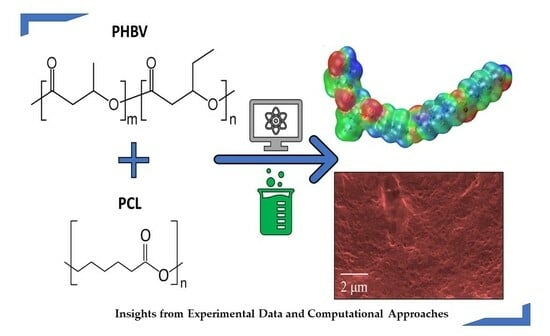

Influence of γ-Irradiation on the Electronic Structure and the Chemical and Mechanical Properties of Poly(hydroxybutyrate-valerate)/Poly(caprolactone) Blends: Insights from Experimental Data and Computational Approaches

Abstract

:1. Introduction

2. Materials and Methods

2.1. Preparation of Biodegradable PHBV/PCL Polymeric Blends

2.2. Characterization

2.3. Computational Details

3. Results and Discussion

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Amass, W.; Amass, A.; Tighe, B. A Review of Biodegradable Polymers: Uses, Current Developments in the Synthesis and Characterization of Biodegradable Polyesters, Blends of Biodegradable Polymers and Recent Advances in Biodegradation Studies. Polym. Int. 1998, 47, 89–144. [Google Scholar] [CrossRef]

- Darwis, D.; Mitomo, H.; Enjoji, T.; Yoshii, F.; Makuuchi, K. Enzymatic Degradation of Radiation Crosslinked Poly(ε–Caprolactone). Polym. Degrad. Stab. 1998, 62, 259–265. [Google Scholar] [CrossRef]

- Alaswad, S.O.; Mahmoud, A.S.; Arunachalam, P. Recent Advances in Biodegradable Polymers and Their Biological Applications: A Brief Review. Polymers 2022, 14, 4924. [Google Scholar] [CrossRef] [PubMed]

- Alizadeh-Osgouei, M.; Li, Y.; Wen, C. A Comprehensive Review of Biodegradable Synthetic Polymer-Ceramic Composites and Their Manufacture for Biomedical Applications. Bioact. Mater. 2019, 4, 22–36. [Google Scholar] [CrossRef]

- Yang, Z.; Nollenberger, K.; Albers, J.; Craig, D.; Qi, S. Microstructure of an Immiscible Polymer Blend and Its Stabilization Effect on Amorphous Solid Dispersions. Mol. Pharm. 2013, 10, 2767–2780. [Google Scholar] [CrossRef]

- Korycki, A.; Garnier, C.; Abadie, A.; Nassiet, V.; Sultan, C.T.; Chabert, F. Poly(Etheretherketone)/Poly(Ethersulfone) Blends with Phenolphthalein: Miscibility, Thermomechanical Properties, Crystallization and Morphology. Polymers 2021, 13, 1466. [Google Scholar] [CrossRef]

- Oréfice, R.L.; Pereira, M.M.; Mansur, H.S. Biomateriais: Fundamentos e Aplicações; Cultura Médica: Rio de Janeiro, Brazil, 2006. [Google Scholar]

- Reinaldo, J.D.S.; Nascimento, M.C.B.C.D.; Ito, E.N.; Hage, E., Jr. Rheological, Mechanical and Morphological Properties of Poly(Methyl Methacrylate)/Poly(Ethylene Terephthalate) Blend with Dual Reactive Interfacial Compatibilization. Polímeros 2015, 25, 451–460. [Google Scholar] [CrossRef]

- Song, R.; Murphy, M.; Li, C.; Ting, K.; Soo, C.; Zheng, Z. Current Development of Biodegradable Polymeric Materials for Biomedical Applications. Drug Des. Devel. Ther. 2018, 12, 3117–3145. [Google Scholar] [CrossRef]

- Müller, R.-J.; Kleeberg, I.; Deckwer, W.-D. Biodegradation of polyesters containing aromatic constituents. J. Biotechnol. 2001, 86, 87–95. [Google Scholar] [CrossRef]

- Yoshie, N.; Saito, M.; Inoue, Y. Effect of chemical compositional distribution on solid-state structures and properties of poly(3-hydroxybutyrate-co-3-hydroxyvalerate). Polymer 2004, 45, 1903–1911. [Google Scholar] [CrossRef]

