Integrating Life Cycle Principles in Home Energy Management Systems: Optimal Load PV–Battery–Electric Vehicle Scheduling

Abstract

:1. Introduction

- 1.

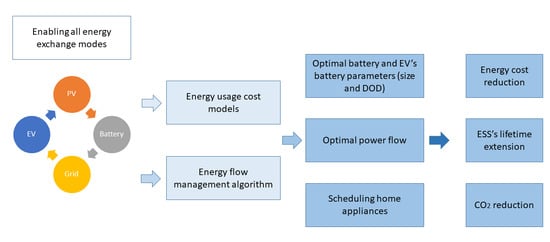

- The possibilities of energy exchange are as follows: EV to grid (EV2G), EV to battery (EV2B), EV to home (EV2H), battery to grid (B2G), battery to EV (B2EV), battery to home (B2H), PV system to home (PV2H), PV system to battery (PV2B), PV system to EV (PV2EV), PV system to grid (PV2G), grid to home (G2H), grid to battery (G2B), and grid to EV (G2EV).

- 2.

- Developing PV, battery, and EV energy usage prices.

- 3.

- Creating an effective energy flow management algorithm.

- 4.

- Optimizing the size and DOD parameters for the battery and EV battery.

- 5.

- Optimizing the operation time of home appliances.

- 6.

- Considering seasonal conditions (winter and summer) in the optimization processes.

- 7.

- Applying the PSO algorithm for solving the previous optimization problems with an interval time of one minute to obtain an accurate solution.

- 8.

- A real case study is considered.

2. Methodology

- 1.

- Describing the system configuration and the dynamic process of energy exchange.

- 2.

- Formulating a mathematical model for PV, battery, and EV systems.

- 3.

- Formulating a mathematical model for selling energy to the grid, DOD and lifecycle relationship, PV/battery/EVs ener-gy-usage costs, objective function, and problem constraints.

- 4.

- Developing an algorithm for achieving optimal energy flow.

- 5.

- Developing an optimization strategy for obtaining optimal ESS parameters and scheduling home appliances focusing on one-minute operation intervals.

- 6.

- Selecting and outlining the case study (load profile, solar radiation, temperature, PV–battery–EV integrated system, and the grid’s buying/selling price).

- 7.

- Selection and assessment of sustainability factors, including modeling and running: estimated battery and EV lifespan, CO2 emission intensity, and the integrated energy systems’ contributions throughout their life cycles.

3. Development

3.1. System Architecture

3.2. System Modeling

3.2.1. PV Model

3.2.2. Battery Model

3.2.3. EV Model

3.2.4. Home Appliance Model

3.3. Problem Formulation

3.3.1. PV Energy Usage Price

3.3.2. Battery Energy Usage Price

3.3.3. EV Battery Energy Usage Price

3.3.4. Selling Energy to the Grid

3.3.5. Depth of Discharge and Life Cycle Relationship

3.3.6. Objective Function

3.3.7. Constraints

3.4. Energy Flow Management Algorithm Development

3.5. Optimization Strategy

3.6. Case Study

3.7. Sustainability Factors Analysis

3.7.1. ESS Lifetime

3.7.2. CO2 Emissions

3.7.3. The Integrated Energy System Contribution

3.7.4. Energy Saving

4. Results

4.1. First Scenario

4.2. Second Scenario

4.3. Third Scenario

4.4. Fourth Scenario

5. Discussion

5.1. Energy Flow and Energy Usage Prices

5.2. Energy Cost

5.3. The ESS Lifetime and Energy Losses

5.4. The Integrated Energy System Contribution

5.5. CO2 Emissions

6. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

Nomenclature

| The simulation time (hour) | |

| The converter charging/discharging efficiency (%) | |

| The temperature coefficient | |

| The vehicle efficiency (kWh/km) | |

| , | The simulated parameters for ESS life cycle calculation |

| The expected amount of charged/discharged energy to/from the battery during its lifespan (kWh) | |

| The capital cost of the battery system (EUR) | |

| The total daily contribution of the battery (EUR) | |

| The total contribution of the battery (EUR) | |

| The levelized cost of storage for the battery (EUR/kWh) | |

| The estimated battery lifetime (year) | |

| The price of the total purchased energy from the PV system, grid, and EV, which is stored in the battery at each time slot t (EUR/kWh) | |

| The battery energy usage price in the time slot t (EUR/kWh) | |

| is the battery energy usage price for the time slot t + 1 (EUR/kWh) | |

| The cost of battery energy usage in the home at each time slot t (EUR) | |

| The infrastructure cost of the battery system (EUR/kWh) | |

| The cost of energy purchased from the battery and stored in the EV battery at each time slot t (EUR) | |

