1. Introduction

Energy demands and consumption have been increasing with rapid population and industrial sector growth. Fossil fuels are considered the primary energy source, even though they are limited in resources and have negative impacts on the environment. Nevertheless, fossil fuels may contain many harmful substances that can induce various environmental issues, e.g., global warming, air pollution, acid rain, and ozone layer depletion, which can negatively influence human health [

1]. Numerous studies have been conducted in hopes of finding alternative fuels that can replace fossil fuels. In addition, it is also very important for the fuel resources to be economically viable, environmentally safe, and available in abundant quantities at a low cost. Among the accessible resources, biodiesel is considered a promising alternative that can be used to replace diesel oil and other petroleum-based fuels [

2].

Biodiesel can be produced from renewable sources that deem it safe, biodegradable, harmless, sulphur-free, and considered an effective lubricant [

3]. The advantages of biodiesel compared to fossil fuels cannot be overstated. The commercialization of biodiesel as a fuel can be carried out by blending it with diesel oil or using it directly as a pure substance. It is also highly compatible with diesel engines, requiring no further modifications or causing undesirable effects on engine performance [

4]. Biodiesel can be generated from a wide range of biomass, including vegetable oils [

5], animal fats [

6], microbial lipids [

7], and waste cooking oil [

8], which are accessible and renewable. Many varieties of vegetable oil have been explored as biodiesel feedstocks that can be categorized into edible oil and non-edible oil groups. To date, the majority of commercial biodiesel is produced from edible oils, including cottonseed oil (CSO) [

9,

10].

The development of biodiesel production starts at a laboratory scale, and scaling up the process is a major challenge. Process simulation can be used to model, predict, and optimize the process in a more economical way. Therefore, process simulation can be employed as an inexpensive tool to scale up for design considerations, production estimations, and product property assessments. In previous studies, we have actively simulated various processes associated with the utilization of vegetable oils as raw materials for biodiesel or other value-added products [

11,

12,

13,

14,

15]. The production of biodiesel from a variety of feedstock can be accomplished by four main pathways: direct use and blending, microemulsion, pyrolysis, as well as transesterification. Among the four methods stated, transesterification is the most widely applied in biodiesel production. Here, the triglycerides are reacted with an alcohol, most preferably methanol, in the presence of a catalyst, transforming them into fatty acid methyl esters (FAMEs) or biodiesel and glycerol as by-products [

16].

Glycerol can be transformed into various products via many different routes, either chemical or biochemical. In particular, value-added products, such as hydrogen, acrolein, glycerol carbonate, dihydroxyacetone, glyceric acid, propylene glycol, benzoic acid, and other value-added products can be obtained [

17]. Among all these products, hydrogen is one of the most promising renewable energies that can be produced through an integrated process with biodiesel production. Glycerol is considered an attractive feedstock for hydrogen production and power generation, as the yields obtained from biodiesel production can meet its demand in the market [

18,

19,

20]. The catalytic reforming of glycerol for the production of hydrogen and other energy carriers/chemicals is achieved via glycerol dehydrogenation on the catalytically active side, followed by water–gas shift or methanation reactions.

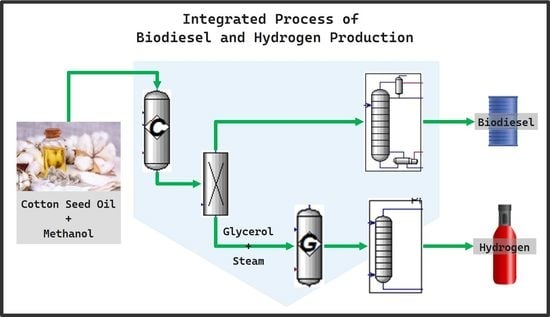

Therefore, in this work, ASPEN Hysys v11 was used to model and simulate an integrated process of CSO transesterification for biodiesel production and glycerol steam reforming to produce hydrogen. The simulation focused on the properties of the biodiesel products, which are further evaluated using the available criteria, and the effect of operating conditions on hydrogen production. To the best of our knowledge, there are no studies that report the simulation process of integrated CSO transesterification for biodiesel production and glycerol steam reforming to produce hydrogen.

