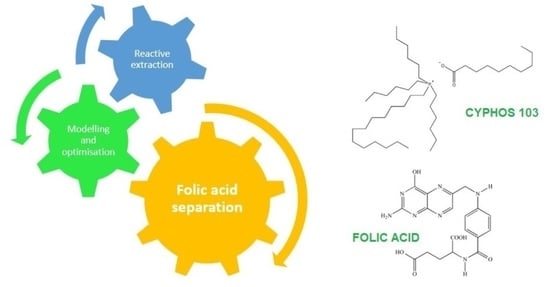

Folic Acid Ionic-Liquids-Based Separation: Extraction and Modelling

Abstract

:1. Introduction

2. Results and Discussions

2.1. Extraction Process

- -

- For concentrations lower than 40 g/L, echi-molecular complexes (involving only one molecule of both FA and ionic liquid) for both cases: [FA][CYPHOS IL103] and [FA][CYPHOS IL104] are formed, while

- -

- For concentrations higher than 40 g/L, the decrease of Z with increasing ionic liquid concentration in the organic phase indicates the formation of complexes involving two molecules of ionic liquid per folic acid molecule: [FA][CYPHOS IL103]2 and [FA][CYPHOS IL104]2. This suggests that it may be more cost-effective to enhance the extractant concentration when the process efficiency is below the optimum level than to raise the process efficiency while maintaining the extractant concentration [42].

2.2. Modeling

3. Materials and Methods

3.1. Extraction Process

3.2. Modeling

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Yang, H.; Zhang, X.; Liu, Y.; Liu, L.; Li, J.; Du, G.; Chen, J. Synthetic Biology-Driven Microbial Production of Folates: Advances and Perspectives. Bioresour. Technol. 2021, 324, 124624. [Google Scholar] [CrossRef]

- Menezo, Y.; Elder, K.; Clement, A.; Clement, P. Folic Acid, Folinic Acid, 5 Methyl TetraHydroFolate Supplementation for Mutations That Affect Epigenesis through the Folate and One-Carbon Cycles. Biomolecules 2022, 12, 197. [Google Scholar] [CrossRef] [PubMed]

- Park, S.Y.; Do, J.R.; Kim, Y.J.; Kim, K.S.; Lim, S.D. Physiological Characteristics and Production of Folic Acid of Lactobacillus plantarum JA71 Isolated from Jeotgal, a Traditional Korean Fermented Seafood. Korean J. Food Sci. Anim. Resour. 2014, 34, 106–114. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- San, H.H.M.; Alcantara, K.P.; Bulatao, B.P.I.; Sorasitthiyanukarn, F.N.; Nalinratana, N.; Suksamrarn, A.; Vajragupta, O.; Rojsitthisak, P.; Rojsitthisak, P. Folic Acid-Grafted Chitosan-Alginate Nanocapsules as Effective Targeted Nanocarriers for Delivery of Turmeric Oil for Breast Cancer Therapy. Pharmaceutics 2023, 15, 110. [Google Scholar] [CrossRef] [PubMed]

- Crider, K.S.; Bailey, L.B.; Berry, R.J. Folic Acid Food Fortification—Its History, Effect, Concerns, and Future Directions. Nutrients 2011, 3, 370–384. [Google Scholar] [CrossRef] [Green Version]

- Quadintel. Global Folic Acid Market Size study, by Application (Dietary Supplements, Cosmetics, Pharmaceuticals, and Other Applications), and Regional Forecasts 2022–2028; Report ID: QI037; Bizwit Research & Consulting: Indore, India, 2022. [Google Scholar]

- Hamzehlou, P.; Akhavan Sepahy, A.; Mehrabian, S.; Hosseini, F. Production of Vitamins B3, B6 and B9 by Lactobacillus isolated from Traditional Yogurt Samples from 3 Cities in Iran, Winter 2016. Appl. Food Biotechnol. 2018, 5, 107–120. [Google Scholar]

