Effect of Guar Gum with Sorbitol Coating on the Properties and Oil Absorption of French Fries

Abstract

:1. Introduction

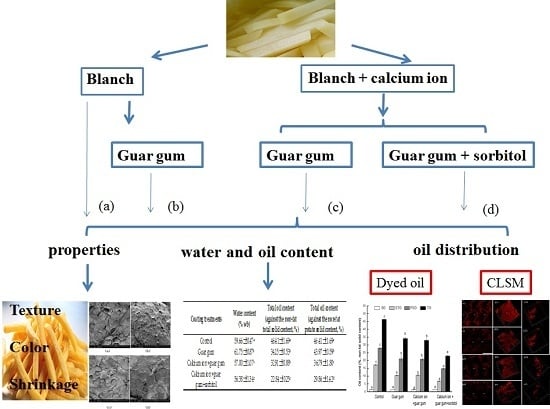

2. Results and Discussion

2.1. Initial Water Content, Solid Content, and Starch Content of Potato

2.2. Effect of Coating on the Water Content and Oil Content

2.3. Effect of Coating on Oil Fractions of French Fries

2.4. Oil Distribution and Microstructure of French Fries

2.5. Texture of French Fries

3. Materials and Methods

3.1. Materials

3.2. Sample Pre-Treatment

3.3. Frying Procedure

4. Analytical Methods

4.1. Water Content, Solid Content and Starch Content

4.2. Determination of Oil Content

4.3. Determination of Color

4.4. Determination of Texture

4.5. Microscopic Analysis

4.6. Statistical Analysis

5. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Tarmizi, A.H.A.; Niranjan, K. Combination of moderate vacuum frying with high vacuum drainage-relationship between process conditions and oil uptake. Food Bioprocess Technol. 2013, 6, 2600–2608. [Google Scholar] [CrossRef]

- Karizaki, V.M.; Sahin, S.; Sumnu, G.; Mosavian, M.T.H.; Luca, A. Effect of ultrasound-assisted osmotic dehydration as a pretreatment on deep fat frying of potatoes. Food Bioprocess Technol. 2013, 6, 3554–3563. [Google Scholar] [CrossRef]

- Van Loon, W.A.M.; Linssen, J.P.H.; Legger, A.; Posthumus, M.A.; Voragen, A.G.J. Identification and olfactometry of French fries flavour extracted at mouth conditions. Food Chem. 2005, 90, 417–425. [Google Scholar] [CrossRef]

- Sayon-Orea, C.; Martinez-Gonzalez, M.A.; Gea, A.; Flores-Gomez, E.; Basterra-Gortari, F.J.; Bes-Rastrollo, M. Consumption of fried foods and risk of metabolic syndrome: The SUN cohort study. Clin. Nutr. 2014, 33, 545–549. [Google Scholar] [CrossRef] [PubMed]

- Tajner-Czopek, A.; Figiel, A.; Carbonell-Barrachina, Á.A. Effects of potato strip size and pre-drying method on French fries quality. Eur. Food Res. Technol. 2007, 227, 757–766. [Google Scholar] [CrossRef]

- Niamnuy, C.; Devahastin, S.; Soponronnarit, S. Some recent advances in microstructural modification and monitoring of foods during drying: A review. J. Food Eng. 2014, 123, 148–156. [Google Scholar] [CrossRef]

- Kim, T.; Moreira, R.G. De-oiling and pretreatment for high-quality potato chips. J. Food Process Eng. 2013, 36, 267–275. [Google Scholar] [CrossRef]

- Varela, P.; Fiszman, S.M. Hydrocolloids in fried foods. A review. Food Hydrocoll. 2011, 25, 1801–1812. [Google Scholar] [CrossRef]

- Huang, L.L.; Zhang, M.; Mujumdar, A.S.; Lim, R.X. Comparison of four drying methods for re-structured mixed potato with apple chips. J. Food Eng. 2011, 103, 279–284. [Google Scholar] [CrossRef]

