Journal Description

Nanomanufacturing

Nanomanufacturing

is an international, peer-reviewed, open access journal on the fabrication of miniaturized devices or objects, their scalability, and their eventual industrial production, published quarterly online by MDPI.

- Open Access— free for readers, with article processing charges (APC) paid by authors or their institutions.

- Rapid Publication: manuscripts are peer-reviewed and a first decision is provided to authors approximately 28.4 days after submission; acceptance to publication is undertaken in 11.6 days (median values for papers published in this journal in the second half of 2024).

- Recognition of Reviewers: APC discount vouchers, optional signed peer review, and reviewer names published annually in the journal.

- Nanomanufacturing is a companion journal of Nanomaterials.

Latest Articles

High-Aspect-Ratio Shape Replica Mold Fabrication Using Nanoimprinting and Silver Ink as Etching Mask

Nanomanufacturing 2025, 5(1), 2; https://doi.org/10.3390/nanomanufacturing5010002 - 15 Jan 2025

Abstract

Effective high-aspect-ratio molds that minimize vacuum processes are becoming increasingly important for producing metalenses and other devices. To fabricate a high-aspect-ratio structure, a metal film must be used as a mask for dry etching, typically achieved via vacuum deposition. To avoid this vacuum

[...] Read more.

Effective high-aspect-ratio molds that minimize vacuum processes are becoming increasingly important for producing metalenses and other devices. To fabricate a high-aspect-ratio structure, a metal film must be used as a mask for dry etching, typically achieved via vacuum deposition. To avoid this vacuum process, we devised a method to develop an etching mask in the air using silver ink. The manufacturing method involved filling the mold with silver ink, baking it, removing silver from the convex parts of the mold with a polyethylene terephthalate film, and placing silver from the concave parts of the mold on top of the ultraviolet (UV)-cured resin using ultraviolet-nanoimprint lithography. The transferred pattern had silver on the convex parts, which was used as a mask for the oxygen dry etching of the UV-curable resin. Consequently, high-aspect-ratio resin shapes were obtained from three types of nano- and micromolds. Additionally, a high-aspect-ratio resin with silver was used as a replica mold to form a silver pattern. This process is effective and allows high-aspect-ratio patterns to be obtained from master molds.

Full article

(This article belongs to the Special Issue Nanoimprinting and Sustainability)

►

Show Figures

Open AccessArticle

Processing and Characterization of Nickel Matrix Nanocomposites Reinforced with Layered Nickel Aluminide Intermetallics Using Mechanical Alloying and Spark Plasma Sintering

by

Zary Adabavazeh, Amir Hossein Shiranibidabadi, Mohammad Hossein Enayati and Fathallah Karimzadeh

Nanomanufacturing 2025, 5(1), 1; https://doi.org/10.3390/nanomanufacturing5010001 - 10 Jan 2025

Abstract

►▼

Show Figures

This research discusses the fabrication of a nickel matrix nanocomposite reinforced with in situ synthesized layered Ni3Al intermetallics using mechanical alloying (MA) and spark plasma sintering (SPS). In contrast to ex situ methods that frequently produce weak interfaces, the in situ

[...] Read more.

This research discusses the fabrication of a nickel matrix nanocomposite reinforced with in situ synthesized layered Ni3Al intermetallics using mechanical alloying (MA) and spark plasma sintering (SPS). In contrast to ex situ methods that frequently produce weak interfaces, the in situ approach enhances bonding and mechanical performance by using layered Ni3Al reinforcements with excellent deformation resistance and load-bearing potential. Twenty-hour milled Ni-Al powders were annealed at 700 °C and consolidated using SPS, achieving approximately 96% theoretical density. The nanocomposite showed exceptional mechanical properties, with a hardness of 350 ± 15 HV in contrast to 200 ± 5 HV for pure Ni, along with higher wear resistance and reduced wear track depth. These improvements resulted from microstructural refinement and the development of hard intermetallic phases. X-ray diffraction (XRD) and transmission electron microscopy (TEM) confirmed the formation of a homogeneous layered Ni3Al structure inside the matrix, showing a crystallite size of around 40 nm post-milling. Layered reinforcements enhanced matrix–reinforcement interactions, thereby minimizing common challenges in traditional composites. This innovative production technique highlights the future potential of Ni3Al-reinforced nanocomposites as high-performance materials for advanced engineering applications, combining outstanding mechanical and tribological properties with strong structural integrity.

Full article

Figure 1

Open AccessArticle

Advancing Towards Higher Contrast, Energy-Efficient Screens with Advanced Anti-Glare Manufacturing Technology

by

Danielle van der Heijden, Anna Casimiro, Jan Matthijs ter Meulen, Kahraman Keskinbora and Erhan Ercan

Nanomanufacturing 2024, 4(4), 241-248; https://doi.org/10.3390/nanomanufacturing4040016 - 15 Dec 2024

Abstract

The pervasive use of screens, averaging nearly 7 h per day globally between mobile phones, computers, notebooks and TVs, has sparked a growing desire to minimize reflections from ambient lighting and enhance readability in harsh lighting conditions, without the need to increase screen

[...] Read more.

