The Effects of Nanoparticles- Zerovalent Iron on Sustainable Biomethane Production through Co-Digestion of Olive Mill Wastewater and Chicken Manure

Abstract

:1. Introduction

2. Materials and Methods

2.1. Substrates

2.2. Analytical Methods

2.3. The Hydrolysis and Acidification Rate, and VS Destruction

2.4. Nanoparticles- Zerovalent Iron Preparation

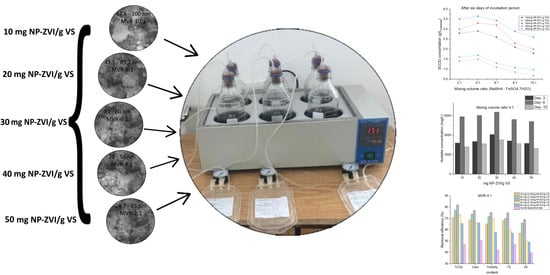

2.5. Experimental Setup

3. Results

3.1. Influence of NP-ZVIs on the AcoD Process

3.1.1. Effects of Dose and Size of NP-ZVIs on the Hydrolysis Percentage

3.1.2. Effects of Dose and Size of NP-ZVIs on the Percentage of Acidification

3.1.3. Effects of Dose and Size NP-ZVI on the Removal Contaminant and Biological Treatment

3.1.4. Effects of Dose and Size of NP-ZVI on the Biogas Yield and Methane Content

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Santamouris, M. Energy Consumption and Environmental Quality of the Building Sector. In Minimizing Energy Consumption, Energy Poverty and Global and Local Climate Change in the Built Environment: Innovating to Zero; Elsevier: Amsterdam, The Netherlands, 2019; pp. 29–64. [Google Scholar] [CrossRef]

- Alrawashde, K.; Talat, N.; Alshorman, A. Multi Stage Flashing Small Scale Plant Combined CHP Plant Driven by Biogas Plant. Int. J. Appl. Sci. Technol. 2017, 7, 51–59. [Google Scholar]

- IEA. World Energy Outlook; IEA: Paris, France, 2019; Chapter 7; pp. 328–333. Available online: https://www.iea.org/reports/world-energy-outlook-2019 (accessed on 5 September 2022).

- Al-Samrraie, L.A.; Alrawashdeh, K.A.B.; Al-Issa, H.A.; Shakhatreh, S.; Hussien, A.A.; Qasem, I. Improve Heavy Metals and Pollutants Removal from the Pharmaceuticals Wastewater Using Washingtonia Robusta: New Extractisssson Process. Civ. Environ. Eng. 2022, 18, 340–349. [Google Scholar] [CrossRef]

- Bkoor Alrawashdeh, K.A.; Gul, E.; Yang, Q.; Yang, H.; Bartocci, P.; Fantozzi, F. Effect of Heavy Metals in the Performance of Anaerobic Digestion of Olive Mill Waste. Processes 2020, 8, 1146. [Google Scholar] [CrossRef]

- Gul, E.; Campana, P.E.; Chandrasekaran, A.; Subbiah, S.; Yang, H.; Yang, Q.; Yan, J.; Li, H.; Desideri, U.; Barelli, L.; et al. Perspectives and State of the Art in Producing Solar Fuels and Chemicals from CO2. In Advanced Technology for the Conversion of Waste into Fuels and Chemicals; Elsevier: Amsterdam, The Netherlands, 2021; pp. 181–219. [Google Scholar] [CrossRef]

- Jurgutis, L.; Slepetiene, A.; Volungevicius, J.; Amaleviciute-Volunge, K. Biogas Production from Chicken Manure at Different Organic Loading Rates in a Mesophilic Full Scale Anaerobic Digestion Plant. Biomass Bioenergy 2020, 141, 105693. [Google Scholar] [CrossRef]

