Replacing Lime with Rice Husk Ash to Reduce Carbon Footprint of Bituminous Mixtures

Abstract

:1. Introduction

Objectives

- Analyze the suitability of HL and RHA individually as fillers by evaluating their essential properties.

- Examine the effect of each filler on the physical and morphological behavior of the resultant bituminous mastics.

- Design dense bituminous macadam mixes using each filler at four percentages (2%, 4%, 6%, and 8%) and compare their mechanical and durability properties at the corresponding optimum bitumen content.

- Analyze the economic viability of each filler by comparing the costs of the prepared mixes.

2. Materials and Methods

2.1. Materials

2.2. Test for Filler Characterization

2.3. Designing and Testing of Bituminous Mastics and Mixes

2.3.1. Preparation of Mastic Samples

2.3.2. Determination of the Physical Properties of Mastic

2.3.3. Morphological Analysis by Optical Microscopy Test

2.3.4. Marshall and Volumetric Properties

2.3.5. Cracking Resistance

2.3.6. Resistance to Moisture Damage

2.3.7. Creep Resistance

3. Results and Discussion

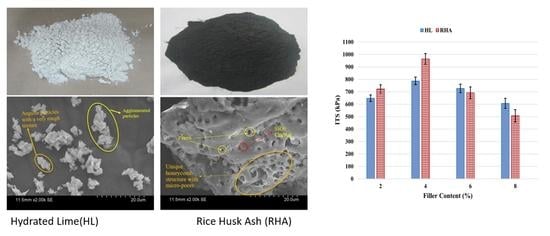

3.1. Filler Characterization

3.2. Mastic Evaluation

3.2.1. Physical Properties of Mastics

3.2.2. Morphological Analysis of Mastic

3.3. Performance of Bituminous Mixes

3.3.1. Marshall and Volumetric Properties

3.3.2. Cracking Resistance

3.3.3. Resistance to Moisture Damage

3.3.4. Creep Resistance

3.4. Cost Analysis

4. Conclusions

- Mixtures containing RHA (up to 4%) were shown to have enhanced Marshall stabilities and volumetric characteristics compared to those containing HL.

- The mixture containing 4% RHA had the lowest optimum binder content; this can be attributed to RHA’s physiochemical characteristics and particle size distribution.

- Compared to the control mixture containing HL, the mixture containing RHA had a nearly 47% higher resistance to cracking and 40% higher resistance to permanent deformation. This was attributed to the RHA micro-particles containing three-dimensional micro sheets and columnar SiO2 crystals, forming a stable and viscous three-dimensional network with bitumen compared to the control mixture.

- Resistance to moisture damage in mixtures containing RHA was found to be slightly better than that of mixtures containing HL. This can be attributed to the active silica in RHA and physiochemical characteristics of RHA, which can adsorb acidic compounds of bitumen, as shown by prior studies [38].

- Mixtures containing RHA had lower carbon footprints than mixtures containing HL. In terms of production cost, mixtures containing RHA cost 5% less than the control mixture containing HL.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Mistry, R.; Karmakar, S.; Kumar Roy, T. Experimental evaluation of rice husk ash and fly ash as alternative fillers in hot-mix asphalt. Road Mater. Pavement Des. 2019, 20, 979–990. [Google Scholar] [CrossRef]

- MORTH (Ministry of Road Transport and Highways). Specifications for Road and Bridge Works (Fifth Revision); Indian Road Congress: New Delhi, India, 2013.

- Kandhal, P.S.; Lynn, C.Y.; Parker, F. Characterization Tests for Mineral Fillers Related to Performance of Asphalt Paving Mixes; NCAT Rep. No. 98-2; Auburn University: Auburn, AL, USA, 1998. [Google Scholar]

- Sargın, Ş.; Saltan, M.; Morova, N.; Serin, S.; Terzi, S. Evaluation of rice husk ash as filler in hot mix asphalt concrete. Constr. Build. Mater. 2013, 48, 390–397. [Google Scholar] [CrossRef]

- Lesueur, D.; Petit, J.; Ritter, H.J. The mechanisms of hydrated lime modification of asphalt mixtures: A state-of-the-art review. Road Mater. Pavement Des. 2013, 14, 1–16. [Google Scholar] [CrossRef]

- Choudhary, J.; Kumar, B.; Gupta, A. Application of waste materials as fillers in bituminous mixes. Waste Manag. 2018, 78, 417–425. [Google Scholar] [CrossRef] [PubMed]

- EEA (European Environment Agency). Air Pollutant Emission Inventory Guidebook; Technical Report No 9; European Environment Agency: Copenhagen, Denmark, 2009. [Google Scholar]

- FAOSTAT. 2014. Available online: http://www.fao.org/faostat/en/#data/QC/visualize (accessed on 16 June 2020).

