Cradle-to-Gate Life Cycle and Economic Assessment of Sustainable Concrete Mixes—Alkali-Activated Concrete (AAC) and Bacterial Concrete (BC)

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Mix Proportions

2.3. Methods

2.3.1. Preparation of Alkali-Activated Concrete Specimens

2.3.2. Preparation of Bacterial Concrete Specimens

Bacterial Growth Conditions and Gram Staining

Casting

2.3.3. Compressive Strength

2.3.4. Life Cycle Assessment (LCA)

Goal and Scope

Life Cycle Inventory Analysis

Life Cycle Impact Assessment

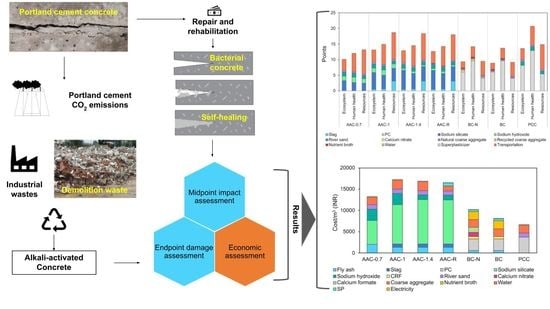

3. Results

3.1. Compressive Strength

3.2. Life Cycle Assessment

3.2.1. Midpoint Assessment

3.2.2. Endpoint Assessment

3.3. Economic Assessment

4. Conclusions

- For different AAC mixtures, contributions from transportation and sodium silicate are the highest for different midpoint damage categories.

- Portland cement is the principal contributor from the BC and PCC mixes to various midpoint damage categories.

- PCC has a GWP that is almost twice that of AAC with an activator modulus of 0.7 (AAC-0.7) and 1.4 times that of BC with nutrients.

- Owing to lower quantities of alkaline activators and only fly ash as a precursor, AAC-0.7 has the lowest environmental impact of all AAC mixes. The electricity consumption by recycled coarse aggregates (RCA) increased the environmental impact caused by AAC with RCA.

- PCC and AAC with an activator modulus of 1 (AAC-1) have the most detrimental effect on the quality of ecosystems and human health. AAC-1 has the highest resource depletion value (18.66) of all the mixes.

- BC (bacterial concrete without nutrients) has the lowest environmental effect of the evaluated mixes for all midpoint damage categories except GWP and endpoint damage categories. BC has the lowest resource depletion value (9.14), which is almost half of ACC-1.

- The cost of AAC mixes is 98.8–159.1%, and the cost of BC mixes is 21.8–54.3% higher than PCC.

- Sodium silicate in AAC mixes, PC, coarse aggregates, and nutrient broth in BC mixes have the highest contribution to the total cost.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Rogelj, J.; Shindell, D.; Jiang, K.; Fifita, S.; Forster, P.; Ginzburg, V.; Handa, C.; Kheshgi, H.; Kobayashi, S.; Kriegler, E.; et al. Global Warming of 1.5 °C—Chapter 2 Mitigation Pathways Compatible with 1.5 °C in the Context of Sustainable Development; Intergovernmental Panel on Climate Change: Geneva, Switzerland, 2018; pp. 93–174. [Google Scholar]

- Keith, D.W.; Holmes, G.; Angelo, D.S.; Heidel, K. A process for capturing CO2 from the atmosphere. Joule 2018, 2, 1573–1594. [Google Scholar] [CrossRef] [Green Version]

- UNEP. Building Sector Emissions Hit Record High, but Low-Carbon Pandemic Recovery Can Help Transform Sector. Available online: https://www.unep.org/news-and-stories/press-release/building-sector-emissions-hit-record-high-low-carbon-pandemic (accessed on 15 June 2021).

- UNFCCC. Adoption of the Paris Agreement; United Nations Framework Convention on Climate Change: Geneva, Switzerland, 2015; Available online: https://unfccc.int/sites/default/files/english_paris_agreement.pdf (accessed on 15 June 2021).