- Al bkoor Alrawashdeh, K. Anaerobic Co-Digestion Efficiency under the Stress Exerted by Different Heavy Metals Concentration: An Energy Nexus Analysis. Energy Nexus 2022, 7, 100099. [Google Scholar] [CrossRef]

- Al bkoor Alrawashdeh, K. Improving Anaerobic Co-Digestion of Sewage Sludge with Thermal Dried Olive Mill Wastewater. Waste Biomass Valorization 2018, 10, 2213–2219. [Google Scholar] [CrossRef]

- Bkoor Alrawashdeh, K.A.; Al-Essa, A.H. Anaerobic Co-Digestion Mill Wastewater—Activated Sludge Effect of Aerobic Pretreatment on the Performance of OMW Anaerobic Digestion. Waste Biomass Valorization 2020, 11, 4781–4788. [Google Scholar] [CrossRef]

- Liao, X.; Li, H.; Cheng, Y.; Chen, N.; Li, C.; Yang, Y. Process Performance of High-Solids Batch Anaerobic Digestion of Sewage Sludge. Environ. Technol. 2014, 35, 2652–2659. [Google Scholar] [CrossRef]

- Azbar, N.; Keskin, T.; Yuruyen, A. Enhancement of Biogas Production from Olive Mill Effluent (OME) by Co-Digestion. Biomass Bioenergy 2008, 32, 1195–1201. [Google Scholar] [CrossRef]

- Al Bkoor Alrawashdeh, K.; Al-Zboon, K.K.; Rabadi, S.A.; Gul, E.; AL-Samrraie, L.A.; Ali, R.; Al-Tabbal, J.A. Impact of Iron Oxide Nanoparticles on Sustainable Production of Biogas through Anaerobic Co-Digestion of Chicken Waste and Wastewater. Front. Chem. Eng. 2022, 4, 974546. [Google Scholar] [CrossRef]

- Yuan, T.; Bian, S.; Ko, J.H.; Liu, J.; Shi, X.; Xu, Q. Exploring the Roles of Zero-Valent Iron in Two-Stage Food Waste Anaerobic Digestion. Waste Manag. 2020, 107, 91–100. [Google Scholar] [CrossRef] [PubMed]

- Domrongpokkaphan, V.; Phalakornkule, C.; Khemkhao, M. In-Situ Methane Enrichment of Biogas from Anaerobic Digestion of Palm Oil Mill Effluent by Addition of Zero Valent Iron (ZVI). Int. J. Hydrogen Energy 2021, 46, 30976–30987. [Google Scholar] [CrossRef]

- Zhang, Y.; Jing, Y.; Quan, X.; Liu, Y.; Onu, P. A Built-in Zero Valent Iron Anaerobic Reactor to Enhance Treatment of Azo Dye Wastewater. Water Sci. Technol. 2011, 63, 741–746. [Google Scholar] [CrossRef] [PubMed]

- Deng, S.; Peng, S.; Xie, B.; Yang, X.; Sun, S.; Yao, H.; Li, D. Influence Characteristics and Mechanism of Organic Carbon on Denitrification, N2O Emission and NO2− Accumulation in the Iron [Fe(0)]-Oxidizing Supported Autotrophic Denitrification Process. Chem. Eng. J. 2020, 393, 124736. [Google Scholar] [CrossRef]

- Tchobanoglous, G.; Angelakis, A.N. Technologies for Wastewater Treatment Appropriate for Reuse: Potential for Applications in Greece. Water Sci. Technol. 1996, 33, 15–24. [Google Scholar] [CrossRef]

- Konadu-Amoah, B.; Hu, R.; Ndé-Tchoupé, A.I.; Gwenzi, W.; Noubactep, C. Metallic Iron (Fe0)-Based Materials for Aqueous Phosphate Removal: A Critical Review. J. Environ. Manag. 2022, 315, 115157. [Google Scholar] [CrossRef]

