Investigating the Effects of Ironing Parameters on the Dimensional Accuracy, Surface Roughness, and Hardness of FFF-Printed Thermoplastics

Abstract

:1. Introduction

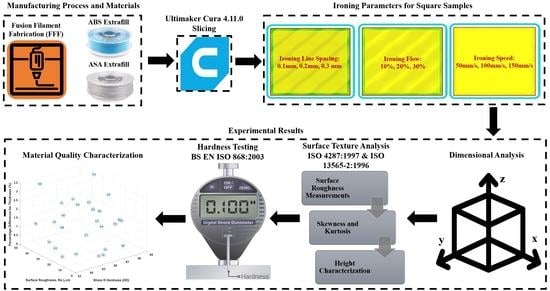

2. Materials and Methods

3. Experimental Results and Discussions

3.1. Dimensional Analysis

3.2. Surface Roughness Analysis

3.2.1. Skewness and Kurtosis

3.2.2. Height Characterization

3.3. Hardness Testing

4. Material Quality Characterization

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Gomes, T.E.; Cadete, M.S.; Dias-de-Oliveira, J.; Neto, V. Controlling the properties of parts 3D printed from recycled thermoplastics: A review of current practices. Polym. Degrad. Stab. 2022, 196, 109850. [Google Scholar] [CrossRef]

- Butt, J.; Shirvani, H. Additive, subtractive, and hybrid manufacturing processes. In Advances in Manufacturing and Processing of Materials and Structures; CRC Press: Boca Raton, FL, USA, 2018; pp. 187–218. [Google Scholar]

- Gardner, J.M.; Stelter, C.J.; Sauti, G.; Kim, J.W.; Yashin, E.A.; Wincheski, R.A.; Schniepp, H.C.; Siochi, E.J. Environment control in additive manufacturing of high-performance thermoplastics. Int. J. Adv. Manuf. Technol. 2022, 119, 6423–6433. [Google Scholar] [CrossRef]

- Gao, J. Production of multiple material parts using a desktop 3D printer. In Advances in Manufacturing Technology XXXI. In Proceedings of the 15th International Conference on Manufacturing Research, Incorporating the 32nd National Conference on Manufacturing Research, University of Greenwich, London, UK, 5–7 September 2017; IOS Press: Amsterdam, The Netherlands, 2017; Volume 6, p. 148. [Google Scholar]

- Butt, J.; Oxford, P.; Sadeghi-Esfahlani, S.; Ghorabian, M.; Shirvani, H. Hybrid Manufacturing and Mechanical Characterization of Cu/PLA Composites. Arab. J. Sci. Eng. 2020, 45, 9339–9356. [Google Scholar] [CrossRef]

- Syrlybayev, D.; Zharylkassyn, B.; Seisekulova, A.; Akhmetov, M.; Perveen, A.; Talamona, D. Optimisation of strength properties of FDM printed parts—A critical review. Polymers 2021, 13, 1587. [Google Scholar] [CrossRef]

- Vanaei, H.; Shirinbayan, M.; Deligant, M.; Raissi, K.; Fitoussi, J.; Khelladi, S.; Tcharkhtchi, A. Influence of process parameters on thermal and mechanical properties of polylactic acid fabricated by fused filament fabrication. Polym. Eng. Sci. 2020, 60, 1822–1831. [Google Scholar] [CrossRef]

- Buj-Corral, I.; Domínguez-Fernández, A.; Durán-Llucià, R. Influence of print orientation on surface roughness in fused deposition modeling (FDM) processes. Materials 2019, 12, 3834. [Google Scholar] [CrossRef] [Green Version]

- Butt, J.; Bhaskar, R.; Mohaghegh, V. Investigating the effects of extrusion temperatures and material extrusion rates on FFF-printed thermoplastics. Int. J. Adv. Manuf. Technol. 2021, 117, 2679–2699. [Google Scholar] [CrossRef]

- Nguyen, V.H.; Huynh, T.N.; Nguyen, T.P.; Tran, T.T. Single and multi-objective optimization of processing parameters for fused deposition modeling in 3D printing technology. Int. J. Automot. Mech. Eng. 2020, 17, 7542–7551. [Google Scholar] [CrossRef] [Green Version]

- Nuñez, P.J.; Rivas, A.; García-Plaza, E.; Beamud, E.; Sanz-Lobera, A. Dimensional and surface texture characterization in fused deposition modelling (FDM) with ABS plus. Procedia Eng. 2015, 132, 856–863. [Google Scholar] [CrossRef]

- Vyavahare, S.; Kumar, S.; Panghal, D. Experimental study of surface roughness, dimensional accuracy and time of fabrication of parts produced by fused deposition modelling. Rapid Prototyp. J. 2020, 26, 1535–1554. [Google Scholar] [CrossRef]

