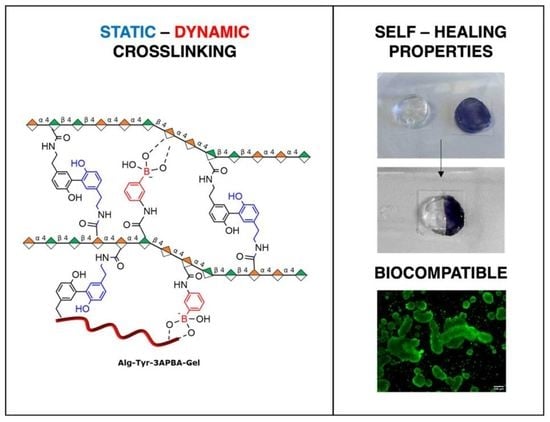

Alginate–Gelatin Self-Healing Hydrogel Produced via Static–Dynamic Crosslinking

Abstract

:1. Introduction

2. Results and Discussion

2.1. Alginate Functionalization

Characterization of Alginate Functionalization

2.2. Hydrogel Formulation

2.2.1. Swelling Test

2.2.2. Rheological Characterization

2.2.3. Self-Healing Test

2.2.4. Cytotoxicity

3. Materials and Methods

3.1. Materials

3.2. Functionalization of Sodium Alginate with Tyramine

3.3. Functionalization of Sodium Alginate with Tyramine and 3-Aminophenylboronic Acid

3.4. Alginate–Gelatin Ink Formulation

3.5. Fourier-Transform Infrared Spectroscopy (FT-IR) and Nuclear Magnetic Resonance (NMR)

3.6. Swelling Test

3.7. Rheology

3.8. Self-Healing of Alg-Tyr-3APBA-d

3.9. Cell Culture (HT29)

3.10. Cytotoxicity

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Sample Availability

References

- Formica, F.A.; Cavalli, E.; Broguiere, N.; Zenobi-Wong, M. Cell-Instructive Alginate Hydrogels Targeting RhoA. Bioconjug. Chem. 2018, 29, 3042–3053. [Google Scholar] [CrossRef] [PubMed]

- Nicolas, J.; Magli, S.; Rabbachin, L.; Sampaolesi, S.; Nicotra, F.; Russo, L. 3D Extracellular Matrix Mimics: Fundamental Concepts and Role of Materials Chemistry to Influence Stem Cell Fate. Biomacromolecules 2020, 21, 1968–1994. [Google Scholar] [CrossRef] [PubMed]

- Tang, S.; Richardson, B.M.; Anseth, K.S. Dynamic Covalent Hydrogels as Biomaterials to Mimic the Viscoelasticity of Soft Tissues. Prog. Mater. Sci. 2021, 120, 100738. [Google Scholar] [CrossRef]

- Cadamuro, F.; Marongiu, L.; Marino, M.; Tamini, N.; Nespoli, L.; Zucchini, N.; Terzi, A.; Altamura, D.; Gao, Z.; Giannini, C.; et al. 3D Bioprinted Colorectal Cancer Models Based on Hyaluronic Acid and Signalling Glycans. Carbohydr. Polym. 2023, 302, 120395. [Google Scholar] [CrossRef]

- Morgan, F.L.C.; Fernández-Pérez, J.; Moroni, L.; Baker, M.B. Tuning Hydrogels by Mixing Dynamic Cross-Linkers: Enabling Cell-Instructive Hydrogels and Advanced Bioinks. Adv. Healthc. Mater. 2022, 11, 2101576. [Google Scholar] [CrossRef]

- Aldana, A.A.; Morgan, F.L.C.; Houben, S.; Pitet, L.M.; Moroni, L.; Baker, M.B. Biomimetic Double Network Hydrogels: Combining Dynamic and Static Crosslinks to Enable Biofabrication and Control Cell-Matrix Interactions. J. Polym. Sci. 2021, 59, 2832–2843. [Google Scholar] [CrossRef]

- Casuso, P.; Odriozola, I.; Pérez-San Vicente, A.; Loinaz, I.; Cabañero, G.; Grande, H.J.; Dupin, D. Injectable and Self-Healing Dynamic Hydrogels Based on Metal(I)-Thiolate/Disulfide Exchange as Biomaterials with Tunable Mechanical Properties. Biomacromolecules 2015, 16, 3552–3561. [Google Scholar] [CrossRef]

- Lee, J.; Silberstein, M.N.; Abdeen, A.A.; Kim, S.Y.; Kilian, K.A. Mechanochemical Functionalization of Disulfide Linked Hydrogels. Mater. Horiz. 2016, 3, 447–451. [Google Scholar] [CrossRef] [Green Version]

