Preliminary Validation of Steel Slag-Aggregate Concrete for Rigid Pavements: A Full-Scale Study

Abstract

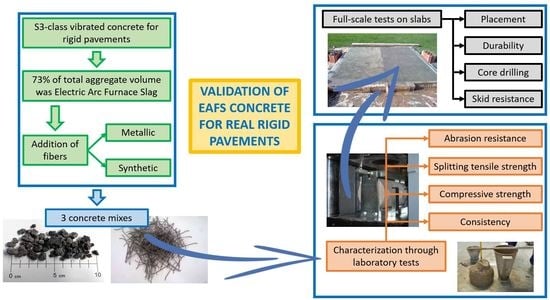

:1. Introduction

2. Materials and Methods

2.1. Raw Materials

2.1.1. Cement, Water, and Admixture

2.1.2. Aggregates

- EAFS was supplied by a recycling plant that usually manages waste from the metallurgical industry. It was received in the laboratory in 3 different sizes, 10/20 mm, 4/10 mm, and 0/4 mm, all of which were used in the preparation of concrete (Figure 2).

2.1.3. Fibers

2.2. Mix Design

2.3. Experimental Plan

2.3.1. Laboratory Tests

2.3.2. Full-Scale Tests

3. Results and Discussion: Laboratory Tests

3.1. Fresh Performance

3.1.1. Consistency

3.1.2. Fresh Density

3.2. Hardened Performance

3.2.1. Hardened Density

3.2.2. Compressive Strength

3.2.3. Modulus of Elasticity

3.2.4. Splitting Tensile Strength

3.2.5. Abrasion Resistance

4. Results and Discussion: Full-Scale Tests

4.1. Placement and Casting

4.2. Degradation Due to Outdoor Exposure

- A cracking appeared on the upper face of the slab made with the SAC mix, without fibers, as shown in Figure 9a. It is thought that the absence of fibers, which inhibit the cracks [35], could explain the appearance of this defect, which may have been caused by the numerous frosts that occur in Burgos. This phenomenon could also have been caused by differences in ambient temperature and humidity during laying.

- There were some chips in the slab made with the SAC/Y mix, which covered approximately 20% of the slab surface. It is believed that this phenomenon was due to an inadequate interaction between the synthetic fibers and the applied surface treatment since the presence of some fibers was observed in most of the chips (Figure 9b). This degradation process was caused by both the frosts typical of this climate and by the absorption of water by the synthetic fibers and its subsequent evaporation due to sunlight.

4.3. Compressive Strength: Core Drilling

4.4. Skid Resistance

5. Conclusions

- The use of EAFS produced concrete with an adequate workability (S3 or S4 slump class) despite the high density and rough shape of this aggregate.

- The interactions between EAFS and metallic and synthetic fibers in the fresh state were different. While metallic fibers maintained the workability, synthetic fibers reduced it. It is thought that this phenomenon was due to the inadequate interaction between synthetic fibers and the plasticizer admixture.

- All the mixes exhibited adequate mechanical properties, which proved the suitability of EAFS for developing concrete pavements of adequate strength. The use of metallic fibers improved all properties, while the use of synthetic fibers delayed the temporal development of compressive strength and elastic stiffness. The interaction between the admixture and the synthetic fibers again explains this phenomenon.

- The use of EAFS as aggregate increased the abrasion resistance of the concrete for rigid pavements compared to the use of natural siliceous aggregate.

- All mixes allowed for the successful production of full-scale slabs with a good appearance and finish by a conventional surface treatment.

- The exposure of the slabs to the outdoor environment for 5 years did not cause major deterioration of the concrete, and only a slight degradation of the surface-treatment layer of the slabs was observed. This degradation consisted of the appearance of cracks, a phenomenon that did not occur with the addition of fibers, and the appearance of chips due to the absorption of water by the synthetic fibers. Throughout these five years, the compressive-strength development was adequate.