3. Results and Discussion

3.1. Biodiesel Production from Cottonseed Oil

Figure 1 depicts the simulation flowsheet for the biodiesel production process from cottonseed oil. Esterification, transesterification, and biodiesel purification are all part of the process. Major key equipment is used in the simulation, involving reactors, process separation units, heat exchangers, and pumps.

Table 5 summarizes codes and descriptions for each piece of process equipment.

The process reactor inlets were CSO (1000 kg/h) as an oil feedstock and methanol as an alcohol source, with a methanol-to-oil ratio of 6:1. The CSO stream was simulated with a composition of triolein (13.08%), trilinolein (42.31%), tripalmitin (20.31%), tristearin (1.86%), and oleic acid (22.43%) as FFA. Since CSO contains more than 1% FFA, it needs to be esterified first before proceeding with the transesterification reaction. Because of data constraints, both the esterification and transesterification reactions were modeled by conversion reactors. The conversion for both processes (esterification and transesterification) was set at 100%.

Temperature is another factor that influences biodiesel yield. According to the literature review, both reactors can be operated at the same operating conditions (65 °C, atmospheric pressure). Most of the remaining methanol, water, glycerol, and biodiesel were found in the output stream of the second reactor. Biodiesel was used as a fuel, which is required to meet the standards available, especially the qualification from the purity level. Excess methanol must be recovered for economic efficiency. The product was then processed through a series of separation steps for methanol recovery, glycerol separation, and biodiesel purification to produce high-quality biodiesel.

Two stages of separation were utilized to maximize the methanol recovery: flash distillation and fractional distillation. Flash distillation requires the outlet of the transesterification process reactor to be heated to 80 °C in a flash drum to form a vapor–liquid mixture. This mixture contains a methanol fraction enriched in the vapor phase and can be used to remove most of the excess methanol. The methanol-rich vapor phase was then cooled down and used as feed. Most of the unreacted methanol was recovered using this method, with a recovery of approximately 65%.

The liquid stream then proceeded to the next stage, which was the glycerol separation. The operation could be carried out using a variety of technologies [

34]. Considering many aspects, membrane separation may be the best candidate for this purpose due to its selectivity and rejection rate for specific components [

38,

39]. Because the high retention of the membrane results in optimal process conditions, membrane separation needs to be performed at high pressure (5.5 bar) and low temperature (25 °C) to protect the membrane material. The residue was 99% glycerol (97.54 kg/h) together with other impurities. The rich biodiesel permeate stream was sent to a fractional distillation column (T-100) for biodiesel refining. About 30% of the excess methanol could be recovered after the fractional distillation process, bringing the total amount of recycled methanol up to 95%. After a series of purification steps, the biodiesel had an ester composition of up to 99.97% at a mass flow rate of 1008 kg/h. The detailed mass and energy balances for each stream are summarized in

Table 6.

The biodiesel product properties obtained from the simulated process in this study were compared to experimental studies utilizing CSO as feedstock (

Table 7). The properties of biodiesel modeled from the simulation process are comparable to other similar experimental studies on biodiesel production from CSO. The properties are also consistent with biodiesel standards from the literature (ASTM D 6751 and EN 14214).

3.2. Glycerol Steam Reforming to Produce Hydrogen

Figure 2 depicts the simulation flowsheet for the hydrogen production process from glycerol. The process was modeled with two reactors, one for the steam reforming process and one for the low-temperature separation (LTS) water–gas shift reaction. The process was followed by purification processes, which include flash distillation, absorption, and distillation. The main equipment involved in the process were reactors, flash tanks, absorption columns, and distillation columns, as well as auxiliary equipment such as pumps, heat exchangers, and compressors.

Table 8 summarizes the codes and descriptions for key equipment.

The mass and energy balances for hydrogen production are summarized in

Table 9. The glycerol stream with a mass flow rate of 97.54 kg/h separated from the biodiesel production product stream was heated to reach the reaction temperature. In addition to glycerol, the steam generated in the steam reforming process also entered the reactor GBR-200 as superheated steam. In the GBR-200 reactor, the hydrogen production process was modeled by four reactions: glycerol steam reforming, glycerol decomposition, water–gas shift reaction, and methanation reaction. To eliminate the carbon dioxide composition from the product stream, the GBR-200 product stream entering the second reactor (GBR-201) underwent a low-temperature water–gas shift reaction. The reactor was modeled with a water–gas reaction only. The output of GBR-200 was then cooled down to separate most of the water formed. The gas stream separated from water was then compressed before entering the absorption column to separate carbon dioxide using DEA as a solvent. The gas stream leaves the absorber with a high concentration of hydrogen and a mass flow rate of 8.45 kg/h.