The pervasive use of screens, averaging nearly 7 h per day globally between mobile phones, computers, notebooks and TVs, has sparked a growing desire to minimize reflections from ambient lighting and enhance readability in harsh lighting conditions, without the need to increase screen brightness. This demand highlights a significant need for advanced anti-glare (AG) technologies, to increase comfort and eventually reduce energy consumption of the devices. Currently used production technologies are limited in their texture designs, which can lead to suboptimal performance of the anti-glare texture. To overcome this design limitation and improve the performance of the anti-glare feature, this work reports a new, cost-effective, high-volume production method that enables much needed design freedom over a large area. This is achieved by combining mastering via large-area Laser Beam Lithography (LBL) and replication by Nanoimprint Lithography (NIL) processes. The environmental impact of the production method, such as regards material consumption, are considered, and the full cycle from design to final imprint is discussed.

Full article

(This article belongs to the Special Issue Nanoimprinting and Sustainability)

►▼

Show Figures

Figure 1

Open AccessFeature PaperReview

A Review of Nanostructure Coating Techniques to Achieve High-Precision Optical Fiber Sensing Applications

by

Sooping Kok, YunIi Go, Xu Wang and Dennis Wong

Nanomanufacturing 2024, 4(4), 214-240; https://doi.org/10.3390/nanomanufacturing4040015 - 29 Nov 2024

Abstract

►▼

Show Figures

Optical fiber sensors have emerged as a critical sensing technology across various fields due to their advantages, including high potential bandwidth, electrical isolation that is safe for utilization in electrically hazardous environments, high reliability, and ease of maintenance. However, conventional optical fiber sensors

[...] Read more.

Optical fiber sensors have emerged as a critical sensing technology across various fields due to their advantages, including high potential bandwidth, electrical isolation that is safe for utilization in electrically hazardous environments, high reliability, and ease of maintenance. However, conventional optical fiber sensors face limitations in achieving high sensitivity and precision. The integration of nanostructures with advanced coating technology is one of the critical solutions to enhancing sensor functionality. This review examined nanostructure coating techniques that are compatible with optical fiber sensors and evaluated etching techniques for the improvement of optical fiber sensing technology. Techniques such as vapor deposition, laser deposition, and sputtering to coat the nanostructure of novel materials on the optical fiber sensors are analyzed. The ability of optical fiber sensors to interact with the environment via etching techniques is highlighted by comparing the sensing parameters between etched and bare optical fibers. This comprehensive overview aims to provide a detailed understanding of nanostructure coating and etching for optical fiber sensing and offer insights into the current state and future prospects of optical fiber sensor technology for sensing performance advancement, emphasizing its potential in future sensing applications and research directions.

Full article

Figure 1

Open AccessFeature PaperArticle

Nanoimprinted Polymeric Structured Surfaces for Facilitating Biofilm Formation of Beneficial Bacteria

by

Yuyan Liu, Xavier Ferrer-Florensa, Claus Sternberg, Paul Kempen, Helmut Schift, Lone Gram and Rafael Taboryski

Nanomanufacturing 2024, 4(4), 202-213; https://doi.org/10.3390/nanomanufacturing4040014 - 27 Nov 2024

Abstract

Initial studies indicate that structured polymer surfaces can support the attachment and biofilm formation of bacteria and thereby provide enhanced positive effects of beneficial bacteria, for instance in biocontrol in aquacultures. In this study, we demonstrate a test platform to further explore the

[...] Read more.

Initial studies indicate that structured polymer surfaces can support the attachment and biofilm formation of bacteria and thereby provide enhanced positive effects of beneficial bacteria, for instance in biocontrol in aquacultures. In this study, we demonstrate a test platform to further explore the surface topography for bacterial attachment and biofilm growth. It is based on a cyclic olefin copolymer (COC) materials platform, and nanoimprint technology was used for the replication of microstructures. The use of nanoimprint technology ensures precise micropattern transfer, enabling easy prototyping. Further, the process parameters of the mold preparation and nanoimprinting are discussed, with the purpose of optimizing the polymer pattern profile. This study has the potential to identify promising surfaces for biofilm growth of beneficial bacteria.

Full article

(This article belongs to the Special Issue Nanoimprinting and Sustainability)

►▼

Show Figures

Figure 1

Open AccessFeature PaperArticle

Glucose Oxidation Performance of Zinc Nano-Hexagons Decorated on TiO2 Nanotube Arrays

by

Ke Wang and Hoda Amani Hamedani

Nanomanufacturing 2024, 4(4), 187-201; https://doi.org/10.3390/nanomanufacturing4040013 - 4 Oct 2024

Abstract

►▼

Show Figures

Electrochemically anodized TiO2 nanotube arrays (NTAs) were used as a support material for the electrodeposition of zinc nanoparticles. The morphology, composition, and crystallinity of the materials were examined using scanning electron microscopy (SEM). Electrochemical impedance spectroscopy (EIS) was performed to evaluate the

[...] Read more.

