Improving the Hybrid Electromagnetic Clamping System by Reducing the Leakage Flux and Enhancing the Effective Flux

Abstract

:1. Introduction

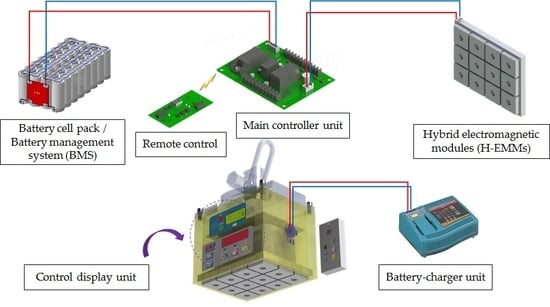

2. Hybrid Electromagnetic Clamping System

2.1. H-EMCS Structure and Components

2.2. Electronic Controller and Charging Process

2.3. Design Process of Hybrid Electromagnetic Modules

2.4. Basic Structure of Conventional Hybrid Electromagnetic Modules

2.5. Basic Operating Principle of Hybrid Electromagnetic Modules

2.5.1. Attachment and Detachment Mode

2.5.2. Magnetic Flux Leakage in the Conventional Model

3. Improving H-EMM Performance through Core Shape Modification

3.1. Conventional Hybrid Electromagnetic Module Model

3.2. Proposed Hybrid Electromagnetic Module Model

3.2.1. Effect of Changing the Lower Core Shape

3.2.2. Effect of Changing Both Lower and Upper Core Shapes

3.2.3. Effect of Changing the Upper Core Dimensions

4. Verification of the Proposed Model

4.1. Simulation Results

4.2. Experimental Results

5. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Wanli, C.; Chenglin, G.; Xiaodong, H. Analysis and Design of a Permanent Magnet Bi-Stable Electro-Magnetic Clutch Unit for In-Wheel Electric Vehicle Drives. Energies 2015, 8, 5598–5612. [Google Scholar] [Green Version]

- Baek, S.-K.; Oh, H.-K.; Kim, S.-W.; Seo, S.-I. A Clamping Force Performance Evaluation of the Electro Mechanical Brake Using PMSM. Energies 2018, 11, 2876. [Google Scholar] [CrossRef]

- Jo, C.; Hwang, S.; Kim, H. Clamping-force control for electromechanical brake. IEEE Trans. Veh. Technol. 2010, 59, 3205–3212. [Google Scholar] [CrossRef]

- Lee, Y.O.; Jang, M.; Lee, W.; Lee, C.W.; Chung, C.C.; Son, Y.S. Novel clamping force control for electric parking brake systems. Mechatronics 2011, 21, 1156–1162. [Google Scholar] [CrossRef]

- Ki, Y.H.; Lee, K.J.; Cheon, J.S.; Ahn, H.S. Design and implementation of a new clamping force estimator in electro-mechanical brake systems. Int. J. Automot. Technol. 2013, 14, 739–745. [Google Scholar] [CrossRef]

- Hemmati, V.E.; Oskouei, R.H.; Chakherlou, T.N. An Experimental Method for Measuring Clamping Force in Bolted Connections and Effect of Bolt Threads Lubrication on its Value. World Acad. Sci. Eng. Technol. Int. J. Mech. Mechatron. Eng. 2008, 2, 1136–1139. [Google Scholar]

- Park, G.; Hyun, D.; Choi, S.B. Development of Clamping Force Estimation Algorithm and Clamp-force Sensor Calibration on Electromechanical Brake Systems. Trans. KSAE 2016, 24, 365–371. [Google Scholar] [CrossRef] [Green Version]

- Saric, S.; Bab-Hadiashar, A.; Hoseinnezhad, R. Clamp-Force Estimation for a Brake-by-Wire System: A Sensor-Fusion Approach. IEEE Trans. Veh. Technol. 2008, 57, 778–786. [Google Scholar] [CrossRef]

- Essam, A.; Bahkali, A. Finite Element Modeling for Thermal Stresses Developed in Riveted and Rivet-Bonded Joints. Int. J. Eng. Technol. IJET IJENS 2011, 11, 106–112. [Google Scholar]

- Nah, H.-S.; Lee, H.-J.; Kim, K.-S.; Kim, J.-H.; Kim, W.-B. Method for estimating the clamping force of high strength bolts subjected to temperature variation. Int. J. Steel Struct. 2009, 9, 123–130. [Google Scholar] [CrossRef]

- Hrvoje, V.; Željko, S.; Željko, H.; Tin, B. A Transformer with Increased Leakage Flux for Didactic Considerations on Magnetic Circuits. Int. J. Electr. Comput. Eng. Syst. 2017, 8, 27–32. [Google Scholar]

- Yoon, M.-H.; Sim, J.-H.; Kim, J.-M.; Lim, M.-S.; Jung, J.-W.; Hong, J.-P. Leakage Flux Reduction Applying Rib-less Structure in V-shape Interior Permanent Magnet Synchronous Motor. J. Magn. 2018, 23, 387–391. [Google Scholar] [CrossRef]

