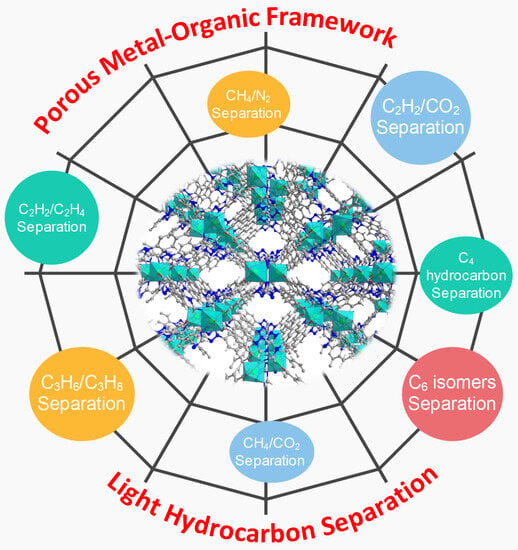

Porous Metal–Organic Frameworks for Light Hydrocarbon Separation

Abstract

:1. Introduction

2. Porous MOFs for Light Hydrocarbon Separation

2.1. CH4/N2 and CH4/CO2 Separation

2.2. C2H2/C2H4 Separation

2.3. C2H2/CO2 Separation

2.4. C3H6/C3H8 Separation

2.5. C4 Hydrocarbon and C6 Isomers Separation

3. Mechanisms and Strategies for Improving the MOFs Separation Ability

- (1)

- Pore size/shape sieving by rigid MOFs. Based on the degree of match between the size/shape of the guest molecule and the pore size/shape of the MOFs, the guest molecule is selectively allowed to pass through.

- (2)

- Breathing effect (gate effect) of flexible MOFs. Under specific external stimuli (e.g., temperature, pressure, gas, etc.), the structure of MOFs changes to allow or prevent the passage of guest molecules.

- (3)

- Hydrogen bonding, van der Waals forces, and exposed electron-rich sites. Hydrogen bonds (e.g., C-H...F, C-H...O, C-H...pi, etc.), van der Waals forces, and exposed electron-rich sites (N- or O-atom, etc.) play key roles in the gas separation process, and they endow the weak interactions between the MOF frameworks and the guest molecules

- (4)

- Open metal sites. Open metal sites can form strong non-bonding interactions with the guest molecules, and sometimes they can even break through the limit and form chemical bonds with the guest molecules.

- (1)

- Selecting organic ligands with compact sizes as raw materials to obtain MOFs with microporous structures.

- (2)

- Designing, constructing, and optimizing the structure of MOFs based on secondary building blocks and topology. For example, introducing open metal sites/functional groups (e.g., -NH2, -OH, -CF3, etc.) into the structure of MOFs not only regulates the pore size/shape of MOFs but also increases the possibility of forming weak interactions between MOFs and guest molecules.

- (3)

- Maximizing the selectivity of MOFs for light hydrocarbons through the synergistic effect of multiple mechanisms.

4. Conclusions and Prospects

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Azzouz, I.; Essoussi, A.; Fleury, J.; Haudebourg, R.; Thiebaut, D.; Vial, J. Feasibility of the preparation of silica monoliths for gas chromatography: Fast separation of light hydrocarbons. J. Chromatogr. A 2015, 1383, 127–133. [Google Scholar] [CrossRef]

- Li, G.; Wang, C.; Wang, Z. Structural effects of microporous polymers on adsorption/separation of C1–C3 light hydrocarbons and CO2 in natural gas. Chem. Eng. J. 2022, 427, 131985. [Google Scholar] [CrossRef]

- Miao, G.; Ma, Y.; Yang, C.; Tong, B.; Li, G.; Xiao, J. The effective synthesis of heat-pump assisted distillation process with multiple columns for light hydrocarbon separation. Chem. Eng. Sci. 2023, 269, 118449. [Google Scholar] [CrossRef]

- Pan, J.; Li, M.; Li, R.; Tang, L.; Bai, J. Design and analysis of LNG cold energy cascade utilization system integrating light hy-drocarbon separation, organic Rankine cycle and direct cooling. Appl. Therm. Eng. 2022, 213, 118672. [Google Scholar] [CrossRef]