- Kampf, N.; Nussinovitch, A. Hydrocolloid coating of cheeses. Food Hydrocoll. 2000, 14, 531–537. [Google Scholar] [CrossRef]

- Singthong, J.; Thongkaew, C. Using hydrocolloids to decrease oil absorption in banana chips. LWT Food Sci. Technol. 2009, 42, 1199–1203. [Google Scholar] [CrossRef]

- Skurtys, O. Food Hydrocolloid Edible Films and Coatings; Nova Science Publishers: New York, NY, USA, 2010; ISBN 9781616682699. [Google Scholar]

- Kima, D.N.; Lima, J.; Baeb, I.Y.; Leeb, H.G.; Leea, S. Effect of hydrocolloid coatings on the heat transfer and oil uptake during frying of potato strips. J. Food Eng. 2011, 102, 317–320. [Google Scholar] [CrossRef]

- Thombare, N.; Jha, U.; Mishra, S.; Siddiqui, M.Z. Guar gum as a promising starting material for diverse applications: A review. Int. J. Biol. Macromol. 2016, 88, 361–372. [Google Scholar] [CrossRef] [PubMed]

- Donhowe, I.G.; Fennema, O. The effects of plasticizers on crystallinity, permeability, and mechanical-properties of methylcellulose films. J. Food Process Preserv. 1993, 17, 247–257. [Google Scholar] [CrossRef]

- Garcıa, M.A.; Ferrero, C.; Bertola, N.; Martino, M.; Zaritzky, N. Edible coatings from cellulose derivatives to reduce oil uptake in fried products. Innov. Food Sci. Emerg. Technol. 2002, 3, 391–397. [Google Scholar] [CrossRef]

- Tavera-Quiroz, M.J.; Urriza, M.; Pinotti, A.; Bertola, N. Plasticized methylcellulose coating for reducing oil uptake in potato chips. J. Sci. Food Agric. 2012, 92, 1346–1353. [Google Scholar] [CrossRef] [PubMed]

- Piermaria, J.; Bosch, A.; Pinotti, A.; Yantorno, O.; Garcia, M.A.; Abraham, A.G. Kefiran films plasticized with sugars and polyols: Water vapor barrier and mechanical properties in relation to their microstructure analyzed by ATR/FT-IR spectroscopy. Food Hydrocoll. 2011, 25, 1261–1269. [Google Scholar] [CrossRef]

- Saurabh, C.K.; Gupta, S.; Bahadur, J.; Mazumder, S.; Variyar, P.S.; Sharma, A. Radiation dose dependent change in physiochemical, mechanical and barrier properties of guar gum based films. Carbohydr. Polym. 2013, 98, 1610–1617. [Google Scholar] [CrossRef] [PubMed]

- Vieira, M.G.A.; Silva, M.A.; Santos, L.O.; Beppu, M.M. Natural-based plasticizers and biopolymer films: A review. Eur. Polym. J. 2011, 47, 254–263. [Google Scholar] [CrossRef]

- Khalil, A.H. Quality of French fried potatoes as influenced by coating with hydrocolloids. Food Chem. 1999, 66, 201–208. [Google Scholar] [CrossRef]

- Simundic, B.; Rade, D.; Lelas, V.; Rimacbrncic, S. Decreasing of oil absorption in potato strips during deep fat frying. J. Food Eng. 2004, 64, 237–241. [Google Scholar] [CrossRef]

- Durán, M.; Pedreschi, F.; Moyano, P.; Troncoso, E. Oil Partition in pre-treated potato slices during frying and cooling. J. Food Eng. 2007, 81, 257–265. [Google Scholar] [CrossRef]

- Moreno, M.C.; Bouchon, P. A different perspective to study the effect of freeze, air, and osmotic drying on oil absorption during potato frying. J. Food Sci. 2008, 73, 122–128. [Google Scholar] [CrossRef] [PubMed]

