On-Farm Supplemental Irrigation of ‘Roja Lisa’ Cactus Pear: Pre- and Postharvest Effects

Abstract

:1. Introduction

2. Materials and Methods

2.1. Experimental Site, Vegetative Material, and Orchard Management

2.2. Treatments and Experimental Design

2.3. Preharvest Determinations

2.3.1. Relative Water Content (RWC)

2.3.2. Crop Production

2.4. Postharvest Determinations

Fruit Quality

2.5. Data Analysis

3. Results

3.1. Preharvest Results

Soil Water Content (θ) and Relative Water Content (RWC)

3.2. Postharvest Results

3.2.1. Fruit Quality

3.2.2. Fruit Decay Incidence

4. Discussion

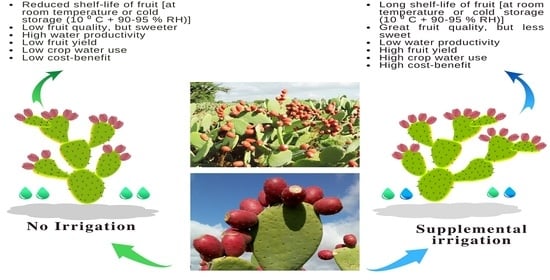

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Nhemachena, C.; Nhamo, L.; Matchaya, G.; Nhemachena, C.R.; Muchara, B.; Karuaihe, S.T.; Mpandeli, S. Climate change impacts on water and agriculture sectors in Southern Africa: Threats and opportunities for sustainable development. Water 2020, 12, 2673. [Google Scholar] [CrossRef]

- Pereira, L.S. Water and agriculture: Facing water scarcity and environmental challenges. Invited overview paper. CIGR J. Agric. Eng. Int. 2005, VII, 1–26. [Google Scholar]

- Louhaich, M.; Nefzaoui, A.; Guevara, J.C. Cactus ecosystem goods and services. In Crop Ecology, Cultivation and Uses of Cactus Pear; Inglese, P., Mondragon, C., Nefzaoui, A., Sáenz, C., Eds.; The Food and Agriculture Organization of the United Nations and the International Centre for Agricultural Research in the Dry Areas: Rome, Italy, 2017; pp. 159–169. [Google Scholar]

- Varnero, M.T.; Homer, I. Biogas production. In Crop Ecology, Cultivation and Uses of Cactus Pear; Inglese, P., Mondragon, C., Nefzaoui, A., Sáenz, C., Eds.; The Food and Agriculture Organization of the United Nations and the International Centre for Agricultural Research in the Dry Areas: Rome, Italy, 2017; pp. 187–193. [Google Scholar]

- Potgieter, J.; D’Aquino, S. Fruit production and post-harvest management. In Crop Ecology, Cultivation and Uses of Cactus Pear; Inglese, P., Mondragon, C., Nefzaoui, A., Sáenz, C., Eds.; The Food and Agriculture Organization of the United Nations and the International Centre for Agricultural Research in the Dry Areas: Rome, Italy, 2017; pp. 51–71. [Google Scholar]

- Prisa, D. Opuntia ficus-indica the key plant in climate change: Characteristics, cultivation and uses. GSC Biol. Pharm. Sci. 2021, 17, 94–105. [Google Scholar] [CrossRef]

- Garcia de Cortázar, V.; Nobel, P.S. Biomass and fruit production for the prickly pear cactus, Opuntia ficus-indica. J. Am. Soc. Hortic. Sci. 1992, 117, 558–562. [Google Scholar] [CrossRef] [Green Version]

- Nerd, A.; Karady, A.; Mizrahi, Y. Out-of-season prickly pear: Fruit characteristics and effect of fertilization and short droughts on productivity. HortScience 1991, 26, 527–529. [Google Scholar] [CrossRef] [Green Version]

- Zegbe, J.A.; Serna-Pérez, A. Irrigation options to save water while enhancing export-size fruit and storability of ‘Smooth Red’ cactus pear. J. Sci. Food Agric. 2018, 98, 5503–5508. [Google Scholar] [CrossRef]

- Konikow, L.F.; Kendy, E. Groundwater depletion: A global problem. Hydrogeol. J. 2005, 13, 317–320. [Google Scholar] [CrossRef]