- Madl, C.M.; Heilshorn, S.C. Rapid Diels−Alder Cross-Linking of Cell Encapsulating Hydrogels. Chem. Mater. 2019, 31, 8035–8043. [Google Scholar] [CrossRef]

- Cadamuro, F.; Russo, L.; Nicotra, F. Biomedical Hydrogels Fabricated Using Diels–Alder Crosslinking. Eur. J. Org. Chem. 2021, 2021, 374–382. [Google Scholar] [CrossRef]

- Figueiredo, T.; Ogawa, Y.; Jing, J.; Cosenza, V.; Jeacomine, I.; Olsson, J.D.M.; Gerfaud, T.; Boiteau, J.G.; Harris, C.; Auzély-Velty, R. Self-Crosslinking Smart Hydrogels through Direct Complexation between Benzoxaborole Derivatives and Diols from Hyaluronic Acid. Polym. Chem. 2020, 11, 3800–3811. [Google Scholar] [CrossRef]

- de Oliveira, M.M.; Nakamura, C.V.; Auzély-Velty, R. Boronate-Ester Crosslinked Hyaluronic Acid Hydrogels for Dihydrocaffeic Acid Delivery and Fibroblasts Protection against UVB Irradiation. Carbohydr. Polym. 2020, 247, 116845. [Google Scholar] [CrossRef] [PubMed]

- Springsteen, G.; Wang, B. A Detailed Examination of Boronic Acid–Diol Complexation. Tetrahedron 2002, 58, 5291–5300. [Google Scholar] [CrossRef]

- Dufort, B.M.; Tibbitt, M.W. Design of Moldable Hydrogels for Biomedical Applications Using Dynamic Covalent Boronic Esters. Mater. Today Chem. 2019, 12, 16–33. [Google Scholar] [CrossRef]

- Chu, W.; Nie, M.; Ke, X.; Luo, J.; Li, J. Recent Advances in Injectable Dual Crosslinking Hydrogels for Biomedical Applications. Macromol. Biosci. 2021, 21, 2100109. [Google Scholar] [CrossRef]

- Amaral, A.J.R.; Gaspar, V.M.; Lavrador, P.; Mano, J.F. Double Network Laminarin-Boronic/Alginate Dynamic Bioink for 3D Bioprinting Cell-Laden Constructs. Biofabrication 2021, 13, 035045. [Google Scholar] [CrossRef]

- Hu, C.; Long, L.; Cao, J.; Zhang, S.; Wang, Y. Dual-Crosslinked Mussel-Inspired Smart Hydrogels with Enhanced Antibacterial and Angiogenic Properties for Chronic Infected Diabetic Wound Treatment via PH-Responsive Quick Cargo Release. Chem. Eng. J. 2021, 411, 128564. [Google Scholar] [CrossRef]

- Liu, Y.; Liu, Y.; Wang, Q.; Han, Y.; Chen, H.; Tan, Y. Doubly Dynamic Hydrogel Formed by Combining Boronate Ester and Acylhydrazone Bonds. Polymers 2020, 12, 487. [Google Scholar] [CrossRef] [Green Version]

- Cheng, Q.; Ding, S.; Zheng, Y.; Wu, M.; Peng, Y.Y.; Diaz-Dussan, D.; Shi, Z.; Liu, Y.; Zeng, H.; Cui, Z.; et al. Dual Cross-Linked Hydrogels with Injectable, Self-Healing, and Antibacterial Properties Based on the Chemical and Physical Cross-Linking. Biomacromolecules 2021, 22, 1685–1694. [Google Scholar] [CrossRef]

- Shen, K.-H.; Yeh, Y.-Y.; Chiu, T.-H.; Wang, R.; Yeh, Y.-C. Dual Dynamic Covalently Crosslinked Alginate Hydrogels with Tunable Properties and Multiple Stimuli-Responsiveness. ACS Biomater. Sci. Eng. 2022, 14, 9. [Google Scholar] [CrossRef]

- Li, Y.; Yang, L.; Zeng, Y.; Wu, Y.; Wei, Y.; Tao, L. Self-Healing Hydrogel with a Double Dynamic Network Comprising Imine and Borate Ester Linkages. Chem. Mater. 2019, 31, 5576–5583. [Google Scholar] [CrossRef]

- Figueiredo, T.; Jing, J.; Jeacomine, I.; Olsson, J.; Gerfaud, T.; Boiteau, J.-G.; Rome, C.; Harris, C.; Auzély-Velty, R. Injectable Self-Healing Hydrogels Based on Boronate Ester Formation between Hyaluronic Acid Partners Modified with Benzoxaborin Derivatives and Saccharides. Biomacromolecules 2020, 21, 230–239. [Google Scholar] [CrossRef]

