Bridging Tools to Better Understand Environmental Performances and Raw Materials Supply of Traction Batteries in the Future EU Fleet

Abstract

:1. Introduction

- To what extent will the environmental performance of future mobility systems improve due to the uptake of EVs and therefore batteries? Is this improvement in line with expectations (e.g., the EU Green Deal and the SGDs)? How relevant is the relative contribution of traction LIBs life-cycle impacts in terms of environmental performance?

- To cover the forecasted demand of traction LIBS for the EU fleet in the future, will the CRMs used for their manufacturing be available in adequate quantity and quality?

- What can the role of recycling in terms of improving the environmental performances of LIBs be? To what extent can it contribute until the production of traction batteries peak and stabilise? At what stage of the LIB value chain are the CRMs to be recycled in the future (i.e., SRMs)?

- In which way are CRMs key to the change of mobility patterns? In which way will the change in mobility patterns affect criticality, e.g., in terms of growing demand for S(C)RMs)?

- How much can circular economy strategies help speed up the change and improve the overall environmental performance of mobility systems? How can trade-offs between different EoL strategies be quantitatively considered?

Aim and Structure of the Paper

2. Literature Review: Main Aspects Affecting the Environmental Assessment of LIBs in the Future EU Fleet

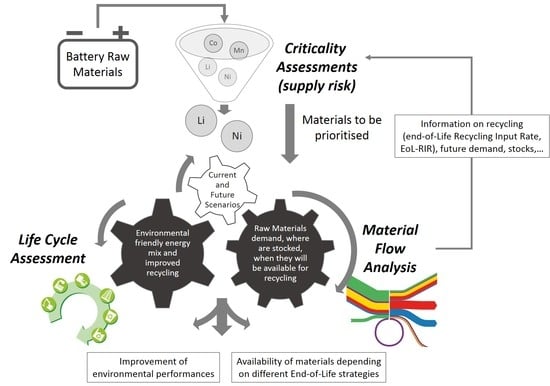

3. Methodology: Modelling Flows and Impacts of LIBs in the EU Fleet

3.1. LCA of Traction LIBs

3.2. MFA of traction LIBs in the EU

| υ ICEV/EV, y | = Unknown whereabouts |

| ϕ coll, y | = Collected ELVs |

| ε EV, y | = ELVs exports |

| γ EV | = ELVs to recycling |

| ι recovery | = ELVs to recovery |

| β direct reuse | = ELVs to direct reuse |

| λ recovery | = ELVs to landfill |

| θ recy | = Recycling efficiency |

| θ reco | = Recovery efficiency |

3.3. Criticality and Supply Risk of LIBs Raw Materials

3.4. Common Inventory and Data Gaps

4. Case-Study: Traction Batteries in the Future EU Fleet

4.1. Description of the Case-study and the Assessed Scenarios

4.1.1. “Base-Case Scenario”

4.1.2. Scenario A: Extension of the LIBs Lifetime Through Their Second-use

4.1.3. Scenario B: Improved EoL Extension of the LIBs Lifetime Through Their Second-use and Improvement of Recycling

4.1.4. Scenario C: Renewable Energy for the Manufacturing Stage

5. Results and Discussion

5.1. Results

5.2. Discussion

6. Conclusions

Supplementary Materials

Author Contributions

Funding

Conflicts of Interest

Disclaimer

References

- EC. Communication from the Commission to the European Parliament, the European Council, the Council, the European economic and social Committee and the Committee of the Regions. The European Green Deal; COM(2019) 640; Publications Office of the EU: Luxemburg, 2019. [Google Scholar]

- EC. Reflection Paper—Towards a Sustainable Europe By 2030; COM(2019) 22 final; Publications Office of the EU: Luxemburg, 2019. [Google Scholar]

- Alonso Raposo, M.; Ciuffo, B.; Ardente, F.; Aurambout, J.P.; Baldini, G.; Braun, R.; Christidis, P.; Christodoulou, A.; Duboz, A.; Felici, S.; et al. The Future of Road Transport—Implications of Automated, Connected, Low-Carbon and Shared Mobility; Publications Office of the EU: Luxemburg, 2019; ISBN 978-92-76-03409-4. [Google Scholar]

- EC. In-Depth Analysis in Support of the Commission Communication COM(2018) 773—A Clean Planet for all A European Long-Term Strategic Vision for a Prosperous, Modern, Competitive and Climate Neutral Economy; Publications Office of the EU: Luxemburg, 2018. [Google Scholar]

