Failures of the Cast-Iron Columns of Historic Buildings—Case Studies †

Abstract

:1. Introduction

2. Design of Cast-Iron Columns

3. Examples of the Rehabilitation of the Existing Cast-Iron Columns

3.1. Shopping and Entertainment Complex ”Manufaktura” in Łódź

3.2. Shopping and Entertainment Complex ”Monopolis” in Łódź

- ultimate stress by axial compression: Rc = 450.6 MPa,

- ultimate stress by axial tension: Rt = 103.8 MPa.

- cross-sectional area: A = 10,526 mm2,

- lowest moment of inertia: J2 = 29,995,276 mm4.

- according to the Schwarz-Rankine formula (1):

- according to the Tetmajer equation (2):

- according to DIN 1051 (4):

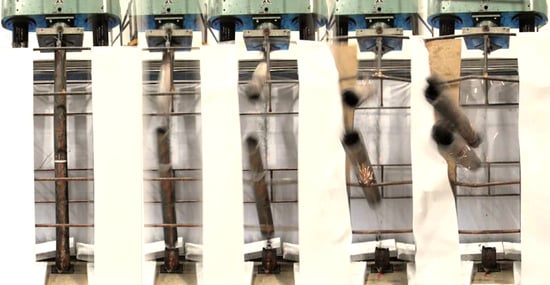

4. The Examples of Cast-Iron Column Failures

4.1. Housing Estate at Tylna st. in Łódź

4.2. Rail Overpasses in Wrocław

5. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Gołdyn, M.; Urban, T. Failures of the Cast-Iron Columns of Historic Buildings—Case Studies. In Proceedings of the 8th Euro-American Congress REHABEND, Granada, Spain, 24–27 March 2020. [Google Scholar]

- Czapliński, K. Dawne Wyroby ze Stopów Żelaza (Historical Elements from Iron Alloys), 1st ed.; Dolnośląskie Wydawnictwo Edukacyjne: Wrocław, Poland, 2009; p. 100. [Google Scholar]

- Hodgkinson, E. Experimental Researches on the Strength of Pillars of Cast Iron and other Materials, 1st ed.; Philosophical Transactions of the Royal Society Part 2; Royal Society: London, UK, 1840; p. 385. [Google Scholar]

- Tetmajer, L. Die Angewandte Elastizitäts- und Festigkeitslehre (The Applied Elasticity and Strength Theory), 1st ed.; Franz Deuticke: Leipzig und Wien, Austria, 1905. [Google Scholar]

- Rondal, J.; Rasmusen, K.J.R. On the strength of cast iron columns. J. Constr. Steel Res. 2014, 60, 1257–1270. [Google Scholar] [CrossRef]

- Brych, I.; Holický, M.; Jung, K.; Sýkora, M. Uncertainty in resistance models for historic cast-iron columns. WIT Trans. Ecol. Environ. 2015, 194, 473–482. [Google Scholar] [CrossRef] [Green Version]

- Friedman, D. Preservation Engineering. Struct. Mag. 2005, 9, 10–12. [Google Scholar]

- Friedman, D. Cast-iron-column strength in renovation design. J. Constr. Facil. 1995, 9, 220–230. [Google Scholar] [CrossRef]

- Heyde, S. Nachweisverfahren für Historische Stützen aus Grauguss (Design Procedure for Historical Cast-Iron Columns). Ph.D. Thesis, Technische Universität Berlin, Berlin, Germany, 2008. [Google Scholar]

- Heyde, S.; Geißler, K. Strength of Concrete Filled Historic Cast-Iron Columns. In Proceedings of the International Conference on Composite Construction in Steel and Concrete, Devil’s Thumb Ranch, Tabernash, CO, USA, 20–24 July 2008. [Google Scholar]

- Marcinowski, J.; Różycki, Z. Reinforcement of Existing Cast-Iron Structural Elements by Means of Fiber Reinforced Composites. Civil Environ. Eng. Rep. (CEER) 2016, 20, 37–45. [Google Scholar] [CrossRef] [Green Version]

- Salmon, E.H. Columns; Hazell, Watson & Viney: London, UK, 1921. [Google Scholar]