- Laiño, J.E.; Levit, R.; de LeBlanc, A.d.M.; Savoy de Giori, G.; LeBlanc, J.G. Characterization of folate production and probiotic potential of Streptococcus gallolyticus subsp. macedonicus CRL415. Food Microbiol. 2019, 79, 20–26. [Google Scholar] [CrossRef]

- Hugenschmidt, S.; Miescher Schwenninger, S.; Lacroix, C. Concurrent high production of natural folate and vitamin B12 using a co-culture process with Lactobacillus plantarum SM39 and Propionibacterium freudenreichii DF13. Process Biochem. 2011, 46, 1063–1070. [Google Scholar] [CrossRef]

- Serrano-Amatriain, C.; Ledesma-Amaro, R.; Lopez-Nicolas, R.; Ros, G.; Jimenez, A.; Revuelta, J.L. Folic acid production by engineered Ashbya gossypii. Metab. Eng. 2016, 38, 473–482. [Google Scholar] [CrossRef]

- Wang, Y.; Liu, L.; Jin, Z.; Zhang, D. Microbial Cell Factories for Green Production of Vitamins. Front. Bioeng. Biotechnol. 2021, 9, 661562. [Google Scholar] [CrossRef]

- Roy, S.; Olokede, O.; Wu, H.; Holtzapple, M. In-situ carboxylic acid separation from mixed-acid fermentation of cellulosic substrates in batch culture. Biomass Bioenergy 2021, 151, 106165. [Google Scholar] [CrossRef]

- Galaction, A.I.; Blaga, A.C.; Cascaval, D. The influence of pH and solvent polarity on the mechanism and efficiency of folic acid extraction with Amberlite LA2. Chem. Ind. Chem. Eng. Q. 2005, 11, 63–68. [Google Scholar] [CrossRef]

- Aras, S.; Demir, Ö.; Gök, A. Reactive extraction of gallic acid by trioctylphosphine oxide in different kinds of solvents: Equilibrium modeling and thermodynamic study. Braz. J. Chem. Eng. 2022. [Google Scholar] [CrossRef]

- Blaga, A.C.; Dragoi, E.N.; Munteanu, R.E.; Cascaval, D.; Galaction, A.I. Gallic Acid Reactive Extraction with and without 1-Octanol as Phase Modifier: Experimental and Modeling. Fermentation 2022, 8, 633. [Google Scholar] [CrossRef]

- Lazar, R.G.; Blaga, A.C.; Dragoi, E.N.; Galaction, A.I.; Cascaval, D. Application of reactive extraction for the separation of pseudomonic acids: Influencing factors, interfacial mechanism, and process modelling. Can. J. Chem. Eng. 2021, 100, S246–S257. [Google Scholar] [CrossRef]

- Georgiana, L.R.; Cristina, B.A.; Niculina, D.E.; Irina, G.A.; Dan, C. Mechanism, influencing factors exploration and modelling on the reactive extraction of 2-ketogluconic acid in presence of a phase modifier. Sep. Purif. Technol. 2020, 255, 117740. [Google Scholar] [CrossRef]

- Demmelmayer, P.; Kienberger, M. Reactive extraction of lactic acid from sweet sorghum silage press juice. Sep. Purif. Technol. 2022, 282, 120090. [Google Scholar] [CrossRef]

- Blaga, A.C.; Malutan, T. Selective Separation of Vitamin C by Reactive Extraction. J. Chem. Eng. Data 2012, 57, 431–435. [Google Scholar] [CrossRef]

- Poştaru, M.; Bompa, A.S.; Galaction, A.I.; Blaga, A.C.; Caşcaval, D. Comparative Study on Pantothenic Acid Separation by Reactive Extraction with Tri-n-octylamine and Di-(2-ethylhexyl) Phosphoric Acid. Chem. Biochem. Eng. Q. 2016, 30, 81–92. [Google Scholar] [CrossRef]