- Zubi, G.; Dufo-López, R.; Carvalho, M.; Pasaoglu, G. The lithium-ion battery: State of the art and future perspectives. Renew. Sustain. Energy Rev. 2018, 89, 292–308. [Google Scholar] [CrossRef]

- Witkamp, B.; van Gijlswijk, R.; Bolech, M.; Coosemans, T.; Hooftman, N. The transition to a Zero Emission Vehicles fleet for cars in the EU by 2050. In Pathways and Impacts: An Evaluation of Forecasts and Backcasting the COP21 Commitments; European Alternative Fuel Observatory (EAFO): Brussels, Belgium, 2017. [Google Scholar]

- Cano, Z.P.; Banham, D.; Ye, S.; Hintennach, A.; Lu, J.; Fowler, M.; Chen, Z. Batteries and fuel cells for emerging electric vehicle markets. Nat. Energy 2018, 3, 279–289. [Google Scholar] [CrossRef]

- Thiel, C.; Nijs, W.; Simoes, S.; Schmidt, J.; van Zyl, A.; Schmid, E. The impact of the EU car CO2 regulation on the energy system and the role of electro-mobility to achieve transport decarbonisation. Energy Policy 2016, 96, 153–166. [Google Scholar] [CrossRef]

- Bobba, S.; Mathieux, F.; Ardente, F.; Blengini, G.A.; Cusenza, M.A.; Podias, A.; Pfrang, A. Life Cycle Assessment of repurposed electric vehicle batteries: An adapted method based on modelling energy flows. J. Energy Storage 2018, 19, 213–225. [Google Scholar] [CrossRef]

- Podias, A.; Pfrang, A.; Di Persio, F.; Kriston, A.; Bobba, S.; Mathieux, F.; Messagie, M.; Boon-Brett, L. Sustainability Assessment of Second Use Applications of Automotive Batteries: Ageing of Li-Ion Battery Cells in Automotive and Grid-Scale Applications. World Electr. Veh. J. 2018, 9, 24. [Google Scholar] [CrossRef] [Green Version]

- EUROBAT. E-Mobility Battery R&D Roadmap 2030—Battery Technology for Vehicle Applications; Association of European Automotive and Industrial Battery Manufacturers (EUROBAT). Available online: https://eurobat.org/sites/default/files/e-mobility_roadmap_presentation_olivier_amiel_final.pdf (accessed on 2015).

- Bobba, S.; Mathieux, F.; Blengini, G.A. How will second-use of batteries affect stocks and flows in the EU? A model for traction Li-ion batteries. Resour. Conserv. Recycl. 2019, 145, 279–291. [Google Scholar] [CrossRef] [PubMed]

- EC. Communication from the Commission to the European Parliament, the European Council, the Council, the European economic and social Committee and the Committee of the Regions; A new Circular Economy Action Plan; For a cleaner and more competitive Europe; COM: 2020/98 final; Publications Office of the EU: Luxemburg, 2020. [Google Scholar]

- Winslow, K.M.; Laux, S.J.; Townsend, T.G. A review on the growing concern and potential management strategies of waste lithium-ion batteries. Resour. Conserv. Recycl. 2018, 129, 263–277. [Google Scholar] [CrossRef]

- EC. Communication from the Commission to the European Parliament, the European Council, the Council, the European economic and social Committee and the Committee of the Regions; A New Industrial Strategy for Europe; COM: 2020; 102 final; Publications Office of the EU: Luxemburg, 2020. [Google Scholar]

- Schrijvers, D.; Hool, A.; Blengini, G.A.; Chen, W.-Q.; Dewulf, J.; Eggert, R.; van Ellen, L.; Gauss, R.; Goddin, J.; Habib, K.; et al. A review of methods and data to determine raw material criticality. Resour. Conserv. Recycl. 2020, 155, 104617. [Google Scholar] [CrossRef]

- IEA. Global EV Outlook 2018: Towards Cross-Modal Electrification; International Energy Agency (IEA): Paris, France, 2018; ISBN 9789264302365. [Google Scholar]

- Olivetti, E.A.; Ceder, G.; Gaustad, G.G.; Fu, X. Lithium-Ion Battery Supply Chain Considerations: Analysis of Potential Bottlenecks in Critical Metals. Joule 2017, 1, 229–243. [Google Scholar] [CrossRef] [Green Version]