Electrochemically anodized TiO2 nanotube arrays (NTAs) were used as a support material for the electrodeposition of zinc nanoparticles. The morphology, composition, and crystallinity of the materials were examined using scanning electron microscopy (SEM). Electrochemical impedance spectroscopy (EIS) was performed to evaluate the electrochemical properties of TiO2 NTAs. Annealing post-anodization was shown to be effective in lowering the impedance of the TiO2 NTAs (measured at 1 kHz frequency). Zinc nanohexagons (NHexs) with a mean diameter of ~300 nm and thickness of 10–20 nm were decorated on the surface of TiO2 NTAs (with a pore diameter of ~80 nm and tube length of ~5 µm) via an electrodeposition process using a zinc-containing deep eutectic solvent. EIS and CV tests were performed to evaluate the functionality of zinc-decorated TiO2 NTAs (Zn/TiO2 NTAs) for glucose oxidation applications. The Zn/TiO2 NTA electrocatalysts obtained at 40 °C demonstrated enhanced glucose sensitivity (160.8 μA mM−1 cm−2 and 4.38 μA mM−1 cm−2) over zinc-based electrocatalysts reported previously. The Zn/TiO2 NTA electrocatalysts developed in this work could be considered as a promising biocompatible electrocatalyst material for in vivo glucose oxidation applications.

Full article

Figure 1

Open AccessFeature PaperArticle

Assembly and Bilayer Liftoff of Periodic Nanostructures with Sub-20 nm Resolution Using Thermal Scanning Probe Lithography

by

Paloma E. S. Pellegrini, Silvia V. G. Nista and Stanislav Moshkalev

Nanomanufacturing 2024, 4(3), 173-186; https://doi.org/10.3390/nanomanufacturing4030012 - 11 Sep 2024

Abstract

►▼

Show Figures

The demands for high resolution fabrication processes are ever-increasing, with new and optimized methodologies being highly relevant across several scientific fields. We systematically investigated thermal scanning probe lithography process and detailed how tuning temperature and probe contact time on the sample can optimize

[...] Read more.

The demands for high resolution fabrication processes are ever-increasing, with new and optimized methodologies being highly relevant across several scientific fields. We systematically investigated thermal scanning probe lithography process and detailed how tuning temperature and probe contact time on the sample can optimize patterning and achieve 10 nm resolution. Additionally, we propose a novel fabrication methodology that integrates thermal scanning probe lithography and bilayer liftoff, achieving sub-20 nm resolution of the final metallized structures. Each step of the process, from sample preparation to the final liftoff, is described in detail. We also present a quantitative analysis comparing the accuracy of the lithography process to that of the bilayer liftoff. Finally, we show the feasibility of using thermal scanning probe lithography for the fabrication of photonic devices by validating our work with promising dipole geometries for this field.

Full article

Graphical abstract

Open AccessPerspective

Fabrication of Surface Acoustic Wave Biosensors Using Nanomaterials for Biological Monitoring

by

Hongze Zhang, Pu Chen, Liquan Yang, Huan Wang and Zhiyuan Zhu

Nanomanufacturing 2024, 4(3), 159-172; https://doi.org/10.3390/nanomanufacturing4030011 - 16 Aug 2024

Cited by 1

Abstract

►▼

Show Figures

Biosensors are a new type of sensor that utilize biologically sensitive materials and microbially active analytes to measure a variety of biological signals. The purpose of monitoring is achieved by combining these sensitive materials with analytes such as proteins, cells, viruses, and bacteria,

[...] Read more.

Biosensors are a new type of sensor that utilize biologically sensitive materials and microbially active analytes to measure a variety of biological signals. The purpose of monitoring is achieved by combining these sensitive materials with analytes such as proteins, cells, viruses, and bacteria, inducing changes in their physical or chemical properties. The use of nanomaterials in fabricating surface acoustic wave (SAW) biosensors is particularly noteworthy for the label-free detection of organisms due to their compact size, portability, and high sensitivity. Recent advancements in the manufacturing techniques of SAW biosensors have significantly enhanced sensor performance and reliability. These techniques not only ensure precise control over sensor dimensions and material properties but also facilitate scalable and cost-effective production processes. As a result, SAW biosensors are poised to become powerful tools for various clinical and rapid detection applications.

Full article

Figure 1

Open AccessFeature PaperArticle

Effect of Corona Treatment Method to Carvacrol Nanocoating Process for Carvacrol/Halloysite-Nanotube/Low-Density-Polyethylene Active Packaging Films Development

by

Aris E. Giannakas, Vassilios K. Karabagias, Amarildo Ndreka, Aikaterini Dimitrakou, Areti A. Leontiou, Katerina Katerinopoulou, Michael A. Karakassides, Charalampos Proestos and Constantinos E. Salmas

Nanomanufacturing 2024, 4(3), 138-158; https://doi.org/10.3390/nanomanufacturing4030010 - 22 Jul 2024

Abstract

►▼

Show Figures

Active food packaging incorporated with natural plant extracts as food preservatives, which will totally replace chemical preservatives gradually, are of major interest. Sequentially to our and other scientists’ previous work, in this paper we present the results of a study on the development

[...] Read more.

