilate carbon in any substrate, and if so, at what rate [

32].

At this point, residue fragmentation and cross-linking with moisture, heat, sunshine, and/or enzymes create persistent residues, which weaken or break the polymer chains. Biodegradation is the next stage of this process. Only when the fragmented residues are fully absorbed as food or energy by the microorganism at an appropriate pace does biodegradation begin. Because it has yet to be shown, the fragmentation of photodegradable (fragmentable) polymers by biodegradation based on polyethylene with pro-oxidants remains an open concern. It failed because of conflicting biodegradable standards and specifications. The most recent developments are bio-based polymers produced from bacterial fermentation, which are focusing on the creation of monomers made of cellulose, fatty acids, and starch from renewable resources [

33].

5. Environmental Biodegradation Steps of the Polymer

The polymer material is employed either during the induction phase, or the polymer chains undergo abiotic degradation (mainly oxidation). Chemicals (impurities, metals, catalyst residues, additives, and so on), energy (light, heat, and sound), the environment, and other factors may all play a role. All of these components may work together throughout fabrication, preservation, in and after service. Exposure to photoirradiation and/or heat energy may accelerate abiotic biodegradation [

34].

Figure 2 depicts the environmental biodegradation processes of polymers.

The real biodegradation occurs after that, with the aid of fragmented microorganisms, and the previously segmented polymer chains further scission and fracture. The degrading bacteria absorb and mineralize the segments of the polymer chain, and this process continues [

35]. Biodegradation of polymer materials has an impact on the morphological characteristics of the polymer as well as its chemical integrity. Surface regions of amorphous polymers deteriorate faster than crystalline regions, which have less free space and more solid linkages across polymer chains.

5.1. Types

Agro-polymers are biomass products, and BDPs are split into two types based on their fabrication technique [

36]. Oil-derived polymers, traditional synthesis from bio-derived monomers, and polymers obtained via microbial processes are the three major types of bio-polyesters. Polysaccharides and proteins are two subcategories within the biomass products category [

37]. Polysaccharides and other agricultural resources are used to produce agro-polymers. Polysaccharides seem to be the most common macromolecule found naturally (complex carbohydrates). The most well-known polysaccharide is starch, which is derived from grains and tubers. Other polysaccharides include chitosan, chitin, and pectin. Proteins derived from amino acids are the second kind of agricultural polymer. The most essential characteristic of polymers is their capacity to regenerate. Casein, collagen, gelatin, and keratin are examples of animal proteins that are commonly utilized in the food business, whereas wheat protein, soy protein, and maize protein are examples of plant proteins. The main bacterial proteins are lactate dehydrogenase, chymotrypsin, and fumarase [

38]. Even though such polymers are primarily utilized in the food business, the packaging industry has yet to discover a method to replace traditional plastics with agro-polymers. Bio-polyesters (BPEs) are the second kind of BDP, and they may be composed of either living or non-living materials (synthetics).

5.2. Examples

There are two types of lactic acid:

D-lactic acid and

L-lactic acid are well-known and widely utilized biopolymers in a variety of sectors. They are produced in two ways: biologically and chemically [

39].

Lactobacillus (bacteria) or fungi are used in the former technique to ferment carbohydrates. Lactic acid may also be formed as a result of chemical chain reactions. When a person’s muscles are fatigued, this response may occur in the body. Lactic acid is mostly utilized in the manufacturing of cosmetics in the industrial sector. Polyhdroxyalkanoates (PHAs) are a form of intracellular biopolymer generated by bacteria as intracellular carbon or energy storage granules because of their biodegradability [

40]. They are utilized in the packaging and medical sectors, among others. The most typical BDPs are petroleum by-products. Petroleum-based polyesters such as polycaprolactone, aliphatic co-polyesters, and aromatic co-polyesters are soft materials at room temperature.

5.3. Non-Pharmacological Applications of Biopolymers

5.3.1. Bio-Plastics (BPs) for Packaging

Bio-based polymers are slowly reaching mainstream use in today’s world, with the packaging being one of the most significant types of it [

41]. As yearly sales rise by 20% to 30%, polymers produced from renewable “raw materials” may soon compete with over-the-counter plastics. Packaging is one of the fastest-expanding businesses on the planet, with plastic accounting for almost 40% of all packaging material [

42]. Despite this, the growing usage of plastics continues to represent a significant environmental risk. Consumers and package makers are starting to note the significance of balancing ecosystems as a result of the growth of digital media, and they are beginning to embrace sustainable packaging materials, with a preference for ecologically friendly and recyclable materials. As a result of these concerns, demand for BPs that replace conventional plastics, particularly biodegradable BPs, is rising [

43]. Films, cover films, bottles, flip-top cartons, shipping bags, trash collection bags, and food service supplies are just a few examples of BP applications. The market for BPs and biopolymers is expected to be worth USD 6.95 billion in 2018 and USD 14.92 billion by 2023, according to estimates. From 2018 through 2023, the annual growth rate is 16.5%. Between 2018 and 2023, this indicates a CAGR of 16.5% [

44]. This strong demand is causing the increase in the use of BPs in packaging in the developing nations.