- All the slabs had a “British Pendulum Number” (BPN) suitable for high-speed roads. The use of fibers increased the roughness of the surface treatment and, therefore, the skid resistance.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Hák, T.; Janoušková, S.; Moldan, B.; Dahl, A.L. Closing the sustainability gap: 30 years after “Our Common Future” society lacks meaningful stories and relevant indicators to make the right decisions and build public support. Ecol. Indic. 2018, 87, 193–195. [Google Scholar] [CrossRef]

- European Aggregates Association (UEPG). Available online: https://uepg.eu/ (accessed on 20 February 2021).

- Maghool, F.; Arulrajah, A.; Du, Y.J.; Horpibulsuk, S.; Chinkulkijniwat, A. Environmental impacts of utilizing waste steel slag aggregates as recycled road construction materials. Clean. Technol. Environ. Policy 2017, 19, 949–958. [Google Scholar] [CrossRef]

- Branca, T.A.; Colla, V.; Algermissen, D.; Granbom, H.; Martini, U.; Morillon, A.; Pietruck, R.; Rosendahl, S. Reuse and recycling of by-products in the steel sector: Recent achievements paving the way to circular economy and industrial symbiosis in europe. Metals 2020, 10, 345. [Google Scholar] [CrossRef] [Green Version]

- Silva, R.V.; De Brito, J.; Dhir, R.K. The influence of the use of recycled aggregates on the compressive strength of concrete: A review. Eur. J. Environ. Civ. Eng. 2015, 19, 825–849. [Google Scholar] [CrossRef]

- Terrones-Saeta, J.M.; Suárez-Macías, J.; Moreno-López, E.R.; Corpas-Iglesias, F.A. Determination of the chemical, physical and mechanical characteristics of electric arc furnace slags and environmental evaluation of the process for their utilization as an aggregate in bituminous mixtures. Materials 2021, 14, 782. [Google Scholar] [CrossRef]

- Pasetto, M.; Baliello, A.; Pasquini, E.; Skaf, M.; Ortega-López, V. Performance-based characterization of bituminous mortars prepared with ladle furnace steel slag. Sustainability 2020, 12, 1777. [Google Scholar] [CrossRef] [Green Version]

- Gupta, N.; Siddique, R.; Belarbi, R. Sustainable and greener self-compacting concrete incorporating industrial by-products: A review. J. Clean. Prod. 2020, 284, 124803. [Google Scholar] [CrossRef]

- Yüksel, İ. A review of steel slag usage in construction industry for sustainable development. Environ. Dev. Sustain. 2017, 19, 369–384. [Google Scholar] [CrossRef]

- Brand, A.S.; Fanijo, E.O. A review of the influence of steel furnace slag type on the properties of cementitious composites. Appl. Sci. 2020, 10, 8210. [Google Scholar] [CrossRef]

- Pasetto, M.; Baliello, A.; Giacomello, G.; Pasquini, E. Sustainable solutions for road pavements: A multi-scale characterization of warm mix asphalts containing steel slags. J. Clean. Prod. 2017, 166, 835–843. [Google Scholar] [CrossRef]

- World Steel Association. Steel Statistical Yearbook. 2019. Available online: https://www.worldsteel.org/steel-by-topic/statistics/steel-statistical-yearbook.html (accessed on 20 February 2021).

- European Association Representing Metallurgical SLAG Producers and Processors (EUROSLAG). Available online: https://www.euroslag.com/ (accessed on 1 November 2020).

- Yildirim, I.Z.; Prezzi, M. Chemical, mineralogical, and morphological properties of steel slag. Adv. Civ. Eng. 2011, 2011, 463638. [Google Scholar] [CrossRef] [Green Version]

- Skaf, M.; Pasquini, E.; Revilla-Cuesta, V.; Ortega-López, V. Performance and durability of porous asphalt mixtures manufactured exclusively with electric steel slags. Materials 2019, 12, 3306. [Google Scholar] [CrossRef] [Green Version]

- Autelitano, F.; Giuliani, F. Optimization of electric arc furnace aggregates replacement in dense-graded asphalt wearing courses. Int. J. Pavement Res. Technol. 2021, 14, 309–317. [Google Scholar] [CrossRef]