Active food packaging incorporated with natural plant extracts as food preservatives, which will totally replace chemical preservatives gradually, are of major interest. Sequentially to our and other scientists’ previous work, in this paper we present the results of a study on the development of a novel active food packaging film based on the incorporation of a natural-halloysite/carvacrol-extract nanohybrid with the commercially used low-density polyethylene. The corona-treatment procedure was employed to incorporate a natural preservative on to the optimum final film. Packaging films are formatted with and without incorporation of natural-halloysite/carvacrol-extract nanohybrid and are coated externally, directly or via corona-treatment, with carvacrol essential oil. Mechanical, physicochemical, and preservation tests indicated that the low-density polyethylene incorporated perfectly with a natural-halloysite/carvacrol-extract nanohybrid. The extra external coating of the film with pure carvacrol extract using the corona-treatment technique led to approximately 100% higher Young Modulus values, slightly decreased ultimate strength by 20%, and exhibited almost stable elongation at break properties. The water vapor and oxygen properties were increased by 45 and 43%, correspondingly, compared to those of pure low-density polyethylene film. Finally, the antioxidant activity of the corona-treated film increased by 28% compared to the untreated film coated with carvacrol because of the controlled release rate of the carvacrol.

Full article

Figure 1

Open AccessArticle

3D Printing of High-Porosity Membranes with Submicron Pores for Microfluidics

by

Julia K. Hoskins and Min Zou

Nanomanufacturing 2024, 4(3), 120-137; https://doi.org/10.3390/nanomanufacturing4030009 - 27 Jun 2024

Abstract

►▼

Show Figures

In this study, we investigate the potential of two-photon lithography (2PL) as a solution to the challenges encountered in conventional membrane fabrication techniques, aiming to fabricate tailor-made membranes with high-resolution submicron pore structures suitable for advanced applications. This approach led to the development

[...] Read more.

In this study, we investigate the potential of two-photon lithography (2PL) as a solution to the challenges encountered in conventional membrane fabrication techniques, aiming to fabricate tailor-made membranes with high-resolution submicron pore structures suitable for advanced applications. This approach led to the development of fabrication techniques and printed membranes that can be adapted to various lab-on-a-chip (LOC) devices. Membranes were fabricated with pore diameters as small as 0.57 µm and porosities of 4.5%, as well as with larger pores of approximately 3.73 µm in diameter and very high porosities that reached up to 60%. Direct 3D printing of membranes offers a pathway for fabricating structures tailored to specific applications in microfluidics, enabling more efficient separation processes at miniature scales. This research represents a significant step towards bridging the gap between membrane technology and microfluidics, promising enhanced capabilities for a wide array of applications in biotechnology, chemical analysis, and beyond.

Full article

Figure 1

Open AccessFeature PaperArticle

Fabrication and Characterization of Electrochemically Deposited CuIn(Ga)Se2 Solar Cells

by

Hareesh Dondapati and Aswini K. Pradhan

Nanomanufacturing 2024, 4(2), 111-119; https://doi.org/10.3390/nanomanufacturing4020008 - 24 May 2024

Abstract

►▼

Show Figures

We have demonstrated a low-cost and simple method for the fabrication of large-area films using the electrodeposition technique. Fairly superior quality CuIn(Ga)Se2 (CIGS) films were deposited by a one-step electrodeposition method using a salt bath followed by annealing in an argon atmosphere

[...] Read more.

We have demonstrated a low-cost and simple method for the fabrication of large-area films using the electrodeposition technique. Fairly superior quality CuIn(Ga)Se2 (CIGS) films were deposited by a one-step electrodeposition method using a salt bath followed by annealing in an argon atmosphere at 550 °C for 1 h. The X-ray analyses demonstrate that the films are crystalline in nature, having a chalcopyrite phase. However, the conversion efficiencies are found to be lower compared to other methods. Our results indicate that CIGS films can be produced effectively via a one-step electrodeposition method. The observed morphology can have a great impact on solar cell efficiency. With suitable modifications, this simple and cheaper manufacturing process will be the best alternative method to the vacuum deposition technique for the fabrication of reliable and flexible CIGS solar cells in the near future.

Full article

Graphical abstract

Open AccessArticle

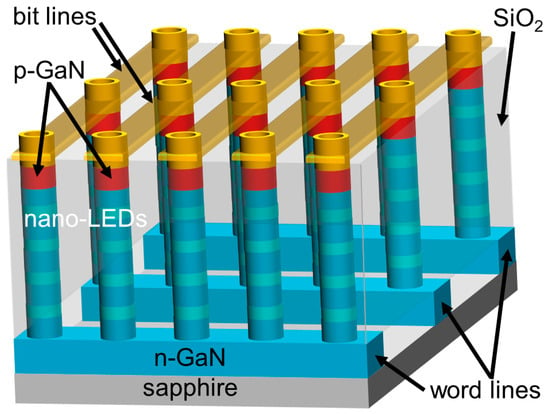

Developments in Mask-Free Singularly Addressable Nano-LED Lithography

by

Martin Mikulics, Andreas Winden, Joachim Mayer and Hilde Helen Hardtdegen

Nanomanufacturing 2024, 4(2), 99-110; https://doi.org/10.3390/nanomanufacturing4020007 - 22 Apr 2024

Cited by 2

Abstract

LED devices are increasingly gaining importance in lithography approaches due to the fact that they can be used flexibly for mask-less patterning. In this study, we briefly report on developments in mask-free lithography approaches based on nano-LED devices and summarize our current achievements

[...] Read more.