- Huang, L.; Krigsvoll, G.; Johansen, F.; Liu, Y.; Zhang, X. Carbon emission of global construction sector. Renew. Sustain. Energy Rev. 2018, 81, 1906–1916. [Google Scholar] [CrossRef] [Green Version]

- Benhelal, E.; Zahedi, G.; Shamsaei, E.; Bahadori, A. Global strategies and potentials to curb CO2 emissions in cement industry. J. Clean. Prod. 2013, 51, 142–161. [Google Scholar] [CrossRef]

- Danish, A.; Mosaberpanah, M.A.; Salim, M.U.; Fediuk, R.; Rashid, M.F.; Waqas, R.M. Reusing marble and granite dust as cement replacement in cementitious composites: A review on sustainability benefits and critical challenges. J. Build. Eng. 2021, 44, 102600. [Google Scholar] [CrossRef]

- Rakhimova, N.R.; Rakhimov, R.; Morozov, V.; Eskin, A. Calcined low-grade clays as sources for zeolite containing material. Period. Polytech. Civ. Eng. 2021, 65, 204–214. [Google Scholar] [CrossRef]

- Barbuta, M.; Bucur, R.D.; Cimpeanu, S.M.; Paraschiv, G.; Bucur, D. Wastes in Building Materials Industry; IntechOpen: London, UK, 2015; Volume 1, pp. 81–99. [Google Scholar] [CrossRef] [Green Version]

- Shao, Y.; Mahoutian, M.; Ghouleh, Z. Carbonation-activated steel slag binder as alternative cementing material. ACI Spec. Publ. 2017, 320, 21.1–21.14. [Google Scholar]

- Marvila, M.T.; Azevedo, A.R.G.D.; Matos, P.R.D.; Monteiro, S.N.; Vieira, C.M.F. Rheological and the fresh state properties of alkali-activated mortars by blast furnace slag. Materials 2021, 14, 2069. [Google Scholar] [CrossRef] [PubMed]

- Ramagiri, K.K.; Kar, A. Effect of high-temperature on the microstructure of alkali-activated binder. Mater. Today 2020, 28, 1123–1129. [Google Scholar] [CrossRef]

- Ramagiri, K.K.; Patil, S.; Mundra, H.; Kar, A. Laboratory investigations on the effects of acid attack on concrete containing portland cement partially replaced with ambient-cured alkali-activated binders. Adv. Concr. Constr. 2020, 10, 221–236. [Google Scholar] [CrossRef]

- Ramagiri, K.K.; Chauhan, D.R.; Gupta, S.; Kar, A.; Adak, D.; Mukherjee, A. High-temperature performance of ambient-cured alkali-activated binder concrete. Innov. Infrastruct. Solut. 2021, 6, 71. [Google Scholar] [CrossRef]

- Torres-Carrasco, M.; Puertas, F. La activación alcalina de diferentes aluminosilicatos como una alternativa al Cemento Portland: Cementos activados alcalinamente o geopolímeros. Rev. Ing. Constr. 2017, 32, 5–12. [Google Scholar] [CrossRef] [Green Version]

- Provis, J.L.; Bernal, S.A. Geopolymers and related alkali-activated materials. Annu. Rev. Mater. Sci. 2014, 44, 299–327. [Google Scholar] [CrossRef]

- Villoria Sáez, P.; Osmani, M. A diagnosis of construction and demolition waste generation and recovery practice in the European Union. J. Clean. Prod. 2019, 241, 118400. [Google Scholar] [CrossRef]

- NITI Aayog. Resource Efficiency and Circular Economy-Current Status and Way Forward; National Institution for Transforming India: New Delhi, India, 2019.

- Akhtar, A.; Sarmah, A.K. Construction and demolition waste generation and properties of recycled aggregate concrete: A global perspective. J. Clean. Prod. 2018, 186, 262–281. [Google Scholar] [CrossRef]

- Pyngrope, M.; Hossiney, N.; Chen, Y.; Thejas, H.K.; Sarath, C.K.; Alex, J.; Lakshmish Kumar, S. Properties of alkali-activated concrete (AAC) incorporating demolished building waste (DBW) as aggregates. Cogent Eng. 2021, 8, 1870791. [Google Scholar] [CrossRef]

- Xiao, J.Z.; Li, J.B. Study on relationships between strength indexes of recycled concrete. J. Build. Mater. 2005, 2, 197–201. (In Chinese) [Google Scholar] [CrossRef]

- Li, X. Recycling and reuse of waste concrete in China: Part I. Material behaviour of recycled aggregate concrete. Resour. Conserv. Recycl. 2008, 53, 36–44. [Google Scholar] [CrossRef]