- Qiao, H.; Maazouz, A.; Lamnawar, K. Study of Morphology, Rheology, and Dynamic Properties toward Unveiling the Partial Miscibility in Poly(lactic acid)—Poly(hydroxybutyrate-co-hydroxyvalerate) Blends. Polymers 2022, 14, 5359. [Google Scholar] [CrossRef] [PubMed]

- Maraveas, C. Production of Sustainable and Biodegradable Polymers from Agricultural Waste. Polymers 2020, 12, 1127. [Google Scholar] [CrossRef] [PubMed]

- Pachekoski, W.M.; Agnelli, J.A.M.; Belem, L.P. Thermal, mechanical and morphological properties of poly (hydroxybutyrate) and polypropylene blends after processing. Mater. Res. 2009, 12, 159–164. [Google Scholar] [CrossRef]

- Pesaranhajiabbas, E.; Misra, M.; Mohanty, A.K. Recent progress on biodegradable polylactic acid based blends and their biocomposites: A comprehensive review. Int. J. Biol. Macromol. 2023, 253, 126231. [Google Scholar] [CrossRef] [PubMed]

- Goonoo, N.; Bhaw-Luximon, A.; Jhurry, D. Biodegradable polymer blends: Miscibility, physicochemical properties and biological response of scaffolds. Polym. Int. 2015, 64, 1289–1302. [Google Scholar] [CrossRef]

- Arif, Z.U.; Khalid, M.Y.; Sheikh, M.F.; Zolfagharian, A.; Bodaghi, M. Biopolymeric sustainable materials and their emerging applications. J. Environ. Chem. Eng. 2022, 10, 108159. [Google Scholar] [CrossRef]

- Yoshie, N.; Nakasato, K.; Fujiwara, M.; Kasuya, K.; Abe, H.; Doi, Y.; Inoue, Y. Effect of Low Molecular Weight Additives on Enzymatic Degradation of Poly(3-Hydroxybutyrate). Polymer 2000, 41, 3227–3234. [Google Scholar] [CrossRef]

- Ibrahim, M.I.; Alsafadi, D.; Alamry, K.A.; Hussein, M.A. Properties and Applications of Poly(3-Hydroxybutyrate-Co-3-Hydroxyvalerate) Biocomposites. J. Polym. Environ. 2021, 29, 1010–1030. [Google Scholar] [CrossRef]

- Bakare, R.A.; Bhan, C.; Raghavan, D. Synthesis and Characterization of Collagen Grafted Poly(Hydroxybutyrate–Valerate) (PHBV) Scaffold for Loading of Bovine Serum Albumin Capped Silver (Ag/BSA) Nanoparticles in the Potential Use of Tissue Engineering Application. Biomacromolecules 2014, 15, 423–435. [Google Scholar] [CrossRef]

- Hammiche, D.; Boukerrou, A.; Ninan, N. Properties of Biocomposites Based on Poly (Hydroxybutyrate-Co-Valerate). In AIP Conference Proceedings; AIP Publishing: Melville, NY, USA, 2018; p. 020117. [Google Scholar]

- Labet, M.; Thielemans, W. Synthesis of Polycaprolactone: A Review. Chem. Soc. Rev. 2009, 38, 3484. [Google Scholar] [CrossRef]

- Sánchez-Safont, E.L.; González-Ausejo, J.; Gámez-Pérez, J.; Lagarón, J.M.; Cabedo, L. Poly(3-Hydroxybutyrate-co-3-Hydroxyvalerate)/Purified Cellulose Fiber Composites by Melt Blending: Characterization and Degradation in Composting Conditions. J. Renew. Mater. 2016, 4, 123–132. [Google Scholar] [CrossRef]

- Balakrishna Pillai, A.; Jaya Kumar, A.; Kumarapillai, H. Biosynthesis of Poly(3-Hydroxybutyrate-Co-3-Hydroxyvalerate) (PHBV) in Bacillus aryabhattai and Cytotoxicity Evaluation of PHBV/Poly(Ethylene Glycol) Blends. 3 Biotech 2020, 10, 32. [Google Scholar] [CrossRef] [PubMed]

- Magalhães, N.F.; Andrade, C.T.D. Properties of Melt-Processed Poly(Hydroxybutyrate-Co-Hydroxyvalerate)/Starch 1:1 Blend Nanocomposites. Polímeros 2013, 23, 366–372. [Google Scholar] [CrossRef]

- Policastro, G.; Panico, A.; Fabbricino, M. Improving Biological Production of Poly(3-Hydroxybutyrate-Co-3-Hydroxyvalerate) (PHBV) Co-Polymer: A Critical Review. Rev. Environ. Sci. Bio/Technol. 2021, 20, 479–513. [Google Scholar] [CrossRef]