LED devices are increasingly gaining importance in lithography approaches due to the fact that they can be used flexibly for mask-less patterning. In this study, we briefly report on developments in mask-free lithography approaches based on nano-LED devices and summarize our current achievements in the different building blocks needed for its application. Individually addressable nano-LED structures can form the basis for an unprecedented fast and flexible patterning, on demand, in photo-chemically sensitive films. We introduce a driving scheme for nano-LEDs in arrays serving for a singularly addressable approach. Furthermore, we discuss the challenges facing nano-LED fabrication and possibilities to improve their performance. Additionally, we introduce LED structures based on a hybrid nanocrystal/nano-LED approach. Lastly, we provide an outlook how this approach could further develop for next generation lithography systems. This technique has a huge potential to revolutionize the field and to contribute significantly to energy and resources saving device nanomanufacturing.

Full article

(This article belongs to the Special Issue Feature Papers for Nanomanufacturing in 2023)

►▼

Show Figures

Figure 1

Open AccessArticle

Solution-Processed Bilayered ZnO Electron Transport Layer for Efficient Inverted Non-Fullerene Organic Solar Cells

by

Walia Binte Tarique, Md Habibur Rahaman, Shahriyar Safat Dipta, Ashraful Hossain Howlader and Ashraf Uddin

Nanomanufacturing 2024, 4(2), 81-98; https://doi.org/10.3390/nanomanufacturing4020006 - 1 Apr 2024

Cited by 2

Abstract

►▼

Show Figures

Organic solar cells (OSCs) are becoming increasingly popular in the scientific community because of their many desirable properties. These features include solution processability, low weight, low cost, and the ability to process on a wide scale using roll-to-roll technology. Enhancing the efficiency of

[...] Read more.

Organic solar cells (OSCs) are becoming increasingly popular in the scientific community because of their many desirable properties. These features include solution processability, low weight, low cost, and the ability to process on a wide scale using roll-to-roll technology. Enhancing the efficiency of photovoltaic systems, particularly high-performance OSCs, requires study into not only material design but also interface engineering. This study demonstrated that two different types of OSCs based on the PTB7-Th:IEICO-4F and PM6:Y6 active layers use a ZnO bilayer electron transport layer (ETL). The ZnO bilayer ETL comprises a ZnO nanoparticle (ZnO NP) and a ZnO layer created from a sol-gel. The effect of incorporating ZnO NPs into the electron transport layer (ETL) was studied; in particular, the effects on the electrical, optical, and morphological properties of the initial ZnO ETL were analyzed. The ability of ZnO films to carry charges is improved by the addition of ZnO nanoparticles (NPs), which increase their conductivity. The bilayer structure had better crystallinity and a smoother film surface than the single-layer sol-gel ZnO ETL. This led to a consistent and strong interfacial connection between the photoactive layer and the electron transport layer (ETL). Therefore, inverted organic solar cells (OSCs) with PTB7-Th:IEICO-4F and PM6:Y6 as photoactive layers exhibit improved power conversion efficiency and other photovoltaic properties when using the bilayer technique.

Full article

Figure 1

Open AccessArticle

UV Nanoimprint Lithography—Impact of Coating Techniques on Pattern Quality

by

Johanna Rimböck, Patrick Schuster, Lisa Vsetecka and Christine Thanner

Nanomanufacturing 2024, 4(1), 69-80; https://doi.org/10.3390/nanomanufacturing4010005 - 14 Mar 2024

Abstract

In this work, three different coating techniques are compared and their applicability for ultraviolet nanoimprint lithography (UV-NIL) is investigated. As UV-NIL is considered a suitable volume manufacturing production solution for various emerging applications, it is mandatory to consider environmental aspects such as operational

[...] Read more.

In this work, three different coating techniques are compared and their applicability for ultraviolet nanoimprint lithography (UV-NIL) is investigated. As UV-NIL is considered a suitable volume manufacturing production solution for various emerging applications, it is mandatory to consider environmental aspects such as operational energy use and material consumption as well as waste management. In this paper, spin coating, spray coating, and inkjet coating are used to coat both a high refractive index resin (n = 1.9) and a filler-free resin (n = 1.5), respectively. Variable Angle Spectroscopy Ellipsometry (VASE) was used to analyze the influence of different process parameters on the resin thickness as well as to compare the refractive index achieved from each coating technology. Finally, the applicability of the different coating methods for UV-NIL was investigated by imprinting the resin layers with different test structures. For the final imprints, the resolution, the surface roughness, and the pattern fidelity over 25 imprints was assessed using AFM. Finally, a comparison of the resin consumption and the process time was performed for each coating method.