The bio-based polymer industry will be substantially expanded in consumer product applications, and government laws that increasingly concentrate on sustainability and green procurement policies will boost the BP and biopolymer market [

45]. Based on their diverse types, BPs and biopolymers are divided into biodegradable and non-biodegradable BPs. Biopolymers and BPs that are not biodegradable are anticipated to be the most popular and fastest-growing. The packaging industry’s rising need is causing the increasing demand for non-biodegradable BPs. Bio-PET seems to be the most popular category of non-biodegradable BPs and biopolymers, owing to its cheap cost and simple production method [

35]. Automotive and transportation, agriculture and horticulture, packaging, consumer goods, textiles, and other end-use industries are among the BP and biopolymer markets. Packaging is the most significant and fastest-growing application for BPs and biopolymers. Food and beverage sectors, for example, require sustainable solutions. Furthermore, advances in industrial and manufacturing technology are pushing food and beverage businesses to use BPs in their packaging [

46]. The use of BP packaging to cover organic foods and high-quality or branded goods is becoming more popular. Natural or organic polymers generated from biomass sources such as carbohydrates, lipids, bacteria, and oils dominate the packaging end-use industry.

Due to its cutting-edge technology and industrial standing, well-established expertise, and creative bio-based product production, Europe now has a market leadership position [

47]. However, the fast adoptions of products are hampered by the unclear efficacy and the lack of transparency of market. Although the use, development, and extension of bio-based and compostable products and materials are highly limited within agriculture, progress has been achieved with the expansion of the use of biodegradable (compostable) and bio-based packing materials due to two key considerations: (a) the open debate for biodegradation about testing agricultural biodegradable plastics for in-soil farm use and (b) the open debate on biodegradation about testing agricultural biodegradable plastics [

48].

The first stymies work on labelling schemes and appropriate certification, such as when used in tandem with the recently developed labelling system concerning agricultural plastic wastes. For almost the same reason, there is indeed a lot of uncertainty about the ways in which these materials work in real-world soil conditions, which is limiting them from being employed in agricultural applications more generally [

49]. When packaging, shipping, distributing, and storing the goods, extreme caution must be exercised. It is required for the transportation and storage of items for a wide range of sectors, including institutional, industrial, and retail. The importance of polymer and the usage of packaging goods provide protection and confinement while also causing a shift in consumer behavior. To wrap various kinds of goods, the packaging business uses a range of materials (polymers, metals, glass, wood, etc.). Plastic constitutes 40% of all packaging. Because of the characteristics of plastics, such as flexibility, impermeability, and high-water resistance, their usage is growing, but new environmental laws have restricted the use of traditional polymers. This is enabled in particular in packaging and handbags, which fuels the need for BPs and biopolymers. Food packaging, pharmaceutical packaging, cosmetic packaging, and shopping bags are just a few of the uses for packaging. Bio-PE is used to pack a variety of cosmetic goods by Procter & Gamble and Johnson & Johnson. Because of its excellent recyclability, PLA is often utilized. For goods such as PLA, PHA, and starch-based polymers, it is difficult to develop eco-friendly packaging manufactured from bio-based polymers for a variety of uses [

35,

50].

5.3.2. Consumer Goods

Circuit boards, housings, speakers, mobile housings, touch screens, computer housings, keyboard components, laptop mice, and vacuum cleaners are just a few examples of where BPs and biopolymers are used in consumer goods. SUPLA has created a PLA that is specifically designed for use in the electronics sector. Kuender also developed the world’s first BP touchscreen computer in conjunction with a Taiwanese OEM/ODM [

51]. Excellent high gloss, high impact resistance, and steady and precise processing may be obtained by mixing PLA mixture into the display. Europe is a significant consumer and producer of BPs and biopolymers. It dominates the BP and biopolymer industries and is utilized directly in the packaging end-use sector. These reasons have prompted collaboration in the development of bio-based polymers, which are expected to transform the plastics industry. Market penetration of BPs and biopolymers has been aided by political and economic circumstances [

52]. BASF in Germany, Nature Works in the United States, Braskem in Brazil, Toray Industries in Japan, Novamont in Japan, Nova Corbion in Italy, Total Corbion in the Netherlands, Biome BPs in the United Kingdom, Mitsubishi Chemical Corporation in Japan, Plantic Technologies in Australia, Bio-On in the Netherlands, and Mitsubishi Chemical Corporation in Japan are among the leading players in this field [

53]. BDPs are a kind of polymer that decomposes rapidly and produces ecologically beneficial by-products, which is a solution to the environmental pollution produced by non-degradable plastics.