- Pramanik, D.; Mandal, A.; Kuar, A.S. An experimental investigation on improvement of surface roughness of ABS on fused deposition modelling process. Mater. Today Proc. 2020, 26, 860–863. [Google Scholar] [CrossRef]

- Khan, M.S.; Mishra, S.B. Minimizing surface roughness of ABS-FDM build parts: An experimental approach. Mater. Today Proc. 2020, 26, 1557–1566. [Google Scholar] [CrossRef]

- Chohan, J.S.; Singh, R.; Boparai, K.S. Mathematical modelling of surface roughness for vapour processing of ABS parts fabricated with fused deposition modelling. J. Manuf. Processes 2016, 24, 161–169. [Google Scholar] [CrossRef]

- Camposeco-Negrete, C. Optimization of printing parameters in fused deposition modeling for improving part quality and process sustainability. Int. J. Adv. Manuf. Technol. 2020, 108, 2131–2147. [Google Scholar] [CrossRef]

- Kumar, S.R.; Sridhar, S.; Venkatraman, R.; Venkatesan, M. Polymer additive manufacturing of ASA structure: Influence of printing parameters on mechanical properties. Mater. Today Proc. 2021, 39, 1316–1319. [Google Scholar] [CrossRef]

- Barreno-Avila, A.F.; Monar-Naranjo, M.; Barreno-Avila, E.M. Fusion deposition modeling (FDM) 3D printing parameters correlation: An analysis of different polymers surface roughness. In IOP Conference Series: Materials Science and Engineering; IOP Publishing: Bandar Lampung, Indonesia, 2021; Volume 1173, p. 012071. [Google Scholar]

- El Magri, A.; Ouassil, S.E.; Vaudreuil, S. Effects of printing parameters on the tensile behavior of 3D-printed acrylonitrile styrene acrylate (ASA) material in Z direction. Polym. Eng. Sci. 2022, 62, 848–860. [Google Scholar] [CrossRef]

- Martínez, J.M.V.; Vega, D.P.; Salguero, J.; Batista, M. Evaluation of the printing strategies design on the mechanical and tribological response of acrylonitrile styrene acrylate (ASA) additive manufacturing parts. Rapid Prototyp. J. 2021, 28, 479–489. [Google Scholar] [CrossRef]

- Butt, J.; Bhaskar, R. Investigating the effects of annealing on the mechanical properties of FFF-printed thermoplastics. J. Manuf. Mater. Processing 2020, 4, 38. [Google Scholar] [CrossRef]

- 3D FilaPrint. Available online: https://shop.3dfilaprint.com/abs-extrafill-sky-blue-175mm-3d-printer-filament-8226-p.asp (accessed on 26 March 2022).

- 3D FilaPrint. Available online: https://shop.3dfilaprint.com/asa-extrafill-white-aluminium-175mm-3d-filaprint-filament-15408-p.asp (accessed on 26 March 2022).

- Alsoufi, M.S.; Elsayed, A.E. Surface roughness quality and dimensional accuracy—A comprehensive analysis of 100% infill printed parts fabricated by a personal/desktop cost-effective FDM 3D printer. Mater. Sci. Appl. 2018, 9, 11–40. [Google Scholar] [CrossRef] [Green Version]

- Ultimaker Cura: Advanced 3D Printing Software, Made Accessible. Available online: https://ultimaker.com/en/products/ultimaker-cura-software (accessed on 26 March 2022).

- Mitutoyo: Surftest SJ-210 [inch/mm]. Available online: https://www.mitutoyo.com/wp-content/uploads/2016/09/J-section-Surftest.pdf (accessed on 26 March 2022).

- ISO 291:2008; Plastics—Standard Atmospheres for Conditioning and Testing. British, European and International Standard: London, UK, 2015.

- ISO 4287:1997; Geometrical Product Specifications (GPS)—Surface Texture: Profile Method—Terms, Definitions and Surface Texture Parameters. British, European and International Standard: London, UK, 2015.

- ISO 13565-2:1996; Geometrical Product Specifications (GPS)—Surface Texture: Profile Method; Surfaces Having Stratified Functional Properties—Part 2: Height Characterization Using the Linear Material Ratio Curve. British, European and International Standard: London, UK, 2012.

- Dong, W.P.; Sullivan, P.J.; Stout, K.J. Comprehensive study of parameters for characterizing three-dimensional surface topography I: Some inherent properties of parameter variation. Wear 1992, 159, 161–171. [Google Scholar] [CrossRef]

- Dong, W.P.; Sullivan, P.J.; Stout, K.J. Comprehensive study of parameters for characterizing three-dimensional surface topography II: Statistical properties of parameter variation. Wear 1993, 167, 9–21. [Google Scholar] [CrossRef]

- Dong, W.P.; Sullivan, P.J.; Stout, K.J. Comprehensive study of parameters for characterising three-dimensional surface topography: III: Parameters for characterising amplitude and some functional properties. Wear 1994, 178, 29–43. [Google Scholar] [CrossRef]

- Dong, W.P.; Sullivan, P.J.; Stout, K.J. Comprehensive study of parameters for characterising three-dimensional surface topography: IV: Parameters for characterising spatial and hybrid properties. Wear 1994, 178, 45–60. [Google Scholar] [CrossRef]

- Thomas, T.R. Characterization of surface roughness. Precis. Eng. 1981, 3, 97–104. [Google Scholar] [CrossRef]

- BS EN ISO 868:2003; Plastics and Ebonite–Determination of Indentation Hardness by Means of a Durometer (Shore Hardness). British, European and International Standard: London, UK, 2018.