- Hong, S.H.; Kim, S.; Park, J.P.; Shin, M.; Kim, K.; Ryu, J.H.; Lee, H. Dynamic Bonds between Boronic Acid and Alginate: Hydrogels with Stretchable, Self-Healing, Stimuli-Responsive, Remoldable, and Adhesive Properties. Biomacromolecules 2018, 19, 2053–2061. [Google Scholar] [CrossRef]

- Hu, C.; Zhang, F.; Long, L.; Kong, Q.; Luo, R.; Wang, Y. Dual-Responsive Injectable Hydrogels Encapsulating Drug-Loaded Micelles for on-Demand Antimicrobial Activity and Accelerated Wound Healing. J. Control. Release 2020, 324, 204–217. [Google Scholar] [CrossRef] [PubMed]

- Hong, S.H.; Shin, M.; Park, E.; Ryu, J.H.; Burdick, J.A.; Lee, H. Alginate-Boronic Acid: PH-Triggered Bioinspired Glue for Hydrogel Assembly. Adv. Funct. Mater. 2020, 30, 1908497. [Google Scholar] [CrossRef]

- Kim, S.D.; Jin, S.; Kim, S.; Son, D.; Shin, M. Tyramine-Functionalized Alginate-Collagen Hybrid Hydrogel Inks for 3D-Bioprinting. Polymers 2022, 14, 3173. [Google Scholar] [CrossRef] [PubMed]

- Nagaki, A.; Moriwaki, Y.; Yoshida, J.I. Flow Synthesis of Arylboronic Esters Bearing Electrophilic Functional Groups and Space Integration with Suzuki–Miyaura Coupling without Intentionally Added Base. Chem. Commun. 2012, 48, 11211–11213. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Ziadlou, R.; Rotman, S.; Teuschl, A.; Salzer, E.; Barbero, A.; Martin, I.; Alini, M.; Eglin, D.; Grad, S. Optimization of Hyaluronic Acid-Tyramine/Silk-Fibroin Composite Hydrogels for Cartilage Tissue Engineering and Delivery of Anti-Inflammatory and Anabolic Drugs. Mater. Sci. Eng. C 2021, 120, 111701. [Google Scholar] [CrossRef]

- Wang, L.; Li, J.; Zhang, D.; Ma, S.; Zhang, J.; Gao, F.; Guan, F.; Yao, M. Dual-Enzymatically Crosslinked and Injectable Hyaluronic Acid Hydrogels for Potential Application in Tissue Engineering. RSC Adv. 2020, 10, 2870–2876. [Google Scholar] [CrossRef] [Green Version]

- Schulz, A.; Gepp, M.M.; Stracke, F.; von Briesen, H.; Neubauer, J.C.; Zimmermann, H. Tyramine-Conjugated Alginate Hydrogels as a Platform for Bioactive Scaffolds. J. Biomed. Mater. Res. A 2019, 107, 114–121. [Google Scholar] [CrossRef] [Green Version]

- Sarker, B.; Papageorgiou, D.G.; Silva, R.; Zehnder, T.; Gul-E-Noor, F.; Bertmer, M.; Kaschta, J.; Chrissafis, K.; Detsch, R.; Boccaccini, A.R. Fabrication of Alginate-Gelatin Crosslinked Hydrogel Microcapsules and Evaluation of the Microstructure and Physico-Chemical Properties. J. Mater. Chem. B 2014, 2, 1470–1482. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Anandan, P.; Vetrivel, S.; Karthikeyan, S.; Jayavel, R.; Ravi, G. Crystal Growth, Spectral and Thermal Analyses of a Semi Organic Nonlinear Optical Single Crystal: L-Tyrosine Hydrochloride. Optoelectron. Adv. Mater.-Rapid Commun. 2012, 6, 1128–1133. [Google Scholar]

- Fertah, M.; Belfkira, A.; Dahmane, E.M.; Taourirte, M.; Brouillette, F. Extraction and Characterization of Sodium Alginate from Moroccan Laminaria Digitata Brown Seaweed. Arab. J. Chem. 2017, 10, S3707–S3714. [Google Scholar] [CrossRef] [Green Version]

- Nastaj, J.; Przewłocka, A.; Rajkowska-Myśliwiec, M. Biosorption of Ni(II), Pb(II) and Zn(II) on Calcium Alginate Beads: Equilibrium, Kinetic and Mechanism Studies. Pol. J. Chem. Technol. 2016, 18, 81–87. [Google Scholar] [CrossRef] [Green Version]

- Lin, S.; Sangaj, N.; Razafiarison, T.; Zhang, C.; Varghese, S. Influence of Physical Properties of Biomaterials on Cellular Behavior. Pharm. Res. 2011, 28, 1422–1430. [Google Scholar] [CrossRef] [Green Version]