- National Food Security Mission. 2016. Available online: https://nfsm.gov.in/StatusPaper/Rice2016.pdf (accessed on 23 June 2020).

- Mistry, R.; Kumar, T. Utilization of rice husk ash in hot mix asphalt concrete as mineral filler replacement. J. Indian Road Cong. 2015, 76, 13–17. [Google Scholar]

- Mehta, P.K. Testing and Correlation of Fly Ash Properties with Respect to Pozzolanic Behavior; University of California: Berkeley, CA, USA, 1984. [Google Scholar]

- Arabani, M.; Tahami, S.A. Assessment of mechanical properties of rice husk ash modified asphalt mixture. Constr. Build. Mater. 2017, 149, 350–358. [Google Scholar] [CrossRef]

- Arabani, M.; Tahami, S.A.; Taghipoor, M. Laboratory investigation of hot mix asphalt containing waste materials. Road Mater. Pavement Des. 2017, 18, 713–729. [Google Scholar] [CrossRef]

- ASTM D854-14; Standard Test Methods for Specific Gravity of Soil Solids by Water Pycnometer. ASTM: West Conshohocken, PA, USA, 2014.

- ASTM D422-63; Standard Test Method for Particle-Size Analysis of Soils. ASTM: West Conshohocken, PA, USA, 2007.

- IS 4031 (Part 2); Methods of Physical Tests for Hydraulic Cement (Determination of Fineness by Blaine Air Permeability Test). IS (Indian Standard): New Delhi, India, 1978.

- ASTM E986-04; Standard Practice for Scanning Electron Microscope Beam Size Characterization. ASTM: West Conshohocken, PA, USA, 2017.

- ASTM C837-09; Standard Test Method for Methylene Blue Index of Clay. ASTM: West Conshohocken, PA, USA, 2009.

- ASTM E1621-13; Standard Guide for Elemental Analysis by Wavelength Dispersive X-ray Fluorescence Spectrometry. ASTM: West Conshohocken, PA, USA, 2010.

- Mistry, R.; Roy, T.K. Performance evaluation of bituminous mix and mastic containing rice husk ash and fly ash as filler. Constr. Build. Mater. 2021, 268, 121187. [Google Scholar] [CrossRef]

- Zhang, J.; Wang, J.; Wu, Y.; Wang, Y.; Wang, Y. Evaluation of the improved properties of SBR/weathered coal modified bitumen containing carbon black. Constr. Build. Mater. 2009, 23, 2678–2687. [Google Scholar] [CrossRef]

- Price, A.; Yeargin, R.; Fini, E.; Abu-Lebdeh, T. Investigating effects of introduction of corncob ash into Portland cements concrete: Mechanical and thermal properties. Am. J. Eng. Appl. Sci. 2014, 7, 133–144. [Google Scholar] [CrossRef] [Green Version]

- Asphalt Institute. Mix Design Methods for Asphalt Concrete and Other Hot-Mix Types: Manual Series No. 2 (MS-2), 6th ed.; Asphalt Institute: Lexington, KY, USA, 1997. [Google Scholar]

- ASTM D6927-15; Standard Test Method for Marshall Stability and Flow of Asphalt Mixtures. ASTM: West Conshohocken, PA, USA, 2015.

- ASTM D3203–17; Standard Test Method for Percent Air Voids in, Compacted Asphalt Mixtures. ASTM: West Conshohocken, PA, USA, 2017.

- ASTM D6931-12; Indirect Tensile (IDT) Strength for Bituminous Mixtures. ASTM: West Conshohocken, PA, USA, 2012.

- T283; Resistance of Compacted Bituminous Mixture to Moisture Induced Damage. AASHTO: Washington, DC, USA, 1989.

- BS 598-111; Method for Determination of Resistance to Permanent Deformation of Bituminous Mixtures Subjected to Uniaxial Loading. British Standards Institution: London, UK, 1995.

