Continuous Separation of Light Olefin/Paraffin Mixtures on ZIF-4 by Pressure Swing Adsorption and Membrane Permeation

Abstract

:1. Introduction

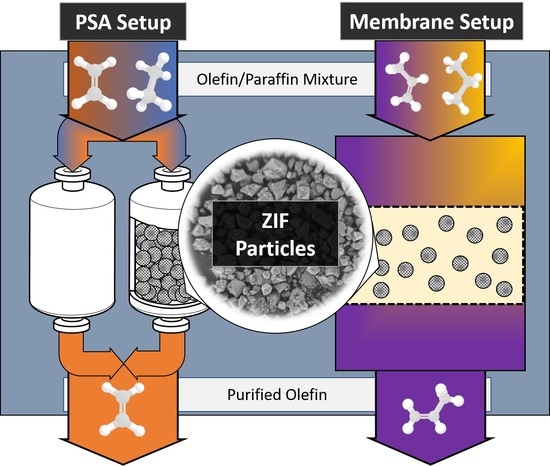

2. Results and Discussion

2.1. Isotherms

2.2. Continuous Separation of Ethane/Ethene

2.3. Continuous Separation of Propane/Propene with MMMs

3. Experimental Section

3.1. Porous Adsorbents

3.1.1. ZIF-4

3.1.2. ZIF-Zni

3.2. Mixed Matrix Membranes

3.3. Apparatus for High-Pressure and Mixed Isotherms

3.4. The Pressure Swing Adsorption Setup

3.5. Membrane Setup

4. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Hartman, M.; Kunz, S.; Himsl, D.; Tangermann, O.; Wagener, A.; Ernst, S. Adsorptive Separation of Isobutene and Isobutane on Cu3(BTC)2. Langmuir 2013, 24, 8634–8642. [Google Scholar] [CrossRef] [PubMed]

- Bendt, S.; Hovestadt, M.; Böhme, U.; Paula, C.; Döpken, M.; Hartmann, M.; Keil, F.J. Olefin/Paraffin Separation Potential of ZIF-9 and ZIF-71: A Combined Experimental and Theoretical Study. Eur. J. Inorg. Chem. 2016, 2016, 4440–4449. [Google Scholar] [CrossRef]

- Hovestadt, M.; Bendt, S.; Mondal, S.S.; Behrens, K.; Reif, F.; Döpken, M.; Holdt, H.-J.; Keil, F.J.; Hartmann, M. Experimental and theoretical analysis of the influence of different linker molecules in Imidazolate Frameworks Potsdam (IFP-n) on the separation of olefin-paraffin mixtures. Langmuir 2017, 33, 11170–11179. [Google Scholar] [CrossRef] [PubMed]

- Hartmann, M.; Böhme, U.; Hovestadt, M.; Paula, C. Adsorptive Separation of Olefin/Paraffin Mixtures with ZIF-4. Langmuir 2015, 31, 12382–12389. [Google Scholar] [CrossRef] [PubMed]

- Narin, G.; Martins, V.F.D.; Campo, M.; Ribeiro, A.M.; Ferreira, A.; Santos, J.C.; Schumann, K.; Rodrigues, A.E. Light olefins/paraffins separation with 13X zeolite binderless beads. Sep. Purif. Technol. 2014, 133, 452–475. [Google Scholar] [CrossRef]

- Geier, S.J.; Mason, J.A.; Bloch, E.D.; Queen, W.L.; Hudson, M.R.; Brown, C.M.; Long, J.R. Selective adsorption of ethylene over ethane and propylene over propane in the metal-organic frameworks M2(dobdc) (M = Mg, Mn, Fe, Co., Ni, Zn). Chem. Sci. 2013, 4, 2054–2061. [Google Scholar] [CrossRef]

- Böhme, U.; Barth, B.; Paula, C.; Kuhnt, A.; Schwieger, W.; Mundstock, A.; Caro, J.; Hartmann, M. Ethene/Ethane and Propene/Propane Separation via the Olefin and Paraffin Selective Metal-Organic Framework Adsorbents CPO-27 and ZIF-8. Langmuir 2013, 29, 8592–8600. [Google Scholar] [CrossRef] [PubMed]