5.3.3. Reuse and Recycle

The recyclates are melted and pelletized in mechanical recycling, which is an easy and energy-efficient technique. The majority of plastics nowadays are recovered mechanically. Unfortunately, these materials are frequently of poor quality, possess qualities inferior to virgin materials, and lack permission for use in food. These factors limit the amount of uses for mechanically recycled plastics, which can be found in items such as watering cans, spray bottles, and cleaning supplies. Due to a lack of demand for recycled materials, a recent survey indicated that only 37% of all collected plastic garbage is actually recycled. In France, Germany, the UK, Spain, and Italy, the recycling rates range from 21 to 42%; however, this figure also takes into account exports for recycling in other nations. The possibility of plastic items to be recycled has recently received a lot of attention. Although this development is significant, the key roadblock appears to be defining the uses for recovered plastics. Recyclability is not very useful unless it truly decreases the consumption of materials made from virgin fossil fuels. Several potential techniques for dissolving polymers into monomers, which can then be utilized to create new polymers, are included in chemical recycling which require more energy compared to mechanical recycling. On the contrary, chemical recycling processes are frequently less sensitive to mixed and contaminated plastics, and the resultant polymers exhibit comparable performance to virgin materials. The technological, economic, and ecological elements of chemical recycling technologies, however, need to be examined more closely because they are still in the early stages of becoming widely used [

54].

Plastics manufactured from renewable feedstock, such as plants, can be used in part or in full in bio-based products. Furthermore, new materials are created from biological waste, industrial side streams and residues, or even CO

2. They all bind carbon from the atmosphere, which is something they all have in common. The carbon in materials produced from fossil fuels, on the other hand, originates from the geosphere and is released into the atmosphere after the useful lives of these materials. By 2020, just 1% of all plastics would be produced using bio-based feedstock. To lead the shift to bio-based plastics, however, a growing number of businesses have emerged. The recycling and waste management systems also need to take this into consideration. Some bio-based plastics, such as bio-PE and bio-PP, are chemically equivalent to the polymers made from fossil fuels and donot need to be managed differently in the waste stream. On the other hand, PLA is a popular bio-based polymer whose quantities are yet insufficient to establish distinct PLA recycling streams. It is sometimes criticized as “non-recyclable” or even hazardous to current recycling streams because of this; however, the arguments are generally unsupported by evidence. In contrast, research reported that up to three weight percent of PLA was safe to use on injection-moulded PP recycling materials and may therefore be redirected into the PP stream. An economically viable dedicated PLA stream may already be possible at volumes greater than this. Moreover, many PLA-based goods may be naturally recycled in composting facilities; however, at present, this is reliant on the regional guidelines and composting equipment [

55].

6. Polymers in Biomedical Applications

As a biocompatible material, BDPs have opened the door to integrating with a variety of medical problems [

56]. BDPs are used in the medical sector since they are less hazardous than other materials. Unlike in typical BDP applications, there are several factors to consider when utilizing biodegradable materials as biomaterials (BMs). Non-toxicity, stabilizability, efficacy, and biocompatibility are among these characteristics. Although it is impossible to gain all of the information about most BDPs, scientists, physicians, and engineers have discovered that certain BDPs may be utilized as BMs which closely interact with live cells. There are two common applications of BMs. BMs can be used in waste items, such as blood bags, catheters, and syringes, representing the first application. The second use is in surgical support materials. BMs may be used for tissue replacement prosthetics such as lenses, dental implants, and breast implants, as well as artificial organs such as artificial hearts and kidneys [

57].

Table 1 highlights a list of some biopolymers and their emerging applications.