- Xu, S.; Liu, R.-S.; Zhang, M.-Y.; Lu, A.-H. Designed synthesis of porous carbons for the separation of light hydrocarbons. Chin. J. Chem. Eng. 2022, 42, 130–150. [Google Scholar] [CrossRef]

- Zhang, R.; Wu, C.; Song, W.; Deng, C.; Yang, M. Energy integration of LNG light hydrocarbon recovery and air separation: Process design and technic-economic analysis. Energy 2020, 207, 118328. [Google Scholar] [CrossRef]

- Li, H.; Li, L.; Lin, R.-B.; Zhou, W.; Zhang, Z.; Xiang, S.; Chen, B. Porous metal-organic frameworks for gas storage and separation: Status and challenges. EnergyChem 2019, 1, 100006. [Google Scholar] [CrossRef]

- Liang, W.; Bhatt, P.M.; Shkurenko, A.; Adil, K.; Mouchaham, G.; Aggarwal, H.; Mallick, A.; Jamal, A.; Belmabkhout, Y.; Eddaoudi, M. A Tailor-Made Interpenetrated MOF with Exceptional Carbon-Capture Performance from Flue Gas. Chem 2019, 5, 950–963. [Google Scholar] [CrossRef]

- Lin, R.-B.; Xiang, S.; Li, B.; Cui, Y.; Qian, G.; Zhou, W.; Chen, B. Our journey of developing multifunctional metal-organic frameworks. Coord. Chem. Rev. 2019, 384, 21–36. [Google Scholar] [CrossRef]

- Cui, Y.; Zhang, J.; He, H.; Qian, G. Photonic functional metal–organic frameworks. Chem. Soc. Rev. 2018, 47, 5740–5785. [Google Scholar] [CrossRef]

- Hu, Z.; Huang, G.; Lustig, W.P.; Wang, F.; Wang, H.; Teat, S.J.; Banerjee, D.; Zhang, D.; Li, J. Achieving exceptionally high luminescence quantum efficiency by immobilizing an AIE molecular chromophore into a metal–organic framework. Chem. Commun. 2015, 51, 3045–3048. [Google Scholar] [CrossRef]

- Pan, M.; Liao, W.M.; Yin, S.Y.; Sun, S.S.; Su, C.Y. Single-Phase White-Light-Emitting and Photoluminescent Color-Tuning Co-ordination Assemblies. Chem. Rev. 2018, 118, 8889–8935. [Google Scholar] [CrossRef] [PubMed]

- Banerjee, D.; Hu, Z.; Li, J. Luminescent metal–organic frameworks as explosive sensors. Dalton Trans. 2014, 43, 10668–10685. [Google Scholar] [CrossRef]

- Chang, Y.; Chen, M.; Fu, Z.; Lu, R.; Gao, Y.; Chen, F.; Li, H.; Frans de Rooij, N.; Lee, Y.-K.; Wang, Y.; et al. Building porphyrin-based MOFs on MXenes for ppb-level NO sensing. J. Mater. Chem. A 2023, 11, 6966–6977. [Google Scholar] [CrossRef]

- Zhao, H.; Ni, J.; Zhang, J.J.; Liu, S.Q.; Sun, Y.J.; Zhou, H.; Li, Y.Q.; Duan, C.Y. A trichromatic MOF composite for multidimen-sional ratiometric luminescent sensing. Chem. Sci. 2018, 9, 2918–2926. [Google Scholar] [CrossRef] [PubMed]

- Levchenko, V.A.; Siah, H.-S.M.; Øien-Ødegaard, S.; Kaur, G.; Fiksdahl, A.; Tilset, M. Catalytic studies of cyclometalated gold(III) complexes and their related UiO-67 MOF. Mol. Catal. 2020, 492, 111009. [Google Scholar] [CrossRef]

- Xia, Q.; Li, Z.; Tan, C.; Liu, Y.; Gong, W.; Cui, Y. Multivariate Metal–Organic Frameworks as Multifunctional Heterogeneous Asymmetric Catalysts for Sequential Reactions. J. Am. Chem. Soc. 2017, 139, 8259–8266. [Google Scholar] [CrossRef]