| The cost of energy purchased from the EV and stored in the battery at each time slot t (EUR) | |

| The cost of grid energy usage for the vehicle trip at each time slot t (EUR) | |

| The cost of energy purchased from the grid and stored in the battery at each time slot t (EUR) | |

| The cost of energy purchased from the grid and stored in the EV battery at each time slot t (EUR) | |

| The power conversion system cost (EUR/kW) | |

| The cost of using PV energy to cover the load at each time slot t (EUR) | |

| The cost of energy purchased from the PV system and stored in the battery at each time slot t (EUR) | |

| The cost of energy purchased from the PV system and stored in the EV battery at each time slot t (EUR) | |

| The cost of EV energy usage cost for the vehicle trip at each time slot t (EUR) | |

| The cost of the battery per unit (EUR/kWh) | |

| The maximum charge rate of the battery during the time slot t (kWh) | |

| The maximum charge rate of the EV battery during the time slot t (kWh) | |

| The ESS energy losses due to the converter efficiency during the charging intervals at each time slot t (kWh) | |

| The amount of CO2 emission produced from the energy consumed in the home at each time slot t (kgCO2) | |

| The vehicle travel distance (km) | |

| The total days within a year | |

| The maximum discharge rate of the battery during the time slot t (kWh) | |

| The maximum discharge rate of the EV battery during the time slot t (kWh) | |

| The ESS energy losses due to the converter efficiency during the discharging intervals at each time slot t (kWh) | |

| Depth of discharge (%) | |

| The energy stored in the battery at each time slot t (kWh) | |

| The energy stored in the battery at t + 1 (kWh) | |

| The battery capacity (kWh). | |

| The energy stored in the EV battery at each time slot t (kWh) | |

| The energy stored in the EV battery at t + 1 (kWh) | |

| The energy consumption of the shifted appliances (kWh) at each time slot t | |

| The number of charging/discharging cycles throughout the day of ESS | |

| The cost of energy losses associated with the ESS charging and discharging process at each time slot t (EUR) | |

| The expected ESS lifetime (years) | |

| The total daily contribution of the EV (EUR) | |

| The total contribution of the EV (EUR) | |

| The replacement cost of the EV battery (EUR) | |

| The levelized cost of storage for the EV battery (EUR/kWh) | |

| The estimated EV lifetime (year) | |

| The price of the total purchased energy from the PV, grid, and battery, which is stored in the EV battery at each time slot t (EUR/kWh) | |

| The EV battery energy usage price in the time slot t (EUR/kWh) | |

| The EV battery energy usage price for the time slot t + 1 (EUR/kWh) | |

| The grid price at each time slot t (EUR/kWh) | |

| The energy selling price to the grid at each time slot t (EUR/kWh) | |

| The CO2 emission intensity (kgCO2/kWh) | |

| The solar irradiance (kW/m2) | |

| The solar irradiance at standard test condition (kW/m2) | |

| The PV energy usage price (EUR/kWh) | |

| The expected number of battery life cycle | |

| The ESS life cycle | |

| The number of charging/discharging cycles of the EV battery | |

| The nominal energy of the EV battery (kWh) | |

| The ON/OFF variable that expressed the shifted appliances operation status (0 or 1) at each time slot t | |

| The amount of charging power to the battery at each time slot t (kW) | |

| The amount of discharging power from the battery at each time slot t (kW) | |

| The power discharged from the battery to the EV at each time slot t (kW) | |

| The power discharged from the battery to the grid at each time slot t (kW) | |

| The power discharged from the battery to the home at each time slot t (kW) | |

| The charging power to the EV battery at each time slot t (kW) | |

| The charged power to the ESS at each time slot t (kWh) | |

| The discharged power from the ESS at each time slot t (kWh) | |

| The discharging power from the EV battery at each time slot t (kW) | |

| The amount of power sent from the EV to the battery at each time slot t (kW) | |

| The power exported from the EV battery to the grid at each time slot t (kW) | |

| The power discharged from the EV battery to the battery at each time slot t (kW) | |

| The amount of power sent from the grid to the battery at each time slot t (kW) | |

| The power imported from the grid for charging the EV battery at each time slot t (kW) | |

| The power sent from the grid to home at each time slot t (kW) | |

| The home load at each time slot t (kW) | |

| The amount of power sent from the PV system to the battery at each time slot t (kW) | |