- Choudhary, J.; Kumar, B.; Gupta, A.C. Feasible utilization of waste limestone sludge as filler in bituminous concrete. Constr. Build. Mater. 2020, 239, 117781. [Google Scholar] [CrossRef]

- ASTM C618; Standard Specification for Coal Fly Ash and Raw or Calcined Natural Pozzolan for Use in Concrete. ASTM: West Conshohocken, PA, USA, 2003.

- FHWA (Federal Highway Administration). User Guidelines for Waste and by Product Materials in Pavement Construction; FHWA Report 97148; Federal Highway Administration: Washington, DC, USA, 2016.

- Ameli, A.; Babagoli, R.; Norouzi, N.; Jalali, F.; Mamaghani, F.P. Laboratory evaluation of the effect of coal waste ash (CWA) and rice husk ash (RHA) on performance of asphalt mastics and Stone matrix asphalt (SMA) mixture. Constr. Build. Mater. 2020, 236, 117557. [Google Scholar] [CrossRef]

- Kütük-Sert, T.; Kütük, S. Physical and Marshall properties of borogypsum used as filler aggregate in asphalt concrete. J. Mater. Civ. Eng. 2013, 25, 266–273. [Google Scholar] [CrossRef]

- Read, J.; Whiteoak, D. Shell Bitumen Handbook, 5th ed.; Thomas Telford: Telford, UK, 2003. [Google Scholar]

- Srivastava, V.C.; Mall, I.D.; Mishra, I.M. Characterization of mesoporous rice husk ash (RHA) and adsorption kinetics of metal ions from aqueous solution onto RHA. J. Hazard. Mater. B 2006, 134, 257–267. [Google Scholar] [CrossRef] [PubMed]

- Kandhal, P.S.; Chakraborty, S. Effect of Asphalt Film Thickness on Short- and Long-Term Aging of Asphalt Paving Mixtures. Transp. Res. Rec. 1996, 1535, 83–90. [Google Scholar] [CrossRef]

- Tapkin, S. Mechanical Evolution asphalt-aggregate mixtures prepared with fly ash as a filler replacement. Can. J. Civ. Eng. 2008, 35, 27–40. [Google Scholar] [CrossRef]

- Fini, E.H.; Hung, A.M.; Roy, A. Active mineral fillers arrest migrations of alkane acids to the interface of bitumen and siliceous surfaces. ACS Sustain. Chem. Eng. 2019, 7, 10340–10348. [Google Scholar] [CrossRef]

- Oldham, D.; Mallick, R.; Fini, E.H. Reducing susceptibility to moisture damage in asphalt pavements using polyethylene terephthalate and sodium montmorillonite clay. Constr. Build. Mater. 2021, 269, 121302. [Google Scholar] [CrossRef]

- Karnati, S.R.; Oldham, D.; Fini, E.H.; Zhang, L. Application of Surface-Modified Silica Nanoparticles with Dual Silane Coupling Agents in Bitumen for Performance Enhancement. Constr. Build. Mater 2020, 244, 118324. [Google Scholar] [CrossRef]

- Mousavi, M.; Fini, E. Silanization Mechanism of Silica Nanoparticles in Bitumen Using 3-Aminopropyl Triethoxysilane (APTES) and 3-Glycidyloxypropyl Trimethoxysilane (GPTMS). ACS Sustain. Chem. Eng. 2020, 8, 3231–3240. [Google Scholar] [CrossRef]

- El Badawy, A.; Rahim, A. Evaluation of Nanoclay Additives for Improving Resistance to Moisture Damage in Hot Mix. 2023. Available online: https://rosap.ntl.bts.gov/view/dot/66358/dot_66358_DS1.pdf (accessed on 11 January 2023).