- Moreno-Vázquez, J.L.; Marañón-Pimentel, B.; López-Córdova, D. Los acuíferos sobrexplotados: Origen, crisis y gestión social. In El Agua en México: Cauces y Encauces; Jiménez-Cisneros, B., Torregorosa y Armenta, M.T., Arboites-Aguiliar, L., Eds.; Academia Mexicana de Ciencia y Consejo Nacional del Agua: Ciudad de México, México, 2010; pp. 79–115. [Google Scholar]

- Postel, S.L. Entering an era of water scarcity: The challenges ahead. Ecol. Appl. 2000, 10, 941–948. [Google Scholar] [CrossRef]

- Oweis, T.; Hachum, A. Supplemental Irrigation: A Highly Efficient Water-Use Practice; International Centre for Agricultural Research in the Dry Areas (ICARDA): Alepo, Syria, 2012; 16p. [Google Scholar]

- Oweis, T.; Hachum, A. Improving water productivity in the dry areas of West Asia and North Africa. In Water Productivity in Agriculture: Limits and Opportunities for Improvement; Kijne, W.J., Barker, R., Molden, D., Eds.; CAB International: Wallingford, UK, 2003; Volume 1, pp. 179–197. [Google Scholar]

- Acosta-Díaz, E.; Acosta-Gallegos, J.A.; Amador-Ramírez, M.D.; Padilla-Ramírez, J.S. Effect of supplemental irrigation on biomass and seed yield of rainfed dry bean in highlands of Mexico. Agric. Téc. Méx. 2009, 35, 157–167. [Google Scholar]

- Abderrazzak, B.; Daoui, K.; Kajji, A.; Ibriz, M.; Dahan, R. Effects of supplemental irrigation and nitrogen applied on yield and yield components of bread wheat at the saïs region of Morocco. J. Exp. Agric. Int. 2013, 3, 904–913. [Google Scholar] [CrossRef] [Green Version]

- Campos, P.F.; Júnior, J.A.; Casaroli, D.; Fontoura, P.R.; Evangelista, A.W.P. Varieties of sugarcane to supplemental irrigation in Brazilian savanna. Eng. Agríc. Jaboticabal 2014, 34, 1139–1149. [Google Scholar] [CrossRef] [Green Version]

- Wale, A.; Sebnie, W.; Girmay, G.; Beza, G. Evaluation of the potentials of supplementary irrigation for improvement of sorghum yield in Wag-Himra, North Eastern, Amhara, Ethiopia. Cogent Food Agric. 2019, 5, 1664203. [Google Scholar] [CrossRef]

- Cavalcante, E.S.; Feitosa de Lacerda, C.; Távora-Costa, R.N.; Gheyi, H.R.; Luzia-Pinho, L.; Sérvulo-Bezerra, F.M.; Cruz de Oliveira, A.; Florentino-Canjá, J. Supplemental irrigation using brackish water on maize in tropical semi-arid regions of Brazil: Yield and economic analysis. Sci. Agric. 2021, 78 (Suppl. 1), e20200151. [Google Scholar] [CrossRef]

- Razouk, R.; Ibijbijen, J.; Kajji, A. Optimal time of supplemental irrigation during fruit development of rainfed olive tree (Olea europaea, cv. Picholine Marocaine) in Morocco. Am. J. Exp. Agric. 2013, 3, 685–697. [Google Scholar] [CrossRef]

- Van Der Merwe, L.L.; Wessels, A.B.; Ferreira, D.I. Supplemental irrigation for spineless cactus pear. Acta Hortic. 1997, 438, 77–82. [Google Scholar] [CrossRef]

- Zegbe, J.A.; Servín-Palestina, M. Supplemental irrigation to save water while growing cactus pear in semi-arid regions. Irrig. Drain. 2021, 70, 269–280. [Google Scholar] [CrossRef]

- Zegbe, J.A. Quality and storability of cactus pear fruit as improved by supplemental irrigation. J. Prof. Assoc. Cactus Dev. 2020, 22, 1–17. [Google Scholar]

- Zegbe, J.A.; Mena-Covarrubias, J. Two reproductive bud thinning alternatives for cactus pear. HortTechnology 2010, 20, 202–205. [Google Scholar] [CrossRef] [Green Version]