- Alrawashdeh, K.A.B.; Al-Samrraie, L.A.; Al Issa, H.A.; Qasem, I.; Hussien, A.A.; Al-Zboon, K.K.; Damseh, R.A.; Gul, E. Prediction and Optimization of Biogas Production from OMW Digestion Using Fenton Pre-Treatment Process with Particle Swarm Optimization. Int. J. Des. Nat. Ecodynamics 2022, 17, 157–168. [Google Scholar] [CrossRef]

- Kassab, G.; Khater, D.; Odeh, F.; Shatanawi, K.; Halalsheh, M.; Arafah, M.; van Lier, J.B. Impact of Nanoscale Magnetite and Zero Valent Iron on the Batch-Wise Anaerobic Co-Digestion of Food Waste and Waste-Activated Sludge. Water 2020, 12, 1283. [Google Scholar] [CrossRef]

- Xu, Y.; Wang, C.; Hou, J.; Wang, P.; You, G.; Miao, L.; Lv, B.; Yang, Y.; Zhang, F. Application of zero valent iron coupling with biological process for wastewater treatment: A review. Rev. Environ. Sci. Bio/Technol. 2017, 16, 667–693. [Google Scholar] [CrossRef]

- Boontian, N. Effect of Zero Valent Iron (ZVI) in Wastewater Treatment: A Review. Appl. Mech. Mater. 2015, 775, 180–184. [Google Scholar] [CrossRef]

- Hu, R.; Cui, X.; Xiao, M.; Qiu, P.; Lufingo, M.; Gwenzi, W.; Noubactep, C. Characterizing the Suitability of Granular Fe0 for the Water Treatment Industry. Processes 2019, 7, 652. [Google Scholar] [CrossRef] [Green Version]

- Lufingo, M.; Ndé-Tchoupé, A.I.; Hu, R.; Njau, K.N.; Noubactep, C. A Novel and Facile Method to Characterize the Suitability of Metallic Iron for Water Treatment. Water 2019, 11, 2465. [Google Scholar] [CrossRef] [Green Version]

- Lien, H.-L.; Zhang, W.-X. Nanoscale Pd/Fe Bimetallic Particles: Catalytic Effects of Palladium on Hydrodechlorination. Appl. Catal. B: Environ. 2007, 77, 110–116. [Google Scholar] [CrossRef]

- Lizama, A.C.; Figueiras, C.C.; Gaviria, L.A.; Pedreguera, A.Z.; Ruiz Espinoza, J.E. Nanoferrosonication: A Novel Strategy for Intensifying the Methanogenic Process in Sewage Sludge. Bioresour. Technol. 2019, 276, 318–324. [Google Scholar] [CrossRef] [PubMed]

- Mouftahi, M.; Tlili, N.; Hidouri, N.; Bartocci, P.; Bkoor Alrawashdeh, K.A.; Gul, E.; Liberti, F.; Fantozzi, F. Biomethanation Potential (BMP) Study of Mesophilic Anaerobic Co-Digestion of Abundant Bio-Wastes in Southern Regions of Tunisia. Processes 2020, 9, 48. [Google Scholar] [CrossRef]

- Pan, X.; Lv, N.; Cai, G.; Zhou, M.; Wang, R.; Li, C.; Ning, J.; Li, J.; Li, Y.; Ye, Z.; et al. Carbon- and Metal-Based Mediators Modulate Anaerobic Methanogenesis and Phenol Removal: Focusing on Stimulatory and Inhibitory Mechanism. J. Hazard. Mater. 2021, 420, 126615. [Google Scholar] [CrossRef]

- Baniamerian, H.; Isfahani, P.G.; Tsapekos, P.; Alvarado-Morales, M.; Shahrokhi, M.; Vossoughi, M.; Angelidaki, I. Application of Nano-Structured Materials in Anaerobic Digestion: Current Status and Perspectives. Chemosphere 2019, 229, 188–199. [Google Scholar] [CrossRef]