| The amount of power sent from the PV system to the EV battery at each time slot t (kW) | |

| The amount of PV power sent to the grid at each time slot t (kW) | |

| The power sent from the PV system to the load at each time slot t (kW) | |

| The rated power of each shifted appliance (kW) | |

| The economic benefit of selling energy from battery to the grid at each time slot t (EUR) | |

| The economic benefit of selling energy from EV to the grid at each time slot t (EUR) | |

| The economic benefit of selling energy from the PV system to the grid at each time slot t (EUR) | |

| The total daily contribution of the PV system (EUR) | |

| The total contribution of the PV system (EUR) | |

| The maximum power of PV module at standard test condition (kW) | |

| The PV output power at each time slot t (kW) | |

| The set of shifted appliances ranged (1, 2, 3, …, X) | |

| The ambient temperature at each time slot t (°C) | |

| The total cost of the purchased energy and stored in the battery at each time slot t (EUR) | |

| The total purchased energy stored in the battery at each time slot t (kWh) | |

| The total cost of the purchased energy and stored in the EV battery at each time slot t (EUR) | |

| The total purchased energy and stored in the EV battery at each time slot t (kWh) | |

| The reference temperature at standard test conditions (°C) | |

| Abbreviations | |

| The simulation time | |

| The converter charging/discharging efficiency (%) | |

| The temperature coefficient | |

| the vehicle efficiency (kWh/km) | |

| The vehicle travel distance (km) | |

| The energy stored in the battery at each time slot t (kWh) | |

| The energy stored in the battery at t + 1 (kWh) | |

| The energy stored in the EV battery at each time slot t (kWh) | |

| The energy stored in the EV battery at t + 1 (kWh) | |

| The solar irradiance (kW/m2) | |

| The solar irradiance at standard test condition (kW/m2) | |

| The amount of charging power to the battery at each time slot t (kW) | |

| The amount of discharging power from the battery at each time slot t (kW) | |

| The charging power to the EV battery at each time slot t (kW) | |

| The discharging power from the EV battery at each time slot t (kW) | |

| The PV output power (kW) | |

| The power discharged from the battery to the EV at each time slot t (kW) | |

| The power discharged from the battery to the grid at each time slot t (kW) | |

| The power discharged from the battery to the home at each time slot t (kW) | |

| The amount of power sent from the EV to the battery at each time slot t (kW) | |

| The power exported from the EV battery to the grid at each time slot t (kW) | |

| The power discharged from the EV battery to the battery at each time slot t (kW) | |

| The amount of power sent from the grid to the battery at each time slot t (kW) | |

| The power imported from the grid for charging the EV battery at each time slot t (kW) | |

| The amount of power sent from the PV to the battery at each time slot t (kW) | |

| The amount of power sent from the PV to the EV battery at each time slot t (kW) | |

| The maximum power of PV module at standard test conditions (kW) | |

| The ambient temperature (°C) | |

| The reference temperature at standard test conditions (°C) |

References

- Our World in Data. Available online: https://ourworldindata.org/energy (accessed on 12 November 2023).

- Proskuryakova, L. Updating energy security and environmental policy: Energy security theories revisited. J. Environ. Manag. 2018, 223, 203–214. [Google Scholar] [CrossRef] [PubMed]

- Gökgöz, F.; Güvercin, M.T. Energy security and renewable energy efficiency in EU. Renew. Sustain. Energy Rev. 2018, 96, 226–239. [Google Scholar] [CrossRef]

- Notton, G.; Nivet, M.L.; Voyant, C.; Paoli, C.; Darras, C.; Motte, F.; Fouilloy, A. Intermittent and stochastic character of renewable energy sources: Consequences, cost of intermittence and benefit of forecasting. Renew. Sustain. Energy Rev. 2018, 87, 96–105. [Google Scholar] [CrossRef]

- Aziz, T.; Ketjoy, N. PV penetration limits in low voltage networks and voltage variations. IEEE Access 2017, 5, 16784–16792. [Google Scholar] [CrossRef]

- Mahesh, M.; Vijaya Bhaskar, D.; Narsa Reddy, T.; Sanjeevikumar, P.; Holm-Nielsen, J.B. Evaluation of ancillary services in distribution grid using large-scale battery energy storage systems. IET Renew. Power Gener. 2020, 14, 4216–4222. [Google Scholar] [CrossRef]

- Al-Saadi, M.; Short, M. Multiagent-Based Control for Plug-and-Play Batteries in DC Microgrids with Infrastructure Compensation. Batteries 2023, 9, 597. [Google Scholar] [CrossRef]

- Eurostat. Available online: https://ec.europa.eu/eurostat/statistics-explained/index.php?title=Energy_consumption_in_households (accessed on 11 November 2023).

