Development of Chitosan Films from Edible Crickets and Their Performance as a Bio-Based Food Packaging Material

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Methods

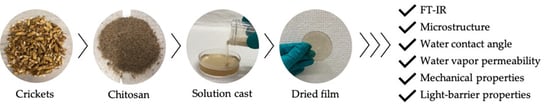

2.2.1. Cricket Chitosan

2.2.2. Solution Casting Films

2.2.3. Molecular Characterization

2.2.4. Scanning Electron Microscopy (SEM)

2.2.5. Water Contact Angle Analysis

2.2.6. Water Vapor Permeability

2.2.7. Mechanical Properties

2.2.8. Color Measurement

2.2.9. Light Barrier Properties

2.2.10. Opacity

2.2.11. Statistical Analysis

3. Results

3.1. Molecular Characterization

3.2. Film Microstructure by Scanning Electron Microscopy

3.3. Mechanical Properties

3.4. Water Vapor Permeability (WVP)

3.5. Color and Optical Properties

3.6. Light Barrier Properties

3.7. Water Contact Angles

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Guillard, V.; Gaucel, S.; Fornaciari, C.; Angellier-Coussy, H.; Buche, P.; Gontard, N. The next generation of sustainable food packaging to preserve our environment in a circular economy context. Front. Nutr. 2018, 5, 121. [Google Scholar] [CrossRef] [Green Version]

- Babu, R.P.; Oconnor, K.; Seeram, R. Current progress on bio-based polymers and their future trends. Prog. Biomater. 2013, 2, 8. [Google Scholar] [CrossRef] [Green Version]

- Wang, H.; Qian, J.; Ding, F. Emerging chitosan-based films for food packaging applications. J. Agric. Food Chem. 2018, 66, 395–413. [Google Scholar] [CrossRef]

- Siripatrawan, U.; Vitchayakitti, W. Improving functional properties of chitosan films as active food packaging by incorporating with propolis. Food Hydrocoll. 2016, 61, 695–702. [Google Scholar] [CrossRef]

- Crizel, T.D.M.; Rios, A.D.O.; Alves, V.D.; Bandarra, N.; Moldao-Martins, M.; Flôres, S.H. Active food packaging prepared with chitosan and olive pomace. Food Hydrocoll. 2018, 74, 139–150. [Google Scholar] [CrossRef]

- Wu, C.; Tian, J.; Li, S.; Wu, T.; Hu, Y.; Chen, S.; Sugawara, T.; Ye, X. Structural properties of films and rheology of film-forming solutions of chitosan gallate for food packaging. Carbohydr. Polym. 2016, 146, 10–19. [Google Scholar] [CrossRef] [PubMed]

- Râpă, M.; Miteluţ, A.C.; Tănase, E.E.; Grosu, E.; Popescu, P.; Popa, M.E.; Rosnes, J.T.; Sivertsvik, M.; Darie-Niţă, R.N.; Vasile, C. Influence of chitosan on mechanical, thermal, barrier and antimicrobial properties of PLA-biocomposites for food packaging. Compos. Part B Eng. 2016, 102, 112–121. [Google Scholar] [CrossRef]

- Rai, S.; Dutta, P.; Mehrotra, G. Lignin incorporated antimicrobial chitosan film for food packaging application. J. Polym. Mater. 2017, 34, 171. [Google Scholar]

- Ashrafi, A.; Jokar, M.; Nafchi, A.M. Preparation and characterization of biocomposite film based on chitosan and kombucha tea as active food packaging. Int. J. Biol. Macromol. 2018, 108, 444–454. [Google Scholar] [CrossRef] [PubMed]

- Shahbazi, Y. The properties of chitosan and gelatin films incorporated with ethanolic red grape seed extract and Ziziphora clinopodioides essential oil as biodegradable materials for active food packaging. Int. J. Biol. Macromol. 2017, 99, 746–753. [Google Scholar] [CrossRef] [PubMed]

- Riaz, A.; Lei, S.; Akhtar, H.M.S.; Wan, P.; Chen, D.; Jabbar, S.; Abid, M.; Hashim, M.M.; Zeng, X. Preparation and characterization of chitosan-based antimicrobial active food packaging film incorporated with apple peel polyphenols. Int. J. Biol. Macromol. 2018, 114, 547–555. [Google Scholar] [CrossRef]