- Pasetto, M.; Baldo, N. Fatigue performance of asphalt concretes made with steel slags and modified bituminous binders. Int. J. Pavement Res. Technol. 2013, 6, 294–303. [Google Scholar] [CrossRef]

- Yu, F.; Fang, Y.; Zhang, Y.; Xu, L.; Bai, R. Mechanical behavior of self-stressing steel slag aggregate concrete filled steel tubular stub columns. Struct. Concr. 2020, 21, 1597–1611. [Google Scholar] [CrossRef]

- Faleschini, F.; Zanini, M.A.; Toska, K. Seismic reliability assessment of code-conforming reinforced concrete buildings made with electric arc furnace slag aggregates. Eng. Struct. 2019, 195, 324–339. [Google Scholar] [CrossRef]

- Václavík, V.; Ondová, M.; Dvorský, T.; Eštoková, A.; Fabiánová, M.; Gola, L. Sustainability potential evaluation of concrete with steel slag aggregates by the LCA method. Sustainability 2020, 12, 9873. [Google Scholar] [CrossRef]

- Arribas, I.; San-José, J.; Vegas, I.; Hurtado, J.; Chica, J. Application of steel slag concrete in the foundation slab and basement wall of the Tecnalia kubik building. In Proceedings of the 6th European Slag Conference (EUROSLAG), Madrid, Spain, 20–22 October 2010; pp. 251–264. [Google Scholar]

- Unión de Empresas Siderúrgicas (UNESID). Available online: http://www.unesid.org (accessed on 20 February 2021). (In Spanish).

- Ortega-López, V.; Fuente-Alonso, J.A.; Santamaría, A.; San-José, J.T.; Aragón, Á. Durability studies on fiber-reinforced EAF slag concrete for pavements. Constr. Build. Mater. 2018, 163, 471–481. [Google Scholar] [CrossRef]

- Li, S.; Xiong, R.; Zhai, J.; Zhang, K.; Jiang, W.; Yang, F.; Yang, X.; Zhao, H. Research progress on skid resistance of basic oxygen furnace (BOF) slag asphalt mixtures. Materials 2020, 13, 2169. [Google Scholar] [CrossRef]

- Fuente-Alonso, J.A.; Ortega-López, V.; Skaf, M.; Aragón, Á.; San-José, J.T. Performance of fiber-reinforced EAF slag concrete for use in pavements. Constr. Build. Mater. 2017, 149, 629–638. [Google Scholar] [CrossRef]

- Kalhori, M.; Ramezanianpour, A.A. Innovative air entraining and air content measurement methods for roller compacted concrete in pavement applications. Constr. Build. Mater. 2021, 279, 122495. [Google Scholar] [CrossRef]

- Awolusi, T.F.; Oke, O.L.; Atoyebi, O.D.; Akinkurolere, O.O.; Sojobi, A.O. Waste tires steel fiber in concrete: A review. Innov. Infrastruct. Solut. 2021, 6, 34. [Google Scholar] [CrossRef]

- Bosela, P.; Delatte, N.; Obratil, R.; Patel, A. Fresh and hardened properties of paving concrete with steel slag aggregate. Propiedades para firmes del hormigón fabricado con áridos siderúrgicos. Carreteras 2009, 4, 55–66. [Google Scholar]

- Bharath, V.; Rao, P. Study on the fibre reinforced concrete using steel slag as the coarse aggregate replacement. Int. J. Eng. Res. 2015, 2, 1322–1326. [Google Scholar]

- EN-Euronorm. Rue de Stassart 36; European Committee for Standardization: Brussels, Belgium.