BDPs have many surgical applications [

56,

58]. BDPs with bioabsorbable characteristics are utilized for bonding, closure, separation, scaffolding, and capsulation. BDPs are used in operations for tissue adhesion and sealing. In this instance, liquid polymers are utilized. The liquid will turn to gel and halt bleeding as soon as it is applied to the damaged tissue. The gelled substance will gradually dissolve and integrate into the body as the damaged tissue heals. Bone fixation using biodegradable pins, screws, and wires follows the same procedures. Biodegradable polymers are used in drug delivery systems. This may include both invasive and non-invasive medication delivery techniques. These polymers serve as a transporter in this instance, and after transporting the medication to the appropriate location, they will rapidly integrate into the body without causing damage. The most basic example encountered in everyday life is pill covers and coatings in various colors. The medication is contained inside the cover, which should be eliminated without causing harm to the body. BDPs are used to create these coverings and coatings.

Over the last two decades, significant progress has been made in the development of biocompatible and biodegradable substances for biomedical and industrial applications [

58]. Biomedical research aims to develop and characterize artificial materials, or “spare parts”, for use in the human body to assess, repair, and enhance physiologic function, as well as to improve survival and quality of life. Inorganic (metals, ceramics, and glasses) and polymeric materials include artificial heart valves (polymeric or carbon-based), synthetic blood vessels, artificial hips (metallic or ceramic), medical adhesives, sutures, dental composites, and polymers for controlled slow drug delivery [

59]. When designing innovative biocompatible materials, bioactivity as it relates to interacting with and becoming integrated into the biological environment, as well as other customizable features dependent on the specific in vivo application, are all taken into account.

Biomimetics is a related field that might be characterized as “the abstraction of outstanding design from nature” or, to put it another way, “stealing ideas from nature”. The goal is to develop materials inspired by nature and integrated with non-biological technologies or processes for non-biological purposes. This is swiftly emerging as a new topic of research. Biocompatible polymers have been a popular focus of research for regulated medication delivery [

6,

60,

61]. It developed out of a need for more precise and extended pharmaceutical delivery. The goal of controlled release devices is to keep medicine within the prescribed limit with a single dose. Localized drug delivery to a specific physiological compartment lowers systemic drug levels, reduces follow-up care, preserves quickly degraded medicines, and improves patient comfort and/or compliance. The architecture of the system determines release rates, which are virtually independent of environmental variables.

7. Pharmaceutical Applications of Biopolymers

Biopolymers have progressively started to replace conventional materials due to their unique features. Although initially they were primarily employed in the food sector, they swiftly found usage in other adjacent industries. Biopolymers were first employed in the pharmaceutical sector for the same reason they were in the food sector: as thickening and emulsifying agents, host molecules, bulking agents, or fibers. Additionally, their application in cosmetics has grown significantly. By the end of 2021, the global biopolymer market is predicted to have grown by approximately 17% from 2017 to 2021, reaching an estimated value of USD 10 billion. With approximately41.5% of the worldwide market, Western Europe dominates the largest market sector. Polymers have been effectively employed in biomedicine in both experimental and in vivo settings, including for drug administration, tissue engineering, wound dressing, and the construction of medical devices with electronics, sensors, and batteries. In addition, biopolymers are perfect materials commonly employed in the food and pharmaceutical industries due to their physical, thermal, mechanical, and optical qualities [

62].

The internal structure-dependent functional qualities of biopolymers, such as microstructure, permeability, and chargeability, may be obtained by modifying the composition and matrix of the polymer. The ability of particles to aggregate and form bonds inside the biopolymer matrix is influenced by their electrical properties. The biopolymer fractions with a high electrical charge are those that inhibit aggregation. Based on these characteristics, biopolymers are effectively employed to create nanoparticles, nanoemulsions, nanogels, or hydrogels that are used as carrier systems in the biomedical industry. To supplement or replace synthetic materials, polysaccharides are the most often employed class of biopolymers. They can be used alone or in mixes with other biopolymers. In both micro- and macrocapsules, encapsulation entails preventing live cells from being destroyed by trapping them in biopolymer membranes. It is a process wherein one or more materials—representing the active component or core material—are embedded or covered with another material or system, which serves as a mantle, shell, carrier, or encapsulant [

63].

The very substantial discrepancy between surface area and volume is a distinguishing characteristic of macrocapsules. As a result, a high quantity of nutrients must be used to provide a proper diffusion gradient for nutrient entry. The crucial nutrients for the cells also fall under this category. Living cells are contained in macrocapsules, which are composed of sizable diffusion chambers that are shaped as flat sheets, hollow fibers, and semi-permeable discs. Both intra- and extra-vascular devices can utilize macrocapsules. Cells are positioned outside the artificial capillaries and linked to the circulation using intravascular devices. They are located close to blood circulation, facilitating the quick movement of beneficial and nourishing materials such asoxygen. Although, the risk of developing thrombosis is the main drawback. To avoid the necessity for direct circulatory access, research is leaning towards use of microcapsules as extra-vascular devices with cells contained within semi-permeable diffusion chambers that are applied transdermally or in the peritoneal cavity. This only requires modest surgery and enables a quick and simple replacement if the graft fails or the transplant needs to be changed for other reasons. Microcapsules efficiently transport helpful compounds and faithfully replicate the release of molecules such as insulin or glucose. The majority of studies concentrate on creating microcapsules with minimal or no inflammatory reactions due to their advantages. Endocrine problems are effectively treated by using this characteristic.