- Kaya, M.; Khadem, S.; Cakmak, Y.S.; Mujtaba, M.; Ilk, S.; Akyuz, L.; Salaberria, A.M.; Labidi, J.; Abdulqadir, A.H.; Deligoz, E. Antioxidative and antimicrobial edible chitosan films blended with stem, leaf and seed extracts of Pistacia terebinthus for active food packaging. RSC Adv. 2018, 8, 3941–3950. [Google Scholar] [CrossRef] [Green Version]

- Wang, Q.; Tian, F.; Feng, Z.; Fan, X.; Pan, Z.; Zhou, J. Antioxidant activity and physicochemical properties of chitosan films incorporated withLycium barbarumfruit extract for active food packaging. Int. J. Food Sci. Technol. 2014, 50, 458–464. [Google Scholar] [CrossRef]

- Mohan, K.; Ganesan, A.R.; Muralisankar, T.; Jayakumar, R.; Sathishkumar, P.; Uthayakumar, V.; Chandirasekar, R.; Revathi, N. Recent insights into the extraction, characterization, and bioactivities of chitin and chitosan from insects. Trends Food Sci. Technol. 2020, 105, 17–42. [Google Scholar] [CrossRef]

- Abidin, N.Z.; Kormin, F.; Abidin, N.Z.; Anuar, N.M.; Abu Bakar, M. The Potential of Insects as Alternative Sources of Chitin: An Overview on the Chemical Method of Extraction from Various Sources. Int. J. Mol. Sci. 2020, 21, 4978. [Google Scholar] [CrossRef]

- Hall, F.G.; Jones, O.G.; O’Haire, M.E.; Liceaga, A.M. Functional properties of tropical banded cricket (Gryllodes sigillatus) protein hydrolysates. Food Chem. 2017, 224, 414–422. [Google Scholar] [CrossRef] [PubMed]

- Luna, G.C.; Martin-Gonzalez, F.S.; Mauer, L.; Liceaga, A. Cricket (Acheta domesticus) protein hydrolysates’ impact on the physicochemical, structural and sensory properties of tortillas and tortilla chips. J. Insects Food Feed 2021, 7, 109–120. [Google Scholar] [CrossRef]

- Malm, M.; Liceaga, A. Physicochemical properties of chitosan from two commonly reared edible cricket species, and its application as a hypolipidemic and antimicrobial agent. Polysaccharides 2021, 2, 339–353. [Google Scholar] [CrossRef]

- Malm, M.J.; Narsimhan, G.; Kokini, J.L. Effect of contact surface, plasticized and crosslinked zein films are cast on, on the distribution of dispersive and polar surface energy using the Van Oss method of deconvolution. J. Food Eng. 2019, 263, 262–271. [Google Scholar] [CrossRef]

- Urbizo-Reyes, U.; Martin-González, M.F.S.; Garcia-Bravo, J.; Liceaga, A.M. Development of chia seed (Salvia hispanica) mucilage films plasticized with polyol mixtures: Mechanical and barrier properties. Int. J. Biol. Macromol. 2020, 163, 854–864. [Google Scholar] [CrossRef] [PubMed]

- Garcia, M.; Pinotti, A.; Martino, M.; Zaritzky, N. Characterization of composite hydrocolloid films. Carbohydr. Polym. 2004, 56, 339–345. [Google Scholar] [CrossRef]

- Kalaycıoğlu, Z.; Torlak, E.; Akın-Evingür, G.; Özen, I.; Erim, F.B. Antimicrobial and physical properties of chitosan films incorporated with turmeric extract. Int. J. Biol. Macromol. 2017, 101, 882–888. [Google Scholar] [CrossRef]

- Souza, V.G.L.; Fernando, A.L.; Pires, J.R.A.; Rodrigues, P.F.; Lopes, A.A.; Fernandes, F.M.B. Physical properties of chitosan films incorporated with natural antioxidants. Ind. Crop. Prod. 2017, 107, 565–572. [Google Scholar] [CrossRef]

- Cerqueira, M.A.; Souza, B.W.S.; Teixeira, J.A.; Vicente, A.A. Effect of glycerol and corn oil on physicochemical properties of polysaccharide films—A comparative study. Food Hydrocoll. 2012, 27, 175–184. [Google Scholar] [CrossRef] [Green Version]