Glycerol steam reforming was simulated with the following operating conditions: reaction temperatures of 400–750 °C and a steam-to-glycerol molar ratio of 0.5–10. The effect of the steam-to-glycerol ratio on product composition is shown in

Figure 3. In steam-deficient environments, the gas products were dominated by CO

2 and CH

4. As the ratio of steam to glycerol increases, the hydrogen fraction in the product stream increases exponentially, reaching a maximum ratio of 4.5. As the ratio continued to increase, the number of unreacted steams increased and the hydrogen fraction decreased simultaneously. From the case study, it can be concluded that the steam-to-glycerol ratio should be around 4.5 to achieve the optimum result.

The effect of reaction temperature on the composition of the produced gas was also simulated, as shown in

Figure 4. At the lowest simulation temperature, the hydrogen fraction is very low, and the process is deemed inefficient. As the temperature continued to rise, the hydrogen composition increased exponentially and dominated the product stream at the highest simulated temperature. The steam reforming reaction is endothermic, and high temperatures are preferred. However, higher reaction temperatures are economically undesirable [

42].

The next parameters to evaluate are hydrogen yield and selectivity. In the reaction process, high yield and selectivity for the desired products are preferable. Simulated data for hydrogen yield and selectivity at different reaction temperatures are shown in

Figure 5 and

Figure 6, respectively. Both parameters showed similar trends. As the temperature rises, the hydrogen yield and selectivity increase significantly. Hydrogen yield and selectivity of 96.68% and 98.1%, respectively, were achieved at the maximum simulated temperature.

3.3. Economic Analysis

As an initial consideration to further investigate the feasibility of the simulated process, a simple economic analysis is required. The economic analysis was carried out via the Aspen process economic analyzer (APEA) to calculate total capital and production costs. External data based on the average market price of CSO, biodiesel, and hydrogen were used for the rough revenue estimation. The projected annual expenditures and revenues are summarized in

Table 10.

From the data reported in

Table 10, the payback period (PBP), rate of return on investment (ROI), and internal rate of return (IRR) were calculated using Equations (3)–(5), respectively, with supplementary assumptions of 11% interest rate (i), 8-year project time (t), and operation of the plant, which starts at the beginning of year 3. ROI does not take into account the time value of money. Meanwhile, IRR takes into account the time value of money and calculates the annual growth rate. The projected net present value (NPV) of the simulated processes is illustrated in

Figure 7. As summarized in

Table 11, the calculated results demonstrate that the integrated process of biodiesel and hydrogen production from CSO in small capacity has quite excellent investment criteria.

where

= lower discount rate chosen,

= higher discount rate chosen, NPV

a = net present value at

, and NPV

b = net present value at

A sensitivity analysis was conducted to examine the impact of production variables such as biodiesel selling price and production capacity on gross margin. Input variable sensitivity limits are set at −50% and +50% of the base case.

Figure 8 shows the results of the sensitivity analysis. There is a steep slope in production capacity compared to the price of biodiesel production. It can be concluded that production capacity has a greater impact on gross margins than biodiesel pricing.

4. Conclusions

This study aims to simulate an integrated process of biodiesel production from CSO and hydrogen production from glycerol, which is the by-product of the main process. In the initial process, CSO is converted to biodiesel via the transesterification process. In addition, since glycerol is a by-product in the initial stage, it is then utilized as the raw material in the following process. The second reaction involves four reactions in the main reactor: steam reforming, glycerol decomposition, water–gas shift, and methanation.

The optimum steam-to-glycerol molar ratio is 4.5, and the higher the reaction temperature, the higher the proportion of hydrogen in the gas stream, leading to higher hydrogen yield and selectivity. However, the energy consumption of this process needs to be further studied, as more energy must be supplied at higher temperatures. A simple economic analysis of the integrated process showed that this process is economically viable.