- Fraser, D.; Nguyen, T.; Kotelsky, A.; Lee, W.; Buckley, M.; Benoit, D.S.W. Hydrogel Swelling-Mediated Strain Induces Cell Alignment at Dentin Interfaces. ACS Biomater. Sci. Eng. 2022, 8, 3568–3575. [Google Scholar] [CrossRef] [PubMed]

- Huanga, M.H.; Yanga, M.C. Swelling and Biocompatibility of Sodium Alginate/Poly(γ-Glutamic Acid) Hydrogels. Polym. Adv. Technol. 2010, 21, 561–567. [Google Scholar] [CrossRef]

- Sarker, B.; Singh, R.; Silva, R.; Roether, J.A.; Kaschta, J.; Detsch, R.; Schubert, D.W.; Cicha, I.; Boccaccini, A.R. Evaluation of Fibroblasts Adhesion and Proliferation on Alginate-Gelatin Crosslinked Hydrogel. PLoS ONE 2014, 9, e107952. [Google Scholar] [CrossRef] [Green Version]

- Stojkov, G.; Niyazov, Z.; Picchioni, F.; Bose, R.K. Relationship between Structure and Rheology of Hydrogels for Various Applications. Gels 2021, 7, 255. [Google Scholar] [CrossRef]

- Cho, S.; Hwang, S.Y.; Oh, D.X.; Park, J. Recent Progress in Self-Healing Polymers and Hydrogels Based on Reversible Dynamic B–O Bonds: Boronic/Boronate Esters, Borax, and Benzoxaborole. J. Mater. Chem. A Mater. 2021, 9, 14630–14655. [Google Scholar] [CrossRef]

- Cantini, M.; Donnelly, H.; Dalby, M.J.; Salmeron-Sanchez, M. The Plot Thickens: The Emerging Role of Matrix Viscosity in Cell Mechanotransduction. Adv. Healthc. Mater. 2020, 9, 1901259. [Google Scholar] [CrossRef] [PubMed]

- Kim, M.H.; Nguyen, H.; Chang, C.Y.; Lin, C.C. Dual Functionalization of Gelatin for Orthogonal and Dynamic Hydrogel Cross-Linking. ACS Biomater. Sci. Eng. 2021, 7, 4196–4208. [Google Scholar] [CrossRef] [PubMed]

| Hydrogel | Alginate (mg) | Gelatin (mg) | Tyramine:Tyrosine (Molar Ratio) | HRP (U/mL) | H2O2 (mM) | Hydrogel% (m/V) | Gelation Time (min) |

|---|---|---|---|---|---|---|---|

| Alg-Tyr-3APBA-Gel-a | 2.6 | 17.3 | 2.5:1 | 1 | 1 | 2 | 1 |

| Alg-Tyr-3APBA-Gel-b | 1.1 | 18.3 | 1:1 | 1 | 1 | 2 | 5 |

| Alg-Tyr-3APBA-Gel-c | 0.45 | 18.7 | 1:2.5 | 1 | 1 | 2 | - |

| Alg-Tyr-3APBA-Gel-d | 2.6 | 17.3 | 2.5:1 | 0.5 | 0.5 | 2 | 5 |

| Alg-Tyr-3APBA-Gel-e | 1.1 | 18.3 | 1:1 | 0.5 | 0.5 | 2 | 15 |

| Alg-Tyr-Gel | 2.6 | 17.3 | 2.5:1 | 0.5 | 0.5 | 2 | 5 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Cadamuro, F.; Ardenti, V.; Nicotra, F.; Russo, L. Alginate–Gelatin Self-Healing Hydrogel Produced via Static–Dynamic Crosslinking. Molecules 2023, 28, 2851. https://doi.org/10.3390/molecules28062851

Cadamuro F, Ardenti V, Nicotra F, Russo L. Alginate–Gelatin Self-Healing Hydrogel Produced via Static–Dynamic Crosslinking. Molecules. 2023; 28(6):2851. https://doi.org/10.3390/molecules28062851

Chicago/Turabian StyleCadamuro, Francesca, Valeria Ardenti, Francesco Nicotra, and Laura Russo. 2023. "Alginate–Gelatin Self-Healing Hydrogel Produced via Static–Dynamic Crosslinking" Molecules 28, no. 6: 2851. https://doi.org/10.3390/molecules28062851

APA StyleCadamuro, F., Ardenti, V., Nicotra, F., & Russo, L. (2023). Alginate–Gelatin Self-Healing Hydrogel Produced via Static–Dynamic Crosslinking. Molecules, 28(6), 2851. https://doi.org/10.3390/molecules28062851