- EC. Communication from the Commission to the European Parliament, the Council, the European Economic and Social Committee and the Committee of the Regions on the 2017 list of Critical Raw Materials for the EU; COM: 2017; 490 final; Publications Office of the EU: Luxemburg, 2017. [Google Scholar]

- Mistry, M.; Gediga, J.; Boonzaier, S. Life cycle assessment of nickel products. Int. J. Life Cycle Assess. 2016, 21, 1559–1572. [Google Scholar] [CrossRef] [Green Version]

- INSG. International Nickel Study Group—The World Nickel Factbook 2018. 2018. Available online: https://insg.org/wp-content/uploads/2019/03/publist_The-World-Nickel-Factbook-2018.pdf (accessed on 15 May 2020).

- Ellingsen, L.A.-W.; Hung, C.R. Research for TRAN Committee—Battery-Powered Electric Vehicles: Market Development and Lifecycle Emissions. European Union, 2018. Available online: https://www.europarl.europa.eu/RegData/etudes/STUD/2018/617457/IPOL_STU(2018)617457_EN.pdf (accessed on 15 May 2020).

- Mathieux, F.; Ardente, F.; Bobba, S.; Nuss, P.; Blengini, G.A.; Alves Dias, P.; Blagoeva, D.; Torres De Matos, C.; Wittmer, D.; Pavel, C.; et al. Critical Raw Materials and the Circular Economy—Background Report; JRC-EC (Joint Research Centre—European Commission) Science-for-Policy Report, EUR 28832 EN; Publications Office of the European Union: Luxembourg, 2017; ISBN 9789279742828. [Google Scholar]

- Ellingsen, L.A.-W.; Majeau-Bettez, G.; Singh, B.; Srivastava, A.K.; Valøen, L.O.; Strømman, A.H. Life Cycle Assessment of a Lithium-Ion Battery Vehicle Pack: LCA of a Li-Ion Battery Vehicle Pack. J. Ind. Ecol. 2014, 18, 113–124. [Google Scholar] [CrossRef] [Green Version]

- Zackrisson, M.; Avellán, L.; Orlenius, J. Life cycle assessment of lithium-ion batteries for plug-in hybrid electric vehicles – Critical issues. J. Clean. Prod. 2010, 18, 1519–1529. [Google Scholar] [CrossRef]

- Majeau-Bettez, G.; Hawkins, T.R.; Strømman, A.H. Life Cycle Environmental Assessment of Lithium-Ion and Nickel Metal Hydride Batteries for Plug-In Hybrid and Battery Electric Vehicles. Environ. Sci. Technol. 2011, 45, 4548–4554. [Google Scholar] [CrossRef]

- Ruiz, V.; Boon-Brett, L.; Steen, M.; Berghe, L. Van den Putting Science into Standards: Workshop—Summary & Outcomes. In Proceedings of the Driving Towards Decarbonisation of Transport: Safety, Performance, Second life and Recycling of Automotive Batteries for e-Vehicles, Workshop Organised by JRC and CEN-CENELEC JRC, Petten, The Netherlands, 22–23 September 2016. [Google Scholar]

- Marmiroli, B.; Messagie, M.; Dotelli, G.; Van Mierlo, J. Electricity Generation in LCA of Electric Vehicles: A Review. Appl. Sci. 2018, 8, 1384. [Google Scholar] [CrossRef] [Green Version]

- Ardente, F.; Tecchio, P.; Bobba, S.; Mathieux, F. Assessment of resource efficiency in a life cycle perspective: The case of reuse. In Proceedings of the Atti del XI Convegno della Rete Italiana LCA—Resource Efficiency e Sustainable Development Goals: Il ruolo del Life Cycle Thinking, ENEA, Siena, Italy, 22–23 June 2017; ISBN 978-88-8286-352-4. [Google Scholar]

- Nuss, P.; Blengini, G.A. Towards better monitoring of technology critical elements in Europe: Coupling of natural and anthropogenic cycles. Sci. Total Environ. 2018, 613, 569–578. [Google Scholar] [CrossRef] [PubMed]