- Hassaini, L.; Kaci, M.; Dehouche, N.; Bruzaud, S. A Degradation Study of Poly(3-Hydroxybutyrate-Co-3-Hydroxyvalerate) and Olive Husk Flour Biocomposites under Marine Environment. Macromol. Symp. 2022, 404, 2100353. [Google Scholar] [CrossRef]

- Rosa, D.S.; Franco, B.L.M.; Calil, M.R. Biodegradabilidade e Propriedades Mecânicas de Novas Misturas Poliméricas. Polímeros 2001, 11, 82–88. [Google Scholar] [CrossRef]

- Phukon, P.; Saikia, J.P.; Konwar, B.K. Bio-Plastic (P-3HB-Co-3HV) from Bacillus circulans (MTCC 8167) and Its Biodegradation. Colloids Surf. B Biointerfaces 2012, 92, 30–34. [Google Scholar] [CrossRef] [PubMed]

- Kaniuk, Ł.; Podborska, A.; Stachewicz, U. Enhanced Mechanical Performance and Wettability of PHBV Fiber Blends with Evening Primrose Oil for Skin Patches Improving Hydration and Comfort. J. Mater. Chem. B 2022, 10, 1763–1774. [Google Scholar] [CrossRef]

- Bittolo Bon, S.; Chiesa, I.; Morselli, D.; Degli Esposti, M.; Fabbri, P.; De Maria, C.; Foggi Viligiardi, T.; Morabito, A.; Giorgi, G.; Valentini, L. Printable Smart 3D Architectures of Regenerated Silk on Poly(3-Hydroxybutyrate-Co-3-Hydroxyvalerate). Mater. Des. 2021, 201, 109492. [Google Scholar] [CrossRef]

- Singh, S.; Ghosh, C.; Roy, P.; Pal, K. Biosynthesis of Folic Acid Appended PHBV Modified Copper Oxide Nanorods for PH Sensitive Drug Release in Targeted Breast Cancer Therapy. Int. J. Pharm. 2022, 622, 121831. [Google Scholar] [CrossRef]

- Rodrigues, A.A.; Batista, N.A.; Malmonge, S.M.; Casarin, S.A.; Agnelli, J.A.M.; Santos, A.R.; Belangero, W.D. Osteogenic Differentiation of Rat Bone Mesenchymal Stem Cells Cultured on Poly (Hydroxybutyrate-Co-Hydroxyvalerate), Poly (ε-Caprolactone) Scaffolds. J. Mater. Sci. Mater. Med. 2021, 32, 138. [Google Scholar] [CrossRef] [PubMed]

- Baqeri, N.; Shahsavari, S.; Dahouee, I.A.; Shirmard, L.R. Design of Slow-Release Methotrexate Drug Delivery System Using PHBV Magnetic Nanoparticles and Evaluation of Its Cytotoxicity. J. Drug Deliv. Sci. Technol. 2022, 77, 103854. [Google Scholar] [CrossRef]

- Kaniuk, Ł.; Stachewicz, U. Development and Advantages of Biodegradable PHA Polymers Based on Electrospun PHBV Fibers for Tissue Engineering and Other Biomedical Applications. ACS Biomater. Sci. Eng. 2021, 7, 5339–5362. [Google Scholar] [CrossRef] [PubMed]

- Qahtani, M.; Wu, F.; Misra, M.; Gregori, S.; Mielewski, D.F.; Mohanty, A.K. Experimental Design of Sustainable 3D-Printed Poly(Lactic Acid)/Biobased Poly(Butylene Succinate) Blends via Fused Deposition Modeling. ACS Sustain. Chem. Eng. 2019, 7, 14460–14470. [Google Scholar] [CrossRef]

- Arif, Z.U.; Khalid, M.Y.; Noroozi, R.; Hossain, M.; Shi, H.H.; Tariq, A.; Ramakrishna, S.; Umer, R. Additive Manufacturing of Sustainable Biomaterials for Biomedical Applications. Asian J. Pharm. Sci. 2023, 18, 100812. [Google Scholar] [CrossRef] [PubMed]

- Sá, M.L.D.; Carvalho, É.M.D.; Calvacante, J.; Araque, L.M.; Reis Sobrinho, J.F.; Barbosa, R.; Alves, T.S. Biodegradation of Poly (3-Hydroxybutyrate)/Eggshellsystems. Mater. Res. 2018, 21. [Google Scholar] [CrossRef]