- Jiang, W.; Dionysiou, D.D.; Kong, M.; Liu, Z.; Sui, Q.; Lyu, S. Utilization of Formic Acid in Nanoscale Zero Valent Iron-Catalyzed Fenton System for Carbon Tetrachloride Degradation. Chem. Eng. J. 2020, 380, 122537. [Google Scholar] [CrossRef]

- Wang, S.; Yuan, R.; Liu, C.; Zhou, B. Effect of Fe2+ Adding Period on the Biogas Production and Microbial Community Distribution during the Dry Anaerobic Digestion Process. Process Saf. Environ. Prot. 2020, 136, 234–241. [Google Scholar] [CrossRef]

- WANG, L.; ZHOU, Q.; LI, F. Avoiding Propionic Acid Accumulation in the Anaerobic Process for Biohydrogen Production. Biomass Bioenergy 2006, 30, 177–182. [Google Scholar] [CrossRef]

- Flaherty, D.W. Direct Synthesis of H2O2 from H2 and O2 on Pd Catalysts: Current Understanding, Outstanding Questions, and Research Needs. ACS Catal. 2018, 8, 1520–1527. [Google Scholar] [CrossRef] [Green Version]

- Huang, Y.-X.; Guo, J.; Zhang, C.; Hu, Z. Hydrogen Production from the Dissolution of Nano Zero Valent Iron and Its Effect on Anaerobic Digestion. Water Res. 2016, 88, 475–480. [Google Scholar] [CrossRef] [PubMed]

- Xu, H.; Chang, J.; Wang, H.; Liu, Y.; Zhang, X.; Liang, P.; Huang, X. Enhancing Direct Interspecies Electron Transfer in Syntrophic-Methanogenic Associations with (Semi)Conductive Iron Oxides: Effects and Mechanisms. Sci. Total Environ. 2019, 695, 133876. [Google Scholar] [CrossRef] [PubMed]

- Kong, X.; Yu, S.; Xu, S.; Fang, W.; Liu, J.; Li, H. Effect of Fe0 Addition on Volatile Fatty Acids Evolution on Anaerobic Digestion at High Organic Loading Rates. Waste Manag. 2018, 71, 719–727. [Google Scholar] [CrossRef] [PubMed]

- Al bkoor Alrawashdeh, K.; Pugliese, A.; Slopiecka, K.; Pistolesi, V.; Massoli, S.; Bartocci, P.; Bidini, G.; Fantozzi, F. Codigestion of Untreated and Treated Sewage Sludge with the Organic Fraction of Municipal Solid Wastes. Fermentation 2017, 3, 35. [Google Scholar] [CrossRef] [Green Version]

- Alrawashdeh, K.A.B.; Slopiecka, K.; Alshorman, A.A.; Bartocci, P.; Fantozzi, F. Pyrolytic Degradation of Olive Waste Residue (OWR) by TGA: Thermal Decomposition Behavior and Kinetic Study. J. Energy Power Eng. 2017, 11, 497–510. [Google Scholar] [CrossRef] [Green Version]

- Goulding, D.A.; Fox, P.F.; O’Mahony, J.A. Milk Proteins: An Overview. In Milk Proteins; Elsevier: Amsterdam, The Netherlands, 2020; pp. 21–98. [Google Scholar] [CrossRef]

- Abdelsalam, E.; Samer, M.; Attia, Y.A.; Abdel-Hadi, M.A.; Hassan, H.E.; Badr, Y. Effects of Co and Ni Nanoparticles on Biogas and Methane Production from Anaerobic Digestion of Slurry. Energy Convers. Manag. 2017, 141, 108–119. [Google Scholar] [CrossRef]

- APHA. Standard Methods Committee of the American Public Health Association, American Water Works Association, and Water Environment Federation. 4500-p phosphorus. In Standard Methods for the Examination of Water and Wastewater; Lipps, W.C., Baxter, T.E., Braun-Howland, E., Eds.; APHA Press: Washington, DC, USA, 2018. [Google Scholar] [CrossRef]

