One-Pot Synthesis of Nitrogen-Doped TiO2 with Supported Copper Nanocrystalline for Photocatalytic Environment Purification under Household White LED Lamp

Abstract

:1. Introduction

2. Results and Discussion

3. Materials and Methods

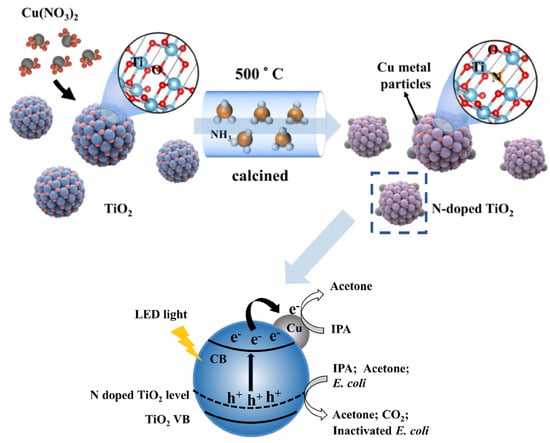

3.1. Preparation of Photocatalysts

3.2. Photocatalytic Degradation of Pollutants

3.3. Evaluation of Anti-Bacteria

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Conflicts of Interest

Sample Availability

References

- Gaya, U.I.; Abdullah, A.H. Heterogeneous photocatalytic degradation of organic contaminants over titanium dioxide: A review of fundamentals, progress and problems. J. Photochem. Photobiol. C Photochem. Rev. 2008, 9, 1–12. [Google Scholar] [CrossRef]

- Vohra, A.; Goswami, D.Y.; Deshpande, D.A.; Block, S.S. Enhanced photocatalytic disinfection of indoor air. Appl. Catal. B Environ. 2006, 64, 57–65. [Google Scholar] [CrossRef]

- Laxma Reddy, P.V.; Kavitha, B.; Kumar Reddy, P.A.; Kim, K.H. TiO2-based photocatalytic disinfection of microbes in aqueous media: A review. Environ. Res. 2017, 154, 296–303. [Google Scholar] [CrossRef] [PubMed]

- Baruah, S.; Dutta, J. Nanotechnology applications in pollution sensing and degradation in agriculture. Environ. Chem. Lett. 2009, 7, 191–204. [Google Scholar] [CrossRef]

- Qiu, X.; Miyauchi, M.; Sunada, K.; Minoshima, M.; Liu, M.; Lu, Y.; Li, D.; Shimodaira, Y.; Hosogi, Y.; Kuroda, Y.; et al. Hybrid CuxO/TiO2 Nanocomposites As Risk-Reduction Materials in Indoor. ACS Nano 2012, 6, 1609–1618. [Google Scholar] [CrossRef]

- Pelaez, M.; Nolan, N.T.; Pillai, S.C.; Seery, M.K.; Falaras, P.; Kontos, A.G.; Dunlop, P.S.M.; Hamilton, J.W.J.; Byrne, J.A.; O’Shea, K.; et al. A review on the visible light active titanium dioxide photocatalysts for environmental applications. Appl. Catal. B Environ. 2012, 125, 331–349. [Google Scholar] [CrossRef] [Green Version]

- Fujishima, A.; Zhang, X.; Tryk, D.A. TiO2 photocatalysis and related surface phenomena. Surf. Sci. Rep. 2008, 63, 515–582. [Google Scholar] [CrossRef]

- Hashimoto, K.; Irie, H.; Fujishima, A. TiO2 photocatalysis: A historical overview and future prospects. Jpn. J. Appl. Phys. 2005, 44, 8269–8285. [Google Scholar] [CrossRef]

- Ni, M.; Leung, M.K.H.; Leung, D.Y.C.; Sumathy, K. A review and recent developments in photocatalytic water-splitting using TiO2 for hydrogen production. Renew. Sustain. Energy Rev. 2007, 11, 401–425. [Google Scholar] [CrossRef]

- Ohno, T.; Akiyoshi, M.; Umebayashi, T.; Asai, K.; Mitsui, T.; Matsumura, M. Preparation of S-doped TiO2 photocatalysts and their photocatalytic activities under visible light. Appl. Catal. A Gen. 2004, 265, 115–121. [Google Scholar] [CrossRef]

- Ren, W.; Ai, Z.; Jia, F.; Zhang, L.; Fan, X.; Zou, Z. Low temperature preparation and visible light photocatalytic activity of mesoporous carbon-doped crystalline TiO2. Appl. Catal. B Environ. 2007, 69, 138–144. [Google Scholar] [CrossRef]

