A State-of-the-Art Review on the Incorporation of Recycled Concrete Aggregates in Geopolymer Concrete

Abstract

:1. Introduction

2. Contextual Background

2.1. Geopolymer Concrete

2.2. Recycled Concrete Aggregates

2.3. Previous Review Studies

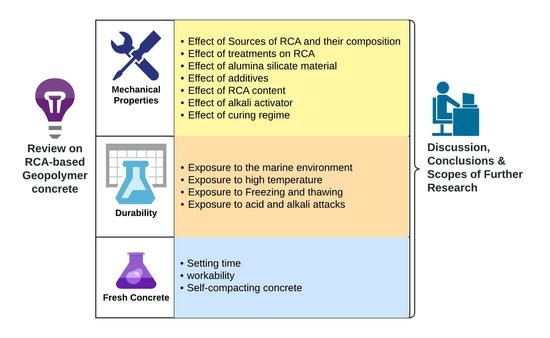

3. Research Methodology

3.1. Systematic Review

3.2. Data Extraction

4. Findings and Discussions

4.1. Mechanical Properties of RCA-Based Geopolymers

4.1.1. Effect of Sources of RCA and Their Composition

4.1.2. Effect of Treatments on RCA

4.1.3. Effect of Alumina Silicate Material

4.1.4. Effect of Additives

4.1.5. Effect of RCA Content

4.1.6. Effect of Alkali Activator

4.1.7. Effect of Curing Regime

4.2. The Durability of RCA-Based Geopolymer Concrete

4.2.1. Exposure to a Marine Environment

4.2.2. Exposure to High Temperature

4.2.3. Exposure to Freezing and Thawing

4.2.4. Exposure to Acid and Alkali Attacks

4.3. Properties of Fresh RCA-Based Geopolymer Concrete

4.3.1. Setting Time

4.3.2. Workability

4.3.3. Self-Compacting Concrete

5. Scopes for Further Research

- Self-compacting RCA-based GC, which can be cured in ambient temperature with CS, ranged in structural application. (Neglect)

- Applying RCA-based GC in a simulated coastal environment. (Neglect)

- Using the solid alkali activator. The previous studies are conducted on a two-part geopolymer concrete using a liquid alkali activator. (Neglect)

- The optimum temperature and time for curing. There is no agreement among researchers on this aspect. (Confusion)

- The effect of RCA on the compressive strength of GC. There is no agreement among researchers on this aspect. Some believe that RCA increases CS, and others state that RCA decreases CS. (Confusion)

- The effect of RCA on the setting time and flowability. There is no agreement among researchers on this aspect. (Confusion)

- The various treatment of RCA applied in GC. There are no studies on this aspect. (Application)

- Identify the optimum amount of GC mix components for developing RCA-based GC. The effect of considerable amounts of silica fume on an FA/silica fume GC. The impact of multiple ratios of waste concrete powder to FA and FA to ferrochrome ash should be considered in future studies. (Application)

6. Discussion and Conclusions

- Mechanical properties of RCA-based geopolymer concrete

- There are three sources for RCA in the literature: concrete lab specimens, CDW landfilled, and demolished buildings. Specific gravity, density, dry density, saturated density, bulk density, and apparent density of RCA are less than NA.

- There are some techniques for RCA treatment, including coating aggregates with geopolymer slurry or cement and so on to improve the properties of RCA. However, there is no study on the implications of treated RCA in GC.

- Increasing the aluminosilicate content, such as GGBS in a GGBS-based GC, GGBS in a GGBS FA-based GC, and the amount of UFS in a UFS FA-based GC, GGBS in GGBS an MK-based GC, MK in an MK FA-based GC results in enhancing CS. Besides, increasing the ratio of Portland cement in a Portland cement FA-based GC improves CS.

- Glass fibre, carbon fibre, nano-SiO2, steel fibre, polyvinyl alcohol fibre, graphene oxide, basalt fibre, rice husk ash, low-calcium bentonite, hypergolic coal, iron filling, and silica fume are reported as the additives that improve RCA-based GC. Besides, using textile mill effluent instead of freshwater improves the CS of GC.

- There are diverse ideas regarding the effect of RCA on the CS of GC. Some researchers believe that RCA harms CS, so just a few percentages of NA should be replaced by RCA, and further RCA will drop CS significantly. Thus, the optimum amount of RCA should be determined for each GC mix. On the other hand, there exists evidence that RCA increases CS, and it is possible to use 100% RCA, while the drop in CS is negligible.

- The alkali-activator-related factors, such as NaOH molarity, SS/SH ratio, sodium silicate modulus, and alkali-solution-to-binder ratio, affect the properties of RCA-based geopolymer.

- GC does not have an exact curing temperature and time depending on the aluminosilicates and alkali activator. GC can be cured ambient, but a higher temperature helps accelerate chemical reactions, create a good bond between alumina and silica, and increase CS. However, a higher temperature or additional curing time causes microcracks and a decline in compressive and flexural strength. The reaction of GC in higher temperatures depends on the type of materials, activator, activator-to-binder ratio, and curing regime. A higher temperature results in a decline in the CS of RCA-based GC, but in some cases, CS increases up to 200 °C heating and then will drop. Moreover, increasing the time of exposure to fire increases the damage. Besides, some additives, such as PVA and basalt fibre, positively impact the GC properties in higher temperatures.

- The durability of RCA-based geopolymer concrete.

- Incorporating RCA increases permeability, chloride penetration, and water absorption. However, the suitability of this type of GC for the marine environment depends on the kinds of aluminosilicate material, the ratio of alkali solution to the binder, and NaOH molarity. The percentages of RCA or patterns of RCA replacement in fine or coarse aggregates also have a noticeable impact. Some materials positively affect the marine durability of RCA-based GC, such as PVA, graphene oxide, carbon fibres, and bentonite, and replacing 5% to 15% of FA with OPC.

- GC demonstrates better freeze–thaw resistance than OPC concrete, resulting in better strength after freezing and thawing cycles. Some materials positively impact the freezing and thawing durability of a GC, including PVA and basalt fibres.

- RCA harms the acid attack resistance of GC. Some factors can improve it: adding bentonite, higher NaOH molarity, and increasing the ratio of the alkali activator to the binder.

- Properties of fresh RCA-based geopolymer concrete.

- Several factors affect the setting time of RCA-based GC, including bonding-to-aggregate ratio, NaOH concentration, SS/SH ratio, water/binder ratio, RCA content, and the type of aggregates. GGBS and fine waste concrete (as a binder) decrease the setting time. However, adding MK instead of a portion of FA results in a longer setting time. There is no agreement on the effect of RCA in the setting time. Some studies demonstrate that adding RCA results in shorter or longer setting times.