- Plaza, M.G.; Ferreira, A.F.P.; Santos, J.C.; Ribeiro, A.M.; Müller, U.; Trukhan, N.; Loureiro, J.M.; Rodrigues, A.E. Propane/propylene separation by adsorption using shaped copper trimesate MOF. Microporous Mesoporous Mater. 2012, 157, 101–111. [Google Scholar] [CrossRef]

- Dewar, J. A review of the pi-complex theory. Bull. Soc. Chim. Fr. 1951, 18, C71–C79. [Google Scholar]

- Chatt, J.; Duncanson, L.A. 586. Olefin co-ordination compounds. Part III. Infra-red spectra and structure: Attempted preparation of acetylene complexes. J. Chem. Soc. (Resumed) 1953, 2939–2947. [Google Scholar] [CrossRef]

- Gucuyener, C.; van den Bergh, J.; Gascon, J.; Kapteijn, F. Ethane/Ethene Separation Turned on Its Head: Selective Ethane Adsorption on the Metal-Organic Framework ZIF-7 through a Gate-Opening Mechanism. J. Am. Chem. Soc. 2010, 132, 17704–17706. [Google Scholar] [CrossRef] [PubMed]

- Fu, H.-R.; Wang, F.; Zhang, J. A stable zinc-4-carboxypyrazole framework with high uptake and selectivity of light hydrocarbons. Dalton Trans. 2015, 44, 2893–2896. [Google Scholar] [CrossRef] [PubMed]

- He, Y.; Song, C.; Ling, Y.; Wu, C.; Krishna, R.; Chen, B. A new MOF-5 homologue for selective separation of methane from C2 hydrocarbons at room temperature. APL Mater. 2014, 2, 124102. [Google Scholar] [CrossRef]

- Chen, Y.; Qiao, Z.; Wu, H.; Lv, D.; Shi, R.; Xia, Q.; Zhou, J.; Li, Z. An ethane-trapping MOF PCN-250 for highly selective adsorption of ethane over ethylene. Chem. Eng. Sci. 2018, 175, 110–117. [Google Scholar] [CrossRef]

- Liang, W.; Zhang, Y.; Wang, X.; Wu, Y.; Zhou, X.; Xiao, J.; Li, Y.; Wang, H.; Li, Z. Asphalt-derived high surface area activated porous carbons for the effective adsorption separation of ethane and ethylene. Chem. Eng. Sci. 2017, 162, 192–202. [Google Scholar] [CrossRef]

- Jakobtorweihen, S.; Keil, F.J. Adsorption of alkanes, alkenes and their mixtures in single-walled carbon nanotubes and bundles. Mol. Simul. 2009, 35, 90–99. [Google Scholar] [CrossRef]

- Hovestadt, M.; Schmitz, J.V.; Weissenberger, T.; Reif, F.; Kaspereit, M.; Schwieger, W.; Hartmann, M. Scale-up of the Synthesis of Zeolitic Imidazolate Framework ZIF-4. Chem. Ing. Tech. 2017, 89, 1374–1378. [Google Scholar] [CrossRef]

- Phan, A.; Doonan, C.J.; Uribe-Romo, F.J.; Knobler, C.B.; Okeeffe, M.; Yaghi, O.M. Synthesis, structure, and carbon dioxide capture properties of zeolitic imidazolate frameworks. Acc. Chem. Res. 2010, 43, 58–67. [Google Scholar] [CrossRef] [PubMed]

- Jee, J.-G.; Kim, M.-B.; Lee, C.-H. Pressure swing adsorption processes to purify oxygen using a carbon molecular sieve. Chem. Eng. Sci. 2005, 60, 869–882. [Google Scholar] [CrossRef]

- Shah, M.; Mondal, P.; Nayak, A.; Bordoloi, A. Hydrogen from Natural Gas. In Sustainable Utilization of Natural Resources; CRC Press: Boca Raton, FL, USA, 2017; pp. 81–120. [Google Scholar]

