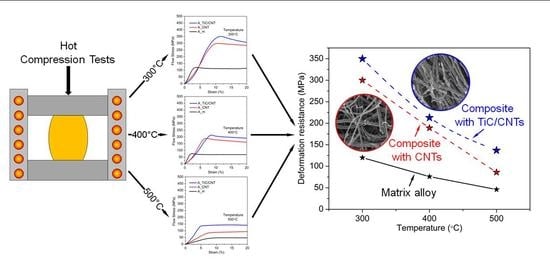

Increasing the Flow Stress during High-Temperature Deformation of Aluminum Matrix Composites Reinforced with TiC-Coated CNTs

Abstract

:1. Introduction

2. Materials and Methods

3. Results and Discussion

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Poletti, C.; Balog, M.; Simancik, F.; Degischer, H.P. High-temperature strength of compacted sub-micrometer aluminium powder. Acta Mater. 2010, 58, 3781–3789. [Google Scholar] [CrossRef]

- Samal, P.; Vundavilli, P.R.; Meher, A.; Mahapatra, M.M. Recent progress in aluminum metal matrix composites: A review on processing, mechanical and wear properties. J. Manuf. Process. 2020, 59, 131–152. [Google Scholar] [CrossRef]

- Deev, V.B.; Prusov, E.S.; Ri, E.H. Physical Methods of Processing the Melts of Metal Matrix Composites: Current State and Prospects. Russ. J. Non-Ferr. Met. 2022, 63, 292–304. [Google Scholar] [CrossRef]

- Grilo, J.; Carneiro, V.H.; Teixeira, J.C.; Puga, H. Manufacturing Methodology on Casting-Based Aluminium Matrix Composites: Systematic Review. Metals 2021, 11, 436. [Google Scholar] [CrossRef]

- Jendrzejewski, R.; Łubiński, J.; Śliwiński, G. Wear Resistance Enhancement of Al6061 Alloy Surface Layer by Laser Dispersed Carbide Powders. Materials 2020, 13, 3683. [Google Scholar] [CrossRef]

- Li, K.; Liu, X.; Zhao, Y. Research Status and Prospect of Friction Stir Processing Technology. Coatings 2019, 9, 129. [Google Scholar] [CrossRef] [Green Version]

- Jendrzejewski, R.; Van Acker, K.; Vanhoyweghen, D.; Śliwiński, G. Metal matrix composite production by means of laser dispersing of SiC and WC powder in Al alloy. Appl. Surf. Sci. 2009, 255, 5584–5587. [Google Scholar] [CrossRef]

- Li, W.; Assadi, H.; Gaertner, F.; Yin, S. A review of advanced composite and nanostructured coatings by solid-state cold spraying process. Crit. Rev. Solid State Mater. Sci. 2019, 44, 109–156. [Google Scholar] [CrossRef] [Green Version]

- Aborkin, A.V.; Alymov, M.I.; Arkhipov, V.E.; Khrenov, D.S. Formation of heterogeneous powder coatings with a two-level micro-and nanocomposite structure under gas-dynamic spraying conditions. Dokl. Phys. 2018, 63, 50–54. [Google Scholar] [CrossRef]

- Moridi, A.; Hassani-Gangaraj, S.M.; Guagliano, M.; Dao, M. Cold Spray Coating: Review of Material Systems and Future Perspectives. Surf. Eng. 2014, 36, 369–395. [Google Scholar] [CrossRef]

- Liu, J.; Huang, X.; Zhao, K.; Zhu, Z.; Zhu, X.; An, L. Effect of reinforcement particle size on quasistatic and dynamic mechanical properties of Al-Al2O3 composites. J. Alloy. Compd. 2019, 797, 1367–1371. [Google Scholar] [CrossRef]

- Kang, Y.C.; Chan, S.L.I. Tensile properties of nanometric Al2O3 particulate-reinforced aluminum matrix composites. Mater. Chem. Phys. 2004, 85, 438–443. [Google Scholar] [CrossRef]

- Prabhu, B.; Suryanarayana, C.; An, L.; Vaidyanathan, R. Synthesis and characterization of high volume fraction Al-Al2O3 nanocomposite powders by high-energy milling. Mater. Sci. Eng. A 2006, 425, 192–200. [Google Scholar] [CrossRef]

- Saravanan, L.; Senthilvelan, T. Investigations on the hot workability characteristics and deformation mechanisms of aluminium alloy-Al2O3 nanocomposite. Mater. Des. 2015, 79, 6–14. [Google Scholar] [CrossRef]

- Kashyap, K.T.; Patil, R.G. On Young’s modulus of multi-walled carbon nanotubes. Bull. Mater. Sci. 2008, 31, 185–187. [Google Scholar] [CrossRef] [Green Version]