Full article

(This article belongs to the Special Issue Nanoimprinting and Sustainability)

►▼

Show Figures

Figure 1

Open AccessArticle

Influence of Anodic Aluminum Oxide Nanostructures on Resistive Humidity Sensing

by

Chin-An Ku, Chia-Wei Hung and Chen-Kuei Chung

Nanomanufacturing 2024, 4(1), 58-68; https://doi.org/10.3390/nanomanufacturing4010004 - 8 Mar 2024

Cited by 2

Abstract

Humidity nanosensors play a vital role in modern technology industries, including weather forecasts, industrial manufacturing, agriculture, food and chemistry storage. In recent years, research on humidity sensors has focused on different materials such as ceramics, polymers, carbon-based materials, semiconductors, MXenes or triboelectric nanogenerators,

[...] Read more.

Humidity nanosensors play a vital role in modern technology industries, including weather forecasts, industrial manufacturing, agriculture, food and chemistry storage. In recent years, research on humidity sensors has focused on different materials such as ceramics, polymers, carbon-based materials, semiconductors, MXenes or triboelectric nanogenerators, each with their own advantages and disadvantages. Among them, anodic aluminum oxide (AAO) is a well-known ceramic humidity sensor material with a long history of research and development. AAO humidity sensors offer advantages such as simple manufacturing processes, controllable nanostructures, high thermal stability and biocompatibility. However, traditional AAO fabrication still has disadvantages like high costs and longer process times. Hence, finding a low-cost and efficient method to fabricate AAO for controlling different nanostructures to meet the requirements is consistently a major research topic. From our previous studies, we have studied the relationship between the AAO capacitive humidity sensor and its nanostructures. In this paper, we explore the effect of an AAO nanoporous structure controlled by an anodization voltage of 20–40 V on the resistive-type humidity sensor performance instead of a capacitive one. We efficiently apply one-step hybrid pulse anodization at 25 °C to significantly reduce the processing time compared to the traditional two-step process under 0–10 °C. The AAO nanostructures and their impact on sensor measurements of humidity at 20–80 RH% will be discussed in detail. An electrical resistive sensing mechanism is established for further performance improvement by controlling anodization voltage.

Full article

(This article belongs to the Special Issue Feature Papers for Nanomanufacturing in 2023)

►▼

Show Figures

Figure 1

Open AccessArticle

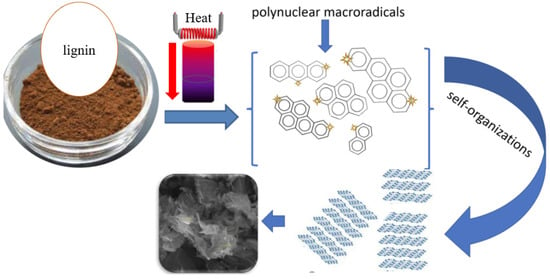

Safe Explosion Works Promoted by 2D Graphene Structures Produced under the Condition of Self-Propagation High-Temperature Synthesis

by

Alexander Petrovich Voznyakovskii, Mikhail Alekseevich Ilyushin, Aleksei Alexandrovich Vozniakovskii, Irina Vladimirovna Shugalei and Georgy Georgievich Savenkov

Nanomanufacturing 2024, 4(1), 45-57; https://doi.org/10.3390/nanomanufacturing4010003 - 8 Feb 2024

Cited by 1

Abstract

►▼

Show Figures

The paper presents the results of a study on the effectiveness of few-layer graphene synthesized under SHS conditions from lignin as a modifying additive in creating composite pyrotechnic complexes based on porous silicon and calcium perchlorate. It was found that the addition of

[...] Read more.

The paper presents the results of a study on the effectiveness of few-layer graphene synthesized under SHS conditions from lignin as a modifying additive in creating composite pyrotechnic complexes based on porous silicon and calcium perchlorate. It was found that the addition of few-layer graphene (20–30 wt. %) could significantly increase the probability of the ignition of pyrotechnic compositions by laser diode (infrared) radiation (wavelength of 976 nm and power of 15 MW/m2) compared to the initial pyrotechnic compositions. Using few-layer graphene also leads to a sharp increase in sensitivity to infrared laser radiation and the initiation of explosive transformations in retrofitted pyrotechnic compositions compared to the initial pyrotechnic compositions. Due to the high productivity and low cost of the technique for synthesizing few-layer graphene, the use of composite pyrotechnic compositions modified with few-layer graphene is profitable in the actual industry. A phenomenological model of the formation mechanism of 2D graphene structures under the conditions of the SHS process is proposed.