As materials for encapsulation, several biocompatible polymers have been employed. This requires a biopolymer to fulfill the following requirements: (i) stability and absence of interaction with the drug it contains; (ii) non-interference with cellular function or viability; (iii) non-toxicity, low cost, and biodegradability; (iv) molecular weight, solubility properties, glass transition temperature, microstructure, and chemical functionality allowing for proper drug diffusion and release; (v) biosafety; and (vi) biocompatibility [

64].

The controlled release techniques may change depending on the mechanism governing the release of active agents from the delivery system. As a result, biopolymer erosion, diffusion, and swelling may occur before diffusion or degradation. To control the release of macromolecules, hydrogels must first be hydrolyzed. Water-insoluble biopolymers must then be solubilized by reactions with groups hanging from the covalently bonded atoms of the polymer, and finally, hydrolytically labile bonds within the covalently bonded atoms of the biopolymer must be broken. The biopolymer present in controlled release device allows an encapsulated medicine or other active agents to pass through the outer membrane of capsules during the diffusion process. Diffusion-controlled systems require a drug delivery system that is stable in the biological setting and retains its size and form despite swelling or deterioration. When additional bioactive chemicals are mixed with biopolymers, for instance, the medicine must be able to permeate through the molecular structure of the polymer or via its pores to reach the biological environment. The biopolymer itself must stay unchanged at this point. Devices with swelling controlled release mechanisms are those that, while initially dry, swell after they enter the body and encounter bodily fluids or water. Changing the environmental conditions of delivery systems can cause the ability of biopolymers to swell. This is one of the most significant and practical properties of biopolymers since it allows for the control of medication or integrated active ingredient release by adjusting temperature or pH. Last but not least, a biodegradation of polymers in the body is a natural procedure that allows the active component to be entirely removed [

65].

The use of synthetic polymers as encapsulating agents for various medicinal compounds has long been of interest. Despite having better pharmacokinetics than small-molecule medications, their buildup in the body has led to toxicity concerns. The choice of the appropriate compounds based on the requirement and desired effects are the main challenge with the reorientation of the medical business towards the usage of biopolymers. Not all biopolymers are effective drug encapsulation agents. Since oral or intravenous administration is the two most common routes of administration, the active ingredient must be released to the target location at the appropriate time, safely, and without any negative side effects. The biopolymers based on polysaccharides, such as sodium alginate, chitosan, agar, starch, and cellulose, are the most widely utilized and the subject of this review. They have minimal toxicity, exhibit non-immunogenic behavior, interact synergistically with other biopolymers and polymers, and are compatible with tissues and cells. These polysaccharides are used to create microcapsules, microspheres, or nanocapsules and are stable both in vitro and in vivo. They demonstrated significant levels of biocompatibility and biodegradability when evaluated in vivo, which facilitated treatment, reduced side effects, and enhanced the state of health. Their high solubility makes them ideal for use as disintegrants in tablets that are soluble in water. For instance, the starch and chitosan coating added to tablets enhanced their aesthetic presentation, shielded the medication from deterioration, and masked the compound’s bad flavor. Alginate, a vegan alternative to gelatin, or cellulose for hard capsules, was substituted for gelatin when utilized as capsule material [

66].

A relevant category of controlled-release systems is the mechanism that governs the release of the chemical in question. The most common approach is diffusion. A reservoir device, in which the bioactive material (drug) is confined and encircled by an inert diffusion barrier, is the first type of diffusion-controlled system. These systems include membranes, capsules, microcapsules, liposomes, and hollow fibers. The active chemical is spread or dissolved in an inert polymer in a monolithic device, on the other hand. The rate-limiting phase in drug release is drug diffusion through the polymer matrix, much as it is in reservoir systems, and release rates are limited by the polymer used and its influence on the diffusing and partitioning ratio of the drug to be released [

67,

68].