- Zhu, Y.Y.; Lan, G.; Fan, Y.; Veroneau, S.S.; Song, Y.; Micheroni, D.; Lin, W. Merging Photoredox and Organometallic Catalysts in a Metal–Organic Framework Significantly Boosts Photocatalytic Activities. Angew. Chem. Int. Ed. 2018, 57, 14090–14094. [Google Scholar] [CrossRef]

- Ahamad, M.N.; Shahid, M.; Ahmad, M.; Sama, F. Cu(II) MOFs Based on Bipyridyls: Topology, Magnetism, and Exploring Sensing Ability toward Multiple Nitroaromatic Explosives. ACS Omega 2019, 4, 7738–7749. [Google Scholar] [CrossRef]

- Field, B.; Schiffrin, A.; Medhekar, N.V. Correlation-induced magnetism in substrate-supported 2D metal-organic frameworks. npj Comput. Mater. 2022, 8, 227. [Google Scholar] [CrossRef]

- Zorlu, Y.; Erbahar, D.; Cetinkaya, A.; Bulut, A.; Erkal, T.S.; Yazaydin, A.O.; Beckmann, J.; Yucesan, G. A cobalt arylphosphonate MOF–superior stability, sorption and magnetism. Chem. Commun. 2019, 55, 3053–3056. [Google Scholar] [CrossRef] [PubMed]

- El-Bindary, M.A.; El-Desouky, M.G.; El-Bindary, A.A. Metal-organic frameworks encapsulated with an anticancer compound as drug delivery system: Synthesis, characterization, antioxidant, anticancer, antibacterial, and molecular docking investigation. Appl. Organomet. Chem. 2022, 36, e6660. [Google Scholar] [CrossRef]

- Drout, R.J.; Robison, L.; Farha, O.K. Catalytic applications of enzymes encapsulated in metal–organic frameworks. Coord. Chem. Rev. 2019, 381, 151–160. [Google Scholar] [CrossRef]

- Gui, R.; Jin, H.; Bu, X.; Fu, Y.; Wang, Z.; Liu, Q. Recent advances in dual-emission ratiometric fluorescence probes for chemo/biosensing and bioimaging of biomarkers. Coord. Chem. Rev. 2019, 383, 82–103. [Google Scholar] [CrossRef]

- Zhang, D.; Zhou, Y.; Cuan, J.; Gan, N. A lanthanide functionalized MOF hybrid for ratiometric luminescence detection of an anthrax biomarker. CrystEngComm 2018, 20, 1264–1270. [Google Scholar] [CrossRef]

- Aljohani, M.M.; Al-Qahtani, S.D.; Alshareef, M.; El-Desouky, M.G.; El-Bindary, A.A.; El-Metwaly, N.M.; El-Bindary, M.A. Highly efficient adsorption and removal bio-staining dye from industrial wastewater onto mesoporous Ag-MOFs. Process. Saf. Environ. Prot. 2023, 172, 395–407. [Google Scholar] [CrossRef]

- Alrefaee, S.H.; Aljohani, M.; Alkhamis, K.; Shaaban, F.; El-Desouky, M.G.; El-Bindary, A.A.; El-Bindary, M.A. Adsorption and effective removal of organophosphorus pesticides from aqueous solution via novel metal-organic framework: Adsorption isotherms, kinetics, and optimization via Box-Behnken design. J. Mol. Liq. 2023, 384, 122206. [Google Scholar] [CrossRef]

- Barnett, B.R.; Gonzalez, M.I.; Long, J.R. Recent Progress Towards Light Hydrocarbon Separations Using Metal–Organic Frameworks. Trends Chem. 2019, 1, 159–171. [Google Scholar] [CrossRef]

- Cui, W.; Hu, T.; Bu, X. Metal–Organic Framework Materials for the Separation and Purification of Light Hydrocarbons. Adv. Mater. 2020, 32, e1806445. [Google Scholar] [CrossRef]

- Fu, M.; Wang, Y.; Wang, X.; Sun, D. Metal-Organic Framework Materials for Light Hydrocarbon Separation. ChemPlusChem 2021, 86, 387–395. [Google Scholar] [CrossRef]

