Striving for a Safer and More Ergonomic Workplace: Acceptability and Human Factors Related to the Adoption of AR/VR Glasses in Industry 4.0

Abstract

:1. Introduction

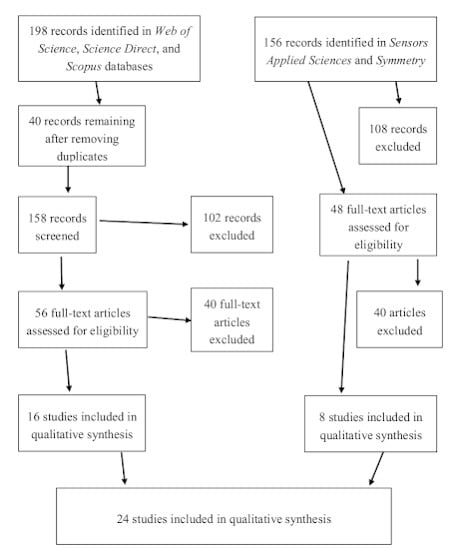

2. Materials and Methods

- RQ1: Are AR/VR systems or devices proposed for industrial use capable of meeting the needs of the industry (including sustainability)?

- RQ2: Are these AR/VR devices designed to ensure easy use and efficient training of factory operators?

- RQ3: Do the proposals of the reviewed research papers place sufficient emphasis on creating ergonomic workplaces?

- We have formulated the following hypothesis: VR and AR devices and applications may not yet be suitable for implementations in the industry (still requiring further development and substantial testing).

3. Results

3.1. Adoption and Challenges of AR/VR Glasses

3.2. Industrial Environment

3.3. Usability and Sustainability

4. Discussion

Author Contributions

Funding

Conflicts of Interest

Appendix A

| Research or Application Area | Publi-Cation | Key Technologies | Main Purpose |

|---|---|---|---|

| literature review, reference model of I4.0, key technologies of I4.0, smart factory of I4.0 | (Alcácer, 2019) [1] | Industrial Internet of Things, cloud computing, big data, AR | The Industry 4.0 environment is examined in this paper, describing the so-called enabling technologies and systems over the manufacturing environment. |

| systematic review, smart factory, industrial operator support | (Syberfeldt, 2017) [12] | AR smart glasses | Of the 12 selected smart glasses reviewed, the most suitable and usable was determined based on the analysis of 18 parameters, including battery power, mass, ergonomic factors, etc. Despite the results indicating that the Epson Moverio BT 300 [33] was the most suitable, the authors claimed that improvements were still required before implementation could take place in smart factories. |

| media, fashion, technology | (Hertz, 2019) [10] | VR glasses | The acceptance and user reactions are assessed in this study by surveying consumers. Deductions and patterns are actively sought to determine whether trends and specific consumer preferences can be observed. |

| industrial use, technology acceptance, usability, user expectations | (Terheoven, 2018) [13] | AR smart glasses | Tasks were coordinated to employees to determine how suitable smart glasses were, with ergonomic factors taken into consideration. Fifty-nine employees were surveyed, observing the influence of these devices on mental strain and job quality. |

| manufacturing environment, future smart factories, ergonomic assessment, musculoskeletal disorders evaluation | (Mengoni, 2018) [16] | spatial AR | This study proposed the use of a spatial AR-based system, which is intended to support manual work in two ways: Firstly, to support the workers in the training phase of their job, and to help workers improve their posture by alerting them when incorrect postures are detected. This is to avoid musculoskeletal disorders, thus reducing absence from work and significantly improving operator well-being. |

| industrial environment, engine assembly, human–robot collaboration | (Danielsson, 2018) [18] | AR | This study presents the results of surveys, where employees were questioned about their attitude towards AR technology. The employees had a positive view on adopting AR. |

| remote maintenance industry 4.0 | Masoni, 2017) [19] | AR | To improve the maintenance services of factories and industrial plants, an AR-based system is discussed, which could allow unskilled operators to repair machines with the remote guidance of a skilled operator. |

| education, teaching factory, product design | (Mourtzis, 2018) [17] | AR | To ensure the effective introduction of young engineers to the designing process of a factory, AR is used to visualize the product, providing the opportunity to interact. This helps engineers not only to perceive the final result but also to inspect it and find design flaws. |

| computer-aided design, smart manufacturing, industry 4.0, adaptive manufacturing | (Zhang, 2018) [20] | AR, 3D printing | Smart factories require interconnectivity in order to function properly, a feature many factories lack today. To provide the platform for human-machine interactions, an AR tablet device has been used in a prototype system, which intends to provide an interface for communication with machines and workstations. |