- Kwan, W.H.; Ramli, M.; Kam, K.J.; Sulieman, M.Z. Influence of the amount of recycled coarse aggregate in concrete design and durability properties. Constr. Build. Mater. 2012, 26, 565–573. [Google Scholar] [CrossRef]

- Liu, Q.; Xiao, J.; Sun, Z. Experimental study on the failure mechanism of recycled concrete. Cem. Concr. Res. 2011, 41, 1050–1057. [Google Scholar] [CrossRef]

- Abdollahnejad, Z.; Mastali, M.; Falah, M.; Luukkonen, T.; Mazari, M.; Illikainen, M. Construction and Demolition Waste as Recycled Aggregates in Alkali-Activated Concretes. Materials 2019, 12, 4016. [Google Scholar] [CrossRef] [Green Version]

- Turner, L.K.; Collins, F.G. Carbon dioxide equivalent (CO2-e) emissions: A comparison between geopolymer and OPC cement concrete. Constr. Build. Mater. 2013, 43, 125–130. [Google Scholar] [CrossRef]

- Fořt, J.; Vejmelková, E.; Koňáková, D.; Alblová, N.; Čáchová, M.; Keppert, M.; Rovnaníková, P.; Černý, R. Application of waste brick powder in alkali activated aluminosilicates: Functional and environmental aspects. J. Clean. Prod. 2018, 194, 714–725. [Google Scholar] [CrossRef]

- Katz, A. Properties of concrete made with recycled aggregate from partially hydrated old concrete. Cem. Concr. Res. 2003, 33, 703–711. [Google Scholar] [CrossRef]

- Movassaghi, R. Durability of Reinforced Concrete Incorporating Recycled Concrete as Aggregate (RCA). Master’s Thesis, University of Waterloo, Waterloo, ON, Canada, 2006. Available online: http://hdl.handle.net/10012/2884 (accessed on 1 June 2021).

- Mastali, M.; Abdollahnejad, Z.; Pacheco-Torgal, F. 15—Carbon dioxide sequestration of fly ash alkaline-based mortars containing recycled aggregates and reinforced by hemp fibers: Mechanical properties and numerical simulation with a finite element method. In Carbon Dioxide Sequestration in Cementitious Construction Materials; Woodhead Publishing: New Delhi, India, 2018; pp. 373–391. [Google Scholar] [CrossRef]

- de Juan, M.S.; Gutiérrez, P.A. Study on the influence of attached mortar content on the properties of recycled concrete aggregate. Constr. Build. Mater. 2009, 23, 872–877. [Google Scholar] [CrossRef]

- Abbas, A.; Fathifazl, G.; Burkan Isgor, O.; Razaqpur, A.; Fournier, B.; Foo, S. Proposed Method for Determining the Residual Mortar Content of Recycled Concrete Aggregates. J. ASTM Int. 2007, 5, 1–12. [Google Scholar] [CrossRef]

- Akbarnezhad, A.; Ong, K.C.G.; Zhang, M.H.; Tam, C.T.; Foo, T.W.J. Microwave-assisted beneficiation of recycled concrete aggregates. Constr. Build. Mater. 2011, 25, 3469–3479. [Google Scholar] [CrossRef]

- Yanagibashi, K.; Inoue, K.; Seko, S.; Tsuji, D. A study on cyclic use of aggregate for structural concrete. In Proceedings of the SB05: The 2005 World Sustainable Building Conference, Tokyo, Japan, 27–29 September; pp. 9–11.

- Shima, H.; Tateyashiki, H.; Matsuhashi, R.; Yoshida, Y. An Advanced Concrete Recycling Technology and its Applicability Assessment through Input-Output Analysis. J. Adv. Concr. Technol. 2005, 3, 53–67. [Google Scholar] [CrossRef] [Green Version]

- Sidiq, A.; Setunge, S.; Gravina, R.J.; Giustozzi, F. Self-repairing cement mortars with microcapsules: A microstructural evaluation approach. Constr. Build. Mater. 2020, 232, 117239. [Google Scholar] [CrossRef]

- Kane, J.W.; Tomer, A. Shifting into an Era of Repair: Us Infrastructure Spending Trends. Brookings. Available online: https://www.brookings.edu/research/shifting-into-an-era-of-repair-us-infrastructure-spending-trends/ (accessed on 15 June 2021).