- Ma, W.; Wang, J.; Li, Y.; Yin, L.; Wang, X. Poly(3-Hydroxybutyrate-Co-3-Hydroxyvalerate) Co-Produced with l-Isoleucine in Corynebacterium Glutamicum WM001. Microb. Cell Fact. 2018, 17, 93. [Google Scholar] [CrossRef] [PubMed]

- El-Hadi, A.; Schnabel, R.; Straube, E.; Müller, G.; Henning, S. Correlation between Degree of Crystallinity, Morphology, Glass Temperature, Mechanical Properties and Biodegradation of Poly (3-Hydroxyalkanoate) PHAs and Their Blends. Polym. Test. 2002, 21, 665–674. [Google Scholar] [CrossRef]

- Vinhas, G.M.; Almeida, Y.M.B.D.; Lima, M.A.G.D.A.; Santos, L.A. Estudo Das Propriedades e Biodegradabilidade de Blendas de Poliéster/Amido Submetidas Ao Ataque Microbiano. Quim. Nova 2007, 30, 1584–1588. [Google Scholar] [CrossRef]

- Imre, B.; Pukánszky, B. Compatibilization in Bio-Based and Biodegradable Polymer Blends. Eur. Polym. J. 2013, 49, 1215–1233. [Google Scholar] [CrossRef]

- Samir, A.; Ashour, F.H.; Hakim, A.A.A.; Bassyouni, M. Recent Advances in Biodegradable Polymers for Sustainable Applications. Npj Mater. Degrad. 2022, 6, 68. [Google Scholar] [CrossRef]

- Kumar, R.; Sadeghi, K.; Jang, J.; Seo, J. Mechanical, Chemical, and Bio-Recycling of Biodegradable Plastics: A Review. Sci. Total Environ. 2023, 882, 163446. [Google Scholar] [CrossRef] [PubMed]

- Vroman, I.; Tighzert, L. Biodegradable Polymers. Materials 2009, 2, 307–344. [Google Scholar] [CrossRef]

- Nakajima-Kambe, T.; Edwinoliver, N.G.; Maeda, H.; Thirunavukarasu, K.; Gowthaman, M.K.; Masaki, K.; Mahalingam, S.; Kamini, N.R. Purification, Cloning and Expression of an Aspergillus Niger Lipase for Degradation of Poly(Lactic Acid) and Poly(ε-Caprolactone). Polym. Degrad. Stab. 2012, 97, 139–144. [Google Scholar] [CrossRef]

- Sahu, S.; Kaur, A.; Khatri, M.; Singh, G.; Arya, S.K. A Review on Cutinases Enzyme in Degradation of Microplastics. J. Environ. Manag. 2023, 347, 119193. [Google Scholar] [CrossRef]

- Shi, K.; Jing, J.; Song, L.; Su, T.; Wang, Z. Enzymatic Hydrolysis of Polyester: Degradation of Poly(ε-Caprolactone) by Candida antarctica Lipase and Fusarium solani Cutinase. Int. J. Biol. Macromol. 2020, 144, 183–189. [Google Scholar] [CrossRef]

- Feng, S.; Yue, Y.; Chen, J.; Zhou, J.; Li, Y.; Zhang, Q. Biodegradation Mechanism of Polycaprolactone by a Novel Esterase MGS0156: A QM/MM Approach. Environ. Sci. Process. Impacts 2020, 22, 2332–2344. [Google Scholar] [CrossRef]

- Erdal, N.B.; Lando, G.A.; Yadav, A.; Srivastava, R.K.; Hakkarainen, M. Hydrolytic Degradation of Porous Crosslinked Poly(ε-Caprolactone) Synthesized by High Internal Phase Emulsion Templating. Polymers 2020, 12, 1849. [Google Scholar] [CrossRef]

- Heimowska, A.; Morawska, M.; Bocho-Janiszewska, A. Biodegradation of Poly(ε-Caprolactone) in Natural Water Environments. Polish J. Chem. Technol. 2017, 19, 120–126. [Google Scholar] [CrossRef]

- Sreeja, S.D.; Sailaja, G.S. In Vitro Osteogenic Differentiation and Biomineralization Facet of Phosphorylated Porous Poly(3-Hydroxybutyrate-Co-3-Hydroxyvalerate)/Poly(ε-Caprolactone): An Osteogenic Platform for Regenerative Bone Tissue Engineering. ACS Appl. Polym. Mater. 2023, 5, 8270–8283. [Google Scholar] [CrossRef]