- Gong, H.; Rallabandi, V.; McIntyre, M.L.; Hossain, E.; Ionel, D.M. Peak reduction and long term load forecasting for large residential communities including smart homes with energy storage. IEEE Access 2021, 9, 19345–19355. [Google Scholar] [CrossRef]

- Mohandes, B.; Acharya, S.; El Moursi, M.S.; Al-Sumaiti, A.S.; Doukas, H.; Sgouridis, S. Optimal design of an islanded microgrid with load shifting mechanism between electrical and thermal energy storage systems. IEEE Trans. Power Syst. 2020, 35, 2642–2657. [Google Scholar] [CrossRef]

- International Renewable Energy Agency (IRENA). Renewable Power Generation Costs in 2020; International Renewable Energy Agency (IRENA): Abu Dhabi, United Arab Emirates, 2021. [Google Scholar]

- Rana, M.M.; Uddin, M.; Sarkar, M.R.; Shafiullah, G.M.; Mo, H.; Atef, M. A review on hybrid photovoltaic–Battery energy storage system: Current status, challenges, and future directions. J. Energy Storage 2022, 51, 104597. [Google Scholar] [CrossRef]

- Meliani, M.; Barkany, A.E.; Abbassi, I.E.; Darcherif, A.M.; Mahmoudi, M. Energy management in the smart grid: State-of-the-art and future trends. Int. J. Eng. Bus. Manag. 2021, 13, 18479790211032920. [Google Scholar] [CrossRef]

- SA Power Networks. Available online: https://www.sapowernetworks.com.au/public/download.jsp?id=310828 (accessed on 1 December 2023).

- Dong, S.; Kremers, E.; Brucoli, M.; Rothman, R.; Brown, S. Improving the feasibility of household and community energy storage: A techno-enviro-economic study for the UK. Renew. Sustain. Energy Rev. 2020, 131, 110009. [Google Scholar] [CrossRef]

- Omar, N.; Monem, M.A.; Firouz, Y.; Salminen, J.; Smekens, J.; Hegazy, O.; Gaulous, H.; Mulder, G.; van den Bossche, P.; Coosemans, T.; et al. Lithium iron phosphate based battery–Assessment of the aging parameters and development of cycle life model. Appl. Energy 2014, 113, 1575–1585. [Google Scholar] [CrossRef]

- Haddadian, H.; Noroozian, R. Multi-microgrids approach for design and operation of future distribution networks based on novel technical indices. Appl. Energy 2017, 185, 650–663. [Google Scholar] [CrossRef]

- Mbungu, N.T.; Bansal, R.C.; Naidoo, R.; Miranda, V.; Bipath, M. An optimal energy management system for a commercial building with renewable energy generation under real-time electricity prices. Sustain. Cities Soc. 2018, 41, 392–404. [Google Scholar] [CrossRef]

- Tabar, V.S.; Jirdehi, M.A.; Hemmati, R. Sustainable planning of hybrid microgrid towards minimizing environmental pollution, operational cost and frequency fluctuations. J. Clean. Prod. 2018, 203, 1187–1200. [Google Scholar] [CrossRef]

- Kusakana, K. Optimal peer-to-peer energy management between grid-connected prosumers with battery storage and photovoltaic systems. J. Energy Storage 2020, 32, 101717. [Google Scholar] [CrossRef]

- Al Muala, Z.A.; Bany Issa, M.A.; Sansó-Rubert Pascual, D.; Bello Bugallo, P.M. Realistic Home Energy Management System Considering the Life Cycle of Photovoltaic and Energy Storage Systems. Sustainability 2023, 15, 11205. [Google Scholar] [CrossRef]

- Bouakkaz, A.; Haddad, S.; Martín-García, J.A.; Gil-Mena, A.J.; Jiménez-Castañeda, R. Optimal scheduling of household appliances in off-grid hybrid energy system using PSO algorithm for energy saving. Int. J. Renew. Energy Res. 2019, 9, 427–436. [Google Scholar]

- Bhattacharjee, A.; Samanta, H.; Ghosh, A.; Mallick, T.K.; Sengupta, S.; Saha, H. Optimized integration of hybrid renewable sources with long-life battery energy storage in microgrids for peak power shaving and demand side management under different tariff scenario. Energy Technol. 2021, 9, 2100199. [Google Scholar] [CrossRef]