- Alves, L.; Alves, L.; Mello, M.; Barros, S.D. Characterization of bioconcrete and the properties for self-healing. Proceedings 2019, 38, 4. [Google Scholar] [CrossRef] [Green Version]

- ONS. Construction Output in Great Britain: May 2016, Office for National Statistics. Available online: https://www.ons.gov.uk/businessindustryandtrade/constructionindustry/bulletins/constructionoutputingreatbritain/may2016 (accessed on 1 June 2021).

- Best, R.D. Global Investments on the Construction and Maintenance of Infrastructure as Share of GDP in 2018. Available online: https://www.statista.com/statistics/566787/average-yearly-expenditure-on-economic-infrastructure-as-percent-of-gdp-worldwide-by-country/ (accessed on 15 June 2021).

- Wu, M.; Johannesson, B.; Geiker, M. A review: Self-healing in cementitious materials and engineered cementitious composite as a self-healing material. Constr. Build. Mater. 2012, 28, 571–583. [Google Scholar] [CrossRef]

- Termkhajornkit, P.; Nawa, T.; Yamashiro, Y.; Saito, T. Self-healing ability of fly ash–cement systems. Cem. Concr. Compos. 2009, 31, 195–203. [Google Scholar] [CrossRef]

- Jonkers, H.M.; Thijssen, A.; Muyzer, G.; Copuroglu, O.; Schlangen, E. Application of bacteria as self-healing agent for the development of sustainable concrete. Ecol. Eng. 2010, 36, 230–235. [Google Scholar] [CrossRef]

- De Muynck, W.; De Belie, N.; Verstraete, W. Microbial carbonate precipitation in construction materials: A review. Ecol. Eng. 2010, 36, 118–136. [Google Scholar] [CrossRef]

- Erşan, Y.Ç.; Hernandez-Sanabria, E.; Boon, N.; de Belie, N. Enhanced crack closure performance of microbial mortar through nitrate reduction. Cem. Concr. Compos. 2016, 70, 159–170. [Google Scholar] [CrossRef]

- Zhang, W.; Zheng, Q.; Ashour, A.; Han, B. Self-healing cement concrete composites for resilient infrastructures: A review. Compos. B. Eng. 2020, 189, 107892. [Google Scholar] [CrossRef]

- Achal, V.; Mukerjee, A.; Sudhakara Reddy, M. Biogenic treatment improves the durability and remediates the cracks of concrete structures. Constr. Build. Mater. 2013, 48, 1–5. [Google Scholar] [CrossRef]

- Chahal, N.; Siddique, R.; Rajor, A. Influence of bacteria on the compressive strength, water absorption and rapid chloride permeability of fly ash concrete. Constr. Build. Mater. 2012, 28, 351–356. [Google Scholar] [CrossRef]

- Sonali Sri Durga, C.; Ruben, N.; Sri Rama Chand, M.; Venkatesh, C. Performance studies on rate of self healing in bio concrete. Mater. Today 2020, 27, 158–162. [Google Scholar] [CrossRef]

- Jena, S.; Basa, B.; Panda, K.C.; Sahoo, N.K. Impact of Bacillus subtilis bacterium on the properties of concrete. Mater. Today 2020, 32, 651–656. [Google Scholar] [CrossRef]

- Khaliq, W.; Ehsan, M.B. Crack healing in concrete using various bio influenced self-healing techniques. Constr. Build. Mater. 2016, 102, 349–357. [Google Scholar] [CrossRef]

- Shaheen, N.; Khushnood, R.A.; Ud din, S. Bioimmobilized limestone powder for autonomous healing of cementitious systems: A feasibility study. Adv. Mater. Sci. Eng. 2018, 2018, 7049121. [Google Scholar] [CrossRef] [Green Version]

- Khushnood, R.A.; ud din, S.; Shaheen, N.; Ahmad, S.; Zarrar, F. Bio-inspired self-healing cementitious mortar using Bacillus subtilis immobilized on nano-/micro-additives. J. Intell. Mater. Syst. Struct. 2018, 30, 3–15. [Google Scholar] [CrossRef]