- Rondal, J.; Rasmussen, K.J.R. On the Strength of Cast Iron Columns; Research Report No R829; The University of Sydney Department of Civil Engineering: Sydney, NSW, Australia, 2003; p. 25. [Google Scholar]

- Marcinowski, J.; Różycki, Z. Oszacowanie nośności wyboczeniowej słupów żeliwnych w rewitalizo-wanych obiektach historycznych (Estimation of the buckling capacity of cast-iron columns in the revitalized historic buildings). In Proceedings of the 56th Scientific Conference of the Committee of Civil Engineering of Polish Academy of Science and Committee of Science of the Polish Association of Civil Engineers and Technicians, Kielce—Krynica, Poland, 19–24 September 2010; pp. 683–690. [Google Scholar]

- Österreich-Ungarischer Bauratgeber-Bauindustrielles Handbuch (Austro-Hungarian Building and Industrial Handbook), 2nd ed.; Verlag von Moritz Perles: Wien, Austria, 1914.

- DIN 1051. Berechnungsgrundlagen für Gusseisen im Hochbau (Design Principles for Cast-Iron Structural Elements in Buildings); Deutsches Institut für Normung: Berlin, Germany, 1937. [Google Scholar]

- Niezgodziński, M.E.; Niezgodziński, T. Wzory, Wykresy i Tablice Wytrzymałościowe (Equations, Charts and Design Tables), 4th ed.; PWN: Warszawa, Poland, 1984. [Google Scholar]

- PN-90-B-03200 Konstrukcje stalowe. Obliczenia Statyczne i Projektowanie (Steel Strucutres. Static Calculations nad Design); Polski Komitet Normalizacyjny: Warszawa, Poland, 1990. [Google Scholar]

- Untersuchungsbericht über Gusssäulen MA39—VFA 2007-1038.01 (Test Report on Cast-Iron Columns); Magistrat der Stadt Wien Magistratsabteilung 39 Prüf-, Überwachungs- und Zertifizierungsstelle der Stadt Wien VFA—Labors für Bautechnik: Vienna, Austria, August 2007.

- Urban, T.; Gołdyn, M. Raport z Badania Słupa Żeliwnego (Report from the Test of Cast-Iron Column); Department of Concrete Structures, Lodz Univeristy of Technology: Łódź, Poland, 2018. [Google Scholar]

- Czkwianianc, A.; Bodzak, P.; Kozicki, J.; Urban, T. Badania niszczące żeliwnych dźwigarów stropowych dawnej przędzalni w Manufakturze w Łodzi (Destructive tests on cast-iron girders of the former spinning mill in Manufaktura in Łódź). Zesz. Nauk. Politech. Łódzkiej 2008, 57, 22–37. [Google Scholar]

- Kozicki, J.; Ryniecki, M. Projekt Wzmocnienia Słupów Żeliwnych w Budynku F (Detailed Design of the Strengthening of Cast-Iron Columns in Building F); Biuro Projektowe dr inż. Jan Kozicki, Łódź, Marzec: Łódź, Poland, 2012. [Google Scholar]

- Czapliński, K.; Gawron, K. O żeliwnych elementach konstrukcyjnych i dekoracyjnych (About cast-iron strucutual and decorative elements). Przegląd Bud. 2011, 4, 56–59. [Google Scholar]

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Gołdyn, M.; Urban, T. Failures of the Cast-Iron Columns of Historic Buildings—Case Studies. Infrastructures 2020, 5, 71. https://doi.org/10.3390/infrastructures5090071

Gołdyn M, Urban T. Failures of the Cast-Iron Columns of Historic Buildings—Case Studies. Infrastructures. 2020; 5(9):71. https://doi.org/10.3390/infrastructures5090071

Chicago/Turabian StyleGołdyn, Michał, and Tadeusz Urban. 2020. "Failures of the Cast-Iron Columns of Historic Buildings—Case Studies" Infrastructures 5, no. 9: 71. https://doi.org/10.3390/infrastructures5090071

APA StyleGołdyn, M., & Urban, T. (2020). Failures of the Cast-Iron Columns of Historic Buildings—Case Studies. Infrastructures, 5(9), 71. https://doi.org/10.3390/infrastructures5090071