- Gu, C.; Liu, J.; Sholl, D.S. High-Throughput Screening of Anion-Pillared Metal–Organic Frameworks for the Separation of Light Hydrocarbons. J. Phys. Chem. C 2021, 125, 20076–20086. [Google Scholar] [CrossRef]

- He, H.; Guo, B.; Liu, Y.; Zhang, L.; Huang, W. Post-Synthetic Modification of Zirconium Metal-Organic Frameworks for Ad-sorption and Separation of Light Hydrocarbons. Cryst. Growth Des. 2020, 20, 4882–4885. [Google Scholar] [CrossRef]

- Zhao, J.; Pan, T.; Jiang, F.; Duan, J.; Jin, W. Polycrystalline Metal-Organic Framework Membranes for Separation of Light Hy-drocarbons. Chem. Eur. J. 2023, 29, e202301132. [Google Scholar] [CrossRef] [PubMed]

- Altintas, C.; Avci, G.; Daglar, H.; Azar, A.N.V.; Erucar, I.; Velioglu, S.; Keskin, S. An extensive comparative analysis of two MOF databases: High-throughput screening of computation-ready MOFs for CH4 and H2 adsorption. J. Mater. Chem. A 2019, 7, 9593–9608. [Google Scholar] [CrossRef]

- He, Y.; Zhou, W.; Qian, G.; Chen, B. Methane storage in metal–organic frameworks. Chem. Soc. Rev. 2014, 43, 5657–5678. [Google Scholar] [CrossRef]

- Saha, D.; Grappe, H.A.; Chakraborty, A.; Orkoulas, G. Postextraction Separation, On-Board Storage, and Catalytic Conversion of Methane in Natural Gas: A Review. Chem. Rev. 2016, 116, 11436–11499. [Google Scholar] [CrossRef]

- Zhang, F.; Shang, H.; Zhai, B.; Li, X.; Zhang, Y.; Wang, X.; Li, J.; Yang, J. Thermodynamic-kinetic synergistic separation of CH4/N2 on a robust aluminum-based metal-organic framework. AIChE J. 2023, 69, e18079. [Google Scholar] [CrossRef]

- Qin, L.; Li, Y.; Liang, F.; Li, L.; Lan, Y.; Li, Z.; Lu, X.; Yang, M.; Ma, D. A microporous 2D cobalt-based MOF with pyridyl sites and open metal sites for selective adsorption of CO2. Microporous Mesoporous Mater. 2022, 341, 112098. [Google Scholar] [CrossRef]

- Jiang, C.; Hao, C.; Wang, X.; Liu, H.; Wei, X.; Xu, H.; Wang, Z.; Ouyang, Y.; Guo, W.; Dai, F.; et al. Constructing C2H2 anchoring traps within MOF interpenetration nets as C2H2/CO2 and C2H2/C2H4 bifunctional separator. Chem. Eng. J. 2023, 453, 139713. [Google Scholar] [CrossRef]

- Li, X.; Cao, C.; Fan, Z.; Liu, J.; Pham, T.; Forrest, K.A.; Niu, Z. An aliphatic MOF with a molecular sieving effect for efficient C2H2/C2H4 separation. Dalton Trans. 2023. [CrossRef]

- Pal, S.C.; Ahmed, R.; Manna, A.K.; Das, M.C. Potential of a pH-Stable Microporous MOF for C2H2/C2H4 and C2H2/CO2 Gas Separations under Ambient Conditions. Inorg. Chem. 2022, 61, 18293–18302. [Google Scholar] [CrossRef]

- Pal, A.; Chand Pal, S.; Cui, H.; Lin, R.-B.; Singha, D.; Kumar Rana, M.; Chen, B.; Das, M.C. A microporous water stable MOF for consistent and selective C2H2/C2H4 separation. Sep. Purif. Technol. 2023, 320, 124208. [Google Scholar] [CrossRef]

- Huang, H.; Gu, Y.; Wang, L.; Jia, T.; Kitagawa, S.; Li, F. A scalable stable porous coordination polymer synthesized from low-cost precursors for efficient C2H2/C2H4 separation. Green Chem. 2023. [CrossRef]