- Basavarajappa, P.S.; Patil, S.B.; Ganganagappa, N.; Reddy, K.R.; Raghu, A.V.; Reddy, C.V. Recent progress in metal-doped TiO2, non-metal doped/codoped TiO2 and TiO2 nanostructured hybrids for enhanced photocatalysis. Int. J. Hydrogen Energy 2020, 45, 7764–7778. [Google Scholar] [CrossRef]

- Asahi, R.; Morikawa, T.; Ohwaki, T.; Aoki, K.; Taga, Y. Visible-light photocatalysis in nitrogen-doped titanium oxides. Science 2001, 293, 269–271. [Google Scholar] [CrossRef]

- Rengifo-Herrera, J.A.; Mielczarski, E.; Mielczarski, J.; Castillo, N.C.; Kiwi, J.; Pulgarin, C. Escherichia coli inactivation by N, S co-doped commercial TiO2 powders under UV and visible light. Appl. Catal. B Environ. 2008, 84, 448–456. [Google Scholar] [CrossRef]

- Chen, X.; Xie, Z.; Liang, Y.; Wei, J.; Zhu, Y.; Huo, Y.; Zhang, X.; Wang, H. Hybridizing TiO2 with Nitrogen-Doped Carbon: A New Route to A Highly Visible Light-Active Photocatalyst. ChemistrySelect 2017, 2, 1565–1572. [Google Scholar] [CrossRef]

- Li, G.; Zou, B.; Feng, S.; Shi, H.; Liao, K.; Wang, Y.; Wang, W.; Zhang, G. Synthesis of N-Doped TiO2 with good photocatalytic property. Phys. B Condens. Matter 2020, 588, 412184. [Google Scholar] [CrossRef]

- Dunnill, C.W.; Parkin, I.P. Nitrogen-doped TiO2 thin films: Photocatalytic applications for healthcare environments. Dalton Trans. 2011, 40, 1635–1640. [Google Scholar] [CrossRef] [PubMed]

- Kumar, S.G.; Devi, L.G. Review on modified TiO2 photocatalysis under UV/visible light: Selected results and related mechanisms on interfacial charge carrier transfer dynamics. J. Phys. Chem. A 2011, 115, 13211–13241. [Google Scholar] [CrossRef]

- Low, J.; Yu, J.; Jaroniec, M.; Wageh, S.; Al-Ghamdi, A.A. Heterojunction Photocatalysts. Adv. Mater. 2017, 29. [Google Scholar] [CrossRef] [PubMed]

- Tada, H.; Kiyonaga, T.; Naya, S.I. Rational design and applications of highly efficient reaction systems photocatalyzed by noble metal nanoparticle-loaded titanium(IV) dioxide. Chem. Soc. Rev. 2009, 38, 1849–1858. [Google Scholar] [CrossRef]

- Zhai, S.; Yang, X.; Tang, M.; Gu, W.; Teng, F. Facile Synthesis of Cu Quantum Dots-TiO2 Nanosheets Schottky Junction and Improved Photocatalytic Degradation Activity. ChemistrySelect 2020, 5, 5693–5700. [Google Scholar] [CrossRef]

- Hao, W.; Zhao, L.; Li, X.; Qin, L.; Han, S.; Kang, S.Z. Cu nanoclusters incorporated mesoporous TiO2 nanoparticles: An efficient and stable noble metal-free photocatalyst for light driven H2 generation. Int. J. Hydrogen Energy 2021, 46, 6461–6473. [Google Scholar] [CrossRef]

- Wu, N.L.; Lee, M.S. Enhanced TiO2 photocatalysis by Cu in hydrogen production from aqueous methanol solution. Int. J. Hydrogen Energy 2004, 29, 1601–1605. [Google Scholar] [CrossRef]

- Chiang, L.F.; Doong, R. An Cu-TiO2 nanorods with enhanced ultraviolet- and visible-light photoactivity for bisphenol A degradation. J. Hazard. Mater. 2014, 277, 84–92. [Google Scholar] [CrossRef] [PubMed]

- Gu, L.; Wang, J.; Cheng, H.; Du, Y.; Han, X. Synthesis of nano-sized anatase TiO2 with reactive (001) facets using lamellar protonated titanate as precursor. Chem. Commun. 2012, 48, 6978–6980. [Google Scholar] [CrossRef] [PubMed]

- Miao, L.; Tanemura, S.; Toh, S.; Kaneko, K.; Tanemura, M. Heating-sol-gel template process for the growth of TiO2 nanorods with rutile and anatase structure. Appl. Surf. Sci. 2004, 238, 175–179. [Google Scholar] [CrossRef]