- The effect of RCA on workability is diverse, and decreases and increases in workability of GC by adding RCA are reported. Influential factors on GC’s workability include the aluminosilicate material type, AAS/b ratio, w/b ratio, SS/SH ratio, and NaOH molarity.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

Appendix A

| Reference | Aluminosilicates | RCA | Compacting or Self-Compacting | Superplasticizer | Curing Condition | Max 28-Day CS (MPa) | Remarks | ||

|---|---|---|---|---|---|---|---|---|---|

| Replacement Percentages | Coarse or Fine | Source of RCA | |||||||

| [17] | FFA, ultrafine slag | 25%, 50%, and 100% | NM | WS | NM | Y | A | 46 | Ultrafine slag is used as an additive and a substitution for FA from 0% to 30%. The best CS is for the addition of 30% UFS and 100% RCA, reaching to 46.24 MPa. |

| [22] | FFA, Silica Fume | 0%, 10%, 20%, 30%, 40%, 50%, 60%, 70%, 80%, 90%, 100% | C | DC | NM | N | O | 55 | The optimum amount of RCA is considered 40% and 50%. They evaluated the leaching characteristics and found that RCA decreases the leaching of arsenic. |

| [23] | FA, silica Fume | 0%, 10%, 50% | C | DC | NM | Y | O | 56 | They found that As, Cr, and Se leaching in RCA-based GC is lower than in NA-based GC. CSs are 42, 54, and 56 MPa for 0%, 10%, and 50% RCA. |

| [25] | FA | 100% | CF | LS | NM | Y | A | 34 | They analysed the effect of SH molarity on hollow steel columns grouted with RCA GC, and SH 14 M shows better results than using NA. |

| [26] | GGBS | 0%, 25%, 50%, 75%, 100% | CF | LS | NM | N | O | 65 | Effect of various percentages of RCA, and three binder contents of 300, 400, and 500 kg/m3 were evaluated on freeze/thaw cycling. 500 kg/m3 and 100% RCA show around 65 MPa CS. |

| [27] | MK, OPC | 100% | CF | NM | NM | Y | NM | 30 | Replacing 30% cement with MK demonstrates better CS than just using MK. |

| [32] | MK, GBFS | 100% | F | NM | NM | N | O | 47 | The best result for 0.4% polyvinyl alcohol as an additive can be seen. |

| [33] | FA, GGBS | 50% and 100% | C | LS | C | Y | A | 42 | Graphene oxide increases CS by 20.53–21.55% and 9.58–13.59% for 50% and 100% RCA content, respectively. |

| [34] | MK, FA | 30% 70%, 100% | C | WS | NM | Y | A | 41 | Aggregate replacement pattern was studied for both partial and total replacement of just coarse aggregates, and the best result is for 70% coarse RCA. |

| [35] | FA, GGBS | 100% | C | DB | C | Y | O | 48 | The optimum curing regime is 80 °C for 12–24 h. |

| [36] | CFA | 100% | C | LS | C | Y | O | 35 | 10% is an optimum content for bentonite as an additive, leading to an increase in CS and split tensile strength. |

| [37] | FFA | 50%, 80%, 100% | C | LS | C | Y | O | 62 | The optimum ratio of SS/SH is 1.5. The optimum ratio of glass fibre is 3% of the weight of concrete for 50% RCA with CS of 62 MPa. |

| [41] | GGBS, FA | 100% | C | LS | C | N | O | 38 | The effect of water-glass modules is studied. The impact of the mould size on the CS was also considered, with the larger size showing higher CS. |

| [44] | CF, FFA | 50%, 100% | F | LS | NM | Y | O | 49 | The effect of carbon fibre was studied. For 100% fine RCA, 0.2% carbon fibre provides a proper CS. 50% RCA shows the best CS and abrasion resistance. |

| [45] | FA, Ferrochrome ash | 10%, 20%, 30%, 40%, 50% | C | DC, LS | C | Y | O | 30 | The optimum percentage of RCA is 20%. |

| [46] | FA | 0%, 50%, 100% | C | WS | C | N | O | 72 | The CS for RCA-based GC was higher than their OPC-based counterpart. 86, 72, and 55 for 0%, 50%, and 100% RCA. |

| [47] | FA, fine waste concrete | 50% | F | LS | NM | N | A | NM | They stated that the bond between RCA and GP paste is strengthened compared with GC with NA, OPC concrete with NA, and OPC concrete with RCA. |

| [58] | FA, GGBS | 100% | NM | LS | NM | N | A | 32 | Three various types of effluent are used instead of freshwater, including sugar mill effluent mix (SF), fertilizer mill effluent mix (FF), and textile mill effluent mix (TF). The best one is TF, with a 133% improvement in CS. |

| [59] | CFA | 100% | C | LS | NM | N | A | 38 | The effect of rice husk (RH) and nano-SiO2 was studied. RH has a better impact on CS compared with nano-SiO2. |

| [60] | FFA, MK | 60%, 65%, 70% | NM | LS | C | N | O | 47 | The optimum content of steel fibre could not be found. The optimum amount of RCA is 65%, with a CS of 47 MPa. |

| [61] | FA | 40% | C | LS | C | N | O, A | 43 | Curing in ambient and oven temperature were studied, so oven heating at 60 °C provides better CS. |

| [62] | GGBS, FA | 100% | C | DC | C | Y | O | 80 | They evaluated the effect of various GGBS/FA ratios and W/b ratios. |

| [63] | GGBS, FA | 0%, 30%, 50%, 70%, and 100% | C | DC | C | Y | O | 62 | The effect of various RCA percentages and the water-to-binder ratio was evaluated. |

| [64] | MK | 100% | CF | DC | C | Y | A | 29 | The effect of iron filling was evaluated. Its optimum amount is 1%. |

| [65] | GGBS | 0%, 25%, 50%, 70%, and 100% | C | DC | C | Y | A, H | 56 | The optimum of RCA is 50%, leading to a CS of around 56 MPa |

| [70] | MK, GGBS | 100% | F | NM | C | N | O | 42 | The effect of basalt fibre was studied, and the optimum amount is 1.2%. |

| [71] | FA, slag | 30%, 50%, 70%, 100% | C | CB | C | N | O | 29 | The effect of hypergolic and calcined coal gangues was studied, and both provide the range of structural CS. Hypergolic demonstrates better CS. |

| [72] | FA | 100% | C | NM | C | Y | A, O | 35 | The effect of curing temperature, alkaline solution to FA ratio, and superplasticizer was assessed, and two models were evaluated for predicting compressive strength. Lignosulfonate superplasticizer is not appropriate for GC. |

| [73] | GGBS | 0%,10%, 20%, 30%, 40%, 50%, 60%, 70%, 80%, 90%, 100% | F | NM | NM | Y | A | NM | They used the gene expression programming model to predict CS and mass loss in higher temperatures. 30% RCA is considered the optimum. |

| [74] | FFA, CFA | 0%, 25%, 50%, 75%, and 100% | F | LS | NM | Y | O | 47 | FFA/CFA 1:1 and 25% RCA suggested. |

| [75] | FA | 100% | C | Old concrete | C | N | A | 35 | Alkaline activator/FA ratios of 0.4, 0.45, and 0.5 were compared, and the optimum ratio was introduced as 0.4, which is economical and provides the highest CS. |

| [76] | CFA and Cement | 100% | C | LS | C | N | O | 49 | The optimum amount of nano-SiO2 as an additive is around 1%. |

| [77] | CFA, MK | 100% | C | LS | C | N | O | 47 | They evaluated the effect of the replacement of MK instead of FA for NA- and RCA-based GC. |

| [81] | GGBS, MK | 0%, 50%, 100% | C | DC | C | Y | O | 47 | They evaluated the effect of various GGBS/MK ratios. |

| [87] | FFA | 30% | C | LS | SC | Y | O | 15 | A self-compacting GC was developed. |

| [88] | FFA, GGBS | 0%, 10%, 20%, 30%, 40%, and 50% | LS | NM | Y | O | 57 | 30% is considered the optimum percentage of RCA. | |

| [89] | GGBS | 0%, 25%, 50%, 75%, and 100% | C | LS | NM | Y | A, H | 57 for 50% RCA | The effect of various percentages of RCA in a GC cured in ambient temperature was studied. |