- Boe, K.; Batstone, D.J.; Angelidaki, I. An Innovative Online VFA Monitoring System for the Anerobic Process, Based on Headspace Gas Chromatography. Biotechnol. Bioeng. 2007, 96, 712–721. [Google Scholar] [CrossRef] [Green Version]

- Ahuja, N.; Ansari, A.; Rajput, R.; Singh, P. Synthesis and Characterization of Zero Valent Iron Nanoparticles for Textile Wastewater Treatment. Pollution 2020, 6, 773–783. [Google Scholar] [CrossRef]

- Song, H.; Clarke, W.P.; Blackall, L.L. Concurrent Microscopic Observations and Activity Measurements of Cellulose Hydrolyzing and Methanogenic Populations during the Batch Anaerobic Digestion of Crystalline Cellulose. Biotechnol. Bioeng. 2005, 91, 369–378. [Google Scholar] [CrossRef]

- Switzenbaum, M.S.; Farrell, J.B.; Pincince, A.B. Relationship between the van Kleeck and Mass-Balance Calculation of Volatile Solids Loss. Water Environ. Res. 2003, 75, 377–380. [Google Scholar] [CrossRef] [PubMed]

- Ismail, Z.Z.; Talib, A.R. Assessment of anaerobic co-digestion of agro wastes for biogas recovery: A bench scale application to date palm wastes. Energy Environ. 2014, 5, 591–600. [Google Scholar]

- Cheah, Y.-K.; Vidal-Antich, C.; Dosta, J.; Mata-Álvarez, J. Volatile Fatty Acid Production from Mesophilic Acidogenic Fermentation of Organic Fraction of Municipal Solid Waste and Food Waste under Acidic and Alkaline PH. Environ. Sci. Pollut. Res. 2019, 26, 35509–35522. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Park, J.-H.; Kang, H.-J.; Park, K.-H.; Park, H.-D. Direct Interspecies Electron Transfer via Conductive Materials: A Perspective for Anaerobic Digestion Applications. Bioresour. Technol. 2018, 254, 300–311. [Google Scholar] [CrossRef]

- Hamza, R.A.; Zaghloul, M.S.; Iorhemen, O.T.; Sheng, Z.; Tay, J.H. Optimization of Organics to Nutrients (COD:N:P) Ratio for Aerobic Granular Sludge Treating High-Strength Organic Wastewater. Sci. Total Environ. 2019, 650, 3168–3179. [Google Scholar] [CrossRef]

- Shubair, T.; Eljamal, O.; Matsunaga, N. Evaluation of Nanoscale Zero Valent Iron Particles for the Removal of Cesium from Aqueous Solutions. IOP Conf. Ser. Mater. Sci. Eng. 2018, 454, 012104. [Google Scholar] [CrossRef]

- Pullin, H.; Springell, R.; Parry, S.; Scott, T. The Effect of Aqueous Corrosion on the Structure and Reactivity of Zero-Valent Iron Nanoparticles. Chem. Eng. J. 2017, 308, 568–577. [Google Scholar] [CrossRef] [Green Version]

- Zhao, Z.; Zhang, Y.; Li, Y.; Quan, X.; Zhao, Z. Comparing the Mechanisms of ZVI and Fe3O4 for Promoting Waste-Activated Sludge Digestion. Water Res. 2018, 144, 126–133. [Google Scholar] [CrossRef]

- Peng, H.; Zhang, Y.; Tan, D.; Zhao, Z.; Zhao, H.; Quan, X. Roles of Magnetite and Granular Activated Carbon in Improvement of Anaerobic Sludge Digestion. Bioresour. Technol. 2018, 249, 666–672. [Google Scholar] [CrossRef]