- Diaz-Pérez, J.C.; Shackel, K.A.; Sutter, E.G. Relative water content and water potential of tissue cultured apple shoots under water deficits. J. Exp. Bot. 1995, 46, 111–118. [Google Scholar] [CrossRef]

- Pérez-Pérez, J.G.; Syvertsen, J.P.; Botía, P.; García-Sánchez, F. Leaf water relations and net gas exchange responses of salinized carrizo citrange seedlings during drought stress and recovery. Ann. Bot. 2007, 100, 335–345. [Google Scholar] [CrossRef] [Green Version]

- Popescu, M.; Popescu, G.C. Diurnal changes in leaf photosynthesis and relative water content of grapevine. Curr. Trends Nat. Sci. 2014, 3, 74–81. [Google Scholar]

- Tolk, J.A. Soils, permanent wilting points. In Encyclopedia of Water Science; Stewart, B.A., Howell, T.A., Eds.; Marcel Dekket Pub: New York, NY, USA, 2003; pp. 927–929. [Google Scholar]

- Ghrab, M.; Masmoudi, M.M.; Ben Mechlia, N. Water productivity in fruit trees orchards under water scarcity. Acta Hortic. 2017, 1150, 317–322. [Google Scholar] [CrossRef]

- Zegbe, J.A.; Serna-Pérez, A.; Mena-Covarrubias, J. Mineral nutrition enhances yield and affects fruit quality of ‘Cristalina’ cactus pear. Sci. Hortic. 2014, 167, 63–70. [Google Scholar] [CrossRef]

- Smith, M.R.; Rao, I.M.; Merchant, A. Source-sink relationships in crop plants and their influence on yield development and nutritional quality. Front. Plant Sci. 2018, 9, 1889. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Heldt, H.-W.; Piechulla, B. Phloem transport distributes photoassimilates to various sites of consumption and storage. In Plant Biochemistry, 5th ed.; Heldt, H.-W., Piechulla, B., Eds.; Academic Press: Cambridge, MA, USA, 2021; pp. 323–333. [Google Scholar]

- Crisosto, C.H.; Johnson, R.S.; Luza, J.G.; Crisosto, G.M. Irrigation regimes affect fruit soluble solids concentration and rate of water loss of ‘O’Henry’ peaches. HortScience 1994, 29, 1169–1171. [Google Scholar] [CrossRef] [Green Version]

- Mpelasoka, B.S.; Behboudian, M.H.; Dixon, J.; Neal, S.M.; Caspari, H.W. Improvement of fruit quality and storage potential of ‘Braeburn’ apple through deficit irrigation. J. Hortic. Sci. Biotechnol. 2000, 75, 615–621. [Google Scholar] [CrossRef]

- Lufu, R.; Ambaw, A.; Opara, U.L. Water loss of fresh fruit: Influencing pre-harvest, harvest and postharvest factors. Sci. Hortic. 2020, 272, 109519. [Google Scholar] [CrossRef]

- Cantwell, M. Post-harvest management of fruits and vegetable stems. In Agro-Ecology, Cultivation, and Uses of Cactus Pear; Barbera, G., Inglese, P., Pimienta-Barrios, E., Eds.; Plant Production and Protection 132; Food and Agriculture Organization of the United Nations: Rome, Italy, 1995; pp. 120–136. [Google Scholar]

- Corrales García, J.; Hernández Silva, J.L. Cambios en la calidad postcosecha de variedades de tuna con y sin semilla. Rev. Fitotec. Mex. 2005, 28, 9–16. [Google Scholar]

- Corrales Garcia, J.; Franco Moreno, F.; Rodriguez Campos, J. Fruit characterization of twenty accessions of cactus pear (Opuntia spp.) II. Changes in post-harvest. Acta Hortic. 2006, 728, 205–209. [Google Scholar] [CrossRef]

- Maguire, K.M.; Lang, A.; Banks, N.H.; Hall, A.; Hopcroft, D.; Bennett, R. Relationship between water vapour permeance of apples and micro-cracking of the cuticle. Postharvest Biol. Technol. 1999, 17, 89–96. [Google Scholar] [CrossRef]

- Faedda, R.; Daquino, S.; Granata, G.; Pane, A.; Palma, A.; Sanzani, S.M.; Schena, L.; Cacciola, S.O. Postharvest fungal diseases of cactus pear fruit in southern Italy. Acta Hortic. 2016, 1144, 215–218. [Google Scholar] [CrossRef]