- Martins, V.F.D.; Ribeiro, A.M.; Santos, J.C.; Loureiro, J.M.; Gleichmann, K.; Ferreira, A.; Rodrigues, A.E. Development of gas-phase SMB technology for light olefin/paraffin separations. AIChE J. 2016, 62, 2490–2500. [Google Scholar] [CrossRef]

- Nandi, S.; Haldar, S.; Chakraborty, D.; Vaidhyanathan, R. Strategically designed azolyl-carboxylate MOFs for potential humid CO2 capture. J. Mater. Chem. A 2017, 5, 535–543. [Google Scholar] [CrossRef]

- Friebe, S.; Mundstock, A.; Unruh, D.; Renz, F.; Caro, J. NH2-MIL-125 as membrane for carbon dioxide sequestration: Thin supported MOF layers contra Mixed-Matrix-Membranes. J. Membr. Sci. 2016, 516, 185–193. [Google Scholar] [CrossRef]

- Pan, Y.; Li, T.; Lestari, G.; Lai, Z. Effective separation of propylene/propane binary mixtures by ZIF-8 membranes. J. Membr. Sci. 2012, 390, 93–98. [Google Scholar] [CrossRef]

- Mundstock, A.; Wang, N.; Friebe, S.; Caro, J. Propane/propene permeation through Na-X membranes: The interplay of separation performance and pre-synthetic support functionalization. Microporous Mesoporous Mater. 2015, 215, 20–28. [Google Scholar] [CrossRef]

- Bhave, R.; Kuritz, T.; Powell, L.; Adcock, D. Membrane-Based Energy Efficient Dewatering of Microalgae in Biofuels Production and Recovery of Value Added Co-Products. Environ. Sci. Technol. 2012, 46, 5599–5606. [Google Scholar] [CrossRef] [PubMed]

- Merkel, T.C.; Bondar, V.I.; Nagai, K.; Freeman, B.D.; Pinnau, I. Gas sorption, diffusion, and permeation in poly(dimethylsiloxane). J. Polym. Sci. Part B Polym. Phys. 2000, 38, 415–434. [Google Scholar] [CrossRef]

- Dechnik, J.; Gascon, J.; Doonan, C.J.; Janiak, C.; Sumby, C.J. Mixed-Matrix Membranes. Angew. Chem. Int. Ed. 2017, 56, 9292–9310. [Google Scholar] [CrossRef] [PubMed]

- Seoane, B.; Coronas, J.; Gascon, I.; Benavides, M.E.; Karvan, O.; Caro, J.; Kapteijn, F.; Gascon, J. Metal-organic framework based mixed matrix membranes: A solution for highly efficient CO2 capture? Chem. Soc. Rev. 2015, 44, 2421–2454. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Zhang, Y.; Feng, X.; Yuan, S.; Zhou, J.; Wang, B. Challenges and recent advances in MOF-polymer composite membranes for gas separation. Inorg. Chem. Front. 2016, 3, 896–909. [Google Scholar] [CrossRef]

- Galizia, M.; Chi, W.S.; Smith, Z.P.; Merkel, T.C.; Baker, R.W.; Freeman, B.D. 50th Anniversary Perspective: Polymers and Mixed Matrix Membranes for Gas and Vapor Separation: A Review and Prospective Opportunities. Macromolecules 2017, 50, 7809–7843. [Google Scholar] [CrossRef]

- Thommes, M.; Kaneko, K.; Alexander, V.N.; James, P.O.; Rodriguez-Reinoso, F.; Rouquerol, J.; Kenneth, S.W.S. Physisorption of gases, with special reference to the evaluation of surface area and pore size distribution (IUPAC Technical Report). In Pure and Applied Chemistry; IUPAC Blackwell Science: Research Triangle Park, NC, USA, 2015; Volume 87, p. 1051. [Google Scholar]