- Alsoufi, M.S.; Elsayed, A.E. Quantitative analysis of 0% infill density surface profile of printed part fabricated by personal FDM 3D printer. Int. J. Eng. Technol. 2018, 7, 44–52. [Google Scholar] [CrossRef] [Green Version]

| # | Parameters | Description |

|---|---|---|

| 1 | Infill density (%) | 100 |

| 2 | Infill pattern | Lines |

| 3 | Layer height (mm) | 0.2 |

| 4 | Nozzle size (mm) | 0.4 |

| 5 | Flow (%) | 100 |

| 6 | Extrusion temperature (°C) | 240 for ABS and 250 for ASA |

| 7 | Print bed temperature (°C) | 95 for ABS and 100 for ASA |

| 8 | Deposition speed (mm/s) | 50 |

| 9 | Fan speed (%) | 100 |

| Samples | Parameters | Time | Samples | Parameters | Time |

|---|---|---|---|---|---|

| R | No ironing | 1 h 24 min | S14 | 0.2 L, 20 F, 100 S | 1 h 26 min |

| S1 | 0.1 L, 10 F, 50 S | 1 h 30 min | S15 | 0.2 L, 20 F, 150 S | 1 h 26 min |

| S2 | 0.1 L, 10 F, 100 S | 1 h 28 min | S16 | 0.2 L, 30 F, 50 S | 1 h 27 min |

| S3 | 0.1 L, 10 F, 150 S | 1 h 28 min | S17 | 0.2 L, 30 F, 100 S | 1 h 26 min |

| S4 | 0.1 L, 20 F, 50 S | 1 h 30 min | S18 | 0.2 L, 30 F, 150 S | 1 h 26 min |

| S5 | 0.1 L, 20 F, 100 S | 1 h 28 min | S19 | 0.3 L, 10 F, 50 S | 1 h 26 min |

| S6 | 0.1 L, 20 F, 150 S | 1 h 28 min | S20 | 0.3 L, 10 F, 100 S | 1 h 25 min |

| S7 | 0.1 L, 30 F, 50 S | 1 h 30 min | S21 | 0.3 L, 10 F, 150 S | 1 h 25 min |

| S8 | 0.1 L, 30 F, 100 S | 1 h 28 min | S22 | 0.3 L, 20 F, 50 S | 1 h 26 min |

| S9 | 0.1 L, 30 F, 150 S | 1 h 28 min | S23 | 0.3 L, 20 F, 100 S | 1 h 25 min |

| S10 | 0.2 L, 10 F, 50 S | 1 h 27 min | S24 | 0.3 L, 20 F, 150 S | 1 h 25 min |

| S11 | 0.2 L, 10 F, 100 S | 1 h 26 min | S25 | 0.3 L, 30 F, 50 S | 1 h 26 min |

| S12 | 0.2 L, 10 F, 150 S | 1 h 26 min | S26 | 0.3 L, 30 F, 100 S | 1 h 25 min |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Butt, J.; Bhaskar, R.; Mohaghegh, V. Investigating the Effects of Ironing Parameters on the Dimensional Accuracy, Surface Roughness, and Hardness of FFF-Printed Thermoplastics. J. Compos. Sci. 2022, 6, 121. https://doi.org/10.3390/jcs6050121

Butt J, Bhaskar R, Mohaghegh V. Investigating the Effects of Ironing Parameters on the Dimensional Accuracy, Surface Roughness, and Hardness of FFF-Printed Thermoplastics. Journal of Composites Science. 2022; 6(5):121. https://doi.org/10.3390/jcs6050121

Chicago/Turabian StyleButt, Javaid, Raghunath Bhaskar, and Vahaj Mohaghegh. 2022. "Investigating the Effects of Ironing Parameters on the Dimensional Accuracy, Surface Roughness, and Hardness of FFF-Printed Thermoplastics" Journal of Composites Science 6, no. 5: 121. https://doi.org/10.3390/jcs6050121

APA StyleButt, J., Bhaskar, R., & Mohaghegh, V. (2022). Investigating the Effects of Ironing Parameters on the Dimensional Accuracy, Surface Roughness, and Hardness of FFF-Printed Thermoplastics. Journal of Composites Science, 6(5), 121. https://doi.org/10.3390/jcs6050121