- Fu, X.P.; Wang, Y.L.; Liu, Q.Y. Metal-organic frameworks for C2H2/CO2 separation. Dalton Trans. 2020, 49, 16598–16607. [Google Scholar] [CrossRef]

- Niu, Z.; Cui, X.; Pham, T.; Verma, G.; Lan, P.C.; Shan, C.; Xing, H.; Forrest, K.A.; Suepaul, S.; Space, B.; et al. MOF-based Ultra-Strong Acetylene Nano-trap for Highly Efficient C2H2/CO2 Separation. Angew. Chem. Int. Ed. 2021, 60, 5283–5288. [Google Scholar] [CrossRef]

- Xie, X.-J.; Zeng, H.; Xie, M.; Chen, W.; Hua, G.-F.; Lu, W.; Li, D. A metal-organic framework for C2H2/CO2 separation under highly humid conditions: Balanced hydrophilicity/hydrophobicity. Chem. Eng. J. 2022, 427, 132033. [Google Scholar] [CrossRef]

- Li, H.; Ji, Z.; Chen, C.; Di, Z.; Liu, Y.; Wu, M. A Microporous Metal–Organic Framework for Efficient C2H2/CO2 and C2H6/CH4 Separation. Cryst. Growth Des. 2021, 21, 2277–2282. [Google Scholar] [CrossRef]

- Jiang, K.; Gao, Y.; Zhang, P.; Lin, S.; Zhang, L. A new perchlorate-based hybrid ultramicroporous material with rich bare oxygen atoms for high C2H2/CO2 separation. Chin. Chem. Lett. 2023, 34, 108039. [Google Scholar] [CrossRef]

- Ding, Q.; Zhang, S. Recent Advances in the Development of Metal–Organic Frameworks for Propylene and Propane Separation. Energy Fuels 2022, 36, 7337–7361. [Google Scholar] [CrossRef]

- Grande, C.A.; Rodrigues, A.E. Propane/Propylene Separation by Pressure Swing Adsorption Using Zeolite 4A. Ind. Eng. Chem. Res. 2005, 44, 8815–8829. [Google Scholar] [CrossRef]

- Khalighi, M.; Chen, Y.F.; Farooq, S.; Karimi, I.A.; Jiang, J.W. Propylene/Propane Separation Using SiCHA. Ind. Eng. Chem. Res. 2013, 52, 3877–3892. [Google Scholar] [CrossRef]

- Macreadie, L.K.; Idrees, K.B.; Smoljan, C.S.; Farha, O.K. Expanding Linker Dimensionality in Metal-Organic Frameworks for sub-Ångstrom Pore Control for Separation Applications. Angew. Chem. Int. Ed. 2023, 62, e202304094. [Google Scholar] [CrossRef]

- Yu, L.; Han, X.; Wang, H.; Ullah, S.; Xia, Q.; Li, W.; Li, J.; da Silva, I.; Manuel, P.; Rudić, S.; et al. Pore Distortion in a Metal–Organic Framework for Regulated Separation of Propane and Propylene. J. Am. Chem. Soc. 2021, 143, 19300–19305. [Google Scholar] [CrossRef]

- Xie, Y.; Shi, Y.; Morales, E.M.C.; El Karch, A.; Wang, B.; Arman, H.; Tan, K.; Chen, B. Optimal Binding Affinity for Sieving Separation of Propylene from Propane in an Oxyfluoride Anion-Based Metal–Organic Framework. J. Am. Chem. Soc. 2023, 145, 2386–2394. [Google Scholar] [CrossRef] [PubMed]

- Gehre, M.; Guo, Z.; Rothenberg, G.; Tanase, S. Sustainable Separations of C4 -Hydrocarbons by Using Microporous Materials. ChemSusChem 2017, 10, 3947–3963. [Google Scholar] [CrossRef]

- Assen, A.H.; Virdis, T.; De Moor, W.; Moussa, A.; Eddaoudi, M.; Baron, G.; Denayer, J.F.; Belmabkhout, Y. Kinetic separation of C4 olefins using Y-fum-fcu-MOF with ultra-fine-tuned aperture size. Chem. Eng. J. 2021, 413, 127388. [Google Scholar] [CrossRef]