- Reich, R.; Ziegler, W.T.; Rogers, K.A. Adsorption of Methane, Ethane, and Ethylene Gases and Their Binary and Ternary Mixtures and Carbon Dioxide on Activated Carbon at 212–301 K and Pressures to 35 Atmospheres. Ind. Eng. Chem. Process Des. Dev. 1980, 19, 336–344. [Google Scholar] [CrossRef]

- Szepesy, L.; Illes, V. Adsorption of gases and gas mixtures. III. Investigation of the adsorption equilibria of binary gas mixtures. Acta Chim. Hung. Tomus 1963, 35, 245. [Google Scholar]

- Kaul, B.K. A modern version of volumetric apparatus for measuring gas-solid equilibrium data. Ind. Eng. Chem. Res. 1987, 26, 928–933. [Google Scholar] [CrossRef]

- Sakurovs, R.; Day, S.; Weir, S. Relationships between the critical properties of gases and their high pressure sorption behavior on coals. Energy Fuels 2010, 24, 1781–1787. [Google Scholar] [CrossRef]

- Polanyi, M. Adsorption from the point of view of the Third Law of Thermodynamics. Verh. Deut. Phys. Ges. 1914, 16, 1012–1016. [Google Scholar]

- Bennett, T.D.; Keen, D.A.; Tan, J.-C.; Barney, E.R.; Goodwin, A.L.; Cheetham, A.K. Thermal Amorphization of Zeolitic Imidazolate Frameworks. Angew. Chem. Int. Ed. 2011, 50, 3067–3071. [Google Scholar] [CrossRef] [PubMed]

- Ruthven, D.M.; Farooq, S.; Knaebel, K.S. Pressure Swing Adsorption; VCH Publishers: Weinheim, Germany, 1994; p. 352. [Google Scholar]

- Skarstrom, C.W. Method and Apparatus for Fractionating Gaseous Mixtures by Adsorption. Google Patents. U.S. Patent 2944627, 7 December 1960. [Google Scholar]

- Rao, M.B.; Sircar, S. Concentration Swing Adsorption: Novel Processes for Bulk Liquid Separations. In Precision Process Technology: Perspectives for Pollution Prevention; Weijnen, M.P.C., Drinkenburg, A.A.H., Eds.; Springer: Dordrecht, The Netherlands, 1993; pp. 345–352. [Google Scholar]

Sample Availability: Samples of the compounds ZIF-4 and ZIF-zni are available from the authors. |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Hovestadt, M.; Friebe, S.; Helmich, L.; Lange, M.; Möllmer, J.; Gläser, R.; Mundstock, A.; Hartmann, M. Continuous Separation of Light Olefin/Paraffin Mixtures on ZIF-4 by Pressure Swing Adsorption and Membrane Permeation. Molecules 2018, 23, 889. https://doi.org/10.3390/molecules23040889

Hovestadt M, Friebe S, Helmich L, Lange M, Möllmer J, Gläser R, Mundstock A, Hartmann M. Continuous Separation of Light Olefin/Paraffin Mixtures on ZIF-4 by Pressure Swing Adsorption and Membrane Permeation. Molecules. 2018; 23(4):889. https://doi.org/10.3390/molecules23040889

Chicago/Turabian StyleHovestadt, Maximilian, Sebastian Friebe, Lailah Helmich, Marcus Lange, Jens Möllmer, Roger Gläser, Alexander Mundstock, and Martin Hartmann. 2018. "Continuous Separation of Light Olefin/Paraffin Mixtures on ZIF-4 by Pressure Swing Adsorption and Membrane Permeation" Molecules 23, no. 4: 889. https://doi.org/10.3390/molecules23040889

APA StyleHovestadt, M., Friebe, S., Helmich, L., Lange, M., Möllmer, J., Gläser, R., Mundstock, A., & Hartmann, M. (2018). Continuous Separation of Light Olefin/Paraffin Mixtures on ZIF-4 by Pressure Swing Adsorption and Membrane Permeation. Molecules, 23(4), 889. https://doi.org/10.3390/molecules23040889