- Manzur, T.; Rahman, F.; Afroz, S.; Huq, R.S.; Efaz, I.H. Potential of a microbiologically induced calcite precipitation process for durability enhancement of masonry aggregate concrete. J. Mater. Civ. Eng. 2017, 29, 04016290. [Google Scholar] [CrossRef]

- Papanikolaou, I.; Arena, N.; Al-Tabbaa, A. Graphene nanoplatelet reinforced concrete for self-sensing structures—A lifecycle assessment perspective. J. Clean. Prod. 2019, 240, 118202. [Google Scholar] [CrossRef]

- Alazhari, M.; Sharma, T.; Heath, A.; Cooper, R.; Paine, K. Application of expanded perlite encapsulated bacteria and growth media for self-healing concrete. Constr. Build. Mater. 2018, 160, 610–619. [Google Scholar] [CrossRef]

- Xu, J.; Wang, X.; Zuo, J.; Liu, X. Self-Healing of Concrete Cracks by Ceramsite-Loaded Microorganisms. Adv. Mater. Sci. Eng. 2018, 2018, 5153041. [Google Scholar] [CrossRef] [Green Version]

- Wang, J.; Van Tittelboom, K.; De Belie, N.; Verstraete, W. Use of silica gel or polyurethane immobilized bacteria for self-healing concrete. Constr. Build. Mater. 2012, 26, 532–540. [Google Scholar] [CrossRef]

- Luo, M.; Qian, C. Influences of bacteria-based self-healing agents on cementitious materials hydration kinetics and compressive strength. Constr. Build. Mater. 2016, 121, 659–663. [Google Scholar] [CrossRef]

- Wang, J.Y.; Soens, H.; Verstraete, W.; De Belie, N. Self-healing concrete by use of microencapsulated bacterial spores. Cem. Concr. Res. 2014, 56, 139–152. [Google Scholar] [CrossRef]

- Paine, K. Bacteria-based self-healing concrete: Effects of environment, exposure and crack size. In Proceedings of the RILEM Conference on Microorganisms-Cementitious Materials Interactions, Delft, The Netherlands, 23 June 2016; Wiktor, V., Jonkers, H., Bertron, A., Eds.; RILEM Publications S.A.R.L.: Paris, France, 2016. [Google Scholar]

- BIS. IS 12269 Ordinary Portland Cement, 53 Grade—Specification; Bureau of Indian Standards: New Delhi, India, 2013.

- ASTM. C150/C150M Standard Specification for Portland Cement; ASTM International: West Conshohocken, PA, USA, 2020. [Google Scholar]

- BIS. IS 383 Coarse and Fine Aggregate for Concrete—Specification (Third Revision); Bureau of Indian Standards: New Delhi, India, 2016.

- El-Hassan, H.; Ismail, N. Effect of process parameters on the performance of fly ash/GGBS blended geopolymer composites. J. Sustain. Cem.-Based Mater. 2018, 7, 122–140. [Google Scholar] [CrossRef]

- El-Hassan, H.; Shehab, E.; Al-Sallamin, A. Influence of different curing regimes on the performance and microstructure of alkali-activated slag concrete. J. Mater. Civ. Eng. 2018, 30, 04018230. [Google Scholar] [CrossRef]

- Salmasi, F.; Mostofinejad, D. Investigating the effects of bacterial activity on compressive strength and durability of natural lightweight aggregate concrete reinforced with steel fibers. Constr. Build. Mater. 2020, 251, 119032. [Google Scholar] [CrossRef]

- ASTM. C39/C39M-18 Standard Test Method for Compressive Strength of Cylindrical Concrete Specimens; ASTM International: West Conshohocken, PA, USA, 2018. [Google Scholar]

- Moreno Ruiz, E.; Valsasina, L.; FitzGerald, D.; Symeonidis, A.; Turner, D.; Müller, J.; Minas, N.; Bourgault, G.; Vadenbo, C.; Ioannidou, D.; et al. Documentation of Changes Implemented in Ecoinvent Database v3. 7 & v3. 7.1; Ecoinvent Association: Zürich, Switzerland, 2020. Available online: https://www.ecoinvent.org/files/change_report_v3_7_1_20201217.pdf (accessed on 15 June 2021).