| supply chain, industry 4.0 scheduling, | (Dolgui, 2018) [9] | - | Analyzing the fundamentals of control and systems theory to supply chains and operations management. |

| User experience evaluation, Interactive operation, Motion sickness | (Yu, 2019) [24] | VR glasses | The authors of the paper developed questionnaires to evaluate the user experience of various mobile VR glasses (which can be readily used after installing the VR application on the smartphone). |

| User experience; Human Factors, Industry 4.0, Production system design, Human Interaction | (Peruzzini, 2017) [25] | Eye tracking system (Tobii) biosensors | As great emphasis is placed on the well-being and safety of workers, the monitoring of human interactions is crucial to assess their physical and mental workload. This integrated monitoring of human factors allows for the amendment of future factory designs. |

| Maintenance, Training simulation, Industrial application | (Quandt, 2018) [21] | AR, simulators | Two case studies are discussed in this study, which are used to formulate requirements towards AR technology for industrial applications. Cost efficiency and a short setup time were two significant requirements (among many others), providing the future designers of AR technology lucid guidelines to adhere to. |

| Industry 4.0, social sustainability | (Gregori, 2018) [30] | IoT | This paper discusses the integration of workers within the digitalized factory. An IoT infrastructure is proposed, which improves the well-being and productivity of the workers by acquiring human-related data. This is used to identify bottlenecks and prevent occupation-related diseases, having human performance in focus. |

| Behavior intention, Privacy, Trust | (Yildirim, 2018) [29] | IoT, Adaptive Neuro-Fuzzy Inference systems, Wearable devices Partial Least Square Modelling | Despite being usable in many fields of industry, the use of IoT bears many inherent risks, including the violation of privacy. This study analyses the factors which influence the employees’’ decision to use wearable devices at work. Results indicate that the strongest motivation for using wearable IoT devices is their perceived usefulness. |

| User interface, Performance | (Kim, 2019) [28] | AR, head-worn display | This paper investigated how the types of HWDs and UI designs affected job performance. |

| Camera network design, Camera placement, Human factors | (Bogaerts, 2019) [11] | VR, Submodular function maximization | To facilitate the designing process of a camera network, a VR Human interface was developed, enabling humans to design the network layout. The results indicate that the layouts designed by humans were more intuitive and efficient than the automated designs, which also require human interaction, thus proving to be less effective. |

| Real-time motion tracking, Adaptive filter, Visual-inertial fusion, Pose estimation | (Fang, 2017) [14] | Mobile AR/VR, | Mobile AR/VR applications require an uninterrupted stream from the built-in camera to provide the user-experience the users expect. Latency often limits the use of these applications, and this study has proposed a new method of motion tracking by using visual-inertial sensors, providing better adaptability. Experiments have validated the proposed method. |

| recursive estimation, performance monitoring, early warning systems | (Ruppert, 2018) [22] | indoor positioning system, paced conveyor | To cope with the increasing variability of production, the paper has proposed a system based on various sensors which are used to measure performance and ensure the handling of varying product complexity. |

| deep learning, data preprocessing, Human Activity Recognition (HAR), Industry 4.0 | (Zheng, 2018) [26] | Internet of things (IoT) | Human activity recognition is vital in the processes of a smart factory. The detection of human activities is improved in this paper, as different methods are discussed, along with their efficiency. The multichannel method proved to be the most efficient, outperforming other machine learning techniques with a 97.2% recognition rate in the experiments conducted. |

| Industry 4.0, industrial operator support, fog computing, cloudlet | (Fernández-Caramés, 2018) [15] | Internet of things (IoT), AR, Microsoft HoloLens | In Navantia’s “Shipyard 4.0”, a new AR architecture is presented, which relies on the use of cloudlets and fog computing to assist operators wearing smart glasses. The presented method proved to be exceptionally efficient when handling larger file sizes, as opposed to fog computing alone, which proved to handle small payloads (<128 kB) efficiently. |

| orthogonal frequency-division multiple access (OFDMA), multiuser | (Ahn, 2018) [31] | VR, wireless LAN, wireless VR | To enhance the user experience of VR devices, a wireless multiuser VR communication architecture is proposed with the employment of multiple WLAN standards. This proves to be easily implemented, as commercial WLAN chipsets can be used. |

| remanufacturing, sustainable manufacturing, Industry 4.0, smart factory | (Yang, 2018) [23] | intelligent machining | This study addresses the conventional “take-make-consume-dispose” model of manufacturing, providing a feasible alternative. A new model (circular economy model) is proposed, which prescribes the design of products to be inherently regenerative and restorative by design. Two case studies were used to exemplify this proposed remanufacturing process. |

| mobile virtual reality, hand interface, interaction, immersion, VR sickness | (Han, 2017) [27] | VR, leap motion | To improve user immersion in VR applications, a gaze-based hand interaction is proposed in this paper. The results indicated that 45.24% of respondents testing the method reported a high degree of immersion, and VR sickness was not reported by the participants of the experiments. |

References

- Alcácer, V.; Cruz-Machado, V. Scanning the Industry 4.0: A Literature Review on Technologies for Manufacturing Systems. Eng. Sci. Technol. Int. J. 2019. In press. [Google Scholar] [CrossRef]

- Ashton, K. That “Internet of Things” Thing: In the Real World Things Matter More than Ideas, RFID Journal. 2009. Available online: https://www.rfidjournal.com/articles/view?4986 (accessed on 5 July 2019).