- Bunger, A.; Moyano, P.; Rioseco, V. NaCl soaking treatment for improving the quality of French-fried potatoes. Food Res. Int. 2003, 36, 161–166. [Google Scholar] [CrossRef]

- Garmakhany, A.D.; Mirzaei, H.O.; Nejad, M.K.; Maghsudlo, Y. Study of oil uptake and some quality attributes of potato chips affected by hydrocolloids. Eur. J. Lipid Sci. Technol. 2008, 110, 1045–1049. [Google Scholar] [CrossRef]

- Sothornvit, R. Edible coating and post-frying centrifuge step effect on quality of vacuum-fried banana chips. J. Food Eng. 2011, 107, 319–325. [Google Scholar] [CrossRef]

- Yu, L.; Li, J.; Ding, S.; Hang, F.; Fan, L. Effect of guar gum with glycerol coating on the properties and oil absorption of fried potato chips. Food Hydrocoll. 2016, 54, 211–219. [Google Scholar] [CrossRef]

- Millin, T.M.; Medina-Meza, I.G.; Walters, B.C.; Huber, K.C.; Rasco, B.A.; Ganjyal, G.M. Frying Oil Temperature: Impact on Physical and Structural Properties of French Fries During the Par and Finish Frying Processes. Food Bioprocess Technol. 2016, 9, 2080–2091. [Google Scholar] [CrossRef]

- Casas, J.A.; Mohedano, A.F.; Garcıa-Ochoa, F. Viscosity of guar gum and xanthan/guar gum mixture solutions. J. Sci. Food Agric. 2000, 80, 1722–1727. [Google Scholar] [CrossRef]

- Vina, S.Z.; Mugridge, A.; García, M.A.; Ferreyra, R.M.; Martino, M.N.; Chaves, A.R. Effects of polyvinylchloride films and edible starch coatings on quality aspects of refrigerated Brussels sprouts. Food Chem. 2007, 103, 701–709. [Google Scholar] [CrossRef]

- Albert, S.; Mittel, G.S. Comparative evaluation of edible coatings to reduce fat uptake in a deep-fried cereal product. Food Res. Int. 2002, 35, 445–458. [Google Scholar] [CrossRef]

- Patsioura, A.; Vauvre, J.M.; Kesteloot, R.; Jamme, F.; Hume, P.; Vitrac, O. Microscopic imaging of biphasic oil-air flow in French fries using synchrotron radiation. AIChE J. 2015, 61, 1427–1446. [Google Scholar] [CrossRef]

- Dana, D.; Saguy, I.S. Mechanism of oil uptake during deep-fat frying and the surfactant effect-theory and myth. Adv. Colloid Interface 2006, 128–130, 267–272. [Google Scholar] [CrossRef] [PubMed]

- Pedreschi, F.; Cocio, C.; Moyano, P.; Troncoso, E. Oil distribution in potato slices during frying. J. Food Eng. 2008, 87, 200–212. [Google Scholar] [CrossRef]

- Pedreschi, F.; Aguilera, J.M. Some changes in potato chips during frying observed by confocal laser scanning microscopy (CLSM). Food Sci. Technol. Int. 2002, 8, 197–201. [Google Scholar] [CrossRef]

- Pedreschi, F.; Aguilera, J.; Arbildua, J. CLSM study of oil location in fried potato slices. Microsc. Microanal. 1999, 37, 21–22. [Google Scholar]

- Bouchon, P.; Aguilera, J.A. Microstructural analysis of frying potatoes. Int. J. Food Sci. Technol. 2001, 36, 669–676. [Google Scholar] [CrossRef]

- Mariscal, M.; Bouchon, P. Comparison between atmospheric and vacuum frying of apple slices. Food Chem. 2008, 107, 1561–1569. [Google Scholar] [CrossRef]