- Wang, L.; Xue, W.; Zhu, H.; Guo, X.; Huang, H.; Zhong, C. Stepwise Engineering the Pore Aperture of a Cage-like MOF for the Efficient Separation of Isomeric C4 Paraffins under Humid Conditions. Angew. Chem. Int. Ed. 2023, 62, e202218596. [Google Scholar] [CrossRef]

- Jansen, C.; Assahub, N.; Spiess, A.; Liang, J.; Schmitz, A.; Xing, S.; Gokpinar, S.; Janiak, C. The Complexity of Comparative Adsorption of C6 Hydrocarbons (Benzene, Cyclohexane, n-Hexane) at Metal-Organic Frameworks. Nanomaterials 2022, 12, 3614. [Google Scholar] [CrossRef] [PubMed]

- Wang, H.; Dong, X.; Lin, J.; Teat, S.J.; Jensen, S.; Cure, J.; Alexandrov, E.V.; Xia, Q.; Tan, K.; Wang, Q.; et al. Topologically guided tuning of Zr-MOF pore structures for highly selective separation of C6 alkane isomers. Nat. Commun. 2018, 9, 1745. [Google Scholar] [CrossRef] [PubMed]

- Xie, F.; Yu, L.; Wang, H.; Li, J. Metal-Organic Frameworks for C6 Alkane Separation. Angew. Chem. Int. Ed. 2023, 62, e202300722. [Google Scholar] [CrossRef]

- Chen, J.; Wang, J.; Guo, L.; Li, L.; Yang, Q.; Zhang, Z.; Yang, Y.; Bao, Z.; Ren, Q. Adsorptive Separation of Geometric Isomers of 2-Butene on Gallate-Based Metal–Organic Frameworks. ACS Appl. Mater. Interfaces 2020, 12, 9609–9616. [Google Scholar] [CrossRef] [PubMed]

- Velasco, E.; Xian, S.; Wang, H.; Teat, S.J.; Olson, D.H.; Tan, K.; Ullah, S.; Popp, T.M.O.; Bernstein, A.D.; Oyekan, K.A.; et al. Flexible Zn-MOF with Rare Underlying scu Topology for Effective Separation of C6 Alkane Isomers. ACS Appl. Mater. Interfaces 2021, 13, 51997–52005. [Google Scholar] [CrossRef]

| Adsorbate | Kinetic Diameter/nm | Adsorbate | Kinetic Diameter/nm |

|---|---|---|---|

| N2 | 0.364–0.380 | n-C4H10 | 0.4687 |

| CO2 | 0.33 | i-C4H10 | 0.5278 |

| CH4 | 0.375 | 1-Butene | 0.45 |

| C2H2 | 0.33 | cis-2-butene | 0.423 |

| C2H4 | 0.4163 | 1,3-Butadiene | 0.52 |

| C3H6 | 0.4678 | n-C6H14 | 0.43 |

| C3H8 | 0.43–0.5118 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Gao, X.; Yan, W.-H.; Hu, B.-Y.; Huang, Y.-X.; Zheng, S.-M. Porous Metal–Organic Frameworks for Light Hydrocarbon Separation. Molecules 2023, 28, 6337. https://doi.org/10.3390/molecules28176337

Gao X, Yan W-H, Hu B-Y, Huang Y-X, Zheng S-M. Porous Metal–Organic Frameworks for Light Hydrocarbon Separation. Molecules. 2023; 28(17):6337. https://doi.org/10.3390/molecules28176337

Chicago/Turabian StyleGao, Xiang, Wen-Hui Yan, Bo-Yang Hu, Yu-Xin Huang, and Shi-Mei Zheng. 2023. "Porous Metal–Organic Frameworks for Light Hydrocarbon Separation" Molecules 28, no. 17: 6337. https://doi.org/10.3390/molecules28176337

APA StyleGao, X., Yan, W. -H., Hu, B. -Y., Huang, Y. -X., & Zheng, S. -M. (2023). Porous Metal–Organic Frameworks for Light Hydrocarbon Separation. Molecules, 28(17), 6337. https://doi.org/10.3390/molecules28176337