- Herman, M.; Pentek, T.; Otto, B. Design Principles for Industry 4.0 Scenarios: A Literature Review; Technische Universität Dortmund: Dortmund, Germany, 2016. [Google Scholar] [CrossRef]

- Guzsvinecz, T.; Szucs, V.; Sik-Lanyi, C. Suitability of the Kinect Sensor and Leap Motion Controller—A Literature Review. Sensors 2019, 19, 1072. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Heath and Safety Executive. Available online: http://www.hse.gov.uk/humanfactors/introduction.htm (accessed on 1 July 2019).

- Grant, M. Sustainability 2020. Available online: https://www.investopedia.com/terms/s/sustainability.asp (accessed on 6 April 2020).

- PRISMA Guidelines. Available online: http://prisma-statement.org/PRISMAStatement/FlowDiagram.aspx (accessed on 27 December 2018).

- Kitchenham, B. Procedures for Performing Systematic Reviews; Keele University: Staffordshire, UK, 2004; Volume 33. [Google Scholar]

- Dolgui, A.; Ivanov, D.; Sethi, S.; Sokolov, B. Control theory applications to operations systems, supply chain management and industry 4.0 networks. IFAC Pap. Online 2018, 51, 1536–1641. [Google Scholar] [CrossRef]

- Hertz, M.; Rauschnabel, P.A. Understanding the diffusion of virtual reality glasses: The role of media fashion and technology. Technol. Forecast. Soc. Chang. 2019, 138, 228–242. [Google Scholar] [CrossRef]

- Bogaerts, B.; Sels, S.; Vanlanduit, S.; Penne, R. Interactive camera network design using a virtual reality interface. Sensors 2019, 19, 1003. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Syberfeldt, A.; Danielsson, O.; Gustavsson, P. Augmented reality smart glasses in the smart factory: Product evaluation guidelines and review of available products. IEEE Access 2017, 5, 9118–9130. [Google Scholar] [CrossRef]

- Terhoeven, J.; Schiefelbein, F.P.; Wischniewski, S. User expectations on smart glasses as work assistance in electronics manufacturing. Procedia CIRP 2018, 72, 1028–1032. [Google Scholar] [CrossRef]

- Fang, W.; Zheng, L.; Deng, H.; Zhang, H. Real-time motion tracking for mobile augmented/virtual reality using adaptive visual-inertial fusion. Sensors 2019, 17, 1037. [Google Scholar] [CrossRef] [Green Version]

- Fernández-Caramés, T.M.; Fraga-Lamas, P.; Suárez-Albela, M.; Vilar-Montesinos, M. A Fog computing and cloudlet based augmented reality systems for the industry 4.0 shipyard. Sensors 2018, 18, 1798. [Google Scholar] [CrossRef] [Green Version]

- Mengoni, M.; Ceccacci, S.; Generosi, A.; Leopardi, A. Spatial augmented reality: An application for human work in smart manufacturing environment. Procedia Manuf. 2018, 17, 476–483. [Google Scholar] [CrossRef]

- Mourtzis, D.; Zogopulos, V.; Vlachou, E. Augmented reality supported product design towards industry 4.0: A teaching factory paradigm. Procedia Manuf. 2018, 23, 207–212. [Google Scholar] [CrossRef]

- Danielsson, O.; Syberfelt, A.; Holm, M.; Wang, L. Operators perspective on augmented reality as a support tool in engine assembly. Procedia CIRP 2018, 72, 45–50. [Google Scholar] [CrossRef]

- Masoni, R.; Ferrise, F.; Bordegoni, M.; Gattullo, M.; Uva, A.E.; Fiorentino, M.; Carrabba, E.; Di Donato, M. Supporting remote maintenance in industry 4.0 through augmented reality. Procedia Manuf. 2017, 11, 1296–1302. [Google Scholar] [CrossRef]

- Zhang, Y.; Kwok, T.H. Design and Interaction Interface using Augmented Reality for smart Manufacturing. Procedia Manuf. 2018, 26, 1278–1286. [Google Scholar] [CrossRef]