- Debandi, M.V.; Bernal, D.C.; Francois, N.J. Development of biodegradable films based on chitosan/glycerol blends suitable for biomedical applications. J. Tissue Sci. Eng. 2016, 7, 2157–7552. [Google Scholar] [CrossRef]

- Chen, S.; Wei, X.; Sui, Z.; Guo, M.; Geng, J.; Xiao, J.; Huang, D. Preparation of Antioxidant and antibacterial chitosan film from Periplaneta americana. Insects 2021, 12, 53. [Google Scholar] [CrossRef] [PubMed]

- Domján, A.; Bajdik, J.; Pintye-Hódi, K. Understanding of the plasticizing effects of glycerol and PEG 400 on chitosan films using solid-state NMR spectroscopy. Macromolecules 2009, 42, 4667–4673. [Google Scholar] [CrossRef]

- Rodríguez-Núñez, J.R.; Madera-Santana, T.J.; Sánchez-Machado, D.I.; López-Cervantes, J.; Valdez, H.S. Chitosan/hydrophilic plasticizer-based films: Preparation, physicochemical and antimicrobial properties. J. Polym. Environ. 2013, 22, 41–51. [Google Scholar] [CrossRef]

- Schaefer, J.; Kramer, K.; Garbow, J.; Jacob, G.; Stejskal, E.; Hopkins, T.; Speirs, R. Aromatic cross-links in insect cuticle: Detection by solid-state 13C and 15N NMR. Science 1987, 235, 1200–1204. [Google Scholar] [CrossRef]

- Khayrova, A.; Lopatin, S.; Varlomov, V. Method of Producing Covalent-Linked Chitosan-Melanin Complex from Black Soldier Fly Hermetia Illucens. Russia Patent RU2728458C1, 29 July 2020. [Google Scholar]

- Saenz-Mendoza, A.I.; Zamudio-Flores, P.B.; García-Anaya, M.C.; Velasco, C.R.; Acosta-Muñiz, C.H.; Ornelas-Paz, J.D.J.; Hernández-González, M.; Vargas, A.; Aguilar-González, M.Á.; Salgado-Delgado, R. Characterization of insect chitosan films from Tenebrio molitor and Brachystola magna and its comparison with commercial chitosan of different molecular weights. Int. J. Biol. Macromol. 2020, 160, 953–963. [Google Scholar] [CrossRef]

- Flores, Z.; San-Martin, D.; Beldarraín-Iznaga, T.; Leiva-Vega, J.; Villalobos-Carvajal, R. Effect of homogenization method and carvacrol content on microstructural and physical properties of chitosan-based films. Foods 2021, 10, 141. [Google Scholar] [CrossRef]

- Liu, M.; Zhou, Y.; Zhang, Y.; Yu, C.; Cao, S. Preparation and structural analysis of chitosan films with and without sorbitol. Food Hydrocoll. 2013, 33, 186–191. [Google Scholar] [CrossRef]

- Liu, Z.; Ge, X.; Lu, Y.; Dong, S.; Zhao, Y.; Zeng, M. Effects of chitosan molecular weight and degree of deacetylation on the properties of gelatine-based films. Food Hydrocoll. 2012, 26, 311–317. [Google Scholar] [CrossRef]

- Liu, Y.T.; Yuan, Y.; Duan, S.Q.; Li, C.; Hu, B.; Liu, A.P.; Wu, D.T.; Cui, H.Y.; Lin, L.; He, J.L.; et al. Preparation and characterization of chitosan films with three kinds of molecular weight for food packaging. Int. J. Biol. Macromol. 2020, 155, 249–259. [Google Scholar] [CrossRef] [PubMed]

- Bumgardner, J.; Murali, V.; Su, H.; Jenkins, O.; Velasquez-Pulgarin, D.; Jennings, J.; Sivashanmugam, A.; Jayakumar, R. Characterization of chitosan matters. In Chitosan Based Biomaterials; Jennings, J.A., Bumgardner, J.D., Eds.; Woodhead Publishing: Cambridge, UK, 2017; Volume 1, pp. 81–114. [Google Scholar]