- Mbungu, N.T.; Bansal, R.C.; Naidoo, R. Smart energy coordination of a hybrid wind/PV with battery storage connected to grid. J. Eng. 2019, 2019, 5109–5113. [Google Scholar] [CrossRef]

- Mbungu, N.T.; Ismail, A.A.; Bansal, R.C.; Hamid, A.K.; Naidoo, R.M. An optimal energy management scheme of a vehicle to home. In Proceedings of the 2022 IEEE 21st Mediterranean Electrotechnical Conference (MELECON), Palermo, Italy, 14–16 June 2022. [Google Scholar]

- Zhang, S.; Tang, Y. Optimal schedule of grid-connected residential PV generation systems with battery storages under time-of-use and step tariffs. J. Energy Storage 2019, 23, 175–182. [Google Scholar] [CrossRef]

- Li, Y.; Peng, J.; Jia, H.; Zou, B.; Hao, B.; Ma, T.; Wang, X. Optimal battery schedule for grid-connected photovoltaic-battery systems of office buildings based on a dynamic programming algorithm. J. Energy Storage 2022, 50, 104557. [Google Scholar] [CrossRef]

- Azaroual, M.; Ouassaid, M.; Maaroufi, M. Optimum energy flow management of a grid-tied photovoltaic-wind-battery system considering cost, reliability, and CO2 emission. Int. J. Photoenergy 2021, 2021, 5591456. [Google Scholar] [CrossRef]

- Mohammad, A.; Zuhaib, M.; Ashraf, I. An optimal home energy management system with integration of renewable energy and energy storage with home to grid capability. Int. J. Energy Res. 2022, 46, 8352–8366. [Google Scholar] [CrossRef]

- Wang, M.; Abdalla, M.A.A. Optimal Energy Scheduling Based on Jaya Algorithm for Integration of Vehicle-to-Home and Energy Storage System with Photovoltaic Generation in Smart Home. Sensors 2022, 22, 1306. [Google Scholar] [CrossRef]

- Munankarmi, P.; Wu, H.; Pratt, A.; Lunacek, M.; Balamurugan, S.P.; Spitsen, P. Home energy management system for price-responsive operation of consumer technologies under an export rate. IEEE Access 2022, 10, 50087–50099. [Google Scholar] [CrossRef]

- Lee, J.O.; Kim, Y.S. Novel battery degradation cost formulation for optimal scheduling of battery energy storage systems. Int. J. Electr. Power Energy Syst. 2022, 137, 107795. [Google Scholar] [CrossRef]

- Seal, S.; Boulet, B.; Dehkordi, V.R. Centralized model predictive control strategy for thermal comfort and residential energy management. Energy 2020, 212, 118456. [Google Scholar] [CrossRef]

- Bouakkaz, A.; Mena, A.J.G.; Haddad, S.; Ferrari, M.L. Efficient energy scheduling considering cost reduction and energy saving in hybrid energy system with energy storage. J. Energy Storage 2021, 33, 101887. [Google Scholar] [CrossRef]

- Huy, T.H.B.; Dinh, H.T.; Kim, D. Multi-objective framework for a home energy management system with the integration of solar energy and an electric vehicle using an augmented ε-constraint method and lexicographic optimization. Sustain. Cities Soc. 2023, 88, 104289. [Google Scholar] [CrossRef]

- Mohamed, F.A.; Koivo, H.N. Online management of microgrid with battery storage using multiobjective optimization. In Proceedings of the 2007 International Conference on Power Engineering, Energy and Electrical Drives, Setubal, Portugal, 12–14 April 2007. [Google Scholar]

- Abdalla, M.A.A.; Min, W.; Mohammed, O.A.A. Two-stage energy management strategy of EV and PV integrated smart home to minimize electricity cost and flatten power load profile. Energies 2020, 13, 6387. [Google Scholar] [CrossRef]

- Branker, K.; Pathak, M.J.M.; Pearce, J.M. A review of solar photovoltaic levelized cost of electricity. Renew. Sustain. Energy Rev. 2011, 15, 4470–4482. [Google Scholar] [CrossRef]

- Lai, C.S.; McCulloch, M.D. Levelized cost of electricity for solar photovoltaic and electrical energy storage. Appl. Energy 2017, 190, 191–203. [Google Scholar] [CrossRef]

- Shen, W.; Chen, X.; Qiu, J.; Hayward, J.A.; Sayeef, S.; Osman, P.; Meng, K.; Dong, Z.Y. A comprehensive review of variable renewable energy levelized cost of electricity. Renew. Sustain. Energy Rev. 2020, 133, 110301. [Google Scholar] [CrossRef]