| [91] | FA | 100% 0%, 25%, 50%, 75%, 100% | C F | DB | C | N | O | 36 | Replacement of C RCA has a negligible impact on CS, and the optimum F RCA is 25%. |

| [92] | FFA | 100% | C | LS | NM | Y | O | 65 | They evaluated the effect of NaOH molarity, curing time, and temperature. The best result was for NaOH M = 12 and curing at 90 °C for 24 h. |

| [93] | Waste concrete fine, FA | 100% | FC | LS | NM | N | A | 32 | They examined the binder to aggregate (b/A) ratio, SH molarity, SS/SH ratio, curing regime, and RCA on the CS and initial setting time. The highest CS obtained for NaOH=10 M and SS/SH: 1.1. |

| [95] | FA, GGBS | 25% | F | LS | NM | N | A | 63 | They compared the effect of AAS/b on the CS and acid and alkali attack. There were around 63 and 38 MPa for AAS/b of 0.4 and 0.6, respectively. |

| [96] | MK, bottom ash | 100% | NM | DC | NM | N | A | 45 | Various sizes of crushed aggregates of 5, 2, and 1 mm are incorporated. The best results for CS are 40 to 45 MPa for aggregates smaller than 2 mm. |

| [100] | CFA | 100% | C | LS | SC | N | O | 38 | They evaluated the effect of NaOH molarity, so the optimum NaOH molarity was reported to be 12 M. |

| [101] | CFA | 100% | C | LS | NM | N | A, O | 37 | 12 is the optimum SH molarity. CS is 27.8 to 36.8 MPa for heated curing and 8.6 to 12.2 MPa for ambient curing. |

| [103] | MK | 10%, 20%, and 30% | C | NM | NM | Y | A | 28 | The effect of SS/SH was studied. Increasing the SS/SH ratio improves CS. By adding 30% RCA and SS/SH = 3, CS decreases by 28%, but it is still in the range of structural application. |

| [110] | FFA, GGBS | 0%, 10%, 20%, 30%, and 40% | C | NM | NM | Y | O | NM | The various RCA percentages were studied, and 30% is considered the optimum percentage of RCA. |

| [111] | GGBS | 0%, 25%, 50%, 75%, and 100% | C | LS | NM | N | O | 70 | CS drops of 8%, 40%, 47, 64%, and 91% for 100, 200, 400, 600 and 800 °C for 1 hr heating are observed. |

| [120] | GGBS | 20%, 30%, and 40% | C | LS | NM | N | A | 44 | Good resistance in freeze–thaw was observed with the CS reduction between 7% and 14% for 100, 200, and 300 freeze–thaw cycles. |

| [123] | FFA | 100% | C | DC | S | Y | NM | NM | They evaluated the effects of SH molarity and SS/SH ratio on fresh and hardened GC properties. 2.5 was the optimum SS/SH. |

| [128] | FA, GGBS | 100% | C | LS | NM | Y | A | 35 | They used this RCA-based GC to produce a large-scale column and tested and analysed a different number of bars and the distances between them. |

| [129] | MK | 100% | CF | LS | C | Y | A | 26 | The application of RCA-based GC in a wall was evaluated. |

| [130] | FA | 0%, 50%, 100% | NM | NM | C | N | O | NM | Study on steel tubular columns filled with RCA-based GC and OPC, resulting in a drop in CS by adding RCA while ductility improved. |

| [131] | FA | 0%, 50%, 100% | C | WS | C | N | O | NM | A study on the steel tubular columns filled with RCA GC and OPC resulted in a drop in CS; adding RCA improved ductility. |

| [132] | FA | 0%, 50%, 100% | C | NM | C | N | O | 72 | CSs are 86, 72, and 55 MPa for 0%, 50%, and 100% RCA |

| [133] | FFA | 20%, 30%, 40%, 50%, and 60% | C | LS | NM | Y | O | 32 | 40% RCA is an optimum RCA percentage for fresh and hardened specifications. |

References

- Institute, C.R. Resource Efficiency in the Building Sector; DG Environment: Rotterdam, The Netherlands, 2014. [Google Scholar]

- Nikmehr, B.; Hosseini, M.R.; Wang, J.; Chileshe, N.; Rameezdeen, R. BIM-Based Tools for Managing Construction and Demolition Waste (CDW): A Scoping Review. Sustainability 2021, 13, 8427. [Google Scholar] [CrossRef]

- Kabirifar, K.; Mojtahedi, M.; Wang, C.; Tam, V.W.Y. Construction and demolition waste management contributing factors coupled with reduce, reuse, and recycle strategies for effective waste management: A review. J. Clean. Prod. 2020, 263, 121265. [Google Scholar] [CrossRef]

- Ajayi, S.O.; Oyedele, L.O.; Akinade, O.O.; Bilal, M.; Owolabi, H.A.; Alaka, H.A.; Kadiri, K.O. Reducing waste to landfill: A need for cultural change in the UK construction industry. J. Build. Eng. 2016, 5, 185–193. [Google Scholar] [CrossRef]

- Zoghi, M.; Kim, S. Dynamic modeling for life cycle cost analysis of BIM-based construction waste management. Sustainability 2020, 12, 2483. [Google Scholar] [CrossRef] [Green Version]

- Purchase, C.K.; Al Zulayq, D.M.; O’Brien, B.T.; Kowalewski, M.J.; Berenjian, A.; Tarighaleslami, A.H.; Seifan, M. Circular economy of construction and demolition waste: A literature review on lessons, challenges, and benefits. Materials 2021, 15, 76. [Google Scholar] [CrossRef] [PubMed]

- Geissdoerfer, M.; Savaget, P.; Bocken, N.M.P.; Hultink, E.J. The Circular Economy—A new sustainability paradigm? J. Clean. Prod. 2017, 143, 757–768. [Google Scholar] [CrossRef] [Green Version]

- Bilal, M.; Khan, K.I.A.; Thaheem, M.J.; Nasir, A.R. Current state and barriers to the circular economy in the building sector: Towards a mitigation framework. J. Clean. Prod. 2020, 276, 123250. [Google Scholar] [CrossRef]

- Jacobsen, N.B. Industrial symbiosis in Kalundborg, Denmark: A quantitative assessment of economic and environmental aspects. J. Ind. Ecol. 2006, 10, 239–255. [Google Scholar] [CrossRef]

- Brambilla, G.; Lavagna, M.; Vasdravellis, G.; Castiglioni, C.A. Environmental benefits arising from demountable steel-concrete composite floor systems in buildings. Resour. Conserv. Recycl. 2019, 141, 133–142. [Google Scholar] [CrossRef]

- Zhao, X.; Webber, R.; Kalutara, P.; Browne, W.; Pienaar, J. Construction and demolition waste management in Australia: A mini-review. Waste Manag. Res. 2022, 40, 34–46. [Google Scholar] [CrossRef] [PubMed]

- Wang, B.; Yan, L.; Fu, Q.; Kasal, B. A Comprehensive Review on Recycled Aggregate and Recycled Aggregate Concrete. Resour. Conserv. Recycl. 2021, 171, 105565. [Google Scholar] [CrossRef]

- Ahmed Shaikh, F.U.; Nath, P.; Hosan, A.; John, M.; Biswas, W.K. Sustainability assessment of recycled aggregates concrete mixes containing industrial by-products. Mater. Today Sustain. 2019, 5, 100013. [Google Scholar] [CrossRef]