- Saudi, S.; Jun, S.; Fialkova, S.; Surendran, V.; Chandrasekaran, A.; Bhattarai, S.R.; Sankar, J.; Bhattarai, N. Incorporating Nanoconfined Chitin-Fibrils in Poly (ε-caprolactone) Membrane Scaffolds Improves Mechanical and Chemical Properties for Biomedical Application. J. Biomed. Mater. Res. Part A 2023, 111, 1185–1199. [Google Scholar] [CrossRef] [PubMed]

- Espinoza, S.M.; Patil, H.I.; San Martin Martinez, E.; Casañas Pimentel, R.; Ige, P.P. Poly-ε-Caprolactone (PCL), a Promising Polymer for Pharmaceutical and Biomedical Applications: Focus on Nanomedicine in Cancer. Int. J. Polym. Mater. Polym. Biomater. 2020, 69, 85–126. [Google Scholar] [CrossRef]

- Mohamed, R.M.; Yusoh, K. A Review on the Recent Research of Polycaprolactone (PCL). Adv. Mater. Res. 2015, 1134, 249–255. [Google Scholar] [CrossRef]

- Oluwabunmi, K.E.; Zhao, W.; D’Souza, N.A. Carbon Capture Utilization for Biopolymer Foam Manufacture: Thermal, Mechanical and Acoustic Performance of PCL/PHBV CO2 Foams. Polymers 2021, 13, 2559. [Google Scholar] [CrossRef] [PubMed]

- Adams, B.; Abdelwahab, M.; Misra, M.; Mohanty, A.K. Injection-Molded Bioblends from Lignin and Biodegradable Polymers: Processing and Performance Evaluation. J. Polym. Environ. 2018, 26, 2360–2373. [Google Scholar] [CrossRef]

- Voronova, M.I.; Gurina, D.L.; Surov, O.V. Properties of Poly(3-Hydroxybutyrate-Co-3-Hydroxyvalerate)/Polycaprolactone Polymer Mixtures Reinforced by Cellulose Nanocrystals: Experimental and Simulation Studies. Polymers 2022, 14, 340. [Google Scholar] [CrossRef]

- Liu, H.; Gao, Z.; Hu, X.; Wang, Z.; Su, T.; Yang, L.; Yan, S. Blending Modification of PHBV/PCL and Its Biodegradation by Pseudomonas Mendocina. J. Polym. Environ. 2017, 25, 156–164. [Google Scholar] [CrossRef]

- Nevoralová, M.; Koutný, M.; Ujčić, A.; Starý, Z.; Šerá, J.; Vlková, H.; Šlouf, M.; Fortelný, I.; Kruliš, Z. Structure Characterization and Biodegradation Rate of Poly(ε-Caprolactone)/Starch Blends. Front. Mater. 2020, 7, 141. [Google Scholar] [CrossRef]

- Leja, K.; Lewandowicz, G. Polymer Biodegradation and Biodegradable Polymers—A Review. Polish J. Environ. Stud. 2010, 19, 255–266. [Google Scholar]

- Hu, J.-Z.; Zhou, Y.-C.; Huang, L.-H.; Lu, H.-B. Development of Biodegradable Polycaprolactone Film as an Internal Fixation Material to Enhance Tendon Repair: An in Vitro Study. BMC Musculoskelet. Disord. 2013, 14, 246. [Google Scholar] [CrossRef]

- Akter, N.; Khan, R.A.; Salmieri, S.; Sharmin, N.; Dussault, D.; Lacroix, M. Fabrication and Mechanical Characterization of Biodegradable and Synthetic Polymeric Films: Effect of Gamma Radiation. Radiat. Phys. Chem. 2012, 81, 995–998. [Google Scholar] [CrossRef]

- Elsawy, M.A.; Fekry, M.; Sayed, A.M.; Maziad, N.A.; Saad, G.R. Physico-Chemical Characteristics of Biodegradable Poly(Lactic Acid) and Poly(Lactic Acid)/Chitosan Nano-Composites Under the Influence of Gamma Irradiation. J. Polym. Environ. 2023, 31, 2705–2714. [Google Scholar] [CrossRef]

- Gandhi, K.; Kriz, D.; Salovey, R.; Narkis, M.; Wallerstein, R. Crosslinking of Polycaprolactone in the Pre-Gelation Region. Polym. Eng. Sci. 1988, 28, 1484–1490. [Google Scholar] [CrossRef]

- Naikwadi, A.T.; Sharma, B.K.; Bhatt, K.D.; Mahanwar, P.A. Gamma Radiation Processed Polymeric Materials for High Performance Applications: A Review. Front. Chem. 2022, 10, 837111. [Google Scholar] [CrossRef] [PubMed]