- Granata, G.; Faedda, R.; Ochoa, M.J. Diseases of cactus pear. In Crop Ecology, Cultivation and Uses of Cactus Pear; Inglese, P., Mondragon, C., Nefzaoui, A., Sáenz, C., Eds.; The Food and Agriculture Organization of the United Nations and the International Centre for Agricultural Research in the Dry Areas: Rome, Italy, 2017; pp. 115–123. [Google Scholar]

| Year/Irrigation Treatment | ETo (mm) | IWA (mm) | CWU (mm) |

|---|---|---|---|

| 2018 | 588 | 0 | 155 |

| Non-irrigated | 588 | 219 | 374 |

| Supplemental irrigation | |||

| 2019 | 657 | 0 | 50 |

| Non-irrigated | 657 | 247 | 297 |

| Supplemental irrigation | |||

| 2020 | 522 | 0 | 113 |

| Non-irrigated | 522 | 24 | 137 |

| Supplemental irrigation |

| Year/Irrigation Treatment | TFY (t ha−1) | CFY (t ha−1) | MMFF (g) | Water Productivity (kg m−3) | |

|---|---|---|---|---|---|

| CFY | TFY | ||||

| 2018 | |||||

| Non-irrigated | 17.3a * | 14.0a | 113.4a | 9.1a | 11.1a |

| Supplemental irrigation | 18.4a | 16.7a | 117.7a | 4.5b | 4.9b |

| Least significant difference | 9.3 | 9.6 | 29.6 | 4.1 | 3.0 |

| Significance (p > F) | 0.77 | 0.52 | 0.74 | 0.03 | 0.002 |

| Coefficient of variation (%) | 30.1 | 36.1 | 14.8 | 35.0 | 21.3 |

| 2019 | |||||

| Non-irrigated | 17.7a | 13.7b | 109.3b | 27.4a | 35.4a |

| Supplemental irrigation | 32.3a | 28.5a | 126.9a | 9.6b | 10.9b |

| Least significant difference | 15.1 | 14.5 | 14.3 | 9.4 | 10.6 |

| Significance (p > F) | 0.05 | 0.05 | 0.02 | 0.004 | 0.001 |

| Coefficient of variation (%) | 35.0 | 39.6 | 7.0 | 29.4 | 26.4 |

| 2020 | |||||

| Non-irrigated | 23.8a | 19.4b | 103.8a | 17.2a | 21.1a |

| Supplemental irrigation | 29.1a | 26.3a | 133.0b | 19.3a | 21.3a |

| Least significant difference | 5.6 | 5.4 | 15.3 | 4.0 | 4.1 |

| Significance (p > F) | 0.06 | 0.02 | 0.004 | 0.25 | 0.93 |

| Coefficient of variation (%) | 12.2 | 13.6 | 7.5 | 12.6 | 11.2 |

| Fruit Size Distribution (%) | ||||

|---|---|---|---|---|

| Grades (Equatorial Diameter, cm) | ||||

| Year/Irrigation Treatment | 1 (7.0–6.0) | 2 (5.9–5.0) | 3 (4.9–4.0) | 4 (3.9–3.5) |

| 2018 | ||||

| Non-irrigated | 24.0a * | 56.0a | 19.1a | 0.9a |

| Supplemental irrigation | 33.4a | 57.7a | 7.8a | 1.11a |

| Least significant difference | 34.3 | 17.7 | 21.3 | 1.6 |

| Significance (p > F) | 0.53 | 0.82 | 0.24 | 0.72 |

| Coefficient of variation (%) | 69.2 | 18.0 | 91.5 | 96.4 |

| 2019 | ||||

| Non-irrigated | 7.2b | 70.2a | 21.7a | 0.8a |

| Supplemental irrigation | 22.2a | 64.6a | 12.9a | 0.3a |

| Least significant difference | 9.1 | 10.2 | 11.1 | 1.6 |

| Significance (p > F) | 0.01 | 0.23 | 0.10 | 0.48 |

| Coefficient of variation (%) | 36.0 | 8.8 | 37.0 | 166.7 |

| 2020 | ||||

| Non-irrigated | 8.3b | 73.1a | 17.0a | 1.6a |

| Supplemental irrigation | 19.7a | 70.7a | 9.6b | 0.0b |

| Least significant difference | 5.8 | 5.5 | 4.5 | 0.9 |

| Significance (p > F) | 0.00 | 0.32 | 0.01 | 0.01 |

| Coefficient of variation (%) | 23.8 | 4.4 | 19.6 | 69.2 |

| Irrigation/Fruit Condition | Fresh Mass of Fruit (g) | Fresh Mass of Peel (g) | Fresh Mass of Pulp (g) | ||||||