- Aghdam, F.H.; Ghaemi, S.; Kalantari, N.T. Evaluation of loss minimization on the energy management of multi-microgrid based smart distribution network in the presence of emission constraints and clean productions. J. Clean. Prod. 2018, 196, 185–201. [Google Scholar] [CrossRef]

- Zakeri, B.; Syri, S. Electrical energy storage systems: A comparative life cycle cost analysis. Renew. Sustain. Energy Rev. 2015, 42, 569–596. [Google Scholar] [CrossRef]

- Schoenung, S.M. Economic Analysis of Large-Scale Hydrogen Storage for Renewable Utility Applications; Sandia National Laboratories (SNL): Albuquerque, NM, USA, 2011. [Google Scholar]

- Kintner-Meyer, M.C.; Balducci, P.J.; Jin, C.; Nguyen, T.B.; Elizondo, M.A.; Viswanathan, V.V.; Guo, X.; Tuffner, F.K. Energy Storage for Power Systems Applications: A Regional Assessment for the Northwest Power Pool (NWPP); Pacific Northwest National Lab. (PNNL): Richland, WA, USA, 2010. [Google Scholar]

- Dallinger, D.; Link, J.; Büttner, M. Smart grid agent: Plug-in electric vehicle. IEEE Trans. Sustain. Energy 2014, 5, 710–717. [Google Scholar] [CrossRef]

- Jain, M.; Saihjpal, V.; Singh, N.; Singh, S.B. An overview of variants and advancements of PSO algorithm. Appl. Sci. 2022, 12, 8392. [Google Scholar] [CrossRef]

- Kennedy, J.; Eberhart, R. Particle swarm optimization. In Proceedings of the ICNN’95-International Conference on Neural Networks, Perth, WA, Australia, 27 November–1 December 1995. [Google Scholar]

- Menos-Aikateriniadis, C.; Lamprinos, I.; Georgilakis, P.S. Particle swarm optimization in residential demand-side management: A review on scheduling and control algorithms for demand response provision. Energies 2022, 15, 2211. [Google Scholar] [CrossRef]

- Nguyen, T.H.; Nguyen, L.V.; Jung, J.J.; Agbehadji, I.E.; Frimpong, S.O.; Millham, R.C. Bio-inspired approaches for smart energy management: State of the art and challenges. Sustainability 2020, 12, 8495. [Google Scholar] [CrossRef]

- Dinh, H.T.; Yun, J.; Kim, D.M.; Lee, K.H.; Kim, D. A home energy management system with renewable energy and energy storage utilizing main grid and electricity selling. IEEE Access 2020, 8, 49436–49450. [Google Scholar] [CrossRef]

- SECONDSOL. Available online: https://www.secondsol.com/en/anzeige/15345/modules/crystalline/poly/rec/225-wp-235-wp-poly (accessed on 20 December 2023).

- European Commission. Photovoltaic. Available online: https://re.jrc.ec.europa.eu/pvg_tools/en/#HR (accessed on 29 December 2023).

- Open-Meteo. Available online: https://open-meteo.com/en/docs/historical-weather-api (accessed on 30 December 2023).

- Red Eléctrica de España (REDE). Active Energy Invoicing Price. Available online: https://www.esios.ree.es/en/pvpc?date=11-02-2022 (accessed on 30 December 2023).

- Red Eléctrica de España (REDE). Self-Consumption Surplus Energy Price for the Simplified Compensation Mechanism (pvpc). Available online: https://www.esios.ree.es/en/analsis/1739?vis=1&start_date=08052019t00%3a00&end_date=03042022t23%3a00&compare_start_date=07052019t00%3a00&groupby=hour&compare_indicators=1013,1014,1015 (accessed on 30 December 2023).

- WccSolar. Available online: https://www.wccsolar.net/baterias-litio?lang=en (accessed on 31 December 2023).

- KIA. Available online: https://www.kia.com/uk/new-cars/niro/specification.carcode.niro-ev_2022/?shareData={%22trimCode%22:{}}&previewMode=1 (accessed on 2 January 2024).

- EV Database. Available online: https://ev-database.org/car/1338/Kia-e-Niro-64-kWh (accessed on 2 January 2024).

- Office of Energy Efficiency & Renewable Energy. Available online: https://www.energy.gov/eere/vehicles/articles/fotw-1272-january-9-2023-electric-vehicle-battery-pack-costs-2022-are-nearly (accessed on 17 December 2023).