- Shiroud Heidari, B.; Ruan, R.; Vahabli, E.; Chen, P.; De-Juan-Pardo, E.M.; Zheng, M.; Doyle, B. Natural, Synthetic and Commercially-Available Biopolymers Used to Regenerate Tendons and Ligaments. Bioact. Mater. 2023, 19, 179–197. [Google Scholar] [CrossRef] [PubMed]

- Oliveira, L.M.; Araujo, P.L.B.; Araujo, E.S. The Effect of Gamma Radiation on Mechanical Properties of Biodegradable Polymers Poly(3-Hydroxybutyrate) and Poly(3-Hydroxybutyrate-Co-3-Hydroxyvalerate). Mater. Res. 2012, 16, 195–203. [Google Scholar] [CrossRef]

- Rosário, F.; Corradini, E.; Casarin, S.A.; Agnelli, J.A.M. Effect of Gamma Radiation on the Properties of Poly(3-Hydroxybutyrate-Co-3-Hydroxyvalerate)/Poly(ε-Caprolactone) Blends. J. Polym. Environ. 2013, 21, 789–794. [Google Scholar] [CrossRef]

- Yang, H.; Liu, J. Thermal Analysis of Poly(3-Hydroxybutyrate-Co-3-Hydroxyvalerate) Irradiated under Vacuum. Polym. Int. 2004, 53, 1677–1681. [Google Scholar] [CrossRef]

- Luk, J.Z.; Rondeau, E.; Trau, M.; Cooper-White, J.; Grøndahl, L. Characterisation of Amine Functionalised Poly(3-Hydroxybuturate-Co-3-Hydroxyvalerate) Surfaces. Polymer 2011, 52, 3251–3258. [Google Scholar] [CrossRef]

- ASTM ASTM D 638-02; Standard Test Method for Tensile Properties of Plastics. ASTM: West Conshohocken, PA, USA, 2002.

- Canevarolo, S.V., Jr. (Ed.) Técnicas de Caracterização de Polímeros; Artliber Editora Ltda: São Paulo, Brazil, 2004. [Google Scholar]

- ASTM ASTM D 4065-95; Standard Practice for Determining and Reporting Dynamic Mechanical Properties of Plastics. ASTM: West Conshohocken, PA, USA, 1995.

- Frisch, M.J.; Trucks, G.W.; Schlegel, H.B.; Scuseria, G.E.; Robb, M.; Cheeseman, J.; Scalmani, G.; Barone, V.; Mennucci, B.; Petersson, G.A.; et al. Gaussian 09 (Revision A02); Gaussian Inc.: Wallingford, CT, USA, 2009. [Google Scholar]

- Sousa, S.F.; Fernandes, P.A.; Ramos, M.J. General Performance of Density Functionals. J. Phys. Chem. A 2007, 111, 10439–10452. [Google Scholar] [CrossRef]

- Legge, F.S.; Nyberg, G.L.; Peel, J.B. DFT Calculations for Cu-, Ag-, and Au-Containing Molecules. J. Phys. Chem. A 2001, 105, 7905–7916. [Google Scholar] [CrossRef]

- Ody, K.S.; de Jesus, J.P.A.; Cava, C.E.; Albuquerque, A.R.; Maia, A.S.; Sambrano, J.R.; La Porta, F.A. Avaliação da Estrutura Eletrônica da Fase Monoclinica do Óxido de Nióbio com Base no uso de Diferentes Funcionais de Densidade. Quim. Nova 2021, 44, 1124–1131. [Google Scholar] [CrossRef]

- Jiménez-Hoyos, C.A.; Janesko, B.G.; Scuseria, G.E. Evaluation of Range-Separated Hybrid Density Functionals for the Prediction of Vibrational Frequencies, Infrared Intensities, and Raman Activities. Phys. Chem. Chem. Phys. 2008, 10, 6621. [Google Scholar] [CrossRef] [PubMed]

- Wolinski, K.; Hinton, J.F.; Pulay, P. Efficient Implementation of the Gauge-Independent Atomic Orbital Method for NMR Chemical Shift Calculations. J. Am. Chem. Soc. 1990, 112, 8251–8260. [Google Scholar] [CrossRef]

- Ditchfield, R. Self-Consistent Perturbation Theory of Diamagnetism. Mol. Phys. 1974, 27, 789–807. [Google Scholar] [CrossRef]

- Lu, T.; Chen, F. Multiwfn: A Multifunctional Wavefunction Analyzer. J. Comput. Chem. 2012, 33, 580–592. [Google Scholar] [CrossRef] [PubMed]