- Tavakoli, D.; Hashempour, M.; Heidari, A. Use of waste materials in concrete: A review. Pertanika J. Sci. Technol 2018, 26, 499–522. [Google Scholar]

- Ghorbani, S.; Sharifi, S.; Ghorbani, S.; Tam, V.W.; de Brito, J.; Kurda, R. Effect of crushed concrete waste’s maximum size as partial replacement of natural coarse aggregate on the mechanical and durability properties of concrete. Resour. Conserv. Recycl. 2019, 149, 664–673. [Google Scholar] [CrossRef]

- Sabău, M.; Remolina Duran, J. Prediction of Compressive Strength of General-Use Concrete Mixes with Recycled Concrete Aggregate. Int. J. Pavement Res. Technol. 2022, 15, 73–85. [Google Scholar] [CrossRef]

- Lim, Y.Y.; Pham, T.M. Effective utilisation of ultrafine slag to improve mechanical and durability properties of recycled aggregates geopolymer concrete. Clean. Eng. Technol. 2021, 5, 100330. [Google Scholar]

- Petroche, D.M.; Ramirez, A.D. The Environmental Profile of Clinker, Cement, and Concrete: A Life Cycle Perspective Study Based on Ecuadorian Data. Buildings 2022, 12, 311. [Google Scholar] [CrossRef]

- Chen, C.; Habert, G.; Bouzidi, Y.; Jullien, A. Environmental impact of cement production: Detail of the different processes and cement plant variability evaluation. J. Clean. Prod. 2010, 18, 478–485. [Google Scholar] [CrossRef]

- Davidovits, J. 30 years of successes and failures in geopolymer applications. Market trends and potential breakthroughs. In Proceedings of the Geopolymer 2002 Conference, Melbourne, Australia, 28–29 October 2002; p. 29. [Google Scholar]

- Imtiaz, L.; Kashif-ur-Rehman, S.; Alaloul, W.S.; Nazir, K.; Javed, M.F.; Aslam, F.; Musarat, M.A. Life Cycle Impact Assessment of Recycled Aggregate Concrete, Geopolymer Concrete, and Recycled Aggregate-Based Geopolymer Concrete. Sustainability 2021, 13, 13515. [Google Scholar] [CrossRef]

- Sanusi, O.; Tempest, B.; Ogunro, V.; Gergely, J. Leaching characteristics of geopolymer cement concrete containing recycled concrete aggregates. J. Hazard. Toxic Radioact. Waste 2016, 20, 04016002. [Google Scholar] [CrossRef]

- Sanusi, O.; Tempest, B.; Ogunro, V. Mitigating leachability from fly ash based geopolymer concrete using recycled concrete aggregate (RCA). In Geo-Frontiers 2011: Advances in Geotechnical Engineering; American Society of Civil Engineers: Dallas, TX, USA, 2011; pp. 1315–1324. [Google Scholar]

- Hassan, A.; Arif, M.; Shariq, M. A review of properties and behaviour of reinforced geopolymer concrete structural elements- A clean technology option for sustainable development. J. Clean. Prod. 2020, 245, 118762. [Google Scholar] [CrossRef]

- Alalikhan, A.A.; Habelalmateen, M.A.; Alhabbobi, A.M. Strengthening of short hollow steel columns using grouted geopolymer concrete with recycled components. Technology 2018, 9, 832–841. [Google Scholar]

- Uğurlu, A.İ.; Karakoç, M.B.; Özcan, A. Effect of binder content and recycled concrete aggregate on freeze-thaw and sulfate resistance of GGBFS based geopolymer concretes. Constr. Build. Mater. 2021, 301, 124246. [Google Scholar] [CrossRef]

- Al-Jaberi, L.; Al-Saraj, A.-S.K.W.; Al-Serai, A.-S.J.S. Scanning Electron Microscopy of Metakaolin Based Geopolymer Concrete. J. Phys. Conf. Ser. 2021, 2114, 012061. [Google Scholar] [CrossRef]

- Fernández-Jiménez, A.; Palomo, A. Characterisation of fly ashes. Potential reactivity as alkaline cements. Fuel 2003, 82, 2259–2265. [Google Scholar] [CrossRef]

- Muhammad Nasir, A.; Khan, K.; Javed, M.F.; Aslam, F.; Muhammad Ghulam, Q.; Faraz, M.I. Prediction of Mechanical Properties of Fly-Ash/Slag-Based Geopolymer Concrete Using Ensemble and Non-Ensemble Machine-Learning Techniques. Materials 2022, 15, 3478. [Google Scholar] [CrossRef]

- Jindal, B.B.; Alomayri, T.; Hasan, A.; Kaze, C.R. Geopolymer concrete with metakaolin for sustainability: A comprehensive review on raw material’s properties, synthesis, performance, and potential application. Environ. Sci. Pollut. Res. 2022, 1–26. [Google Scholar] [CrossRef]

- Alabi, S.A.; Mahachi, J. Chloride ion penetration performance of recycled concrete with different geopolymers. Mater. Today Proc. 2021, 38, 762–766. [Google Scholar] [CrossRef]

- Sahin, F.; Uysal, M.; Canpolat, O.; Cosgun, T.; Dehghanpour, H. The effect of polyvinyl fibers on metakaolin-based geopolymer mortars with different aggregate filling. Constr. Build. Mater. 2021, 300, 124257. [Google Scholar] [CrossRef]

- Bhardwaj, B.; Kumar, P. Performance Assessment of Graphene Oxide–Reinforced Sustainable Geopolymer Concrete. J. Mater. Civ. Eng. 2021, 33, 04021322. [Google Scholar] [CrossRef]

- Zhang, H.; Wan, K.; Wu, B.; Hu, Z. Flexural behavior of reinforced geopolymer concrete beams with recycled coarse aggregates. Adv. Struct. Eng. 2021, 24, 3281–3298. [Google Scholar] [CrossRef]

- Wang, J.; Xie, J.; Wang, C.; Zhao, J.; Liu, F.; Fang, C. Study on the optimum initial curing condition for fly ash and GGBS based geopolymer recycled aggregate concrete. Constr. Build. Mater. 2020, 247, 118540. [Google Scholar] [CrossRef]

- Waqas, R.M.; Butt, F.; Danish, A.; Alqurashi, M.; Mosaberpanah, M.A.; Masood, B.; Hussein, E.E. Influence of Bentonite on Mechanical and Durability Properties of High-Calcium Fly Ash Geopolymer Concrete with Natural and Recycled Aggregates. Materials 2021, 14, 7790. [Google Scholar] [CrossRef]

- Mehta, S.; Bhandari, M. Effect of glass fiber and recycled aggregates on Geopolymer concrete. In Proceedings of the 2nd Indo-European Conference on Sustainable Materials, Environment and Construction, Mohali, India, 23–24 September 2021. [Google Scholar]

- Ahmad Zaidi, F.H.; Ahmad, R.; Al Bakri Abdullah, M.M.; Abd Rahim, S.Z.; Yahya, Z.; Li, L.Y.; Ediati, R. Geopolymer as underwater concreting material: A review. Constr. Build. Mater. 2021, 291, 123276. [Google Scholar] [CrossRef]

- Shehata, N.; Mohamed, O.A.; Sayed, E.T.; Abdelkareem, M.A.; Olabi, A.G. Geopolymer concrete as green building materials: Recent applications, sustainable development and circular economy potentials. Sci. Total Environ. 2022, 836, 155577. [Google Scholar] [CrossRef] [PubMed]