- European Environment Agency (EEA). Available online: https://www.eea.europa.eu/data-and-maps/daviz/sds/co2-emission-intensity-from-electricity-generation-6/@@view (accessed on 20 December 2023).

- IRENA and IEA-PVPS. End of Life Management: Solar Photovoltaic Panels; National Renewable Energy Lab. (NREL): Golden, CO, USA, 2016. [Google Scholar]

- Fioriti, D.; Scarpelli, C.; Pellegrino, L.; Lutzemberger, G.; Micolano, E.; Salamone, S. Battery lifetime of electric vehicles by novel rainflow-counting algorithm with temperature and C-rate dynamics: Effects of fast charging, user habits, vehicle-to-grid and climate zones. J. Energy Storage 2023, 59, 106458. [Google Scholar] [CrossRef]

- Lehtola, T.A.; Zahedi, A. Electric vehicle battery cell cycle aging in vehicle to grid operations: A review. IEEE J. Emerg. Sel. Top. Power Electron. 2019, 9, 423–437. [Google Scholar] [CrossRef]

| Scenario | PV | Battery | EV | Grid | EFMSA | Optimizing ESS Parameters | Household Appliance Scheduling |

|---|---|---|---|---|---|---|---|

| 1 | ✗ | ✗ | ✓ | ✓ | ✗ | ✗ | ✗ |

| 2 | ✓ | ✓ | ✓ | ✓ | ✓ | ✗ | ✗ |

| 3 | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ | ✗ |

| 4 | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ |

| Winter | Summer | |

|---|---|---|

| Cost (EUR) | 6.620 | 5.723 |

| Grid Imported Energy (kWh) | 90.264 | 89.053 |

| CO2 Emissions (kgCO2/kWh) | 15.976 | 15.762 |

| Energy Losses (kWh) | 4.291 | 4.230 |

| Energy Loss Cost (EUR) | 0.595 | 0.587 |

| EV Lifetime (Years) | 9.230 | 10.401 |

| Winter | Summer | |

|---|---|---|

| Cost (EUR) | 5.210 | 5.083 |

| Grid Imported Energy (kWh) | 40.725 | 56.264 |

| CO2 Emissions (kgCO2/kWh) | 7.208 | 9.958 |

| Energy Losses (kWh) | 3.535 | 3.757 |

| Energy Loss Cost (EUR) | 0.462 | 0.517 |

| EV Lifetime (Years) | 13.141 | 11.085 |

| PV Daily Financial Contribution (EUR) | 0.271 | 0.530 |

| Battery Daily Financial Contribution (EUR) | 0.226 | 0 |

| EV Daily Financial Contribution (EUR) | 1.019 | 0.337 |

| Total Financial Contribution (EUR) | 1.516 | 0.867 |

| Winter | Summer | |

|---|---|---|

| Cost (EUR) | 4.905 | 4.831 |

| Grid Imported Energy (kWh) | 36.946 | 47.520 |

| CO2 Emissions (kgCO2/kWh) | 6.539 | 8.411 |

| Energy Losses (kWh) | 3.179 | 3.389 |

| Energy Loss Cost (EUR) | 0.387 | 0.459 |

| EV Lifetime (Years) | 19.053 | 17.363 |

| PV Daily Financial Contribution (EUR) | 0.271 | 0.530 |

| Battery Daily Financial Contribution (EUR) | 0.129 | 0.007 |

| EV Daily Financial Contribution (EUR) | 1.237 | 0.418 |

| Total Financial Contribution (EUR) | 1.637 | 0.955 |

| Winter | Summer | |

|---|---|---|

| Cost (EUR) | 4.760 | 4.708 |

| Grid Imported Energy (kWh) | 36.364 | 47.879 |

| CO2 Emissions (kgCO2/kWh) | 6.436 | 8.474 |

| Energy Losses (kWh) | 3.143 | 3.284 |

| Energy Loss Cost (EUR) | 0.381 | 0.445 |

| EV Lifetime (Years) | 19.120 | 17.687 |

| PV Daily Financial Contribution (EUR) | 0.267 | 0.631 |

| Battery Daily Financial Contribution (EUR) | 0.080 | 0 |

| EV Daily Financial Contribution (EUR) | 1.271 | 0.342 |

| Total Financial Contribution (EUR) | 1.618 | 0.973 |

| Winter | Summer | |||

|---|---|---|---|---|

| Scenario | Cost (EUR) | Cost Reduction (%) | Cost (EUR) | Cost Reduction (%) |

| 1 | 6.620 | - | 5.723 | - |

| 2 | 5.210 | 21.299 | 5.083 | 11.182 |

| 3 | 4.905 | 25.906 | 4.831 | 15.586 |

| 4 | 4.74 | 28.398 | 4.708 | 17.735 |

| Winter | Summer | |||||||

|---|---|---|---|---|---|---|---|---|

| Scenario | Energy Losses (kWh) | Energy Losses Reduction (%) | Losses Cost (EUR) | Losses Cost Reduction (%) | Energy Losses (kWh) | Energy Losses Reduction (%) | Losses Cost (EUR) | Losses Cost Reduction (%) |