- De Meester, S.; Nachtergaele, P.; Debaveye, S.; Vos, P.; Dewulf, J. Using material flow analysis and life cycle assessment in decision support: A case study on WEEE valorization in Belgium. Resour. Conserv. Recycl. 2019, 142, 1–9. [Google Scholar] [CrossRef]

- Mancini, L.; Benini, L.; Sala, S. Resource footprint of Europe: Complementarity of material flow analysis and life cycle assessment for policy support. Environ. Sci. Policy 2015, 54, 367–376. [Google Scholar] [CrossRef]

- Ramirez, D.A.B.; Ochoa, G.E.V.; Peña, A.R.; Escorcia, Y.C. Bibliometric analysis of nearly a decade of research in electric vehicles: A dynamic approach. ARPN J. Eng. Appl. Sci. 2018, 13, 4730–4736. [Google Scholar]

- Zhao, X.; Wang, S.; Wang, X. Characteristics and Trends of Research on New Energy Vehicle Reliability Based on the Web of Science. Sustainability 2018, 10, 3560. [Google Scholar] [CrossRef] [Green Version]

- Schmitt, G.; Scott, J.; Davis, A.; Utz, T. Patents and progress; intellectual property showing the future of electric vehicles. In Proceedings of the EVS29 Symposium, Montréal, QC, Canada, 19–22 June 2016; Volume 8, pp. 635–645. [Google Scholar]

- Messagie, M.; Boureima, F.S.; Coosemans, T.; Macharis, C.; Mierlo, J. Van A range-based vehicle life cycle assessment incorporating variability in the environmental assessment of different vehicle technologies and fuels. Energies 2014, 7, 1467–1482. [Google Scholar] [CrossRef]

- Harvey, L.D.D. Resource implications of alternative strategies for achieving zero greenhouse gas emissions from light-duty vehicles by 2060. Appl. Energy 2018, 212, 663–679. [Google Scholar] [CrossRef]

- Notter, D.A.; Gauch, M.; Widmer, R.; Wäger, P.; Stamp, A.; Zah, R.; Althaus, H.-J. Contribution of Li-Ion Batteries to the Environmental Impact of Electric Vehicles. Environ. Sci. Technol. 2010, 44, 6550–6556. [Google Scholar] [CrossRef] [PubMed]

- Girardi, P.; Gargiulo, A.; Brambilla, P.C. A comparative LCA of an electric vehicle and an internal combustion engine vehicle using the appropriate power mix: The Italian case study. Int. J. Life Cycle Assess. 2015, 20, 1127–1142. [Google Scholar] [CrossRef]

- ISO 14040:2006. Environmental Management—Life Cycle Assessment—Requirements and Guidelines; UNI EN ISO (International Standard Organisation), 2006. [Google Scholar]

- Recharge Association. PEFCR—Product Environmental Footprint Category Rules for High Specific Energy Rechargeable Batteries for Mobile Applications. 2018. Available online: https://ec.europa.eu/environment/eussd/smgp/pdf/PEFCR_Batteries.pdf (accessed on 15 May 2020).

- Peters, J.F.; Baumann, M.; Zimmermann, B.; Braun, J.; Weil, M. The environmental impact of Li-Ion batteries and the role of key parameters—A review. Renew. Sustain. Energy Rev. 2017, 67, 491–506. [Google Scholar] [CrossRef]

- Ellingsen, L.A.-W.; Hung, C.R.; Strømman, A.H. Identifying key assumptions and differences in life cycle assessment studies of lithium-ion traction batteries with focus on greenhouse gas emissions. Transp. Res. Part D Transp. Environ. 2017, 55, 82–90. [Google Scholar] [CrossRef]

- Peters, J.F.; Weil, M. Providing a common base for life cycle assessments of Li-Ion batteries. J. Clean. Prod. 2018, 171, 704–713. [Google Scholar] [CrossRef]

- Cusenza, M.A.; Bobba, S.; Ardente, F.; Cellura, M.; Di Persio, F. Energy and environmental assessment of a traction lithium-ion battery pack for plug-in hybrid electric vehicles. J. Clean. Prod. 2019, 215, 634–649. [Google Scholar] [CrossRef]

- Philippot, M.; Álvarez, G.; Ayerbe, E.; Van Mierlo, J.; Messagie, M. Eco-Efficiency of a Lithium-Ion Battery for Electric Vehicles: Influence of Manufacturing Country and Commodity Prices on GHG Emissions and Costs. Batteries 2019, 5, 23. [Google Scholar] [CrossRef] [Green Version]