- Wong, E.W.; Sheehan, P.E.; Lieber, C.M. Nanobeam mechanics: Elasticity, strength, and toughness of nanorods and nanotubes. Science 1997, 277, 1971–1975. [Google Scholar] [CrossRef]

- Lourie, O.; Wagner, H.D. Evaluation of Young’s modulus of carbon nanotubes by micro-Raman spectroscopy. J. Mater. Res. 1998, 13, 2418–2422. [Google Scholar] [CrossRef]

- Yu, M.F.; Lourie, O.; Dyer, M.J.; Moloni, K.; Kelly, T.F.; Ruoff, R.S. Strength and breaking mechanism of multiwalled carbon nanotubes under tensile load. Science 2000, 287, 637–640. [Google Scholar] [CrossRef] [Green Version]

- Peng, B.; Locascio, M.; Zapol, P.; Li, S.; Mielke, S.L.; Schatz, G.C.; Espinosa, H.D. Measurements of near-ultimate strength for multiwalled carbon nanotubes and irradiation-induced crosslinking improvements. Nat. Nanotechnol. 2008, 3, 626–631. [Google Scholar] [CrossRef]

- Liu, Z.Y.; Xiao, B.L.; Wang, W.G.; Ma, Z.Y. Elevated temperature tensile properties and thermal expansion of CNT/2009Al composites. Compos. Sci. Technol. 2012, 72, 1826–1833. [Google Scholar] [CrossRef]

- Lee, W.S.; Sue, W.C.; Lin, C.F. The effects of temperature and strain rate on the properties of carbon-fiber-reinforced 7075 aluminum alloy metal-matrix composite. Compos. Sci. Technol. 2000, 60, 1975–1983. [Google Scholar] [CrossRef]

- Cao, L.; Chen, B.; Wan, J.; Kondoh, K.; Guo, B.; Shen, J.; Li, J.S. Superior high-temperature tensile properties of aluminum matrix composites reinforced with carbon nanotubes. Carbon 2022, 191, 403–414. [Google Scholar] [CrossRef]

- Aborkin, A.V.; Khor’kov, K.S.; Ob’edkov, A.M.; Kremlev, K.V.; Izobello, A.Y.; Volochko, A.T.; Alymov, M.I. Evolution of Multiwalled Carbon Nanotubes and Related Nanostructures during the Formation of Alumomatrix Composite Materials. Tech. Phys. Lett. 2019, 45, 20–23. [Google Scholar] [CrossRef]

- Aborkin, A.V.; Babin, D.M.; Zalesnov, A.I.; Prusov, E.S.; Ob’edkov, A.M.; Alymov, M.I. Effect of ceramic coating on carbon nanotubes interaction with matrix material and mechanical properties of aluminum matrix nanocomposite. Ceram. Int. 2020, 46, 19256–19263. [Google Scholar] [CrossRef]

- Aborkin, A.V.; Khorkov, K.S.; Prusov, E.S.; Ob’edkov, A.M.; Kremlev, K.V.; Perezhogin, I.A.; Alymov, M.I. Effect of Increasing the Strength of Aluminum Matrix Nanocomposites Reinforced with Microadditions of Multiwalled Carbon Nanotubes Coated with TiC Nanoparticles. Nanomaterials 2019, 9, 1596. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Kremlev, K.V.; Ob’edkov, A.M.; Semenov, N.M.; Kaverin, B.S.; Ketkov, S.Y.; Vilkov, I.V.; Andreev, P.V.; Gusev, S.A.; Aborkin, A.V. Synthesis of Hybrid Materials Based on Multiwalled Carbon Nanotubes Decorated with WC1–x Nanocoatings of Various Morphologies. Tech. Phys. Lett. 2019, 45, 348–351. [Google Scholar] [CrossRef]

- Aborkin, A.V.; Elkin, A.I.; Reshetniak, V.V.; Ob’edkov, A.M.; Sytschev, A.E.; Leontiev, V.G.; Titov, D.D.; Alymov, M.I. Thermal expansion of aluminum matrix composites reinforced by carbon nanotubes with in-situ and ex-situ designed interfaces ceramics layers. J. Alloy. Compd. 2021, 872, 159593. [Google Scholar] [CrossRef]

- Guo, B.; Luo, S.; Wu, Y.; Song, M.; Chen, B.; Yu, Z.; Li, W. Regulating the interfacial reaction between carbon nanotubes and aluminum via copper nano decoration. Mater. Sci. Eng. A 2021, 821, 141576. [Google Scholar] [CrossRef]