- Shyu, S.-L.; Hwang, L.S. Effects of processing conditions on the quality of vacuum fried apple chips. Food Res. Int. 2001, 34, 133–142. [Google Scholar] [CrossRef]

- Maadyrad, A.; Ghiassi Tarzi, G.; Bassiri, A.; Bamenimoghadam, M. Process optimization in vacuum frying of kiwi slices using response surface methodology. J. Food Biosci. Technol. 2011, 1, 33–40. [Google Scholar]

- Zhang, T.; Li, J.; Ding, Z.; Fan, L. Effects of Initial Moisture Content on the Oil Absorption Behavior of Potato Chips during Frying Process. Food Bioprocess Technol. 2016, 9, 331–340. [Google Scholar] [CrossRef]

| Material | Initial Water Content (% wb) | Solid Content (% wb) | Starch Content (% wb) |

|---|---|---|---|

| Raw potato | 81.5 ± 0.4 a | 18.5 ± 0.4 a | 13.1 ± 0.2 a |

| Bleached potato | 83.7 ± 3.7 a | 16.3 ± 3.7 a | 10.9 ± 0.1 b |

| Coating Treatments | Water Content (% wb) | Total Oil Content (against the Non-Fat Total Solid Content, %) | Total Oil Content (against the Non-Fat Potato Solid Content, %) |

|---|---|---|---|

| Control | 59.66 0.47 a | 46.41 1.69 a | 46.41 1.69 a |

| Guar gum | 61.75 0.87 b | 34.15 0.53 b | 43.97 0.59 b |

| Calcium ion +guar gum | 57.00 1.07 c | 32.91 0.88 b | 36.79 1.80 c |

| Calcium ion + guar gum + sorbitol | 56.38 1.34 c | 22.84 0.25 c | 29.86 1.42 d |

| Coating Treatments | Hardness | Chewiness | L* | a* | b* |

|---|---|---|---|---|---|

| Control | 1902 ± 81.00 a | 86.09 ± 2.99 a | 53.35 ± 0.63 a | −1.24 ± 0.02 a | 15.82 ± 0.68 a |

| Guar gum | 1869 ± 56.22 a | 85.45 ± 3.90 a | 53.68 ± 0.25 a | −1.27 ± 0.03 a | 15.72 ± 0.35 a |

| Calcium ion + guar gum | 1953 ± 13.39 a | 89.99 ± 4.34 a | 53.98 ± 0.19 a | −1.24 ± 0.07 a | 15.34 ± 0.21 a |

| Calcium ion + guar gum + sorbitol | 1964 ± 35.92 a | 91.03 ± 3.28 a | 54.36 ± 0.82 a | −1.25 ± 0.06 a | 15.06 ± 0.05 a |

© 2017 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Jia, B.; Fan, D.; Li, J.; Duan, Z.; Fan, L. Effect of Guar Gum with Sorbitol Coating on the Properties and Oil Absorption of French Fries. Int. J. Mol. Sci. 2017, 18, 2700. https://doi.org/10.3390/ijms18122700

Jia B, Fan D, Li J, Duan Z, Fan L. Effect of Guar Gum with Sorbitol Coating on the Properties and Oil Absorption of French Fries. International Journal of Molecular Sciences. 2017; 18(12):2700. https://doi.org/10.3390/ijms18122700

Chicago/Turabian StyleJia, Bo, Daming Fan, Jinwei Li, Zhenhua Duan, and Liuping Fan. 2017. "Effect of Guar Gum with Sorbitol Coating on the Properties and Oil Absorption of French Fries" International Journal of Molecular Sciences 18, no. 12: 2700. https://doi.org/10.3390/ijms18122700

APA StyleJia, B., Fan, D., Li, J., Duan, Z., & Fan, L. (2017). Effect of Guar Gum with Sorbitol Coating on the Properties and Oil Absorption of French Fries. International Journal of Molecular Sciences, 18(12), 2700. https://doi.org/10.3390/ijms18122700