Chemical control may be achieved via bio-erodible or pendant links in chemically controlled systems. The use of bio-erodible (or biodegradable) systems is justified since bio-erodible devices are absorbed by the body and therefore do not require surgical removal. The transition of a water-insoluble material into a water-soluble substance is known as polymer bio-erosion. The drug in a bio-erodible system is disseminated equally throughout the polymer, similar to the way it is in monolithic systems. When the polymer that surrounds it erodes, the drug escapes. Water or enzymes trigger bond scission, releasing the drug which is covalently bonded to the polymer in a pendant chain form [

49,

69]. In solvent-activated controlled systems, the active component is dissolved or dispersed inside a polymeric matrix and is impossible to permeate through. As the environmental fluid (e.g., water) enters the matrix, the polymer expands and the glass transition temperature drops below the ambient (host) temperature in one kind of solvent-controlled system [

70]. As a result, the encapsulant’s enlarged polymer becomes stretchy, enabling the medication to pass through.

Figure 3 represents various drug delivery devices.

9. Economic Potential

The market for bio-based polymers is anticipated to reach USD 29.8 billion by 2027, expanding at a CAGR of 18.2% from 2022 to 2027. Sustainable polymers known as “bio-based polymers” are created from renewable resources including biomass, starch, and rubber, among others. Bio-based polymers’ starting components originate from plants, animals, enzymes, or microbes. Polylactic acid, also known as polylactide, is considered to be compostable and biodegradable. One of the key factors influencing the market for bio-based polymers during the projected period is the rise in environmental concerns regarding the disposal and recycling of synthetic polymers. The market expansion for bio-based polymers is also being supported by the increasing acceptance of bio-based materials in the end-use sectors, including packaging, pharmaceutical, construction, and consumer products, among others. Chitosan is one of the most popular bio-based polymers because it has amino groups on its polymer backbone, making it a rare natural cationic polymer. Global bioplastics output in 2021 was 2.42 million tonnes, according to figures released by European Bioplastics in partnership with the nova-Institute. Nevertheless, over the projection period of 2022–2027, the market expansion is projected to be hampered by the high cost of bio-based polymers. The market share of polyhydroxyalkanoates, which was over 30% in 2021, is expected to increase significantly over the course of the projected period. PHAs safeguard the environment and aquatic life by degrading in soil, water, and municipal waste treatment facilities. The demand for the polyethylene sector is being driven by the rising need for rigid and flexible packaging across a variety of industries, including food, beverage, and pharmaceutical industries. Numerous packaging materials, including carry bags, plastic films, and bottles, among others, employ polyhydroxyalkanoate. In 2020, 49 million metric tonnes of bottled drinking water will be produced annually, according to DCC China [

78].

Approximately 58% of the market in 2021 was accounted for by the packaging segments, which are predicted to expand at a noteworthy CAGR. The packaging sector now has increasing need for bio-based polymers due to consumer lifestyle changes and tightening environmental laws regarding the use of synthetic polymers. The packaging business has boosted demand for polymers because of the great durability and water resistance of plastics. Among additional packaging uses for bio-based polymers are shopping bags, cosmetic and personal care packaging, healthcare packaging, and food packaging. All merchants will now be required to pay a levy for the use of plastic shopping bags starting in July 2020, except for those that are biodegradable and those made with at least 25% renewable plant-based resources. The Coca-Cola Company manufactures over 3 million tonnes of plastic packaging annually, according to the Forbes article. These are a few of the elements influencing the packaging market.

In 2021, the Asia Pacific area accounted for up to 42% of the global market for bio-based polymers, because of the booming packaging, food and beverage, and pharmaceutical sectors. The market expansion in the area is being fueled by the presence of growing countries such as China and India. The area demand is further supported by a large supply of raw materials and a readily available workforce. Leading manufacturers of food, drink, and personal care products, including Nestle, PepsiCo, Coca-Cola, LOreal SA, Procter & Gamble, Beiersdorf AG, Unilever PLC, and others, are present in the region, supporting regional growth during the course of the projection period. The China Chain Store and Franchise Association reported that the country’s food and beverage (F&B) market reached over USD 595 billion in 2019. Because bio-based polymers have a high cost of polymerization, their manufacturing costs are typically 20% to 80% higher than those of conventional polymers. In comparison to their petrochemical equivalents, which have been developing quickly for more than 50 years, bio-based products are generally still in the development stage and have not yet reached the same degree of commercialization. Only 1% of the world’s total polymers are produced from bio-based materials, as opposed to 99% of the widely accessible conventional polymers. While standard polymers are available for USD 1/kg to US D 2/kg, bio-based polymers range in price from USD 2/kg to US D 5/kg. Because of this, the market expansion during the projected period is being constrained by the high cost of bio-based polymers [

79].