- Santamaría, A.; Ortega-López, V.; Skaf, M.; Chica, J.A.; Manso, J.M. The study of properties and behavior of self compacting concrete containing Electric Arc Furnace Slag (EAFS) as aggregate. Ain Shams Eng. J. 2020, 11, 231–243. [Google Scholar] [CrossRef]

- Wang, G.; Wang, Y.; Gao, Z. Use of steel slag as a granular material: Volume expansion prediction and usability criteria. J. Hazard. Mater. 2010, 184, 555–560. [Google Scholar] [CrossRef]

- Zhao, Z.; Guan, X.; Xiao, F.; Xie, Z.; Xia, P.; Zhou, Q. Applications of asphalt concrete overlay on Portland cement concrete pavement. Constr. Build. Mater. 2020, 264, 120045. [Google Scholar] [CrossRef]

- Golpasand, G.B.; Farzam, M.; Shishvan, S.S. Behavior of recycled steel fiber reinforced concrete under uniaxial cyclic compression and biaxial tests. Constr. Build. Mater. 2020, 263, 120664. [Google Scholar] [CrossRef]

- Papachristoforou, M.; Anastasiou, E.K.; Papayianni, I. Durability of steel fiber reinforced concrete with coarse steel slag aggregates including performance at elevated temperatures. Constr. Build. Mater. 2020, 262, 120569. [Google Scholar] [CrossRef]

- Silva, R.V.; de Brito, J.; Dhir, R.K. Fresh-state performance of recycled aggregate concrete: A review. Constr. Build. Mater. 2018, 178, 19–31. [Google Scholar] [CrossRef]

- EC-2. Eurocode 2: Design of Concrete Structures. Part 1–1: General Rules and Rules for Buildings; CEN (European Committee for Standardization): Brussels, Belgium, 2010. [Google Scholar]

- Zhao, Z.M.; Liu, K.D.; Chai, J.Y.; Lei, L.L.; Wang, Q.; Qi, X.S.; Liu, R.X. Safety evaluation of reinforced concrete girder bridge after strengthened with pasting technology. In Proceedings of the 4th International Conference on Structures and Building Materials (ICSBM), Guangzhou, China, 15–16 March 2014. [Google Scholar] [CrossRef]

- Liu, H.; Zhu, B.; Wei, H.; Chai, C.; Chen, Y. Laboratory evaluation on the performance of porous asphalt mixture with steel slag for seasonal frozen regions. Sustainability 2019, 11, 6924. [Google Scholar] [CrossRef] [Green Version]

- Agencia Estatal de Meteorología (AEMET). Available online: http://www.aemet.es/es/portada (accessed on 22 February 2021). (In Spanish).

- Nematollahzade, M.; Tajadini, A.; Afshoon, I.; Aslani, F. Influence of different curing conditions and water to cement ratio on properties of self-compacting concretes. Constr. Build. Mater. 2020, 237, 117570. [Google Scholar] [CrossRef]

- Wasilewska, M.; Gardziejczyk, W.; Gierasimiuk, P. Evaluation of skid resistance of exposed aggregate concrete pavement in the initial exploitation period. Roads Bridges Drogi Mosty 2017, 16, 295–308. [Google Scholar] [CrossRef]

- Donbavand, J. Skidding Resistance of Road Surfaces-Implications for New Zealand; National Roads Board: Wellington, New Zealand, 1989; Volume 81.

| Aggregate | Oven-Dried Density (Mg/m3) | Water Absorption (% wt.) | Sand Equivalent (%) | Los Angeles Coefficient (%) |

|---|---|---|---|---|

| Siliceous sand 0/4 mm | 2.65 | 1.41 | 89 | − |

| EAFS 10/20 mm | 3.51 | 3.55 | − | 23 |

| EAFS 4/10 mm | 3.49 | 2.87 | − | 24 |

| EAFS 0/4 mm | 3.64 | 1.12 | 98 | − |

| Fiber Type | Length (mm) | Equal Diameter (mm) | Aspect Ratio | Tensile Strength (MPa) | Young’s Modulus (GPa) |