- Deng, Y.; Li, J.; Li, T.; Gao, X.; Yuan, C. Life cycle assessment of lithium sulfur battery for electric vehicles. J. Power Sources 2017, 343, 284–295. [Google Scholar] [CrossRef] [Green Version]

- Wang, Q.; Liu, W.; Yuan, X.; Tang, H.; Tang, Y.; Wang, M.; Zuo, J.; Song, Z.; Sun, J. Environmental impact analysis and process optimization of batteries based on life cycle assessment. J. Clean. Prod. 2018, 174, 1262–1273. [Google Scholar] [CrossRef]

- EC. Commission Staff working document Accompanying the document Communication from the Commission to the European Parliament, the Council, the European Economic and Social Committee and the Committee of the Regions EUROPE ON THE MOVE An Agenda for a Socially; SWD: 2017; 177 final; Publications Office of the EU: Luxemburg, 2017. [Google Scholar]

- Faria, R.; Marques, P.; Garcia, R.; Moura, P.; Freire, F.; Delgado, J.; de Almeida, A.T. Primary and secondary use of electric mobility batteries from a life cycle perspective. J. Power Sources 2014, 262, 169–177. [Google Scholar] [CrossRef]

- Erkisi-Arici, S.; Egede, P.; Cerdas, F.; Kaluza, A.; Herrmann, C. Life Cycle Assessment of Electric Vehicles—The Influence of Regional Aspects and Future Renewable Energy Targets. In Proceedings of the EVS30 Symposium, Stuttgart, Germany, 9–11 October 2017. [Google Scholar]

- Ahmadi, L.; Yip, A.; Fowler, M.; Young, S.B.; Fraser, R.A. Environmental feasibility of re-use of electric vehicle batteries. Sustain. Energy Technol. Assess. 2014, 6, 64–74. [Google Scholar] [CrossRef]

- Casals, L.C.; Amante García, B.; Canal, C. Second life batteries lifespan: Rest of useful life and environmental analysis. J. Environ. Manag. 2019, 232, 354–363. [Google Scholar] [CrossRef]

- Koch-Ciobotaru, C.; Saez-de-Ibarra, A.; Martinez-Laserna, E.; Stroe, D.-I.; Swierczynski, M.; Rodriguez, P. Second life battery energy storage system for enhancing renewable energy grid integration. In Proceedings of the 2015 IEEE Energy Conversion Congress and Exposition (ECCE), Montreal, QC, Canada, 20–24 September 2015; pp. 78–84. [Google Scholar] [CrossRef]

- Weniger, J.; Tjaden, T.; Quaschning, V. Sizing of residential PV battery systems. Energy Procedia 2014, 46, 78–87. [Google Scholar] [CrossRef] [Green Version]

- UMICORE. Battery Recycling—Our Recycling Process. Available online: http://csm.umicore.com/en/recycling/battery-recycling/our-recycling-process/ (accessed on 15 February 2020).

- EC. The Raw Materials Initiative—Meeting our Critical Needs for Growth and Jobs in Europe; COM: 2008; 699 final; Publications Office of the EU: Luxemburg, 2008. [Google Scholar]

- Blengini, G.A.; Blagoeva, D.; Dewulf, J.; Torres de Matos, C.; Baranzelli, C.; Ciupagea, C.; Dias, P.; Kayam, Y.; Latunussa, C.E.L.; Mancini, L.; et al. Methodology for establishing the EU list of Critical Raw Materials. Publ. Off. Eur. Union 2017. [Google Scholar]

- Turner, D.A.; Williams, I.D.; Kemp, S. Combined material flow analysis and life cycle assessment as a support tool for solid waste management decision making. J. Clean. Prod. 2016, 129, 234–248. [Google Scholar] [CrossRef] [Green Version]

- Mancini, L.; Sala, S.; Recchioni, M.; Benini, L.; Goralczyk, M.; Pennington, D. Potential of life cycle assessment for supporting the management of critical raw materials. Int. J. Life Cycle Assess. 2015, 20, 100–116. [Google Scholar] [CrossRef]

- Golroudbary, S.R.; Calisaya-Azpilcueta, D.; Kraslawski, A. The life cycle of energy consumption and greenhouse gas emissions from critical minerals recycling: Case of lithium-ion batteries. Procedia CIRP 2019, 80, 316–321. [Google Scholar] [CrossRef]