- Lu, T.; Chen, F. Quantitative Analysis of Molecular Surface Based on Improved Marching Tetrahedra Algorithm. J. Mol. Graph. Model. 2012, 38, 314–323. [Google Scholar] [CrossRef]

- Humphrey, W.; Dalke, A.; Schulten, K. VMD: Visual Molecular Dynamics. J. Mol. Graph. 1996, 14, 33–38. [Google Scholar] [CrossRef]

- de Jesus, J.P.A.; Assis, L.C.; de Castro, A.A.; da Cunha, E.F.F.; Nepovimova, E.; Kuca, K.; de Castro Ramalho, T.; La Porta, F.A. Effect of Drug Metabolism in the Treatment of SARS-CoV-2 from an Entirely Computational Perspective. Sci. Rep. 2021, 11, 19998. [Google Scholar] [CrossRef]

- Tubio, C.R.; Valle, X.; Carvalho, E.; Moreira, J.; Costa, P.; Correia, D.M.; Lanceros-Mendez, S. Poly(3-hydroxybutyrate-co-3-hydroxyvalerate) Blends with Poly(caprolactone) and Poly(lactic acid): A Comparative Study. Polymers 2023, 15, 4566. [Google Scholar] [CrossRef]

- Barham, P.J.; Keller, A. The Relationship between Microstructure and Mode of Fracture in Polyhydroxybutyrate. J. Polym. Sci. Part B Polym. Phys. 1986, 24, 69–77. [Google Scholar] [CrossRef]

- Avella, M.; Errico, M.E.; Rimedio, R.; Sadocco, P. Preparation of Biodegradable Polyesters/High-Amylose-Starch Composites by Reactive Blending and Their Characterization. J. Appl. Polym. Sci. 2002, 83, 1432–1442. [Google Scholar] [CrossRef]

- Yoshii, F.; Darwis, D.; Mitomo, H.; Makuuchi, K. Crosslinking of Poly(ε-Caprolactone) by Radiation Technique and Its Biodegradability. Radiat. Phys. Chem. 2000, 57, 417–420. [Google Scholar] [CrossRef]

- Sharma, R.; Ray, A.R. Polyhydroxybutyrate, Its Copolymers and Blends. J. Macromol. Sci. Part C Polym. Rev. 1995, 35, 327–359. [Google Scholar] [CrossRef]

- Aref-Azar, A.; Biddlestone, F.; Hay, J.N.; Haward, R.N. The Effect of Physical Ageing on the Properties of Poly(Ethylene Terephthalate). Polymer 1983, 24, 1245–1251. [Google Scholar] [CrossRef]

- Biddlestone, F.; Harris, A.; Hay, J.N.; Hammond, T. The Physical Ageing of Amorphous Poly(Hydroxybutyrate). Polym. Int. 1996, 39, 221–229. [Google Scholar] [CrossRef]

- Xia, S.; Shen, Y.; Zhou, Y.; Yao, P.; Liu, Q.; Deng, B. Biodegradable Multiblock Copolymers Containing Poly[(3-Hydroxybutyrate)-Co-(3-Hydroxyvalerate)], Poly(ε-Caprolactone), and Polyhedral Oligomeric Silsesquioxane: Synthesis, Characterization, and Tensile Property. Colloid Polym. Sci. 2018, 296, 1667–1677. [Google Scholar] [CrossRef]

- Abdelrazek, E.M.; Hezma, A.M.; El-khodary, A.; Elzayat, A.M. Spectroscopic Studies and Thermal Properties of PCL/PMMA Biopolymer Blend. Egypt. J. Basic Appl. Sci. 2016, 3, 10–15. [Google Scholar] [CrossRef]

- Nanda, M.R.; Misra, M.; Mohanty, A.K. The Effects of Process Engineering on the Performance of PLA and PHBV Blends. Macromol. Mater. Eng. 2011, 296, 719–728. [Google Scholar] [CrossRef]

- Johnson, E.R.; Keinan, S.; Mori-Sánchez, P.; Contreras-García, J.; Cohen, A.J.; Yang, W. Revealing Noncovalent Interactions. J. Am. Chem. Soc. 2010, 132, 6498–6506. [Google Scholar] [CrossRef]

- Silvi, B.; Savin, A. Classification of Chemical Bonds Based on Topological Analysis of Electron Localization Functions. Nature 1994, 371, 683–686. [Google Scholar] [CrossRef]