- Zhang, Q.-L.; Liu, Y.; Ai, G.-M.; Miao, L.-L.; Zheng, H.-Y.; Liu, Z.-P. The Characteristics of a Novel Heterotrophic Nitrification–Aerobic Denitrification Bacterium, Bacillus Methylotrophicus Strain L7. Bioresour. Technol. 2012, 108, 35–44. [Google Scholar] [CrossRef]

- Zhao, Z.; Li, Y.; Yu, Q.; Zhang, Y. Ferroferric Oxide Triggered Possible Direct Interspecies Electron Transfer between Syntrophomonas and Methanosaeta to Enhance Waste Activated Sludge Anaerobic Digestion. Bioresour. Technol. 2018, 250, 79–85. [Google Scholar] [CrossRef] [PubMed]

- Zhang, Y.; Yang, Z.; Xu, R.; Xiang, Y.; Jia, M.; Hu, J.; Zheng, Y.; Xiong, W.; Cao, J. Enhanced Mesophilic Anaerobic Digestion of Waste Sludge with the Iron Nanoparticles Addition and Kinetic Analysis. Sci. Total Environ. 2019, 683, 124–133. [Google Scholar] [CrossRef] [PubMed]

- Kim, H.; Kim, J.; Shin, S.G.; Hwang, S.; Lee, C. Continuous Fermentation of Food Waste Leachate for the Production of Volatile Fatty Acids and Potential as a Denitrification Carbon Source. Bioresour. Technol. 2016, 207, 440–445. [Google Scholar] [CrossRef] [PubMed]

- Conductive Materials in Anaerobic Digestion: From Mechanism to Application. Bioresour. Technol. 2020, 298, 122403. [CrossRef]

- Aboudi, K.; Álvarez-Gallego, C.J.; Romero-García, L.I. Semi-Continuous Anaerobic Co-Digestion of Sugar Beet Byproduct and Pig Manure: Effect of the Organic Loading Rate (OLR) on Process Performance. Bioresour. Technol. 2015, 194, 283–290. [Google Scholar] [CrossRef]

- Pan, X.; Zhao, L.; Li, C.; Angelidaki, I.; Lv, N.; Ning, J.; Cai, G.; Zhu, G. Deep Insights into the Network of Acetate Metabolism in Anaerobic Digestion: Focusing on Syntrophic Acetate Oxidation and Homoacetogenesis. Water Res. 2021, 190, 116774. [Google Scholar] [CrossRef]

- Wu, D.; Zheng, S.; Ding, A.; Sun, G.; Yang, M. Performance of a Zero Valent Iron-Based Anaerobic System in Swine Wastewater Treatment. J. Hazard. Mater. 2015, 286, 1–6. [Google Scholar] [CrossRef]

- Cai, Y.; Wang, J.; Zhao, Y.; Zhao, X.; Zheng, Z.; Wen, B.; Cui, Z.; Wang, X. A New Perspective of Using Sequential Extraction: To Predict the Deficiency of Trace Elements during Anaerobic Digestion. Water Res. 2018, 140, 335–343. [Google Scholar] [CrossRef]

- Xu, R.; Xu, S.; Zhang, L.; Florentino, A.P.; Yang, Z.; Liu, Y. Impact of Zero Valent Iron on Blackwater Anaerobic Digestion. Bioresour. Technol. 2019, 285, 121351. [Google Scholar] [CrossRef]

- Dong, D.; Aleta, P.; Zhao, X.; Choi, O.K.; Kim, S.; Lee, J.W. Effects of Nanoscale Zero Valent Iron (NZVI) Concentration on the Biochemical Conversion of Gaseous Carbon Dioxide (CO2) into Methane (CH4). Bioresour. Technol. 2019, 275, 314–320. [Google Scholar] [CrossRef]

- Zhu, X.; Thi Le, T.; Du, J.; Tiantian Xu, T.; Cui, Y.; Ling, H.; Hoon Kim, S.H. Novel core-shell sulfidated nano-Fe(0) particles for chromate sequestration: Promoted electron transfer and Fe(II) production. Chemosphere 2021, 284, 131379. [Google Scholar] [CrossRef] [PubMed]