- Pillot, C. Lithium ion Battery Raw Material Supply and Demand 2016–2025. In Proceedings of the 7th International AABC Advanced Automotive battery Conference, Mainz, Germany, 12–16 January 2017. [Google Scholar]

- Song, J.; Yan, W.; Cao, H.; Song, Q.; Ding, H.; Lv, Z.; Zhang, Y.; Sun, Z. Material flow analysis on critical raw materials of lithium-ion batteries in China. J. Clean. Prod. 2019, 215, 570–581. [Google Scholar] [CrossRef]

- Helbig, C.; Bradshaw, A.M.; Wietschel, L.; Thorenz, A.; Tuma, A. Supply risks associated with lithium-ion battery materials. J. Clean. Prod. 2018, 172, 274–286. [Google Scholar] [CrossRef]

- Gemechu, E.D.; Sonnemann, G.; Young, S.B. Geopolitical-related supply risk assessment as a complement to environmental impact assessment: The case of electric vehicles. Int. J. Life Cycle Assess. 2017, 22, 31–39. [Google Scholar] [CrossRef]

- Eynard, U.; Bobba, S.; Cusenza, M.A.; Blengini, G.A. Lithium-ion batteries for electric vehicles: Combining Environmental and Social Life Cycle Assessments. In Proceedings of the Life Cycle Thinking in Decision-Making for Sustainability: From Public Policies to Private Businesses, Messina, Italy, 11–12 June 2018. [Google Scholar]

- Gaines, L. Lithium-ion battery recycling processes: Research towards a sustainable course. Sustain. Mater. Technol. 2018, 17, e00068. [Google Scholar] [CrossRef]

- Bauer, C. Ökobilanz von Lithium-Ionen Batterien; Paul Scherrer Institut, Labor für Energiesystem-Analysen (LEA): Villigen, Switzerland, 2010. [Google Scholar]

- Banja, M.; Jégard, M. Renewable technologies in the EU electricity sector: trends and projections. In Analysis in the Framework of the EU 2030 Climate and Energy Strategy; EUR 28897 EN; Publications Office of the European Union: Luxemburg, 2017. [Google Scholar]

- Decker, M.; Vasakova, L. Energy Roadmap 2050. Impact assessment and scenario analysis. In Eur. Comm. Energy Unit A1 Energy Policy Anal Commission Staff Working Paper, SEC(2011) 1565 final; Publications Office of the European Union: Luxemburg, 2011. [Google Scholar]

- Nakamura, S.; Kondo, Y.; Kagawa, S.; Matsubae, K.; Nakajima, K.; Nagasaka, T. MaTrace: Tracing the fate of materials over time and across products in open-loop recycling. Environ. Sci. Technol. 2014, 48, 7207–7214. [Google Scholar] [CrossRef] [PubMed]

- EC. Report on Raw Materials for Battery Applications; Commission Staff Working Document SWD(2018) 245; Publications Office of the European Union: Brussels, Belgium, 2018. [Google Scholar]

- Dahllöf, L.; Romare, M.; Wu, A. Mapping Lithium-Ion Batteries for Vehicles: A study of their Fate in the Nordic Countries; Lithium-Ion Batter; Nordic Council of Ministers: Copenhagen, Demark, 2019.

- Lebedeva, N.; Di Persio, F.; Boon-Brett, L. Lithium Ion Battery Value Chain and Related Opportunities for Europe; EUR 28534 EN; Publications Office of the European Union: Luxembourg, 2017; ISBN 9789279669484. [Google Scholar]

- Schitech Europa 99% Metal Purity Achieved from Recycled Batteries. Available online: https://www.scitecheuropa.eu/99-metal-purity-achieved-from-recycled-batteries/98373/ (accessed on 14 February 2020).

- Campagnol, N.; Hoffman, K.; Lala, A.; Ramsbottom, O. The Future of Nickel: A Class Act. 2017. Available online: https://www.mckinsey.com/industries/metals-and-mining/our-insights/the-future-of-nickel-a-class-act (accessed on 15 May 2020).