Full article

Figure 1

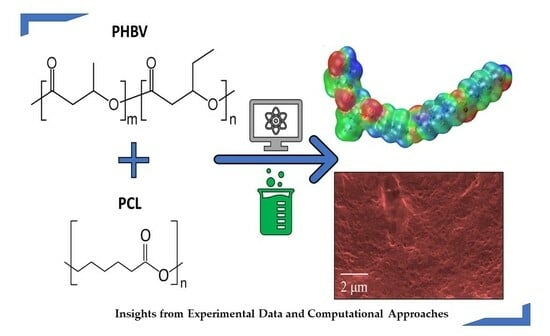

Open AccessArticle

Influence of γ-Irradiation on the Electronic Structure and the Chemical and Mechanical Properties of Poly(hydroxybutyrate-valerate)/Poly(caprolactone) Blends: Insights from Experimental Data and Computational Approaches

by

Francisco Rosario, João Paulo Almirão de Jesus, Suzan Aline Casarin and Felipe de Almeida La Porta

Nanomanufacturing 2024, 4(1), 27-44; https://doi.org/10.3390/nanomanufacturing4010002 - 10 Jan 2024

Abstract

►▼

Show Figures

In this study, we investigated the influence of γ-irradiation (0, 50, and 100 kGy) doses on the chemical and mechanical properties of biodegradable poly(hydroxybutyrate-valerate)/poly(caprolactone) (PHBV/PCL) polymer blends rich in low-molar-mass PCL, which were prepared using a co-rotating twin-screw extruder. In parallel, the density

[...] Read more.

In this study, we investigated the influence of γ-irradiation (0, 50, and 100 kGy) doses on the chemical and mechanical properties of biodegradable poly(hydroxybutyrate-valerate)/poly(caprolactone) (PHBV/PCL) polymer blends rich in low-molar-mass PCL, which were prepared using a co-rotating twin-screw extruder. In parallel, the density functional theory (DFT) and the time-dependent DFT (TD-DFT) methods were used together with a model containing four monomer units to provide an insight into the electronic structure, chemical bonds, and spectroscopic (such as Nuclear Magnetic Resonance (NMR) and Ultraviolet-visible (UV-vis)) properties of PHBV and PCL blend phases, which are critical for predicting and designing new materials with desired properties. We found that an increase in γ-irradiation doses caused splitting instead of crosslinks in the polymer chains, which led to evident deformation and an increase in tensile strength at break of 2.0 to 5.7 MPa for the PHBV/PCL blend. Further, this led to a decrease in crystallinity and proved the occurrence of a more favorable interaction between the blend phases.

Full article

Graphical abstract

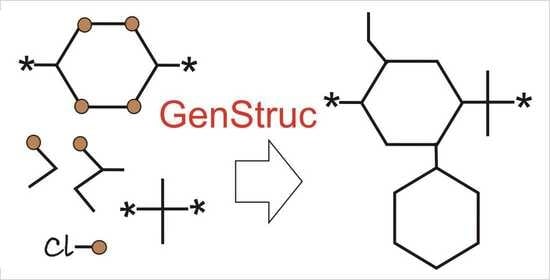

Open AccessArticle

New Polymers In Silico Generation and Properties Prediction

by

Andrey A. Knizhnik, Pavel V. Komarov, Boris V. Potapkin, Denis B. Shirabaykin, Alexander S. Sinitsa and Sergey V. Trepalin

Nanomanufacturing 2024, 4(1), 1-26; https://doi.org/10.3390/nanomanufacturing4010001 - 19 Dec 2023

Cited by 1

Abstract

We present a theoretical approach for the in silico generation of new polymer structures for the systematic search for new materials with advanced properties. It is based on Bicerano’s Regression Model (RM), which uses the structure of the smallest repeating unit (SRU) for

[...] Read more.

We present a theoretical approach for the in silico generation of new polymer structures for the systematic search for new materials with advanced properties. It is based on Bicerano’s Regression Model (RM), which uses the structure of the smallest repeating unit (SRU) for fast and adequate prediction of polymer properties. We have developed the programs (a) GenStruc, for generating the new polymer SRUs using the enumeration and Monte Carlo algorithms, and (b) PolyPred, for predicting properties for a given input polymer as well as for multiple structures stored in the database files. The structure database from the original Bicerano publication is used to create databases of backbones and pendant groups. A database of 5,142,153 unique SRUs is generated using the scaffold-based combinatorial method. We show that using only known backbones of the polymer SRU and varying the pendant groups can significantly improve the predicted extreme values of polymer properties. Analysis of the obtained results for the dielectric constant and refractive index shows that the values of the dielectric constant are higher for polyhydrazides than for polyhydroxylamines. The high value predicted for the refractive index of polythiophene and its derivatives is in agreement with the experimental data.