- Sun, Y.-P.; Li, X.-Q.; Zhang, W.-X.; Wang, H.P. A Method for the Preparation of Stable Dispersion of Zero-Valent Iron Nanoparticles. Colloids Surf. A Physicochem. Eng. Asp. 2007, 308, 60–66. [Google Scholar] [CrossRef]

- Feng, Y.; Zhang, Y.; Quan, X.; Chen, S. Enhanced Anaerobic Digestion of Waste Activated Sludge Digestion by the Addition of Zero Valent Iron. Water Res. 2014, 52, 242–250. [Google Scholar] [CrossRef] [PubMed]

- Ibrahim, S.H.; Abdulaziz, M. The Effect of Different Zero-Valent Iron Sources on Biogas Production from Waste Sludge Anaerobic Digestion. J. Biotechnol. Res. 2016, 2, 59–67. [Google Scholar]

| Mixing Volume Ratio (NaBH4:FeSO4.7H2O) | mg NP-ZVI/ g VS | ||||

|---|---|---|---|---|---|

| 10 | 20 | 30 | 40 | 50 | |

| 2:1 | A10 | A20 | A30 | A40 | A50 |

| 4:1 | B10 | B20 | B30 | B40 | B50 |

| 6:1 | C10 | C20 | C30 | C40 | C50 |

| 8:1 | D10 | D20 | D30 | D40 | D50 |

| 10:1 | E10 | E20 | E30 | E40 | E50 |

| Substrate | Total Solids, TS (%) | Volatile Solids, VS (%) | Ash (%) | Moisture (%) | Fixed Carbone (%) | Phenols (gl −1) | TCOD (gl −1) | BOD5 (gl −1) | pH |

|---|---|---|---|---|---|---|---|---|---|

| OMWW | 7.12 ± 0.96 | 2.92 ± 0.52 | 0.39 ± 0.09 | 92.88 ± 0.97 | 3.81 ± 0.8 | 4.21 ± 0.15 | 53.79 ± 2.04 | 8.43 ± 3.56 | 5.08 ± 1.32 |

| CM | 27.65 ± 2.82 | 5.12 ± 1.02 | 2.31 ± 0.21 | 72.35 ± 2.05 | 20.22 ± 2.7 | 6.83 ± 0.65 | 9.05 ± 1.96 | 7.21 ± 1.08 | 6.39 ± 0.18 |

| Inoculum | 2.51 ± 0.62 | 0.53 ± 0.06 | 0.51 ± 0.07 | 97.49 ± 1.04 | 1.47 ± 0.2 | 2.95 ± 1.36 | 21.82 ± 2.91 | 3.62 ± 2.13 | 6.75 ± 0.95 |

| Mixing Volume Ratio (NaBH4:FeSO4.7H2O) | Hydrolysis (%) | ||||

|---|---|---|---|---|---|

| 10 mg/g VS | 20 mg/g VS | 30 mg/g VS | 40 mg/g VS | 50 mg/g VS | |

| 2:1 | 75.25 | 73.9 | 74.13 | 69.84 | 65.18 |

| 4:1 | 76.88 | 77.13 | 82.32 | 72.08 | 71.77 |

| 6:1 | 73.52 | 74.37 | 78.60 | 65.93 | 72.83 |

| 8:1 | 61.63 | 58.75 | 63.52 | 60.39 | 60.82 |

| 10:1 | 54.61 | 56.91 | 57.26 | 57.67 | 64.65 |

| Mixing Volume Ratio (NaBH4:FeSO4.7H2O) | Biogas (Nm3/kg.VS) | ||||

|---|---|---|---|---|---|

| 10 mg/g VS | 20 mg/g VS | 30 mg/g VS | 40 mg/g VS | 50 mg/g VS | |

| 2:1 | 0.311 ± 0.015 | 0.28 ± 0.051 | 0.282 ± 0.023 | 0.182 ± 0.011 | 0.128 ± 0.002 |