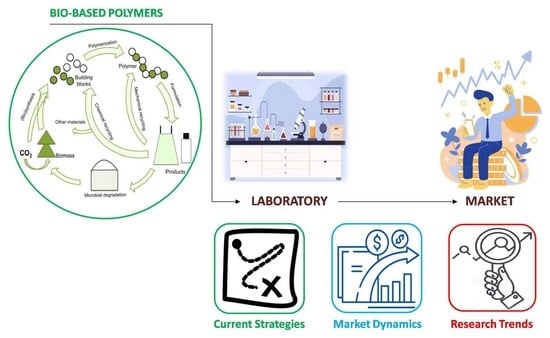

10. Current Strategies, Market Dynamics, and Research Trends

10.1. Current Strategies

Material selection is one of the most important tactics for the successful commercialization of bio-based polymers. The right feedstock must be chosen by researchers before bio-based polymers can be produced. The choice of feedstock is critical since it can alter the characteristics of the polymer and the environmental effect. Several feedstocks are available for the manufacturing of bio-based polymers, including sugarcane, maize, potato, and other biomass sources. For instance, maize is used to make polylactic acid (PLA), which has high processing, biodegradability, and mechanical qualities. The choice of feedstock must take into account its accessibility, affordability, and environmental effect. The process of synthesizing polymers is another important tactic. Bio-based polymers must be produced using specialized polymerization processes that are suited to the particular feedstock. To attain the required molecular weight, crystallinity, and other qualities, the reaction conditions must be optimized. In the case of polyhydroxyalkanoates (PHAs), microbial fermentation is used. The resultant polymer is versatile, biodegradable, and has high mechanical characteristics. In order to achieve consistency in quality, cost-effectiveness, and commercial viability, the polymerization process must be optimized.

Another essential tactic for a successful commercialization is the scaling up of the manufacture of bio-based polymers. To guarantee cost-effectiveness and consistency in quality, the production process must be optimized as part of the scaling-up process. The scale-up procedure must take into account a number of variables, such as reactor size, feedstock supply, and downstream processing. In the scale-up process, the deployment of pilot plants is also crucial. Enzymes are used to depolymerize waste PET, which is followed by purification and repolymerization of the resultant monomers to produce bio-based polyethylene terephthalate (PET). This procedure has been successfully scaled up to allow for the commercial production of bio-based PET. Other crucial tactics in the commercialization of bio-based polymers include certification and regulatory compliance. To guarantee their safety and effectiveness, bio-based polymers must adhere to strict regulatory standards. To guarantee that they adhere to the appropriate criteria for biodegradability, toxicity, and other important factors, testing and certification are required. Testing for biodegradability in a variety of settings, including soil, the ocean, and commercial composting facilities, is often required for the certification of bioplastics. Moreover, bio-based polymers need to adhere to a number of rules, such as the REACH regulation of the European Union, which seeks to ensure the safe use of chemicals in the EU [

45].

10.2. Market Dynamics

The market dynamics of emerging bio-based polymers are influenced by a variety of factors, including regulations, feedstock availability, cost-effectiveness, and competition from other sustainable materials. One of the primary factors influencing the market dynamics of emerging bio-based polymers is regulatory requirements. Governments across the world are implementing regulations to reduce the use of single-use plastics and promote the use of eco-friendly alternatives. For example, the European Union’s Single-Use Plastics Directive aims to reduce the consumption of single-use plastics and promote the use of bio-based and biodegradable materials. Such regulations create a favorable market for bio-based polymers, as companies seek to comply with these requirements.

Another key factor impacting the market dynamics of bio-based polymers is feedstock availability. Bio-based polymers are primarily produced from agricultural crops such as corn and sugarcane. The availability and cost of these feedstocks can significantly impact the cost of bio-based polymers. In recent years, researchers have been exploring alternative feedstocks, such as waste streams from various industries, to reduce the cost of bio-based polymers and increase their availability. Cost-effectiveness is also a significant factor in the market dynamics of bio-based polymers. While bio-based polymers are eco-friendly, they must also be cost-effective to be competitive with traditional plastics. Companies are exploring innovative methods for the production of bio-based polymers to reduce production costs and increase efficiency. For example, researchers are developing microbial fermentation processes for the production of bio-based polymers, which has the potential to reduce production costs significantly.