- Blaga, A.C.; Tucaliuc, A.; Kloetzer, L. Applications of Ionic Liquids in Carboxylic Acids Separation. Membranes 2022, 12, 771. [Google Scholar] [CrossRef]

- de Jesus, S.S.; Filho, R.M. Are ionic liquids eco-friendly? Renew. Sustain. Energy Rev. 2022, 157, 112039–112061. [Google Scholar] [CrossRef]

- Li, Q.; Jiang, X.; Zou, H.; Cao, Z.; Zhang, H.; Xian, M. Extraction of short-chain organic acids using imidazolium-based ionic liquids from aqueous media. J. Chem. Pharm. Res. 2014, 6, 374–381. [Google Scholar]

- Blahusiak, M.; Schlosser, S.; Martak, J. Extraction of butyric acid with a solvent containing ammonium ionic liquid. Sep. Purif. Technol. 2013, 119, 102–111. [Google Scholar] [CrossRef]

- Zare, F.; Ghaedi, M.; Daneshfar, A. Application of an ionic-liquid combined with ultrasonic-assisted dispersion ofgold nanoparticles for micro-solid phase extraction of unmetabolized pyridoxine and folic acid in biological fluids prior to high-performance liquid chromatography. RSC Adv. 2015, 5, 70064–70072. [Google Scholar] [CrossRef]

- Mirjalili, S.; Mirjalili, S.M.; Lewis, A. Grey Wolf Optimizer. Adv. Eng. Softw. 2014, 69, 46–61. [Google Scholar] [CrossRef] [Green Version]

- Raj, G.B.; Dash, K.K. Ultrasound-assisted extraction of phytocompounds from dragon fruit peel: Optimization, kinetics and thermodynamic studies. Ultrason. Sonochem. 2020, 68, 105180. [Google Scholar]

- Abdullah, S.; Pradhan, R.C.; Pradhan, D.; Mishra, S. Modeling and optimization of pectinase-assisted low-temperature extraction of cashew apple juice using artificial neural network coupled with genetic algorithm. Food Chem. 2021, 339, 127862. [Google Scholar] [CrossRef]

- Sodeifian, G.; Ardestani, N.S.; Sajadian, S.A.; Ghorbandoost, S. Application of supercritical carbon dioxide to extract essential oil from Cleome coluteoides Boiss: Experimental, response surface and grey wolf optimization methodology. J. Supercrit. Fluids 2016, 114, 55–63. [Google Scholar] [CrossRef]

- Sukpancharoen, S.; Srinophakun, T.R.; Aungkulanon, P. Grey wolf optimizer (GWO) with multi-objective optimization for biodiesel production from waste cooking oil using central composite design (CCD). Int. J. Mech. Eng. 2020, 9, 1219–1225. [Google Scholar] [CrossRef]

- Samuel, O.D.; Okwu, M.O.; Oyejide, O.J.; Taghinezhad, E.; Afzal, A.; Kaveh, M. Optimizing biodiesel production from abundant waste oils through empirical method and grey wolf optimizer. Fuel 2020, 281, 118701. [Google Scholar] [CrossRef]

- Weast, R.C. Handbook of Chemistry and Physics, 54th ed.; CRC Press: Cleveland, OH, USA, 1974. [Google Scholar]

- Nosrati, S.; Jayakumar, N.; Hashim, M. Performance evaluation of supported ionic liquid membrane for removal of phenol. J. Hazard. Mater. 2011, 192, 1283–1290. [Google Scholar] [CrossRef] [PubMed]

- Matsumoto, M.; Panigrahi, A.; Murakami, Y.; Kondo, K. Effect of Ammonium- and Phosphonium-Based Ionic Liquids on the Separation of Lactic Acid by Supported Ionic Liquid Membranes (SILMs). Membranes 2011, 1, 98–108. [Google Scholar] [CrossRef] [Green Version]

- Fraser, K.J.; MacFarlane, D.R. Phosphonium-Based Ionic Liquids: An Overview. Aust. J. Chem. 2009, 62, 309–321. [Google Scholar] [CrossRef]