- Ryu, G.S.; Lee, Y.B.; Koh, K.T.; Chung, Y.S. The mechanical properties of fly ash-based geopolymer concrete with alkaline activators. Constr. Build. Mater. 2013, 47, 409–418. [Google Scholar] [CrossRef]

- Wang, Q.; Bian, H.; Li, M.; Dai, M.; Chen, Y.; Jiang, H.; Zhang, Q.; Dong, F.; Huang, J.; Ding, Z. Effects of a Water-Glass Module on Compressive Strength, Size Effect and Stress–Strain Behavior of Geopolymer Recycled Aggregate Concrete. Crystals 2022, 12, 218. [Google Scholar] [CrossRef]

- Zhu, Z.; Gu, S.e.; Tang, Z.; Song, L. Experimental Study on Recycling of Waste Concrete Based on Geopolymer Technology. In Environmental Science and Engineering, Proceedings of the International Congress on Environmental Geotechnics, Hangzhou, China, 28 October–1 November 2018; Springer: Singapore, 2018; pp. 336–343. [Google Scholar]

- Quattrone, M.; Cazacliu, B.; Angulo, S.C.; Hamard, E.; Cothenet, A. Measuring the water absorption of recycled aggregates, what is the best practice for concrete production? Constr. Build. Mater. 2016, 123, 690–703. [Google Scholar] [CrossRef]

- Nuaklong, P.; Wongsa, A.; Boonserm, K.; Ngohpok, C.; Jongvivatsakul, P.; Sata, V.; Sukontasukkul, P.; Chindaprasirt, P. Enhancement of mechanical properties of fly ash geopolymer containing fine recycled concrete aggregate with micro carbon fiber. J. Build. Eng. 2021, 41, 102403. [Google Scholar] [CrossRef]

- Saha, S.; Mohanty, T.; Saha, P. Mechanical Properties of Fly Ash and Ferrochrome Ash-Based Geopolymer Concrete Using Recycled Aggregate. In Recent Developments in Sustainable Infrastructure; Springer: Singapore, 2021; pp. 417–426. [Google Scholar]

- Shi, X.S.; Collins, F.G.; Zhao, X.L.; Wang, Q.Y. Mechanical properties and microstructure analysis of fly ash geopolymeric recycled concrete. J. Hazard. Mater. 2012, 237–238, 20–29. [Google Scholar] [CrossRef]

- Ren, X.; Zhang, L. Experimental study of interfacial transition zones between geopolymer binder and recycled aggregate. Constr. Build. Mater. 2018, 167, 749–756. [Google Scholar] [CrossRef]

- Liu, Z.; Cai, C.; Peng, H.; Fan, F. Experimental study of the geopolymeric recycled aggregate concrete. J. Mater. Civ. Eng. 2016, 28, 04016077. [Google Scholar]

- McNeil, K.; Kang, T.H.-K. Recycled concrete aggregates: A review. Int. J. Concr. Struct. Mater. 2013, 7, 61–69. [Google Scholar] [CrossRef] [Green Version]

- Upshaw, M.; Cai, C. Critical review of recycled aggregate concrete properties, improvements, and numerical models. J. Mater. Civ. Eng. 2020, 32, 03120005. [Google Scholar] [CrossRef]

- Ye, T.; Xiao, J.; Duan, Z.; Li, S. Geopolymers made of recycled brick and concrete powder—A critical review. Constr. Build. Mater. 2022, 330, 127232. [Google Scholar] [CrossRef]

- Xu, Z.; Huang, Z.; Liu, C.; Deng, X.; Hui, D.; Deng, S. Research progress on mechanical properties of geopolymer recycled aggregate concrete. Rev. Adv. Mater. Sci. 2021, 60, 158–172. [Google Scholar]

- Younis, K.H.; Salihi, K.A.; Ibrahim, T.K. An Overview of Geo-Polymer Concrete Including Recycled Aggregate. Int. J. Sci. Technol. Res. 2020, 9, 6239–6242. [Google Scholar]

- Munn, Z.; Peters, M.D.; Stern, C.; Tufanaru, C.; McArthur, A.; Aromataris, E. Systematic review or scoping review? Guidance for authors when choosing between a systematic or scoping review approach. BMC Med. Res. Methodol. 2018, 18, 143. [Google Scholar]

- Lima, L.; Trindade, E.; Alencar, L.; Alencar, M.; Silva, L. Sustainability in the construction industry: A systematic review of the literature. J. Clean. Prod. 2021, 289, 125730. [Google Scholar] [CrossRef]

- Babalola, O.; Ibem, E.O.; Ezema, I.C. Implementation of lean practices in the construction industry: A systematic review. Build. Environ. 2019, 148, 34–43. [Google Scholar] [CrossRef]

- Page, M.J.; McKenzie, J.E.; Bossuyt, P.M.; Boutron, I.; Hoffmann, T.C.; Mulrow, C.D.; Shamseer, L.; Tetzlaff, J.M.; Akl, E.A.; Brennan, S.E. The PRISMA 2020 statement: An updated guideline for reporting systematic reviews. Int. J. Surg. 2021, 88, 105906. [Google Scholar] [CrossRef] [PubMed]

- Alhazmi, H.; Shah, S.A.R.; Mahmood, A. Sustainable Development of Innovative Green Construction Materials: A Study for Economical Eco-Friendly Recycled Aggregate Based Geopolymer Concrete. Materials 2020, 13, 4881. [Google Scholar] [CrossRef] [PubMed]

- Nuaklong, P.; Jongvivatsakul, P.; Pothisiri, T.; Sata, V.; Chindaprasirt, P. Influence of rice husk ash on mechanical properties and fire resistance of recycled aggregate high-calcium fly ash geopolymer concrete. J. Clean. Prod. 2020, 252, 119797. [Google Scholar] [CrossRef]

- Xu, Z.; Huang, Z.; Liu, C.; Deng, X.; Hui, D.; Deng, Y.; Zhao, M.; Qin, L. Experimental study on mechanical properties and microstructures of steel fiber-reinforced fly ash-metakaolin geopolymer-recycled concrete. Rev. Adv. Mater. Sci. 2021, 60, 578–590. [Google Scholar] [CrossRef]

- Kanagaraj, B.; Kiran, T.; Anand, N.; Al Jabri, K.; Justin, S. Development and strength assessment of eco-friendly geopolymer concrete made with natural and recycled aggregates. Constr. Innov. 2022, in press.