Competition from other sustainable materials is another factor impacting the market dynamics of bio-based polymers. While bio-based polymers offer a sustainable alternative to traditional plastics, they are not the only option. Companies must compete with other materials, such as recycled plastics and paper-based materials, to provide the most sustainable and cost-effective solutions for their customers. Consumer demand is another significant driver of the market dynamics of emerging bio-based polymers. Consumers are becoming increasingly aware of the environmental impact of traditional plastics and are seeking eco-friendly alternatives. As a result, there is a growing demand for bio-based polymers from consumers who aim to reduce their carbon footprint [

80].

10.3. Research Trends

The rapid development of novel feedstocks is one of the key research themes in the creation of bio-based polymers. Many bio-based polymers are now produced from agricultural crops such as maize and sugarcane, but scientists are also examining additional biomass sources such waste streams from different sectors, agricultural and forestry wastes, and algae. These feedstocks may be more affordable, more readily available, and less in conflict with food crops. Researchers are also searching for ways to develop more productive and environmentally friendly production processes in order to maximize the conversion of these feedstocks into bio-based polymers. The alteration of current materials to enhance their qualities is a significant topic of research in the realm of bio-based polymers. For instance, scientists are researching the ways to modify polylactic acid (PLA) in order to increase its flexibility and robustness. Nowadays, PLA is utilized in many different contexts, including packaging, but its brittleness has restricted its use in other contexts. Other bio-based polymers with potential for use in the medical and pharmaceutical sectors, such as polyhydroxyalkanoates (PHAs), are also being studied for methods to enhance their mechanical qualities.

Another significant trend in research is the biodegradability and compostability of bio-based polymers. These characteristics are crucial to the way bio-based polymers affect the environment and their capacity to reduce plastic waste. To increase the biodegradability and compostability of bio-based polymers, researchers are examining the ways to improve their chemical structure and molecular weight. Researchers are also investigating the possibility of creating novel biodegradable materials that may offer a larger variety of applications, including textiles, electronics, and automobile components. A prominent research topic in the area of bio-based polymers is the upcycling and recycling of materials. Recycling and upcycling have the ability to lessen the environmental impact of bio-based polymers just as well as biodegradable and compostable products in terms of plastic waste reduction. In order to recycle bio-based polymers, scientists are considering several strategies, such as using enzymes and microorganisms to break down the materials into their component components, which may then be utilized to create new bio-based polymers. Another method being researched as a way to lessen waste and advance the circular economy is upcycling, which is turning waste materials into goods with higher value.

Improved characteristics, broader potential applications, and cost-effective large-scale production are the main goals of the current research trends in new bio-based polymers. Significant research is conducted in the areas of examining novel feedstocks, modifying current materials, and enhancing biodegradability and compostability. Investigations into recycling and upcycling are especially crucial in the field of bio-based polymers because they have the potential to cut waste and advance the circular economy. These developments in research are essential for the creation and commercialization of bio-based polymers, which have the potential to drastically lessen the environmental effect of plastics and advance the progression of a more sustainable future [

81].

11. Conclusions

Future growth of the bio-based polymer sector is anticipated to be significant due to the growing need for green chemicals on a worldwide scale. For decades, scientists have been investigating the production of functional polymers. The primary inspirations for the development of bio-based polymers—which are necessary for a society that cares about reducing waste—are compostability and biodegradability. This increase has been fueled by significant advancements in the production of bio-based construction materials and technology for the processing of biomass raw materials. Because of this, the chemical structure of bio-based polymers is uniquely versatile and flexible, enabling them to achieve the desired properties and functions. Such polymers play a major role in biomedical and biotechnological applications as well as industrial applications, where biomolecules that naturally exist are meticulously produced. At the same time, restrictions on the management of polymer design, biostability, and structural dynamics obstruct the efficient production of biocompatible and functionally diverse polymers despite major advancements. In light of this, the significance of functional biosynthetic polymers in the next years has been highlighted, and innovative methods have been created to address the aforementioned difficulties. The most recent technical developments in bio-based polymers are also discussed. Due to the importance of polymer research in our daily lives, demand is growing fast. The production of polymeric materials that are green, sustainable, energy-efficient, high-quality, and affordable will guarantee that the best solutions are available everywhere, and these polymers will be the foundation of the new millennium. In an effort to provide the greatest goods with sustainable qualities, scientists and researchers keep working to develop this material via studies and research. These people are finding successful careers in the rubber, polymer, petroleum, and oil industries because of their increased polymer engineering skills. Conversely, less attention is directed towards the end-of-life fates of polymers. We suggest shifting more of a focus on chemical recycling in the future; chemical recycling recognizes the value in plastic trash and promotes a closed-loop plastic economy. The synthetic polymer community should regularly seek out the systems viewpoint offered by life cycle assessment to help keep us on the path towards sustainability.