- WBPWD (West Bengal Public Works Department). Schedule of Rate for Road and Bridge Works-Vol III.; West Bengal Public Works Department: Kolkata, West Bengal, India, 2018.

| Property | Values | Specified Limits [2] |

|---|---|---|

| Aggregate impact value | 17% | max 27% |

| Los Angeles abrasion value | 20% | max 35% |

| Water absorption value | 1.3% | max 2% |

| Specific gravity | ||

| 2.86 | 2.5–3.0 |

| 2.71 | |

| Combined Flakiness and Elongation Index | 26.3% | max 35% |

| Property | HL | RHA |

|---|---|---|

| Specific Gravity | 2.15 | 2.00 |

| FM | 3.18 | 2.86 |

| UC | 2.33 | 2.92 |

| Specific surface area (m2/kg) | 431.5 | 565.8 |

| MBV (gm/kg) | 0.97 | 1.27 |

| Particle shape and texture (SEM) | Angular particles with uneven texture | Irregular porous particles with very rough texture |

| Chemical composition | ||

| SiO2 | 3.23 | 86.64 |

| CaO | 72.42 | 1.88 |

| Al2O3 | 0.41 | 1.66 |

| Fe2O3 | 0.31 | 1.06 |

| MgO | 0.46 | 0.97 |

| K2O | 0.13 | 0.40 |

| SO3 | 1.22 | 0.12 |

| Loss on ignition (LOI) | 21.69 | 6.15 |

| Filler Type | Amount of Filler (%) | OBC (%) | Marshall Stability (kN) | Flow (mm) | VMA (%) | VFB (%) |

|---|---|---|---|---|---|---|

| HL | 2 | 5.2 | 13.85 | 3.82 | 16.18 | 74.57 |

| 4 | 5.17 | 15.75 | 3.77 | 16.07 | 72.59 | |

| 6 | 5.35 | 14.75 | 3.79 | 16.32 | 74.79 | |

| 8 | 5.60 | 14.18 | 3.96 | 16.82 | 74.85 | |

| RHA | 2 | 5.15 | 14.5 | 3.65 | 15.93 | 70.44 |

| 4 | 4.91 | 17.25 | 3.48 | 15.66 | 70.83 | |

| 6 | 5.38 | 16.62 | 3.73 | 16.21 | 73.34 | |

| 8 | 5.42 | 15.93 | 3.82 | 16.5 | 73.87 | |

| Requirements (MORTH 2013) | - | 9.00 (min) | 2–4 | 13.00 (min) | 65–75 | |

| Materials | WBPWD Rates | Quantity in 1 m3 of Dense Bituminous Macadam Grade-II (50 to 75 mm) Thickness | |||

|---|---|---|---|---|---|

| 2% HL | 4% HL | 2% RHA | 4% RHA | ||

| Coarse Aggregate (m3) | 1536.35/m3 | 0.952 | 0.948 | 0.952 | 0.948 |

| Fine Aggregate (m3) | 1167.10/m3 | 0.483 | 0.452 | 0.483 | 0.452 |

| Hydrated Lime (kg) | 7.50/kg | 44 | 88 | 0 | 0 |

| Rice Husk Ash (kg) | 0 | 0 | 0 | 44 | 88 |

| Bitumen (kg) | 35.18/kg | 114.62 | 113.96 | 113.08 | 107.8 |

| Cost in (INR/m3) | 6389 | 6659 | 6005 | 5777 | |

| Transportation cost (INR/MT) | 84/MT | 0 | 0 | 3.696 | 7.392 |

| 0.5% for processing (INR/m3) | 0 | 0 | 300 | 289 | |

| Total Cost (INR/m3) | 6389 | 6659 | 6305 | 6066 | |

| Percentage saving in cost with respect to conventional mix (2% HL) (%) | 0 | −4.22 | 1.31 | 5.06 | |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Mistry, R.; Roy, T.K.; Aldagari, S.; Fini, E.H. Replacing Lime with Rice Husk Ash to Reduce Carbon Footprint of Bituminous Mixtures. C 2023, 9, 37. https://doi.org/10.3390/c9020037

Mistry R, Roy TK, Aldagari S, Fini EH. Replacing Lime with Rice Husk Ash to Reduce Carbon Footprint of Bituminous Mixtures. C. 2023; 9(2):37. https://doi.org/10.3390/c9020037

Chicago/Turabian StyleMistry, Raja, Tapash Kumar Roy, Sand Aldagari, and Elham H. Fini. 2023. "Replacing Lime with Rice Husk Ash to Reduce Carbon Footprint of Bituminous Mixtures" C 9, no. 2: 37. https://doi.org/10.3390/c9020037

APA StyleMistry, R., Roy, T. K., Aldagari, S., & Fini, E. H. (2023). Replacing Lime with Rice Husk Ash to Reduce Carbon Footprint of Bituminous Mixtures. C, 9(2), 37. https://doi.org/10.3390/c9020037