- Xu, T.; Wang, M.; Wang, T. Effects of N Doping on the Microstructures and Optical Properties of TiO2. J. Wuhan Univ. Technol.-Mater. Sci. Ed. 2019, 34, 55–63. [Google Scholar] [CrossRef]

- Yang, G.; Jiang, Z.; Shi, H.; Xiao, T.; Yan, Z. Preparation of highly visible-light active N-doped TiO2 photocatalyst. J. Mater. Chem. 2010, 20, 5301–5309. [Google Scholar] [CrossRef]

- Di Valentin, C.; Pacchioni, G.; Selloni, A.; Livraghi, S.; Giamello, E. Characterization of paramagnetic species in N-doped TiO2 powders by EPR spectroscopy and DFT calculations. J. Phys. Chem. B 2005, 109, 11414–11419. [Google Scholar] [CrossRef]

- Di Valentin, C.; Pacchioni, G.; Selloni, A. Origin of the different photoactivity of N-doped anatase and rutile TiO2. Phys. Rev. B-Condens. Matter Mater. Phys. 2004, 70, 1–4. [Google Scholar] [CrossRef]

- Wolkoff, P.; Nielsen, G.D. Organic compounds in indoor air-their relevance for perceived indoor air quality? Atmos. Environ. 2001, 35, 4407–4417. [Google Scholar] [CrossRef]

- Ombaka, L.M.; Curti, M.; McGettrick, J.D.; Davies, M.L.; Bahnemann, D.W. Nitrogen/Carbon-Coated Zero-Valent Copper as Highly Efficient Co-catalysts for TiO2Applied in Photocatalytic and Photoelectrocatalytic Hydrogen Production. ACS Appl. Mater. Interfaces 2020, 12, 30365–30380. [Google Scholar] [CrossRef] [PubMed]

- Ouyang, S.; Ye, J. β-AgAl1-xGaxO2 solid-solution photocatalysts: Continuous modulation of electronic structure toward high-performance visible-light photoactivity. J. Am. Chem. Soc. 2011, 133, 7757–7763. [Google Scholar] [CrossRef] [PubMed]

- Arsac, F.; Bianchi, D.; Chovelon, J.M.; Ferronato, C.; Herrmann, J.M. Experimental microkinetic approach of the photocatalytic oxidation of isopropyl alcohol on TiO2. Part 1. Surface elementary steps involving gaseous and adsorbed C3HxO species. J. Phys. Chem. A 2006, 110, 4202–4212. [Google Scholar] [CrossRef] [PubMed]

- Venieri, D.; Fraggedaki, A.; Kostadima, M.; Chatzisymeon, E.; Binas, V.; Zachopoulos, A.; Kiriakidis, G.; Mantzavinos, D. Solar light and metal-doped TiO2 to eliminate water-transmitted bacterial pathogens: Photocatalyst characterization and disinfection performance. Appl. Catal. B Environ. 2014, 154–155, 93–101. [Google Scholar] [CrossRef] [Green Version]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Pan, Y.; Wang, Y.; Wu, S.; Chen, Y.; Zheng, X.; Zhang, N. One-Pot Synthesis of Nitrogen-Doped TiO2 with Supported Copper Nanocrystalline for Photocatalytic Environment Purification under Household White LED Lamp. Molecules 2021, 26, 6221. https://doi.org/10.3390/molecules26206221

Pan Y, Wang Y, Wu S, Chen Y, Zheng X, Zhang N. One-Pot Synthesis of Nitrogen-Doped TiO2 with Supported Copper Nanocrystalline for Photocatalytic Environment Purification under Household White LED Lamp. Molecules. 2021; 26(20):6221. https://doi.org/10.3390/molecules26206221

Chicago/Turabian StylePan, Yixiao, Yifei Wang, Shimiao Wu, Yating Chen, Xiangrong Zheng, and Ning Zhang. 2021. "One-Pot Synthesis of Nitrogen-Doped TiO2 with Supported Copper Nanocrystalline for Photocatalytic Environment Purification under Household White LED Lamp" Molecules 26, no. 20: 6221. https://doi.org/10.3390/molecules26206221

APA StylePan, Y., Wang, Y., Wu, S., Chen, Y., Zheng, X., & Zhang, N. (2021). One-Pot Synthesis of Nitrogen-Doped TiO2 with Supported Copper Nanocrystalline for Photocatalytic Environment Purification under Household White LED Lamp. Molecules, 26(20), 6221. https://doi.org/10.3390/molecules26206221