- Linshuai, Z.; Shuxiang, G.; Huadong, Y.; Yu, S. Design and principle analysis for electromagnetic brake clamping mechanism of a novel slave manipulator. In Proceedings of the 2016 IEEE International Conference on Mechatronics and Automation, Harbin, China, 7–10 August 2016; pp. 490–495. [Google Scholar]

- Luo, M.; Luo, D.; Dujic, J.; Allmeling, J. Leakage flux modelling of multi-winding transformer using permeance magnetic circuit. In Proceedings of the 2016 IEEE Applied Power Electronics Conference and Exposition, Long Beach, CA, USA, 20–24 March 2016; pp. 1108–1114. [Google Scholar]

- Ma, J.; Qu, R.; Li, J.; Jia, S. Structural Optimization of a Permanent-Magnet Direct-Drive Generator Considering Eccentric Electromagnetic Force. IEEE Trans. Magn. 2015, 51, 8100904. [Google Scholar] [CrossRef]

- Liangliang, W.; Baichao, C.; Yushun, L.; Cuihua, T.; Jiaxin, Y.; Yuxin, B.; Tianan, Z. Performance Investigation and Optimization of a Novel Hybrid Saturated-Core Fault-Current Limiter Considering the Leakage Effect. Energies 2018, 11, 61. [Google Scholar] [Green Version]

- Caiyan, Q.; Chaoning, Z.; Haiyan, L. H-Shaped Multiple Linear Motor Drive Platform Control System Design Based on an Inverse System Method. Energies 2017, 10, 1990. [Google Scholar] [Green Version]

- Woo, K.I.; Kwon, B.I. Characteristic analysis and modification of PM-type magnetic circuit breaker. IEEE Trans. Magn. 2004, 40, 691–694. [Google Scholar] [CrossRef]

- Felipe, T.; Marilia, A.S.; Aly, F.F.; David, G.D. Theoretical and Experimental Analysis of an Induction Planar Actuator with Different Secondaries. Sensors 2016, 16, 407. [Google Scholar]

| Items | Value | - | ||

|---|---|---|---|---|

| Winding | Material | Copper | Φ1.0mm, 20turns | |

| Magnet | Alnico | Grade | Alnico5 | Br 1.1 (T) |

| NdFeB | Grade | N38 | Br 1.3 (T) | |

| Core | Upper | Material | S45C | Magnetic steel |

| Lower | Material | S45C | ||

| Parts | Unit | Size | Description | |

|---|---|---|---|---|

| Magnet | NdFeB | mm | 31, 16, 9 t | width, length, thickness (all dimensions are fixed) |

| Alnico | mm | 42, 42, 18 t | ||

| Core | Upper | mm | 50, 50, 20 t | width (x), length (y), thickness (z) (all dimensions are variable) |

| Lower | mm | 50, 50, 20 t | width (x), length (y), thickness (z) (width and length are variable) | |

| Parts | Unit | Conventional Model | Proposed Model | ||

|---|---|---|---|---|---|

| Lower core | Corner | A | mm | 0 | 9.3 |

| B | mm | 0 | 9.3 | ||

| z (thickness) | mm | 20 | 20 | ||

| Upper core | x (width) | mm | 50 | 50 | |

| y (length) | mm | 50 | 50 | ||

| z (thickness) | mm | 20 | 14 | ||

| Array | Unit | Electromagnetic Force | ||

|---|---|---|---|---|

| Basic Model | Proposed Model | Rate | ||

| 2-by-2 | Nm | 454.8 | 499.8 | 9.8% ↑ |

| 4-by-2 | Nm | 907.8 | 1003.8 | 10.6% ↑ |

| 4-by-2 Array | Simulation | Experiment | ||

|---|---|---|---|---|

| Basic Model | Proposed Model | Basic Model | Proposed Model | |

| Electromagnetic force (Nm) | 907.8 | 1003.8 (10.6% ↑) | - | 997.5 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Baek, S.-W.; Yoon, K.-Y. Improving the Hybrid Electromagnetic Clamping System by Reducing the Leakage Flux and Enhancing the Effective Flux. Energies 2019, 12, 3762. https://doi.org/10.3390/en12193762

Baek S-W, Yoon K-Y. Improving the Hybrid Electromagnetic Clamping System by Reducing the Leakage Flux and Enhancing the Effective Flux. Energies. 2019; 12(19):3762. https://doi.org/10.3390/en12193762

Chicago/Turabian StyleBaek, Soo-Whang, and Keun-Young Yoon. 2019. "Improving the Hybrid Electromagnetic Clamping System by Reducing the Leakage Flux and Enhancing the Effective Flux" Energies 12, no. 19: 3762. https://doi.org/10.3390/en12193762

APA StyleBaek, S. -W., & Yoon, K. -Y. (2019). Improving the Hybrid Electromagnetic Clamping System by Reducing the Leakage Flux and Enhancing the Effective Flux. Energies, 12(19), 3762. https://doi.org/10.3390/en12193762