- Quandt, M.; Knoke, B.; Gorldt, C.; Freitag, M.; Thoben, K.D. General Requirements for Industrial Augmented Reality Applications. Procedia CIRP 2018, 72, 1130–1135. [Google Scholar] [CrossRef]

- Ruppert, T.; Abonyi, J. Software sensor for activity-time monitoring and fault detection in product lines. Sensors 2018, 18, 2346. [Google Scholar] [CrossRef] [Green Version]

- Yang, S.; Raghavendra, A.M.R.; Kaminski, J.; Pepin, H. Opportunities for Industry 4.0 to Support Remanufacturing. Appl. Sci. 2018, 8, 1177. [Google Scholar] [CrossRef] [Green Version]

- Yu, M.; Zhou, R.; Wang, H.; Zhao, W. An evaluation for VR glasses system user experience: The influence factors of interactive operation and motion sickness. Appl. Ergon. 2019, 74, 206–213. [Google Scholar] [CrossRef]

- Peruzzini, M.; Grandi, F.; Pellicciari, M. Benchmarking of tools for User experience analysis in Industry. Procedia Manuf. 2017, 11, 806–813. [Google Scholar] [CrossRef]

- Zheng, X.; Wang, M.; Ordieres-Meré, J. Comparison of data preprocessing approaches for applying deep learning to human activity recognition in the context of industry 4.0. Sensors 2018, 18, 2146. [Google Scholar] [CrossRef] [Green Version]

- Han, S.; Kim, J. A study on immersion of hand interaction for mobile platform virtual reality contents. Symmetry 2017, 9, 22. [Google Scholar] [CrossRef] [Green Version]

- Kim, S.; Nussbaum, M.A.; Gabbard, J.L. Influences of augemnted reality head-worn display type and user interface design on performance and usability in simulated warehouse order picking. Appl. Ergon. 2019, 186–193. [Google Scholar] [CrossRef]

- Yildirim, H.; Ali-Eldin, A.M.T. A model for predicting user intention to use wearable IoT devices at the workplace. J. King Saud Univ. Comput. Inf. Sci. 2018. Under Publication. [Google Scholar] [CrossRef]

- Gregori, F.; Papetti, A.; Pandolfi, M.; Peruzzini, M.; Germani, M. Improving a production site from a social point of View: An IoT infrastructure to monitor workers condition. Procedia CIRP 2018, 72, 886–891. [Google Scholar] [CrossRef]

- Ahn, J.; Kim, Y.Y.; Kim, R.Y. Virtual reality-wireless local area network: Wireless connection-oriented virtual reality architecture for next-generation virtual reality devices. Appl. Sci. 2018, 8, 43. [Google Scholar] [CrossRef] [Green Version]

- Qin, J.; Liu, Y.; Grosvenor, R. A Categorical Framework of Manufacturing for Industry 4.0 and Beyond. Procedia CIRP 2016, 52, 173–178. [Google Scholar] [CrossRef] [Green Version]

- EPSON Epson Moverio 300. Available online: https://www.epson.eu/products/see-through-mobile-viewer/moverio-bt-300 (accessed on 22 June 2019).

| Publication Year | Number of Publications in the Web of Science, Science Direct, and Scopus Database | Number of Publications in the Sensors, Applied Sciences, and Symmetry Journals |

|---|---|---|

| 2019 | 4 | 2 |

| 2018 | 9 | 5 |

| 2017 | 3 | 1 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Sik Lanyi, C.; Withers, J.D.A. Striving for a Safer and More Ergonomic Workplace: Acceptability and Human Factors Related to the Adoption of AR/VR Glasses in Industry 4.0. Smart Cities 2020, 3, 289-307. https://doi.org/10.3390/smartcities3020016

Sik Lanyi C, Withers JDA. Striving for a Safer and More Ergonomic Workplace: Acceptability and Human Factors Related to the Adoption of AR/VR Glasses in Industry 4.0. Smart Cities. 2020; 3(2):289-307. https://doi.org/10.3390/smartcities3020016

Chicago/Turabian StyleSik Lanyi, Cecilia, and John Dermott Alexander Withers. 2020. "Striving for a Safer and More Ergonomic Workplace: Acceptability and Human Factors Related to the Adoption of AR/VR Glasses in Industry 4.0" Smart Cities 3, no. 2: 289-307. https://doi.org/10.3390/smartcities3020016

APA StyleSik Lanyi, C., & Withers, J. D. A. (2020). Striving for a Safer and More Ergonomic Workplace: Acceptability and Human Factors Related to the Adoption of AR/VR Glasses in Industry 4.0. Smart Cities, 3(2), 289-307. https://doi.org/10.3390/smartcities3020016