| 4:1 | 0.32 ± 0.046 | 0.335 ± 0.013 | 0.389 ± 0.005 | 0.158 ± 0.004 | 0.107 ± 0.019 |

| 6:1 | 0.264 ± 0.027 | 0.305 ± 0.01 | 0.356 ± 0.07 | 0.136 ± 0.013 | 0.083 ± 0.008 |

| 8:1 | 0.237 ± 0.014 | 0.23 ± 0.021 | 0.245 ± 0.022 | 0.105 ± 0.034 | 0.064 |

| 10:1 | 0.222 ± 0.006 | 0.228 ± 0.015 | 0.238 ± 0.019 | 0.106 ± 0.009 | 0.055 ± 0.015 |

| Mixing Volume Ratio (NaBH4:FeSO4.7H2O) | Methane (%) | ||||

|---|---|---|---|---|---|

| 10 mg/g VS | 20 mg/g VS | 30 mg/g VS | 40 mg/g VS | 50 mg/g VS | |

| 2:1 | 66.47 | 65.08 | 67.08 | 52.43 | 50.05 |

| 4:1 | 67.35 | 66.89 | 68.34 | 49.05 | 46.22 |

| 6:1 | 65.78 | 66.92 | 67.79 | 46.42 | 45.18 |

| 8:1 | 63.11 | 64.88 | 65.93 | 45.38 | 45.1 |

| 10:1 | 56.47 | 59.15 | 65.05 | 44.93 | 42.79 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Bkoor Alrawashdeh, K.A.; Al-Zboon, K.K.; Al-Tabbal, J.A.; AL-Samrraie, L.A.; Al Bsoul, A.; Damseh, R.A.; Khasawneh, A.; Dessouky, Y.; Tonbol, K.; Ali, B.M.; et al. The Effects of Nanoparticles- Zerovalent Iron on Sustainable Biomethane Production through Co-Digestion of Olive Mill Wastewater and Chicken Manure. Fermentation 2023, 9, 183. https://doi.org/10.3390/fermentation9020183

Bkoor Alrawashdeh KA, Al-Zboon KK, Al-Tabbal JA, AL-Samrraie LA, Al Bsoul A, Damseh RA, Khasawneh A, Dessouky Y, Tonbol K, Ali BM, et al. The Effects of Nanoparticles- Zerovalent Iron on Sustainable Biomethane Production through Co-Digestion of Olive Mill Wastewater and Chicken Manure. Fermentation. 2023; 9(2):183. https://doi.org/10.3390/fermentation9020183

Chicago/Turabian StyleBkoor Alrawashdeh, Khalideh Al, Kamel K. Al-Zboon, Jalal A. Al-Tabbal, La’aly A. AL-Samrraie, Abeer Al Bsoul, Rebhi A. Damseh, Ayat Khasawneh, Yasser Dessouky, Kareem Tonbol, Bassma M. Ali, and et al. 2023. "The Effects of Nanoparticles- Zerovalent Iron on Sustainable Biomethane Production through Co-Digestion of Olive Mill Wastewater and Chicken Manure" Fermentation 9, no. 2: 183. https://doi.org/10.3390/fermentation9020183

APA StyleBkoor Alrawashdeh, K. A., Al-Zboon, K. K., Al-Tabbal, J. A., AL-Samrraie, L. A., Al Bsoul, A., Damseh, R. A., Khasawneh, A., Dessouky, Y., Tonbol, K., Ali, B. M., & Youssef, E. E. (2023). The Effects of Nanoparticles- Zerovalent Iron on Sustainable Biomethane Production through Co-Digestion of Olive Mill Wastewater and Chicken Manure. Fermentation, 9(2), 183. https://doi.org/10.3390/fermentation9020183