| 1 | 4.291 | - | 0.595 | - | 4.230 | - | 0.587 | - |

| 2 | 3.535 | 17.618 | 0.462 | 22.352 | 3.757 | 11.182 | 0.517 | 11.925 |

| 3 | 3.179 | 25.914 | 0.387 | 34.957 | 3.389 | 19.881 | 0.459 | 21.805 |

| 4 | 3.144 | 26.730 | 0.381 | 35.966 | 3.285 | 22.340 | 0.445 | 24.190 |

| Winter | Summer | |||||||

|---|---|---|---|---|---|---|---|---|

| Scenario | EV Lifetime (Years) | EV Lifetime Extension (%) | Battery Lifetime (Years) | Battery Lifetime Extension (%) | EV Lifetime (Years) | EV Lifetime Extension (%) | Battery Lifetime (Years) | Battery Lifetime Extension (%) |

| 1 | 9.230 | - | - | - | 10.401 | - | - | - |

| 2 | 13.141 | - | 4.087 | - | 11.085 | 6.576 | - | - |

| 3 | 19.053 | 44.988 | 5.967 | 45.999 | 17.363 | 66.934 | - | - |

| 4 | 19.120 | 45.498 | 7.940 | 94.274 | 17.687 | 70.047 | - | - |

| Winter | Summer | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Scenario | PV (EUR) | Battery (EUR) | EV (EUR) | Daily (EUR) | Operational Lifetime (EUR) | PV (EUR) | Battery (EUR) | EV (EUR) | Daily (EUR) | Operational Lifetime (EUR) |

| 1 | - | - | - | - | - | - | - | - | - | - |

| 2 | 0.271 | 0.226 | 1.019 | 1.516 | 7705 | 0.530 | 0 | 0.337 | 0.867 | 6203 |

| 3 | 0.271 | 0.129 | 1.237 | 1.637 | 11,363 | 0.530 | 0.007 | 0.418 | 0.955 | 7546 |

| 4 | 0.267 | 0.080 | 1.271 | 1.618 | 11,546 | 0.631 | 0 | 0.342 | 0.973 | 7973 |

| Winter | Summer | Average | |||

|---|---|---|---|---|---|

| Scenario | CO2 (kgCO2/kWh) | CO2 Reduction (%) | CO2 (kgCO2/kWh) | CO2 Reduction (%) | CO2 Reduction (%) |

| 1 | 15.976 | - | 15.762 | - | - |

| 2 | 7.208 | 54.882 | 9.958 | 36.819 | 45.850 |

| 3 | 6.539 | 59.068 | 8.411 | 46.638 | 52.853 |

| 4 | 6.436 | 59.713 | 8.474 | 46.234 | 52.973 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Al Muala, Z.A.; Bany Issa, M.A.; Bello Bugallo, P.M. Integrating Life Cycle Principles in Home Energy Management Systems: Optimal Load PV–Battery–Electric Vehicle Scheduling. Batteries 2024, 10, 138. https://doi.org/10.3390/batteries10040138

Al Muala ZA, Bany Issa MA, Bello Bugallo PM. Integrating Life Cycle Principles in Home Energy Management Systems: Optimal Load PV–Battery–Electric Vehicle Scheduling. Batteries. 2024; 10(4):138. https://doi.org/10.3390/batteries10040138

Chicago/Turabian StyleAl Muala, Zaid A., Mohammad A. Bany Issa, and Pastora M. Bello Bugallo. 2024. "Integrating Life Cycle Principles in Home Energy Management Systems: Optimal Load PV–Battery–Electric Vehicle Scheduling" Batteries 10, no. 4: 138. https://doi.org/10.3390/batteries10040138

APA StyleAl Muala, Z. A., Bany Issa, M. A., & Bello Bugallo, P. M. (2024). Integrating Life Cycle Principles in Home Energy Management Systems: Optimal Load PV–Battery–Electric Vehicle Scheduling. Batteries, 10(4), 138. https://doi.org/10.3390/batteries10040138