- Suyatma, N.E.; Tighzert, A.L.; Copinet, A.; Coma, V. Effects of Hydrophilic plasticizers on mechanical, thermal, and surface properties of Chitosan films. J. Agric. Food Chem. 2005, 53, 3950–3957. [Google Scholar] [CrossRef] [PubMed]

- Leceta, I.; Guerrero, P.; de la Caba, K. Functional properties of chitosan-based films. Carbohydr. Polym. 2013, 93, 339–346. [Google Scholar] [CrossRef] [PubMed]

- Ryan, C.C.; Bardosova, M.; Pemble, M.E. Structural and mechanical properties of a range of chitosan-based hybrid networks loaded with colloidal silica and polystyrene particles. J. Mater. Sci. 2017, 52, 8338–8347. [Google Scholar] [CrossRef]

- Huei, C.R. Effect of molecular weight of chitosan with the same degree of deacetylation on the thermal, mechanical, and permeability properties of the prepared membrane. Carbohydr. Polym. 1996, 29, 353–358. [Google Scholar] [CrossRef]

- Tirado-Gallegos, J.; Zamudio-Flores, P.; Espino-Díaz, M.; Salgado-Delgado, R.; Vela-Gutiérrez, G.; Hernández-Centeno, F.; la Peña, H.L.-D.; Hernández-González, M.; Rendón-Villalobos, J.; Ortega-Ortega, A. Chitosan films obtained from Brachystola magna (Girard) and its evaluation on quality attributes in sausages during storage. Molecules 2021, 26, 1782. [Google Scholar] [CrossRef]

- Andersen, S.O. Insect cuticular sclerotization: A review. Insect Biochem. Mol. Biol. 2010, 40, 166–178. [Google Scholar] [CrossRef]

- Sugumaran, M.; Barek, H. Critical analysis of the melanogenic pathway in insects and higher animals. Int. J. Mol. Sci. 2016, 17, 1753. [Google Scholar] [CrossRef] [Green Version]

- Oh, D.X.; Hwang, D.S. A biomimetic chitosan composite with improved mechanical properties in wet conditions. Biotechnol. Prog. 2013, 29, 505–512. [Google Scholar] [CrossRef]

- Khayrova, A.; Lopatin, S.; Varlamov, V. Obtaining chitin, chitosan and their melanin complexes from insects. Int. J. Biol. Macromol. 2021, 167, 1319–1328. [Google Scholar] [CrossRef]

- Khayrova, A.; Lopatin, S.; Varlamov, V. Obtaining chitin/chitosan-melanin complexes from black soldier fly Hermetia Illucens. IOP Conf. Ser. Mater. Sci. Eng. 2020, 809, 012020. [Google Scholar] [CrossRef]

- Khayrova, A.; Lopatin, S.; Varlamov, V. Black soldier fly hermetia illucens as a novel source of chitin and chitosan. Int. J. Sci. 2019, 8, 81–86. [Google Scholar] [CrossRef] [Green Version]

- Ma, J.; Xin, C.; Tan, C. Preparation, physicochemical and pharmaceutical characterization of chitosan from Catharsius molossus residue. Int. J. Biol. Macromol. 2015, 80, 547–556. [Google Scholar] [CrossRef]

- Rivero, S.; Damonte, L.; García, M.A.; Pinotti, A. An insight into the role of glycerol in chitosan films. Food Biophys. 2016, 11, 117–127. [Google Scholar] [CrossRef]

- Qin, Y.-Y.; Zhang, Z.-H.; Li, L.; Yuan, M.-L.; Fan, J.; Zhao, T.-R. Physio-mechanical properties of an active chitosan film incorporated with montmorillonite and natural antioxidants extracted from pomegranate rind. J. Food Sci. Technol. 2013, 52, 1471–1479. [Google Scholar] [CrossRef] [Green Version]

- Rhim, J.-W.; Hong, S.-I.; Park, H.-M.; Ng, P.K.W. Preparation and characterization of chitosan-based nanocomposite films with antimicrobial activity. J. Agric. Food Chem. 2006, 54, 5814–5822. [Google Scholar] [CrossRef] [PubMed]

- Roy, S.; Van Hai, L.; Kim, H.C.; Zhai, L.; Kim, J. Preparation and characterization of synthetic melanin-like nanoparticles reinforced chitosan nanocomposite films. Carbohydr. Polym. 2020, 231, 115729. [Google Scholar] [CrossRef] [PubMed]