- Xie, J.; Wang, J.; Rao, R.; Wang, C.; Fang, C. Effects of combined usage of GGBS and fly ash on workability and mechanical properties of alkali activated geopolymer concrete with recycled aggregate. Compos. Part B Eng. 2019, 164, 179–190. [Google Scholar] [CrossRef]

- Xie, J.; Wang, J.; Zhang, B.; Fang, C.; Li, L. Physicochemical properties of alkali activated GGBS and fly ash geopolymeric recycled concrete. Constr. Build. Mater. 2019, 204, 384–398. [Google Scholar] [CrossRef]

- Alserai, S.J.; Alsaraj, W.K.; Abass, Z.W. Effect of iron filings on the mechanical properties of different types of sustainable concrete. Open Civ. Eng. J. 2018, 12, 441–457. [Google Scholar] [CrossRef]

- Kathirvel, P.; Kaliyaperumal, S.R.M. Influence of recycled concrete aggregates on the flexural properties of reinforced alkali activated slag concrete. Constr. Build. Mater. 2016, 102, 51–58. [Google Scholar] [CrossRef]

- Pani, L.; Francesconi, L.; Rombi, J.; Mistretta, F.; Sassu, M.; Stochino, F. Effect of parent concrete on the performance of recycled aggregate concrete. Sustainability 2020, 12, 9399. [Google Scholar] [CrossRef]

- Le, H.-B.; Bui, Q.-B. Recycled aggregate concretes—A state-of-the-art from the microstructure to the structural performance. Constr. Build. Mater. 2020, 257, 119522. [Google Scholar] [CrossRef]

- Tabsh, S.W.; Abdelfatah, A.S. Influence of recycled concrete aggregates on strength properties of concrete. Constr. Build. Mater. 2009, 23, 1163–1167. [Google Scholar] [CrossRef]

- Ohemeng, E.A.; Ekolu, S.O.; Quainoo, H. Models for predicting strength properties of recycled concretes made with non-treated CRCAs: Empirical approach. Constr. Build. Mater. 2021, 307, 124585. [Google Scholar] [CrossRef]

- Şahin, F.; Uysal, M.; Canpolat, O.; Aygörmez, Y.; Cosgun, T.; Dehghanpour, H. Effect of basalt fiber on metakaolin-based geopolymer mortars containing rilem, basalt and recycled waste concrete aggregates. Constr. Build. Mater. 2021, 301, 124113. [Google Scholar] [CrossRef]

- Liu, C.; Deng, X.; Liu, J.; Hui, D. Mechanical properties and microstructures of hypergolic and calcined coal gangue based geopolymer recycled concrete. Constr. Build. Mater. 2019, 221, 691–708. [Google Scholar] [CrossRef]

- Le, H.-B.; Bui, Q.-B.; Tang, L. Geopolymer recycled aggregate concrete: From experiments to empirical models. Materials 2021, 14, 1180. [Google Scholar] [CrossRef] [PubMed]

- Fakhrian, S.; Behbahani, H.; Mashhadi, S. Predicting post-fire behavior of green geopolymer mortar containing recycled concrete aggregate via GEP approach. J. Soft Comput. Civ. Eng. 2020, 4, 22–45. [Google Scholar]

- Nuaklong, P.; Wongsa, A.; Sata, V.; Boonserm, K.; Sanjayan, J.; Chindaprasirt, P. Properties of high-calcium and low-calcium fly ash combination geopolymer mortar containing recycled aggregate. Heliyon 2019, 5, e02513. [Google Scholar] [CrossRef] [Green Version]

- Le, H.-B.; Bui, Q.-B. Predicting the Compressive Strength of Geopolymer Concrete: An Empirical Model for Both Recycled and Natural Aggregates. In CIGOS 2021, Emerging Technologies and Applications for Green Infrastructure; Springer: Singapore, 2022; pp. 793–802. [Google Scholar]

- Nuaklong, P.; Sata, V.; Wongsa, A.; Srinavin, K.; Chindaprasirt, P. Recycled aggregate high calcium fly ash geopolymer concrete with inclusion of OPC and nano-SiO2. Constr. Build. Mater. 2018, 174, 244–252. [Google Scholar] [CrossRef]

- Nuaklong, P.; Sata, V.; Chindaprasirt, P. Properties of metakaolin-high calcium fly ash geopolymer concrete containing recycled aggregate from crushed concrete specimens. Constr. Build. Mater. 2018, 161, 365–373. [Google Scholar] [CrossRef]

- Junak, J.; Sicakova, A. Effect of surface modifications of recycled concrete aggregate on concrete properties. Buildings 2017, 8, 2. [Google Scholar] [CrossRef] [Green Version]

- Gupta, A.; Mandal, S.; Ghosh, S. Durability of geopolymer coated recycled aggregate concrete exposed to Sulphuric acid. Int. J. Appl. Eng. Res. 2012, 7, 91–103. [Google Scholar]

- Junak, J.; Sicakova, A. Precycled concrete aggregates with modified surface as a filler in concrete. In Proceedings of the International Multidisciplinary Scientific GeoConference SGEM, Albena, Bulgaria, 29 June–5 July 2017; Volume 17, pp. 161–168. [Google Scholar]

- Xie, J.; Chen, W.; Wang, J.; Fang, C.; Zhang, B.; Liu, F. Coupling effects of recycled aggregate and GGBS/metakaolin on physicochemical properties of geopolymer concrete. Constr. Build. Mater. 2019, 226, 345–359. [Google Scholar] [CrossRef]

- Xu, G.; Zhong, J.; Shi, X. Influence of graphene oxide in a chemically activated fly ash. Fuel 2018, 226, 644–657. [Google Scholar] [CrossRef]

- Farhan, N.A.; Sheikh, M.N.; Hadi, M.N.S. Behaviour of Ambient Cured Steel Fibre Reinforced Geopolymer Concrete Columns Under Axial and Flexural Loads. Structures 2018, 15, 184–195. [Google Scholar] [CrossRef]

- Vijaya Prasad, B.; Anand, N.; Kiran, T.; Jayakumar, G.; Sohliya, A.; Ebenezer, S. Influence of fibers on fresh properties and compressive strength of geo-polymer concrete. Mater. Today Proc. 2022, 57, 2355–2363. [Google Scholar] [CrossRef]

- Ahmed, W.; Lim, C.W. Production of sustainable and structural fiber reinforced recycled aggregate concrete with improved fracture properties: A review. J. Clean. Prod. 2021, 279, 123832. [Google Scholar] [CrossRef]

- Balagopal, V.; Panicker, A.S.; Arathy, M.S.; Sandeep, S.; Pillai, S.K. Influence of fibers on the mechanical properties of cementitious composites—A review. Mater. Today Proc. 2022, in press. [CrossRef]

- Ayub, T.; Mahmood, W.; Khan, A.-u.-R. Durability performance of SCC and SCGC containing recycled concrete aggregates: A comparative study. Sustainability 2021, 13, 8621. [Google Scholar] [CrossRef]

- Srinivas, T.; Sukesh Reddy, G. Mechanical properties of geopolymer concrete made with partial replacement of coarse aggregate by recycled aggregate. Int. J. Eng. Adv. Technol. 2019, 9, 2301–2304. [Google Scholar] [CrossRef]

- Parthiban, K.; Saravana Raja Mohan, K. Influence of recycled concrete aggregates on the engineering and durability properties of alkali activated slag concrete. Constr. Build. Mater. 2017, 133, 65–72. [Google Scholar] [CrossRef]

- Behera, M.; Bhattacharyya, S.; Minocha, A.; Deoliya, R.; Maiti, S. Recycled aggregate from C&D waste & its use in concrete–A breakthrough towards sustainability in construction sector: A review. Constr. Build. Mater. 2014, 68, 501–516. [Google Scholar]

- Tran, N.T. Experimental Study of Geopolymer Concrete Using Re-cycled Aggregates Under Various Curing Conditions. In Proceedings of the International Conference on Green Technology and Sustainable Development, Da Nang City, Vietnam, 27–28 November 2020; pp. 469–478. [Google Scholar]

- Krishnan, T.; Purushothaman, R. Optimization and influence of parameter affecting the compressive strength of geopolymer concrete containing recycled concrete aggregate: Using full factorial design approach. In Proceedings of the International Conference on Civil Engineering and Infrastructural Issues in Emerging Economies (ICCIEE 2017), Thanjavur, India, 17–18 March 2017. [Google Scholar]