Full article

(This article belongs to the Special Issue Nanomanufacturing Empowered with Artificial Intelligence)

►▼

Show Figures

Graphical abstract

Open AccessArticle

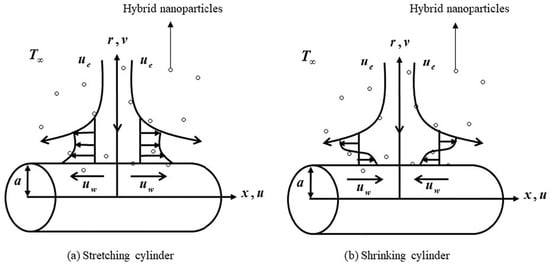

Effects of Variable Viscosity in Unsteady Magnetohydrodynamic Hybrid Nanofluid Flow over Stretching/Shrinking Cylinder with Partial Slip and Stefan Blowing

by

Jagan Kandasamy, Manoj Kumar Narayanaswamy and Sivasankaran Sivanandam

Nanomanufacturing 2023, 3(4), 434-445; https://doi.org/10.3390/nanomanufacturing3040027 - 30 Nov 2023

Cited by 1

Abstract

►▼

Show Figures

In the manufacturing sector, transport phenomena near the stagnation region are frequent, particularly in the polymer and extrusion processes, which require continuous improvement to raise the process’s quality standards. The aim of this study is to explore the improvement of heat and mass

[...] Read more.

In the manufacturing sector, transport phenomena near the stagnation region are frequent, particularly in the polymer and extrusion processes, which require continuous improvement to raise the process’s quality standards. The aim of this study is to explore the improvement of heat and mass transmission using unsteady magnetohydrodynamic (MHD) hybrid nanofluid (HNF) flow over a stretching/shrinking cylinder with variable viscosity and Stefan blowing. The governed equations of heat and mass transfer processes are converted into ordinary differential equations (ODEs) using the appropriate transformations, and the resulting equations are then solved using the MATLAB package bvp4c. With an upsurge in the volume fraction of nanoparticles, the skin friction increases, but the reverse trend is detected with negative values for the unsteadiness constraint. The use of 2D graphs to show how important parameters affect the velocity, temperature, and concentration is thoroughly discussed. There is a discussion of the quantitative findings from the wall shear factor and the heat and mass transfer rates calculated for the stretching/shrinking cases.

Full article

Figure 1

Open AccessArticle

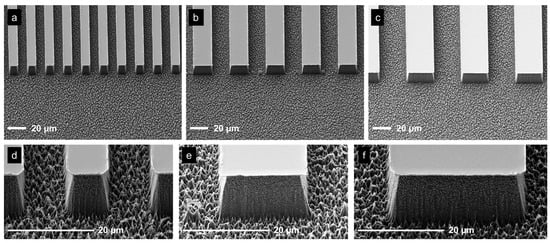

Nanoimprinted Hierarchical Micro-/Nanostructured Substrates for the Growth of Cardiomyocyte Fibers

by

Michael M. Mühlberger, Sonja Kopp, Alison A. Deyett, Markus Pribyl, Michael J. Haslinger, Anica M. Siegel, Philipp Taus, Elena Guillén, Aranxa Torres-Caballero, Bozhidar Baltov, Michael A. Netzer, Sonia Prado-López, Leif Yde, Jan Stensborg, Sasha Mendjan, Steffen Hering and Heinz D. Wanzenboeck

Nanomanufacturing 2023, 3(4), 416-433; https://doi.org/10.3390/nanomanufacturing3040026 - 7 Nov 2023

Cited by 2

Abstract

Investigating the behavior of cardiomyocytes is an important part of drug development. We present a structure and a related nanoimprint-based fabrication method, where the cardiomyocytes form isolated fibers, which is beneficial for drug testing, more closely representing the structure of the cardiomyocytes in

[...] Read more.

Investigating the behavior of cardiomyocytes is an important part of drug development. We present a structure and a related nanoimprint-based fabrication method, where the cardiomyocytes form isolated fibers, which is beneficial for drug testing, more closely representing the structure of the cardiomyocytes in vivo. We found that channel structures with walls with a rough top surface stimulate cardiomyocytes to form such fibers, as desired. Nanoimprint lithography is used as a fast and cost-efficient method to fabricate our hierarchically structured cell growth substrates.

Full article

(This article belongs to the Special Issue Nanoimprinting and Sustainability)

►▼

Show Figures

Figure 1

Highly Accessed Articles

Latest Books

E-Mail Alert

News

Topics

Topic in

Nanomaterials, Polymers, Photonics, Nanomanufacturing, Crystals, Applied Sciences

Nanomaterials for Photonics and Optoelectronics: Practical Applications and Advances

Topic Editors: Luciana R. P. Kassab, Raul Rangel-Rojo, Rafael Salas-MontielDeadline: 31 May 2026

Topic in

Micromachines, Nanomanufacturing, Nanomaterials, Processes, Sustainability

Innovative Synthesis and Applications of Functional Nanomaterials

Topic Editors: Paulraj Arunkumar, Arun ThirumuruganDeadline: 31 August 2026

Conferences

Special Issues

Special Issue in

Nanomanufacturing

Nanomanufacturing: Feature Papers 2024

Guest Editor: Candido Fabrizio PirriDeadline: 28 February 2025

Special Issue in

Nanomanufacturing

Nanostructures for Energy Storage

Guest Editors: Bunshi Fugetsu, Ling Sun, Yanqing Wang, Zhipeng WangDeadline: 30 April 2025

Special Issue in

Nanomanufacturing

Nanoimprinting: From Micro to Nano

Guest Editor: Michael MühlbergerDeadline: 30 September 2025