|---|---|---|---|---|---|---|---|---|---|

| 2018 | 2019 | 2020 | 2018 | 2019 | 2020 | 2018 | 2019 | 2020 | |

| Harvest | |||||||||

| Non-irrigation | 122.7b * | 114.2b | 136.4a | 59.6b | 52.1b | 54.2b | 63.1b | 63.1a | 82.2a |

| Supplemental irrigation | 150.5a | 133.7a | 160.1a | 70.2a | 65.6a | 73.0a | 80.3a | 68.2a | 87.1a |

| Least significant difference | 14.6 | 18.4 | 25.1 | 5.1 | 9.8 | 13.6 | 11.4 | 10.4 | 13.6 |

| Significance (p > F) | 0.003 | 0.04 | 0.06 | 0.002 | 0.01 | 0.02 | 0.01 | 0.28 | 0.41 |

| Coefcient of variation (%) | 11.8 | 7.9 | 12.7 | 12.8 | 8.6 | 13.6 | 13.9 | 11.3 | 15.5 |

| Room temperature ** | |||||||||

| Non-irrigation | 116.2b | 121.2b | 129.6b | 41.0b | 41.5b | 41.6b | 75.2a | 79.7a | 88.0a |

| Supplemental irrigation | 138.8a | 143.4a | 152.4a | 52.8a | 55.7a | 61.4a | 85.9a | 87.7a | 91.0a |

| Least significant difference | 14.4 | 15.6 | 16.0 | 6.1 | 6.7 | 7.5 | 14.5 | 14.3 | 12.6 |

| Significance (p > F) | 0.007 | 0.01 | 0.01 | 0.002 | 0.003 | 0.001 | 0.125 | 0.25 | 0.61 |

| Coefcient of variation (%) | 10.3 | 11.0 | 10.3 | 14.1 | 12.6 | 13.4 | 11.7 | 14.7 | 13.2 |

| Cold room *** | |||||||||

| Non-irrigation | 139.3b | 119.1b | 126.6b | 50.9b | 47.6b | 41.4b | 88.4a | 71.4b | 84.2a |

| Supplemental irrigation | 168.6a | 161.9a | 146.7a | 65.2a | 64.9a | 54.9a | 103.3a | 96.9a | 91.8a |

| Least significant difference | 22.7 | 19.9 | 12.2 | 9.4 | 8.1 | 5.6 | 17.7 | 13.0 | 8.1 |

| Significance (p > F) | 0.02 | 0.001 | 0.01 | 0.01 | 0.002 | 0.002 | 0.09 | 0.003 | 0.06 |

| Coefcient of variation (%) | 8.5 | 11.4 | 12.2 | 11.7 | 11.7 | 16.8 | 8.8 | 14.1 | 12.7 |

| Irrigation/Fruit Condition | Fresh Firmness (Newtons) | Soluble Solids Concentration (Brix) | Dry Mass of Pulp (mg g−1 FW) | ||||||

|---|---|---|---|---|---|---|---|---|---|

| 2018 | 2019 | 2020 | 2018 | 2019 | 2020 | 2018 | 2019 | 2020 | |

| Harvest | |||||||||

| Non-irrigation | 34.6a * | 28.3a | 28.7a | 12.0a | 13.9a | 13.3a | 145.8a | 219.3a | 143.9a |

| Supplemental irrigation | 34.2a | 32.5a | 28.2a | 12.2a | 11.9b | 12.6a | 148.0a | 210.4b | 131.2a |

| Least significant difference | 4.1 | 3.8 | 5.6 | 0.8 | 0.08 | 0.9 | 6.3 | 4.1 | 15.5 |

| Significance (p > F) | 0.85 | 0.08 | 0.86 | 0.5 | 0.001 | 0.11 | 0.50 | 0.000 | 0.09 |

| Coefficient of variation (%) | 18.3 | 14.2 | 18.1 | 6.8 | 6.9 | 6.8 | 5.7 | 1.8 | 10.9 |