- Ren, X.; Zhang, L. Experimental study of geopolymer concrete produced from waste concrete. J. Mater. Civ. Eng. 2019, 31, 04019114. [Google Scholar] [CrossRef]

- Ledesma, E.; Jiménez, J.; Fernández, J.; Galvín, A.; Agrela, F.; Barbudo, A. Properties of masonry mortars manufactured with fine recycled concrete aggregates. Constr. Build. Mater. 2014, 71, 289–298. [Google Scholar] [CrossRef]

- Saha, S.; Rajasekaran, C.; Gupta, P. Performance of eco-friendly mortar mixes against aggressive environments. Adv. Concr. Constr. 2020, 10, 237–245. [Google Scholar]

- Somrang, P.; Wannagon, A.; Choeycharoen, P.; Sornlar, W. Strengthening geopolymer with selective sizes of concrete block waste. Chiang Mai J. Sci. 2021, 48, 1657–1678. [Google Scholar]

- Akhtar, A.; Sarmah, A.K. Construction and demolition waste generation and properties of recycled aggregate concrete: A global perspective. J. Clean. Prod. 2018, 186, 262–281. [Google Scholar] [CrossRef]

- Davidovits, J. Geopolymers. J. Therm. Anal. 1991, 37, 1633–1656. [Google Scholar] [CrossRef]

- Rahman, S.K.; Al-Ameri, R. The Need for a User Friendly Geopolymer Concrete-Ongoing research. In Proceedings of the Concrete 2021, Sydney, Australia, 5–8 September 2021. [Google Scholar]

- Nuaklong, P.; Sata, V.; Chindaprasirt, P. Influence of recycled aggregate on fly ash geopolymer concrete properties. J. Clean. Prod. 2016, 112, 2300–2307. [Google Scholar] [CrossRef]

- Tho-In, T.; Sata, V.; Cao, T.; Chindaprasirt, P. Use of recycled concrete aggregate in high-calcium fly ash geopolymer concrete. In Key Engineering Materials; Trans Tech Publications: Baech, Switzerland, 2017; pp. 163–168. [Google Scholar]

- Alhawat, M.; Ashour, A.; Yildirim, G.; Aldemir, A.; Sahmaran, M. Properties of geopolymers sourced from construction and demolition waste: A review. J. Build. Eng. 2022, 50, 104104. [Google Scholar] [CrossRef]

- Koushkbaghi, M.; Alipour, P.; Tahmouresi, B.; Mohseni, E.; Saradar, A.; Sarker, P.K. Influence of different monomer ratios and recycled concrete aggregate on mechanical properties and durability of geopolymer concretes. Constr. Build. Mater. 2019, 205, 519–528. [Google Scholar] [CrossRef]

- Rodríguez, E.D.; Bernal, S.A.; Provis, J.L.; Paya, J.; Monzo, J.M.; Borrachero, M.V. Effect of nanosilica-based activators on the performance of an alkali-activated fly ash binder. Cem. Concr. Compos. 2013, 35, 1–11. [Google Scholar] [CrossRef]

- Ahmed, M.F.; Nuruddin, M.F.; Shafiq, N. Compressive strength and workability characteristics of low-calcium fly ash-based self-compacting geopolymer concrete. Int. J. Civ. Environ. Eng. 2011, 5, 64–70. [Google Scholar]

- Nath, P.; Sarker, P.K. Use of OPC to improve setting and early strength properties of low calcium fly ash geopolymer concrete cured at room temperature. Cem. Concr. Compos. 2015, 55, 205–214. [Google Scholar] [CrossRef]

- Noushini, A.; Castel, A. The effect of heat-curing on transport properties of low-calcium fly ash-based geopolymer concrete. Constr. Build. Mater. 2016, 112, 464–477. [Google Scholar] [CrossRef]

- Farooq, F.; Jin, X.; Javed, M.F.; Akbar, A.; Shah, M.I.; Aslam, F.; Alyousef, R. Geopolymer concrete as sustainable material: A state of the art review. Constr. Build. Mater. 2021, 306, 124762. [Google Scholar] [CrossRef]

- Olivia, M.; Nikraz, H.R. Strength and water penetrability of fly ash geopolymer concrete. Parameters 2006, 1, 3. [Google Scholar]

- Srinivas, T.; Manoj Anand, P. Permeation properties of geopolymer concrete made with partial replacement of recycled coarse aggregates. Int. J. Innov. Technol. Explor. Eng. 2019, 8, 2987–2990. [Google Scholar] [CrossRef]

- Topal, Ö.; Karakoç, M.B.; Özcan, A. Effects of elevated temperatures on the properties of ground granulated blast furnace slag (GGBFS) based geopolymer concretes containing recycled concrete aggregate. Eur. J. Environ. Civ. Eng. 2021, 26, 4847–4862. [Google Scholar] [CrossRef]

- Sarker, P.K.; Kelly, S.; Yao, Z. Effect of fire exposure on cracking, spalling and residual strength of fly ash geopolymer concrete. Mater. Des. 2014, 63, 584–592. [Google Scholar] [CrossRef] [Green Version]

- Pan, Z.; Sanjayan, J.G.; Collins, F. Effect of transient creep on compressive strength of geopolymer concrete for elevated temperature exposure. Cem. Concr. Res. 2014, 56, 182–189. [Google Scholar] [CrossRef]

- Bakharev, T. Thermal behaviour of geopolymers prepared using class F fly ash and elevated temperature curing. Cem. Concr. Res. 2006, 36, 1134–1147. [Google Scholar] [CrossRef]

- Aygörmez, Y.; Canpolat, O.; Al-mashhadani, M.M. A survey on one year strength performance of reinforced geopolymer composites. Constr. Build. Mater. 2020, 264, 120267. [Google Scholar] [CrossRef]

- Jiang, X.; Xiao, R.; Zhang, M.; Hu, W.; Bai, Y.; Huang, B. A laboratory investigation of steel to fly ash-based geopolymer paste bonding behavior after exposure to elevated temperatures. Constr. Build. Mater. 2020, 254, 119267. [Google Scholar] [CrossRef]

- Celik, A.; Yilmaz, K.; Canpolat, O.; Al-Mashhadani, M.M.; Aygörmez, Y.; Uysal, M. High-temperature behavior and mechanical characteristics of boron waste additive metakaolin based geopolymer composites reinforced with synthetic fibers. Constr. Build. Mater. 2018, 187, 1190–1203. [Google Scholar] [CrossRef]

- Zhao, R.; Yuan, Y.; Cheng, Z.; Wen, T.; Li, J.; Li, F.; Ma, Z.J. Freeze-thaw resistance of Class F fly ash-based geopolymer concrete. Constr. Build. Mater. 2019, 222, 474–483. [Google Scholar] [CrossRef]

- Yunsheng, Z.; Wei, S.; Zongjin, L.; Xiangming, Z.; Chungkong, C. Impact properties of geopolymer based extrudates incorporated with fly ash and PVA short fiber. Constr. Build. Mater. 2008, 22, 370–383. [Google Scholar] [CrossRef]

- Nazarpour, H.; Jamali, M. Mechanical and freezing cycles properties of geopolymer concrete with recycled aggregate. Struct. Concr. 2020, 21, 1004–1012. [Google Scholar] [CrossRef]