- Cormanich, R.A.; Santiago, R.T.; La Porta, F.A.; Freitas, M.P.; Rittner, R.; da Cunha, E.F.F.; Andres, J.; Longo, E.; Ramalho, T.C. Quantum chemical topological analysis of hydrogen bonding in HX…HX and CH3X…HX dimers (X = Br, Cl, F). Molecular Simulation. Mol. Simul. 2015, 41, 600–609. [Google Scholar] [CrossRef]

| Materials | PHBV | PCL | |||||||

|---|---|---|---|---|---|---|---|---|---|

| Tm (°C) | ΔHm (J/g) | %C * | Tm (°C) | ΔHm (J/g) | %C * | Tension at Break (MPa) | Deformation at Break (%) | Elastic Modulus (GPa) | |

| PHBV 0 kGy | 157.0 | 39.0 | 26.7 | - | - | - | 4.2 ± 1.0 | 14.2 ± 2.8 | 0.15 ± 0.02 |

| PHBV 50 kGy | 152.5 | 57.0 | 39.0 | - | - | - | 11.8 ± 2.0 | 1.0 ± 0.1 | 0.10 ± 0.02 |

| PHBV 100 kGy | 156.0 | 43.0 | 29.5 | - | - | - | 17.8 ± 2.0 | 1.0 ± 0.1 | 0.11 ± 0.02 |

| PHBV/PCL 0 kGy | 152.0 | 20.0 | 18.3 | 43.0 | 12.0 | 35.3 | 2.0 ± 0.5 | 35.2 ± 5.6 | 0.11 ± 0.03 |

| PHBV/PCL 50 kGy | 149.0 | 32.0 | 29.2 | 36.0 | 9.0 | 26.5 | 3.9 ± 0.9 | 1.1 ± 0.1 | 0.11 ± 0.02 |

| PHBV/PCL 100 kGy | 151.0 | 29.0 | 26.5 | 42.0 | 5.0 | 14.7 | 5.7 ± 0.9 | 1.0 ± 0.1 | 0.15 ± 0.02 |

| Polymer. | Band Gap | Hardness | Softness | Muliken Electronegativity | Electrophilicity |

|---|---|---|---|---|---|

| PHBV | 6.19 | 3.10 | 0.32 | −4.42 | 39.06 |

| PCL | 6.23 | 3.11 | 0.32 | −4.23 | 35.75 |

| BA | 6.19 | 3.10 | 0.32 | −4.43 | 39.30 |

| BB | 6.22 | 3.11 | 0.32 | −4.20 | 35.30 |

| BC | 6.22 | 3.11 | 0.32 | −4.18 | 34.93 |

| BD | 6.22 | 3.11 | 0.32 | −4.18 | 34.95 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Rosario, F.; Almirão de Jesus, J.P.; Casarin, S.A.; La Porta, F.d.A. Influence of γ-Irradiation on the Electronic Structure and the Chemical and Mechanical Properties of Poly(hydroxybutyrate-valerate)/Poly(caprolactone) Blends: Insights from Experimental Data and Computational Approaches. Nanomanufacturing 2024, 4, 27-44. https://doi.org/10.3390/nanomanufacturing4010002

Rosario F, Almirão de Jesus JP, Casarin SA, La Porta FdA. Influence of γ-Irradiation on the Electronic Structure and the Chemical and Mechanical Properties of Poly(hydroxybutyrate-valerate)/Poly(caprolactone) Blends: Insights from Experimental Data and Computational Approaches. Nanomanufacturing. 2024; 4(1):27-44. https://doi.org/10.3390/nanomanufacturing4010002

Chicago/Turabian StyleRosario, Francisco, João Paulo Almirão de Jesus, Suzan Aline Casarin, and Felipe de Almeida La Porta. 2024. "Influence of γ-Irradiation on the Electronic Structure and the Chemical and Mechanical Properties of Poly(hydroxybutyrate-valerate)/Poly(caprolactone) Blends: Insights from Experimental Data and Computational Approaches" Nanomanufacturing 4, no. 1: 27-44. https://doi.org/10.3390/nanomanufacturing4010002

APA StyleRosario, F., Almirão de Jesus, J. P., Casarin, S. A., & La Porta, F. d. A. (2024). Influence of γ-Irradiation on the Electronic Structure and the Chemical and Mechanical Properties of Poly(hydroxybutyrate-valerate)/Poly(caprolactone) Blends: Insights from Experimental Data and Computational Approaches. Nanomanufacturing, 4(1), 27-44. https://doi.org/10.3390/nanomanufacturing4010002