- Sahnoun, M.; Kriaa, M.; Elgharbi, F.; Ayadi, D.-Z.; Bejar, S.; Kammoun, R. Aspergillus oryzae S2 alpha-amylase production under solid state fermentation: Optimization of culture conditions. Int. J. Biol. Macromol. 2015, 75, 73–80. [Google Scholar] [CrossRef] [PubMed]

- Hong, M.; Jang, I.; Son, Y.; Yi, C.; Park, W. Agricultural by-products and oyster shell as alternative nutrient sources for microbial sealing of early age cracks in mortar. AMB Express 2021, 11, 11. [Google Scholar] [CrossRef]

- Kumar, L.R.; Yellapu, S.K.; Zhang, X.; Tyagi, R.D. Energy balance for biodiesel production processes using microbial oil and scum. Bioresour. Technol. 2019, 272, 379–388. [Google Scholar] [CrossRef]

- Hill, J.; Nelson, E.; Tilman, D.; Polasky, S.; Tiffany, D. Environmental, economic, and energetic costs and benefits of biodiesel and ethanol biofuels. Proc. Natl. Acad. Sci. USA 2006, 103, 11206. [Google Scholar] [CrossRef] [Green Version]

- Myhr, A.; Røyne, F.; Brandtsegg, A.S.; Bjerkseter, C.; Throne-Holst, H.; Borch, A.; Wentzel, A.; Røyne, A. Towards a low CO2 emission building material employing bacterial metabolism (2/2): Prospects for global warming potential reduction in the concrete industry. PLoS ONE 2019, 14, e0208643. [Google Scholar] [CrossRef] [PubMed]

- TSERC. Retail Supply Tariff Order for FY 2018-19—Salient Features. Available online: https://tserc.gov.in/file_upload/uploads/Tariff%20Orders/Tariff%20Schedule/Tariff%20Schedule%20for%20FY2018-19.pdf (accessed on 15 June 2021).

- BIS. IS/ISO 14040 Environmental Management: Life Cycle Assessment; Requirements and Guidelines; Bureau of Indian Standards: New Delhi, India, 2006.

- Hildenbrand, J.; Srocka, M.; Siroth, A. Why We Started the Development of OpenLCA. Available online: https://www.openlca.org/the-idea/ (accessed on 26 June 2021).

- Ntziachristos, L.; Samaras, Z. EMEP/EEA Emission Inventory Guidebook 2009; European Environment Agency (EEA): Copenhagen, Denmark, 2009. [Google Scholar]

- Jessen, C.; Roder, C.; Villa Lizcano, J.F.; Voolstra, C.R.; Wild, C. In-situ effects of simulated overfishing and eutrophication on benthic coral reef algae growth, succession, and composition in the central Red Sea. PLoS ONE 2013, 8, e66992. [Google Scholar] [CrossRef] [Green Version]

- Selman, M.; Greenhalgh, S. Eutrophication: Sources and Drivers of Nutrient Pollution. WRI Policy Note, Water Quality: Utrophication and Hypoxia. Available online: https://files.wri.org/d8/s3fs-public/pdf/eutrophication_sources_and_drivers.pdf (accessed on 26 June 2021).

- Hauschild, M.; Potting, J. Spatial Differentiation in Life Cycle Impact Assessment-The EDIP2003 Methodology. Available online: https://lca-center.dk/wp-content/uploads/2015/08/Spatial-differentiation-in-life-cycle-impact-assessment-the-EDIP2003-methodology.pdf (accessed on 26 June 2021).

- Kim, T.H.; Chae, C.U. Environmental impact analysis of acidification and eutrophication due to emissions from the production of concrete. Sustainability 2016, 8, 578. [Google Scholar] [CrossRef] [Green Version]

- Pulles, T.; Denier van der Gon, H.; Appelman, W.; Verheul, M. Emission factors for heavy metals from diesel and petrol used in European vehicles. Atmos. Environ. 2012, 61, 641–651. [Google Scholar] [CrossRef]

- Fawer, M.; Concannon, M.; Rieber, W. Life cycle inventories for the production of sodium silicates. Int. J. Life Cycle Assess. 1999, 4, 207. [Google Scholar] [CrossRef] [Green Version]

- Koiwanit, J.; Manuilova, A.; Chan, C.; Wilson, M.; Tontiwachwuthikul, P. A comparative study of human health impacts due to heavy metal emissions from a conventional lignite coal-fired electricity generation station, with post-combustion, and oxy-fuel combustion capture technologies. In Greenhouse Gases: Selected Case Studies; Manning, A., Ed.; IntechOpen: London, UK, 2016. [Google Scholar] [CrossRef] [Green Version]