- Gonçalves, A.R.P.; Paredes, X.; Cristino, A.F.; Santos, F.J.V.; Queirós, C.S.G.P. Ionic Liquids—A Review of Their Toxicity to Living Organisms. Int. J. Mol. Sci. 2021, 22, 5612. [Google Scholar] [CrossRef] [PubMed]

- Kebaili, H.; Pérez de los Ríos, A.; José Salar-García, M.; Ortiz-Martínez, V.M.; Kameche, M.; Hernández-Fernández, J.; Hernández-Fernández, F.J. Evaluating the Toxicity of Ionic Liquids on Shewanella sp. for Designing Sustainable Bioprocesses. Front. Mater. 2020, 7, 578411. [Google Scholar] [CrossRef]

- Schlosser, Š.; Marták, J.; Blahušiak, M. Specific phenomena in carboxylic acids extraction by selected types of hydrophobic ionic liquids. Chem. Pap. 2018, 72, 567–584. [Google Scholar] [CrossRef]

- Kurnia, K.A.; Lima, F.; Cláudio, A.F.; Coutinho, J.A.; Freire, M.G. Hydrogen-bond acidity of ionic liquids: An extended scale. Phys. Chem. Chem. Phys. 2015, 17, 18980–18990. [Google Scholar] [CrossRef] [Green Version]

- Gazzali, A.M.; Lobry, M.; Colombeau, L.; Acherar, S.; Azaïs, H.; Mordon, S.; Arnoux, P.; Baros, F.; Vanderesse, R.; Frochot, C. Stability of folic acid under several parameters. Eur. J. Pharm. Sci. 2016, 10, 419–430. [Google Scholar] [CrossRef]

- Marták, J.; Schlosser, S. Extraction of lactic acid by phosphonium ionic liquids. Sep. Purif. Technol. 2007, 57, 483–494. [Google Scholar] [CrossRef]

- DeSimone, D.; Counce, R.; Watson, J. Predicting the loading ratio and optimum extractant concentration for solvent extraction. Chem. Eng. Res. Des. 2020, 161, 271–278. [Google Scholar] [CrossRef]

- Priddy, K.; Keller, P. Artificial Neural Networks: An introduction; SPIE Press: Washington, DC, USA, 2005. [Google Scholar]

- Islam, M.; Yao, X. Evolving Artificial Neural Network Ensembles. In Computational Intelligence: A Compendium; Fulcher, J., Jain, L., Eds.; Springer: Berlin/Heidelberg, Germany, 2008. [Google Scholar]

- Torabi, S.; Safi-Esfahani, F. Improved Raven Roosting Optimization algorithm (IRRO). Swarm Evol. Comput. 2018, 40, 144–154. [Google Scholar] [CrossRef]

- Jessop, P.G. Searching for green solvents. Green Chem. 2011, 13, 1391–1398. [Google Scholar] [CrossRef]

| Ionic Liquid | Molecular Formula | mol. wt., g/mol | Viscosity, cP, 25 °C | log P | Toxicity |

|---|---|---|---|---|---|

| [BMIM][PF6] | C8H15F6N2P | 284.18 | 274 | 4.49 | log EC50 * = 3.32 μM |

| [OMIM][PF6] | C12H23F6N2P | 340.29 | 682 | 6.05 | log EC50 * = 2.24 μM |

| [HMIM][PF6] | C10H19F6N2P | 312.24 | 585 | 5.27 | log EC50 * = 1.25 μM |

| CYPHOS IL 103 | C42H87O2P | 665.11 | 319 | 14.32 | Inhib. ** = 1.5 cm |

| CYPHOS IL 104 | C48H102O2P2 | 773.27 | 805.8 | 18.28 | Inhib. ** = 2.6 cm |

| CYPHOS IL103 conc., M | D | Loading Factor | CYPHOS IL104 conc., M | D | Loading Factor | |