- Berckmans, G.; Messagie, M.; Smekens, J.; Omar, N.; Vanhaverbeke, L.; Van Mierlo, J. Cost projection of state of the art lithium-ion batteries for electric vehicles up to 2030. Energies 2017, 10, 1314. [Google Scholar] [CrossRef] [Green Version]

- Green Car Congress Audi and Umicore Start Closed Loop for Cobalt and Nickel, More than 90% of Co and Ni in e-tron Batteries can be Recovered. Available online: https://www.greencarcongress.com/2019/12/20191218-audiumicore.html (accessed on 15 February 2020).

- Bobba, S.; Andreas, P.; Persio, F.D.; Maarten, M.; Paolo, T.; Cusenza, M.; Umberto, E.; Fabrice, M. Sustainability Assessment of Second Life Applications of Automotive Batteries (SASLAB); Publications Office of the European Union: Luxembourg, 2018; ISBN 978-92-79-92835-2. [Google Scholar]

- Arvidsson, R.; Janssen, M.; Svanström, M.; Johansson, P.; Sandén, B.A. Energy use and climate change improvements of Li/S batteries based on life cycle assessment. J. Power Sources 2018, 383, 87–92. [Google Scholar] [CrossRef]

- Kim, H.C.; Wallington, T.J.; Arsenault, R.; Bae, C.; Ahn, S.; Lee, J. Cradle-to-Gate Emissions from a Commercial Electric Vehicle Li-Ion Battery: A Comparative Analysis. Environ. Sci. Technol. 2016, 50, 7715–7722. [Google Scholar] [CrossRef]

- Dai, Q.; Kelly, J.C.; Gaines, L.; Wang, M. Life cycle analysis of lithium-ion batteries for automotive applications. Batteries 2019, 5, 48. [Google Scholar] [CrossRef] [Green Version]

- Kurland, S.D. Energy use for GWh-scale lithium-ion battery production. Environ. Res. Commun. 2019, 2, 12001. [Google Scholar] [CrossRef]

- EC. Study on the Review of the List of Critical Raw Materials. Non-Critical Raw Materials Factsheets; Publications Office of the European Union: Luxembourg, 2017; ISBN 978-92-79-47937-3. [Google Scholar]

- Mayer, A.; Haas, W.; Wiedenhofer, D.; Krausmann, F.; Nuss, P.; Blengini, G.A. Measuring Progress towards a Circular Economy: A Monitoring Framework for Economy-wide Material Loop Closing in the EU28. J. Ind. Ecol. 2018, 3, 62–76. [Google Scholar] [CrossRef] [Green Version]

- Kuczenski, B.; Davis, C.B.; Rivela, B.; Janowicz, K. Semantic catalogs for life cycle assessment data. J. Clean. Prod. 2016, 137, 1109–1117. [Google Scholar] [CrossRef] [Green Version]

- Nassar, N.T.; Brainard, J.; Gulley, A.; Manley, R.; Matos, G.; Lederer, G.; Bird, L.R.; Pineault, D.; Alonso, E.; Gambogi, J.; et al. Evaluating the mineral commodity supply risk of the U.S. Manufacturing sector. Sci. Adv. 2020, 6, 8. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Li, J.; Liu, W.W.; Zhou, H.M.; Liu, Z.Z.; Chen, B.R.; Sun, W.J. Anode material NbO for Li-ion battery and its electrochemical properties. Rare Met. 2018, 37, 118–122. [Google Scholar] [CrossRef] [Green Version]

- Deloitte Sustainability, British Geological Survey (BGS), Bureau de Recherches Géologiques et Minières (BRGM), Netherlands Organisation for Applied Scientific Research (TNO) Study on the review of the list of Critical Raw Materials; Critical Raw Materials Factsheets; Publications Office of the European Union: Luxembourg, 2017.

- CBMM Niobium application in Lithium-ion batteries: Anodes, cathodes and solid-state electrolytes. In Proceedings of the International Conference on Niobium Based Batteries, Beijing, China, 11 August 2019.

- NiobiumTech. Niobium in Lithium-ion Batteries. Available online: https://niobium.tech/en/Pages/Gateway-Pages/PDF/Briefings/Niobium_in_Li-Ion_Batteries (accessed on 15 February 2018).