- Aiken, T.A.; Gu, L.; Kwasny, J.; Huseien, G.F.; McPolin, D.; Sha, W. Acid resistance of alkali-activated binders: A review of performance, mechanisms of deterioration and testing procedures. Constr. Build. Mater. 2022, 342, 128057. [Google Scholar] [CrossRef]

- Shaikh, F.U.A. Mechanical and durability properties of fly ash geopolymer concrete containing recycled coarse aggregates. Int. J. Sustain. Built Environ. 2016, 5, 277–287. [Google Scholar] [CrossRef] [Green Version]

- Salihi, K.; Younis, K.H. Rheological Behavior of Self-Compacting Geopolymer Concrete Containing Recycled Aggregates: Effect of Na2SiO3/NaOH and Molarity of NAOH. In Key Engineering Materials; Trans Tech Publications: Baech, Switzerland, 2021; pp. 79–84. [Google Scholar]

- Thakur, M.; Bawa, S. Self-Compacting geopolymer Concrete: A review. Mater. Today Proc. 2022, 59, 1683–1693. [Google Scholar] [CrossRef]

- BIBM; CEMBUREAU; ERMCO; EFMCO; EFCA; EFNARC. The European Guidelines for Self-Compacting Concrete; European Federation of Concrete Admixtures Associations (EFCA): Brussels, Belgium, 2005; pp. 1–63. [Google Scholar]

- Sandberg, J.; Alvesson, M. Ways of constructing research questions: Gap-spotting or problematization? Organization 2011, 18, 23–44. [Google Scholar] [CrossRef]

- Hosseini, M.R.; Chileshe, N. Global virtual engineering teams (GVETs): A fertile ground for research in Australian construction projects context. Int. J. Proj. Manag. 2013, 31, 1101–1117. [Google Scholar] [CrossRef]

- Raza, A.; Manalo, A.C.; Rafique, U.; AlAjarmeh, O.S.; Khan, Q.U.Z. Concentrically loaded recycled aggregate geopolymer concrete columns reinforced with GFRP bars and spirals. Compos. Struct. 2021, 268, 113968. [Google Scholar] [CrossRef]

- Alsaraj, W.K.; Fadhi, S.H.; Alserai, S.J. Structural Behavior of Geopolymer Concrete Thin Wall Panels Based on Metakaolin and Recycled Concrete Aggregate. Open Civ. Eng. J. 2019, 13, 109–117. [Google Scholar] [CrossRef]

- Shi, X.-S.; Wang, Q.-Y.; Zhao, X.-L.; Collins, F.G. Structural behaviour of geopolymeric recycled concrete filled steel tubular columns under axial loading. Constr. Build. Mater. 2015, 81, 187–197. [Google Scholar] [CrossRef]

- Shi, X.S.; Wang, Q.-Y.; Zhao, X.L.; Collins, F. Experimental study on strength and ductility of steel tubular stub columns filled with geopolymeric recycled concrete. In Proceedings of the ISTS 2012: Proceedings of the 14th International Symposium on Tubular Structures, London, UK, 12–14 September 2012; pp. 757–764. [Google Scholar]

- Shi, X.S.; Wang, Q.Y.; Zhao, X.L.; Collins, F. Discussion on properties and microstructure of geopolymer concrete containing fly ash and recycled aggregate. In Advanced Materials Research; Trans Tech Publications: Baech, Switzerland, 2012; pp. 1577–1583. [Google Scholar]

- Bhoopesh, J. Strength and behaviour of recycled aggregate geopolymer concrete beams. Adv. Concr. Constr. 2017, 5, 145. [Google Scholar]

| Reference | Specific Gravity (g/cm3) | Fineness Modulus | Water Absorption (%) | Dry Density (g/cm3) | Saturated Density (g/cm3) | Dry-Rodded Unit Weight (g/cm3) | Density (g/cm3) | Bulk Density (g/cm3) | Apparent Density (g/cm3) | Los Angeles (%loss) | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| NA | RCA | NA | RCA | NA | RCA | NA | RCA | NA | RCA | NA | RCA | NA | RCA | NA | RCA | NA | RCA | NA | RCA | |

| [33] | 2.74 | 2.47 | 6.62 | 6.62 | 0.68 | 5.30 | ||||||||||||||

| [34] | 0.7 | 6.6 | 2.835 | 2.647 | ||||||||||||||||

| [44] | 2.63 | 2.38 | 3.01 | 3.06 | 1.07 | 5.5 | 1.764 | 1.256 | ||||||||||||

| [45] | 2.77 | 2.48 | 0.66 | 4.47 | 1.781 | 1.409 | ||||||||||||||

| [59] | 2.65 | 2.26 | 0.61 | 5.90 | 1.511 | 1.241 | 33.9 | 37.1 | ||||||||||||

| [61] | 2.81 | 2.62 | 0.6 | 5.56 | 1.75 | 1.62 | ||||||||||||||

| [70] | 2.86 | 2.46 | ||||||||||||||||||

| [71] | 0.77 | 2.8 | 2.704 | 2.517 | ||||||||||||||||

| [72] | 2.66 | 2.6 | 1.1 | 5.8 | 2.59 | 2.26 | 2.61 | 2.39 | ||||||||||||

| [73] | 2.66 | 2.34 | 2.94 | 2.6 | 1 | 2.5 | 1.68 | 1.376 | ||||||||||||

| [74] | 2.63 | 2.38 | 3.01 | 3.06 | 1.07 | 5.50 | 1.764 | 1.256 | ||||||||||||

| Reference | Chemical Composition (%) | SO3 | SiO2 | Fe2O3 | TiO2 | Al2O3 | CaO | K2O | MgO | Na2O | L.O.I. |

|---|---|---|---|---|---|---|---|---|---|---|---|

| [32] | RCA | - | 60.56 | 5.82 | 0.75 | 0.52 | 12.01 | 1.30 | 1.83 | 2.69 | 14.52 |

| NA (Basalt Sand) | - | 56.9 | 8.1 | 0.9 | 17.6 | 7.0 | 1.9 | 2.1 | 3.8 | 1.15 | |

| [70] | RCA | - | 60.56 | 5.82 | 1.30 | 5.82 | 12.01 | 2.3 | 1.83 | 2.69 | 14.52 |

| NA (Basalt Sand) | - | 57.9 | 8.1 | 0.9 | 17.6 | 7.0 | 1.9 | 2.3 | 3.9 | 0.4 | |

| [75] | RCA | 1.0 | 51.1 | 11.3 | - | 26.1 | 4.7 | - | 1.7 | 1.35 | 0.7 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Nikmehr, B.; Al-Ameri, R. A State-of-the-Art Review on the Incorporation of Recycled Concrete Aggregates in Geopolymer Concrete. Recycling 2022, 7, 51. https://doi.org/10.3390/recycling7040051

Nikmehr B, Al-Ameri R. A State-of-the-Art Review on the Incorporation of Recycled Concrete Aggregates in Geopolymer Concrete. Recycling. 2022; 7(4):51. https://doi.org/10.3390/recycling7040051

Chicago/Turabian StyleNikmehr, Bahareh, and Riyadh Al-Ameri. 2022. "A State-of-the-Art Review on the Incorporation of Recycled Concrete Aggregates in Geopolymer Concrete" Recycling 7, no. 4: 51. https://doi.org/10.3390/recycling7040051

APA StyleNikmehr, B., & Al-Ameri, R. (2022). A State-of-the-Art Review on the Incorporation of Recycled Concrete Aggregates in Geopolymer Concrete. Recycling, 7(4), 51. https://doi.org/10.3390/recycling7040051