|---|---|---|---|---|---|---|

| 1 | 0.03 | 0.52 | 0.43 | 0.02 | 0.43 | 0.43 |

| 2 | 0.06 | 6.24 | 0.53 | 0.05 | 3.95 | 0.57 |

| 3 | 0.12 | 12.99 | 0.28 | 0.10 | 8.19 | 0.32 |

| 4 | 0.18 | 231.18 | 0.20 | 0.15 | 53.51 | 0.23 |

| Subset | Indicator | Type of Solvent | Type of Extractant | Aqueous Phase pH | Extractant Concentration | FA |

|---|---|---|---|---|---|---|

| Training | Mean | 1.155844 | 1.727273 | 4.084416 | 48.7013 | 63.0724 |

| Median | 1 | 2 | 4 | 40 | 79.8336 | |

| Standard Deviation | 0.365086 | 0.718851 | 0.874164 | 28.2191 | 32.09486 | |

| Sample Variance | 0.133288 | 0.516746 | 0.764162 | 796.3175 | 1030.08 | |

| Kurtosis | 1.792505 | −0.94144 | 0.632868 | 0.556316 | −1.11127 | |

| Skewness | 1.935617 | 0.461642 | −0.01714 | 0.909524 | −0.65705 | |

| Minimum | 1 | 1 | 2 | 0 | 6.229 | |

| Maximum | 2 | 3 | 6 | 120 | 98.33493 | |

| Count | 77 | 77 | 77 | 77 | 77 | |

| Testing | Mean | 1.269231 | 1.923077 | 3.75 | 51.15385 | 62.5145 |

| Median | 1 | 2 | 4 | 40 | 81.54103 | |

| Standard Deviation | 0.452344 | 0.796145 | 0.806226 | 26.08861 | 32.47939 | |

| Sample Variance | 0.204615 | 0.633846 | 0.65 | 680.6154 | 1054.911 | |

| Kurtosis | −0.84995 | −1.37721 | 1.646948 | 0.895838 | −1.59354 | |

| Skewness | 1.105353 | 0.143288 | −0.10853 | 1.188646 | −0.49504 | |

| Minimum | 1 | 1 | 2 | 15 | 8.340475 | |

| Maximum | 2 | 3 | 5.75 | 120 | 99.5693 | |

| Count | 26 | 26 | 26 | 26 | 26 |

| Fitness | MSE Training | MSE Testing | Topology | |

|---|---|---|---|---|

| Best | 647.7774 | 0.001544 | 0.000624 | 4:05:01 |

| Worst | 137.7863 | 0.007258 | 0.006111 | 4:08:01 |

| Confidence interval | 318.34 ± 41.06 | 0.004 ± 0.0005 | 0.003 ± 0.0004 | 0.985 ± 0.0018 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Blaga, A.C.; Dragoi, E.N.; Tucaliuc, A.; Kloetzer, L.; Cascaval, D. Folic Acid Ionic-Liquids-Based Separation: Extraction and Modelling. Molecules 2023, 28, 3339. https://doi.org/10.3390/molecules28083339

Blaga AC, Dragoi EN, Tucaliuc A, Kloetzer L, Cascaval D. Folic Acid Ionic-Liquids-Based Separation: Extraction and Modelling. Molecules. 2023; 28(8):3339. https://doi.org/10.3390/molecules28083339

Chicago/Turabian StyleBlaga, Alexandra Cristina, Elena Niculina Dragoi, Alexandra Tucaliuc, Lenuta Kloetzer, and Dan Cascaval. 2023. "Folic Acid Ionic-Liquids-Based Separation: Extraction and Modelling" Molecules 28, no. 8: 3339. https://doi.org/10.3390/molecules28083339

APA StyleBlaga, A. C., Dragoi, E. N., Tucaliuc, A., Kloetzer, L., & Cascaval, D. (2023). Folic Acid Ionic-Liquids-Based Separation: Extraction and Modelling. Molecules, 28(8), 3339. https://doi.org/10.3390/molecules28083339