- Castleden, W.M.; Shearman, D.; Crisp, G.; Finch, P. The mining and burning of coal: Effects on health and the environment. Med. J. Aust. 2011, 195, 333–335. [Google Scholar] [CrossRef]

- Atilgan, B.; Azapagic, A. Life cycle environmental impacts of electricity from fossil fuels in Turkey. J. Clean. Prod. 2015, 106, 555–564. [Google Scholar] [CrossRef]

- Worrell, E.; Price, L.; Martin, N.; Hendriks, C.; Meida, L.O. Carbon dioxide emissions from the global cement industry. Annu. Rev. Environ. Resour. 2001, 26, 303–329. [Google Scholar] [CrossRef]

- Schorcht, F.; Kourti, I.; Scalet, B.M.; Roudier, S.; Sancho, L.D. Best Available Techniques (BAT) Reference Document for the Production of Cement, Lime and Magnesium Oxide; European Commission Joint Research Centre Institute for Prospective Technological Studies: Seville, Spain, 2013. [Google Scholar]

- Huijbregts, M.A.; Steinmann, Z.J.; Elshout, P.M.; Stam, G.; Verones, F.; Vieira, M.D.M.; Hollander, A.; Zijp, M.; van Zelm, R. ReCiPe2016. A Harmonized Life Cycle Impact Assessment Method at Midpoint and Endpoint Level. Report I: Characterization; RIVM Report 2016-0104; National Institute for Human Health and the Environment: Bilthoven, The Netherlands, 2016; Available online: https://www.rivm.nl/bibliotheek/rapporten/2016-0104.pdf (accessed on 15 June 2021).

- Bosoaga, A.; Masek, O.; Oakey, J.E. CO2 capture technologies for cement industry. Energy Procedia 2009, 1, 133–140. [Google Scholar] [CrossRef] [Green Version]

- EuroChlor. The European chlor-alkali industry: An Electricity Intensive Sector Exposed to Carbon Leakage. Brussels, Belgium. 2010. Available online: https://www.eurochlor.org/wp-content/uploads/2019/04/3-2-the_european_chlor-alkali_industry_-_an_electricity_intensive_sector_exposed_to_carbon_leakage.pdf (accessed on 26 June 2021).

| Specification | Fly Ash | Slag | PC |

|---|---|---|---|

| CaO (%) | 3.80 | 37.63 | 65.23 |

| SiO2 (%) | 48.81 | 34.81 | 18.64 |

| Al2O3 (%) | 31.40 | 17.92 | 5.72 |

| MgO (%) | 0.70 | 7.80 | 0.85 |

| SO3 (%) | 0.91 | 0.20 | 2.34 |

| Fe2O3 (%) | 7.85 | 0.66 | 4.54 |

| TiO2 (%) | 2.93 | - | 0.5 |

| K2O (%) | 1.52 | - | 0.59 |

| Na2O (%) | 1.04 | - | - |

| MnO (%) | - | 0.21 | - |

| LOI (%) | 3.00 | 1.41 | 1.69 |

| Strength activity index (%) | 96.46 | 114.46 | - |

| d50 (µm) | 51.90 | 13.93 | - |

| Blaine fineness (m2/kg) * | 327.00 | 386.00 | 285.00 |

| Specific gravity | 2.06 | 2.71 | - |

| Aggregate | Specific Gravity | Water Absorption (%) | Fineness Modulus |

|---|---|---|---|

| Natural coarse aggregate | 2.72 | 0.10 | - |

| River sand | 2.65 | 0.50 | 3.62 |

| Crushed rock fines | 2.65 | 0.36 | 2.89 |

| Mix | AAC-0.7 | AAC-1 | AAC-1.4 | AAC-R | BC-N | BC | PCC |

|---|---|---|---|---|---|---|---|

| Fly ash | 425.00 | 280.00 | 280.00 | 280.00 | 115.00 | 115.00 | - |

| Slag | - | 120.00 | 120.00 | 120.00 | - | - | - |

| PC | - | - | - | - | 335.00 | 335.00 | 450.00 |

| Sodium silicate | 70.13 | 115.07 | 129.43 | 129.00 | - | - | - |

| Sodium hydroxide | 25.08 | 24.93 | 10.57 | 10.60 | - | - | - |

| CRF | - | - | - | - | 750.00 | 750.00 | - |

| River sand | 676.49 | 651.00 | 651.00 | 653.00 | - | - | 623.00 |

| Calcium nitrate | - | - | - | - | 4.78 | - | - |

| Calcium formate | - | - | - | - | 11.96 | - | - |

| Coarse aggregate | 1014.74 | 1209.00 | 1209.00 | 645.00 | 1020.00 | 1020.00 | 1084.00 |