|---|---|---|---|---|---|

| Metallic fibers (RL-45) | 50 | 1.05 | 45 | >1000 | 210 |

| Polypropylene fibers (M-48) | 48 | 0.93 | 50 | >400 | 6 |

| Component | Mix | ||

|---|---|---|---|

| SAC | SAC/M | SAC/Y | |

| Cement | 360 | 360 | 360 |

| Water | 200 | 200 | 200 |

| EAFS 10/20 mm | 550 | 550 | 550 |

| EAFS 4/10 mm | 670 | 670 | 670 |

| EAFS 0/4 mm | 515 | 515 | 515 |

| Siliceous sand 0/4 mm | 500 | 500 | 500 |

| Admixture | 5.4 | 5.4 | 5.4 |

| Fibers | 0 | 45 (metallic) | 3.5 (synthetic) |

| Test | Age (Days) | Standard [30] | Specimen |

|---|---|---|---|

| Hardened density | 28 | EN 12390-7 | 10 × 10 × 10-cm cubic specimens |

| Compressive strength | 7, 28, 90 | EN 12390-3 | 15 × 30-cm cylindrical specimens |

| Modulus of elasticity | 60 | EN 12390-13 | 15 × 30-cm cylindrical specimens |

| Splitting tensile strength | 60 | EN 12390-6 | 15 × 30-cm cylindrical specimens |

| Abrasion | 60 | EN 1340 | Cut cylindrical specimens (see Figure 5 right) |

| Mix | Slump (mm) | Slump class (EN 206 [30]) | Fresh density (Mg/m3) |

|---|---|---|---|

| SAC | 140 | S3 | 2.86 |

| SAC/M | 130 | S3 | 2.87 |

| SAC/Y | 60 | S2 | 2.85 |

| Mix | Hardened Density (Mg/m3) | Modulus of Elasticity (GPa) | Splitting Tensile Strength (MPa) |

|---|---|---|---|

| SAC | 2.46 ± 0.02 | 36 ± 1.2 | 4.20 ± 0.9 |

| SAC/M | 2.53 ± 0.01 | 40 ± 1.5 | 6.94 ± 0.8 |

| SAC/Y | 2.45± 0.02 | 34 ± 1.4 | 5.42 ± 1.1 |

| Mix | Abrasion Resistance | |

|---|---|---|

| Footprint Width (mm) | Footprint Length (mm) | |

| SAC | 66 ± 2 | 13 ± 0.5 |

| SAC/M | 68.5 ± 1 | 13.5 ± 0.5 |

| SAC/Y | 84 ± 4 | 14 ± 1 |

| Mix | Compressive Strength (MPa) |

|---|---|

| SAC | 70.2 ± 2.3 |

| SAC/M | 76.4 ± 2.8 |

| SAC/Y | 69.6 ± 2.1 |

| Slab | Dry Surface | Wet Surface |

|---|---|---|

| SAC | 71 ± 3 | 68 ± 3 |

| SAC/M | 80 ± 4 | 72 ± 4 |

| SAC/Y | 77 ± 3 | 73 ± 4 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Revilla-Cuesta, V.; Ortega-López, V.; Skaf, M.; Pasquini, E.; Pasetto, M. Preliminary Validation of Steel Slag-Aggregate Concrete for Rigid Pavements: A Full-Scale Study. Infrastructures 2021, 6, 64. https://doi.org/10.3390/infrastructures6050064

Revilla-Cuesta V, Ortega-López V, Skaf M, Pasquini E, Pasetto M. Preliminary Validation of Steel Slag-Aggregate Concrete for Rigid Pavements: A Full-Scale Study. Infrastructures. 2021; 6(5):64. https://doi.org/10.3390/infrastructures6050064

Chicago/Turabian StyleRevilla-Cuesta, Víctor, Vanesa Ortega-López, Marta Skaf, Emiliano Pasquini, and Marco Pasetto. 2021. "Preliminary Validation of Steel Slag-Aggregate Concrete for Rigid Pavements: A Full-Scale Study" Infrastructures 6, no. 5: 64. https://doi.org/10.3390/infrastructures6050064

APA StyleRevilla-Cuesta, V., Ortega-López, V., Skaf, M., Pasquini, E., & Pasetto, M. (2021). Preliminary Validation of Steel Slag-Aggregate Concrete for Rigid Pavements: A Full-Scale Study. Infrastructures, 6(5), 64. https://doi.org/10.3390/infrastructures6050064