- Nuss, P.; Eckelman, M.J. Life cycle assessment of metals: A scientific synthesis. PLoS ONE 2014, 9, e101298. [Google Scholar] [CrossRef] [PubMed]

- Dolganova, I.; Bosch, F.; Bach, V.; Baitz, M.; Finkbeiner, M. Life cycle assessment of ferro niobium. Int. J. Life Cycle Assess. 2020, 25, 611–619. [Google Scholar] [CrossRef]

| Battery Chemistry | Type of Vehicle | Weight [kg] | Capacity [kWh] | LCI Data Source for Manufacturing Stage | LCI Data Source for Use Stage | LCI Data Source for EoL Stage |

|---|---|---|---|---|---|---|

| NMC 111 | EV | 253 | 26.6 | [24,44] | [41] | [41,45,67] |

| NMC 424 | EV | n.a. | n.a. | [26,44] | [41] | [41,45,67] |

| NCA | EV | 142 | 18.9 | [44,68] | [41] | [41,45,67] |

| NCA | EV | 154 | 20 | [46] | [41] | [41,45,67] |

| LMO/NMC | PHEV | 175 | 11.4 | [45] | [41] | [41,45,67] |

| LCA | MFA | Criticality (Supply Risk) | Unit | Notes | |

|---|---|---|---|---|---|

| Weight of the battery | X | X | [kg] | ||

| Lifetime | X | X | [year] or [provided kWh] | ||

| Materials content | X | X | X | [kg/kg battery] of [kg/kWh] | |

| Process efficiency (i.e., losses) | X | X | [kg/kg battery] | ||

| Import/export | for transport | for flows and stocks | X | [tonne] | - impacts of transport - outbound/inbound flows - import reliance |

| Collection rate | X | X | [-] | - indirectly availability of SRMs | |

| Battery reuse | X | X | X | [%] | - lower impact of the battery life-cycle (longer lifetime) - stocks increase, creation of new stocks - indirectly availability of SRMs |

| Battery dismantling efficiency | X | X | [%] | ||

| Recycling efficiency | X | X | X | [%] | - impacts of recycling process / avoided materials - available SRMs to be recirculated in the system |

| Quality of recycled materials | X | X | X | [-] | - closed/open loop - available SRMs for specific sectors |

| Materials substitutability | X | X | X | [-] | - increase/decrease of materials content - LCA of different chemistries |

| Future technological change | X | X | X | [-] | - different chemistries, materials, components - potential improve of recycling technologies |

| Geographical considerations | X | X | X (import reliance and production) | [-] | - evaluate transports and import/export flows - EU dependency on third Countries - import reliance |

| WGI | Social (not assessed in this study) | X | [-] | ||

| New energy sources | X | X | [-] | ||

| Trade agreements and restrictions | X | X | [-] |

| Variables | Scenarios | |||

|---|---|---|---|---|

| Base-Case Scenario | Scenario A | Scenario B | Scenario C | |

| Change in European energy mix (current/2030/2050) | X | X | X | X |

| Change in battery material contents (current/2030/2050) | X | X | X | X |

| Batteries are reused in a second life (10% in 2030; 30% in 2050) | X | X | ||

| The recycling rate of lithium and nickel is enhanced (2030/2050) | X | |||

| Energy for manufacturing is completely provided by renewable sources (current/2030/2050) | X | |||

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Bobba, S.; Bianco, I.; Eynard, U.; Carrara, S.; Mathieux, F.; Blengini, G.A. Bridging Tools to Better Understand Environmental Performances and Raw Materials Supply of Traction Batteries in the Future EU Fleet. Energies 2020, 13, 2513. https://doi.org/10.3390/en13102513

Bobba S, Bianco I, Eynard U, Carrara S, Mathieux F, Blengini GA. Bridging Tools to Better Understand Environmental Performances and Raw Materials Supply of Traction Batteries in the Future EU Fleet. Energies. 2020; 13(10):2513. https://doi.org/10.3390/en13102513

Chicago/Turabian StyleBobba, Silvia, Isabella Bianco, Umberto Eynard, Samuel Carrara, Fabrice Mathieux, and Gian Andrea Blengini. 2020. "Bridging Tools to Better Understand Environmental Performances and Raw Materials Supply of Traction Batteries in the Future EU Fleet" Energies 13, no. 10: 2513. https://doi.org/10.3390/en13102513

APA StyleBobba, S., Bianco, I., Eynard, U., Carrara, S., Mathieux, F., & Blengini, G. A. (2020). Bridging Tools to Better Understand Environmental Performances and Raw Materials Supply of Traction Batteries in the Future EU Fleet. Energies, 13(10), 2513. https://doi.org/10.3390/en13102513