- Contreras, A. Wetting of TiC by Al-Cu alloys and interfacial characterization. J. Colloid Interface Sci. 2007, 311, 159–170. [Google Scholar] [CrossRef]

- Huang, C.C.; Qi, L.; Chen, J.; Guan, R.; Ojo, O.A.; Wang, Z.G. Effect of TiC nanoparticles on the hot deformation behavior of AA7075 aluminum alloy. Mater. Charact. 2021, 181, 111508. [Google Scholar] [CrossRef]

- Jagannatham, M.; Chandran, P.; Sankaran, S.; Haridoss, P.; Nayan, N.; Bakshi, S.R. Tensile properties of carbon nanotubes reinforced aluminum matrix composites: A review. Carbon 2020, 160, 14–44. [Google Scholar] [CrossRef]

- Obiedkov, A.M.; Kaverin, B.S.; Egorov, V.A.; Semenov, N.M.; Ketkov, S.Y.; Domrachev, G.A.; Kremlev, K.V.; Gusev, S.A.; Perevezentsev, V.N.; Moskvichev, A.N.; et al. Macroscopic cylinders on the basis of radial-oriented multiwall carbon nanotubes. Lett. Mater. 2012, 3, 152–156. [Google Scholar] [CrossRef]

- Vilkov, I.V.; Kaverin, B.S.; Ob’edkov, A.M.; Semenov, N.M.; Ketkov, S.Y.; Rychagova, E.A.; Gusev, S.A.; Tatarskiy, D.A.; Andreev, P.V.; Aborkin, A.V. Single-step synthesis of tic mesocrystals on the mwcnts surface by the pyrolysis of Cp2TiCl2. Mater. Today Chem. 2022, 24, 100830. [Google Scholar] [CrossRef]

- Aborkin, A.V.; Alymov, M.I.; Sobol’kov, A.V.; Khor’kov, K.S.; Babin, D.M. Effect of the Thermomechanical Treatment Conditions on the Consolidation, the Structure, and the Mechanical Properties of Bulk Al–Mg–C Nanocomposites. Russ. Metall. 2018, 2018, 625–632. [Google Scholar] [CrossRef]

- Ou, L.; Zheng, Z.; Nie, Y.; Jian, H. Hot deformation behavior of 2060 alloy. J. Alloys Compd. 2015, 648, 681–689. [Google Scholar] [CrossRef]

- Avramovic-Cingara, G.; McQueen, H.J.; Perovic, D.D. Comparison of torsion and compression constitutive analyses for elevated temperature deformation of Al–Li–Cu–Mn alloy. Mater. Sci. Technol. 2014, 19, 11–19. [Google Scholar] [CrossRef]

- Rajamuthamilselvan, M.; Rajakumar, S.; Kavitha, S. Effect of Different SiCp Particle Sizes on the Behavior of AA 7075 Hot Deformation Composites Using Processing Maps. Springer Proc. Mater. 2021, 5, 1233–1244. [Google Scholar]

- Lin, H.B. Dynamic recrystallization behavior of 6082 aluminum alloy during hot deformation. Adv. Mech. Eng. 2021, 13, 11. [Google Scholar] [CrossRef]

- Ding, S.; Khan, S.A.; Yanagimoto, J. Constitutive descriptions and microstructure evolution of extruded A5083 aluminum alloy during hot compression. Mater. Sci. Eng. A 2018, 728, 133–143. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Aborkin, A.V.; Bokaryov, D.V.; Pankratov, S.A.; Elkin, A.I. Increasing the Flow Stress during High-Temperature Deformation of Aluminum Matrix Composites Reinforced with TiC-Coated CNTs. Ceramics 2023, 6, 231-240. https://doi.org/10.3390/ceramics6010013

Aborkin AV, Bokaryov DV, Pankratov SA, Elkin AI. Increasing the Flow Stress during High-Temperature Deformation of Aluminum Matrix Composites Reinforced with TiC-Coated CNTs. Ceramics. 2023; 6(1):231-240. https://doi.org/10.3390/ceramics6010013

Chicago/Turabian StyleAborkin, Artemiy V., Dmitriy V. Bokaryov, Sergey A. Pankratov, and Alexey I. Elkin. 2023. "Increasing the Flow Stress during High-Temperature Deformation of Aluminum Matrix Composites Reinforced with TiC-Coated CNTs" Ceramics 6, no. 1: 231-240. https://doi.org/10.3390/ceramics6010013

APA StyleAborkin, A. V., Bokaryov, D. V., Pankratov, S. A., & Elkin, A. I. (2023). Increasing the Flow Stress during High-Temperature Deformation of Aluminum Matrix Composites Reinforced with TiC-Coated CNTs. Ceramics, 6(1), 231-240. https://doi.org/10.3390/ceramics6010013