| RCA | - | - | - | 645.00 | - | - | - |

| Nutrient broth | - | - | - | - | 0.67 | 0.67 | - |

| Water | 68.06 | 85.37 | 77.38 | 67.60 | 157.00 | 157.00 | 150.00 |

| SP | - | - | - | 3.14 | 2.00 | 2.00 | - |

| Density | 2280 | 2485 | 2477 | 2553 | 2396 | 2380 | 2307 |

| Service | Electricity Consumption (kWh) |

|---|---|

| Jaw crusher | 1.61 |

| Autoclave | 1.00 |

| Incubator | 4.08 |

| Raw Material | Distance (km) | Cost/kg (Including Freight, INR) |

|---|---|---|

| Fly ash | 202.0 | 4.8 |

| Slag | 438.0 | 6.6 |

| PC | 231.0 | 8.3 |

| Sodium silicate | 22.8 | 80.2 |

| Sodium hydroxide | 28.4 | 106.2 |

| CRF | 24.2 | 0.7 |

| River sand | 217.0 | 1.5 |

| Calcium nitrate | 22.8 | 210.0 |

| Calcium formate | 22.8 | 96.0 |

| Coarse aggregate | 24.2 | 1.8 |

| RCA | - | - |

| Nutrient broth | 29.2 | 2800.0 |

| Water | - | 0.035 |

| SP | 39.7 | 232.5 |

| Electricity | - | 6.7 |

| Indicator | ReCiPe Midpoint (H) |

|---|---|

| GWP | 5.51 × 1013 |

| FDP | 3.93 × 1012 |

| FETP | 1.74 × 1011 |

| FEP | 4.48 × 109 |

| HTP-cancer | 7.10 × 1010 |

| HTP-no cancer | 2.16 × 1014 |

| METP | 3.00 × 1011 |

| MEP | 3.18 × 1010 |

| ODP | 4.14 × 108 |

| POFP | 1.42 × 1011 |

| TAP | 2.83 × 1011 |

| TETP | 1.05 × 1014 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ramagiri, K.K.; Chintha, R.; Bandlamudi, R.K.; Kara De Maeijer, P.; Kar, A. Cradle-to-Gate Life Cycle and Economic Assessment of Sustainable Concrete Mixes—Alkali-Activated Concrete (AAC) and Bacterial Concrete (BC). Infrastructures 2021, 6, 104. https://doi.org/10.3390/infrastructures6070104

Ramagiri KK, Chintha R, Bandlamudi RK, Kara De Maeijer P, Kar A. Cradle-to-Gate Life Cycle and Economic Assessment of Sustainable Concrete Mixes—Alkali-Activated Concrete (AAC) and Bacterial Concrete (BC). Infrastructures. 2021; 6(7):104. https://doi.org/10.3390/infrastructures6070104

Chicago/Turabian StyleRamagiri, Kruthi Kiran, Ravali Chintha, Radha Kiranmaye Bandlamudi, Patricia Kara De Maeijer, and Arkamitra Kar. 2021. "Cradle-to-Gate Life Cycle and Economic Assessment of Sustainable Concrete Mixes—Alkali-Activated Concrete (AAC) and Bacterial Concrete (BC)" Infrastructures 6, no. 7: 104. https://doi.org/10.3390/infrastructures6070104

APA StyleRamagiri, K. K., Chintha, R., Bandlamudi, R. K., Kara De Maeijer, P., & Kar, A. (2021). Cradle-to-Gate Life Cycle and Economic Assessment of Sustainable Concrete Mixes—Alkali-Activated Concrete (AAC) and Bacterial Concrete (BC). Infrastructures, 6(7), 104. https://doi.org/10.3390/infrastructures6070104