- Cao, W.; Zhou, X.; McCallum, N.C.; Hu, Z.; Ni, Q.Z.; Kapoor, U.; Heil, C.M.; Cay, K.S.; Zand, T.; Mantanona, A.J.; et al. Unraveling the structure and function of melanin through synthesis. J. Am. Chem. Soc. 2021, 143, 2622–2637. [Google Scholar] [CrossRef]

- Roy, S.; Rhim, J.-W. New insight into melanin for food packaging and biotechnology applications. Crit. Rev. Food Sci. Nutr. 2021, 2021, 1–27. [Google Scholar] [CrossRef]

| DDA (%) 1 | Water Vapor Permeability (10−10 g/m·s·Pa) | Water Contact Angle (°) | Instrumental Color and Opacity Properties 2 | |||

|---|---|---|---|---|---|---|

| A. domesticus chitosan | Opacity (mm−1) | L* | a* | b* | ||

| 72 | 2.14 ± 0.07 ab | 101.18 ± 4 bc | 1.6 ± 0.10 b | 71.79 ± 1.04 a | 0.8 ± 0.42 c | 26.49 ± 3.02 b |

| 76 | 2.29 ± 0.06 ab | 97.21 ± 2.4 abc | 1.6 ± 0.04 b | 74.71 ± 0.43 b | −0.02 ± 0.18 b | 24.64 ± 1.39 b |

| 80 | 2.09 ± 0.08 a | 102.99 ± 5.4 c | 1.5 ± 0.14 b | 70.6 ± 0.60 a | 1.44 ± 0.17 de | 30.16 ± 0.56 b |

| G. sigillatus chitosan | ||||||

| 72 | 2.34 ± 0.06 ab | 102.58 ± 4.1 c | 1.6 ± 0.04 b | 72.23 ± 1.85 ab | 1.23 ± 0.2 cd | 25.41 ± 4.75 b |

| 76 | 2.40 ± 0.13 b | 95.48 ± 4.9 ab | 1.7 ± 0.07 b | 69.9 ± 1.42 a | 1.86 ± 0.14 e | 26.4 ± 3.63 b |

| 80 | 2.43 ± 0.17 b | 101.06 ± 5.2 bc | 1.7 ± 0.04 b | 71.96 ± 1 ab | 1.56 ± 0.19 de | 23.65 ± 0.91 b |

| Shrimp chitosan | ||||||

| 70 | 2.91 ± 0.16 c | 93.02 ± 2.3 a | 0.5 ± 0.01 a | 87.97 ± 0.44 c | −2.38 ± 0.23 a | 8.09 ± 0.4 a |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Malm, M.; Liceaga, A.M.; San Martin-Gonzalez, F.; Jones, O.G.; Garcia-Bravo, J.M.; Kaplan, I. Development of Chitosan Films from Edible Crickets and Their Performance as a Bio-Based Food Packaging Material. Polysaccharides 2021, 2, 744-758. https://doi.org/10.3390/polysaccharides2040045

Malm M, Liceaga AM, San Martin-Gonzalez F, Jones OG, Garcia-Bravo JM, Kaplan I. Development of Chitosan Films from Edible Crickets and Their Performance as a Bio-Based Food Packaging Material. Polysaccharides. 2021; 2(4):744-758. https://doi.org/10.3390/polysaccharides2040045

Chicago/Turabian StyleMalm, Morgan, Andrea M. Liceaga, Fernanda San Martin-Gonzalez, Owen G. Jones, Jose M. Garcia-Bravo, and Ian Kaplan. 2021. "Development of Chitosan Films from Edible Crickets and Their Performance as a Bio-Based Food Packaging Material" Polysaccharides 2, no. 4: 744-758. https://doi.org/10.3390/polysaccharides2040045

APA StyleMalm, M., Liceaga, A. M., San Martin-Gonzalez, F., Jones, O. G., Garcia-Bravo, J. M., & Kaplan, I. (2021). Development of Chitosan Films from Edible Crickets and Their Performance as a Bio-Based Food Packaging Material. Polysaccharides, 2(4), 744-758. https://doi.org/10.3390/polysaccharides2040045