| Room temperature ** | |||||||||

| Non-irrigation | 22.2a | 23.1a | 23.5a | 11.4a | 12.8a | 13.3a | 139.7a | 187.1a | 151.1a |

| Supplemental irrigation | 22.3a | 22.5a | 21.7a | 10.8a | 11.0b | 11.3b | 141.4a | 173.8b | 127.7b |

| Least significant difference | 4.9 | 3.8 | 3.7 | 0.8 | 0.7 | 0.4 | 17.5 | 5.3 | 9.5 |

| Significance (p > F) | 0.99 | 0.8 | 0.30 | 0.07 | 0.001 | 0.0001 | 0.8 | 0.001 | 0.001 |

| Coefficient of variation (%) | 17.5 | 18.5 | 15.3 | 5.0 | 6.6 | 5.6 | 10.8 | 3.1 | 12.3 |

| Cold room *** | |||||||||

| Non-irrigation | 33.2a | 29.9b | 31.7a | 11.6a | 12.2a | 13.6a | 129.3a | 191.7a | 150.9a |

| Supplemental irrigation | 33.6a | 33.3a | 30.8a | 11.4a | 11.4b | 13.0b | 134.3a | 187.0a | 147.5a |

| Least significant difference | 4.4 | 2.6 | 3.1 | 0.4 | 0.7 | 0.5 | 18.6 | 12.5 | 8.9 |

| Significance (p > F) | 0.85 | 0.04 | 0.52 | 0.60 | 0.04 | 0.02 | 0.54 | 0.4 | 0.38 |

| Coefficient of variation (%) | 10.6 | 13.1 | 10.3 | 5.6 | 5.8 | 8.1 | 21.7 | 5.5 | 10.4 |

| Storage Conditions | ||

|---|---|---|

| Year/Irrigation Treatments | Room Temperature | Cold Room |

| 2018 | ||

| No irrigation | 1 (4.2) | 2 (8.3) |

| Supplemental irrigation | 2 (8.3) | 4 (16.7) |

| 2019 | ||

| No irrigation | 2 (8.3) | 0 (0) |

| Supplemental irrigation | 2 (8.3) | 7 (29.2) |

| 2020 | ||

| No irrigation | 0 (0) | 0 (0) |

| Supplemental irrigation | 1 (4.2) | 0 (0) |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Melero-Meraz, V.; Zegbe, J.A.; Herrera, M.D.; Guzmán-Maldonado, S.H.; Medina-García, G.; Sánchez-Toledano, B.I.; Cruz-Bravo, R.K.; Servín-Palestina, M. On-Farm Supplemental Irrigation of ‘Roja Lisa’ Cactus Pear: Pre- and Postharvest Effects. Horticulturae 2022, 8, 483. https://doi.org/10.3390/horticulturae8060483

Melero-Meraz V, Zegbe JA, Herrera MD, Guzmán-Maldonado SH, Medina-García G, Sánchez-Toledano BI, Cruz-Bravo RK, Servín-Palestina M. On-Farm Supplemental Irrigation of ‘Roja Lisa’ Cactus Pear: Pre- and Postharvest Effects. Horticulturae. 2022; 8(6):483. https://doi.org/10.3390/horticulturae8060483

Chicago/Turabian StyleMelero-Meraz, Valentín, Jorge A. Zegbe, Mayra Denise Herrera, Salvado H. Guzmán-Maldonado, Guillermo Medina-García, Blanca I. Sánchez-Toledano, Raquel K. Cruz-Bravo, and Miguel Servín-Palestina. 2022. "On-Farm Supplemental Irrigation of ‘Roja Lisa’ Cactus Pear: Pre- and Postharvest Effects" Horticulturae 8, no. 6: 483. https://doi.org/10.3390/horticulturae8060483

APA StyleMelero-Meraz, V., Zegbe, J. A., Herrera, M. D., Guzmán-Maldonado, S. H., Medina-García, G., Sánchez-Toledano, B. I., Cruz-Bravo, R. K., & Servín-Palestina, M. (2022). On-Farm Supplemental Irrigation of ‘Roja Lisa’ Cactus Pear: Pre- and Postharvest Effects. Horticulturae, 8(6), 483. https://doi.org/10.3390/horticulturae8060483