Analysis of the Thermal Retrofitting Potential of the External Walls of Podhale’s Historical Timber Buildings in the Aspect of the Non-Deterioration of Their Technical Condition

Abstract

:1. Introduction

1.1. Overview of Historic Wooden Buildings in the Podhale Region

1.2. Problems of the Thermal Retrofitting of Historic Buildings

1.3. Methodology of Applying External Thermal Insulation

1.3.1. Indications for the Proposed Solutions

- Internal insulation that prevents condensation. The standard [27] recommends that the vapour diffusion thickness Sd of the applied thermal insulation should be greater than 1500 m.

- Internal thermal insulation that minimises condensation. The DIN (Deutsches Institut für Normung) 4108-3 standard [27] allows the application of diffusion resistant materials, for which vapour diffusion thickness Sd is between 0.5 and 1500 m. It is unclear what impact such a large range of Sd values can have on the correctness of applied thermal insulation.

- Internal insulation that permits condensation with proof that the condensate produced during the unfavourable period will evaporate over the course of a base year.

- the existing rainproofing solution of the facade is effective,

- the existing external wall has a thermal resistance of at least RT ≥ 0.39 m2K/W,

- the indoor climate is largely normal,

- the average yearly temperature exceeds 7 °C, and resistance improvement ΔR should not exceed 2.5 or 2.0 m2K/W.

1.3.2. The Technical and Economic Aspects of Selecting an Internal Thermal Insulation System for Walls

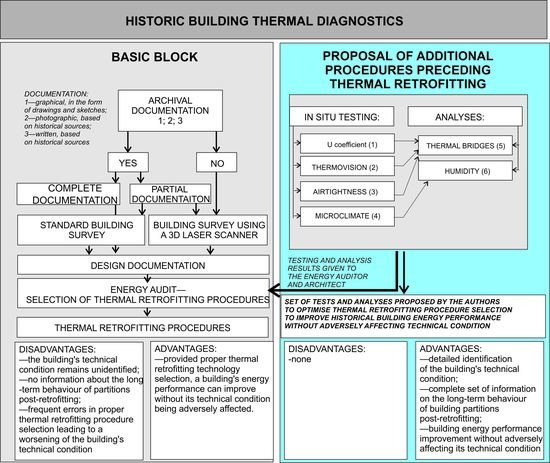

- –

- identification of the actual U heat transfer coefficient (1);

- –

- thermovision testing to diagnose qualitative defects in structural elements (2);

- –

- airtightness testing to identify air penetration of the building’s envelope (3);

- –

- microclimate testing (4).

2. Materials and Methods

2.1. Object of Study

- Footprint—304.74 m2

- Usable floor area—641.33 m2

- Volume—2805.95 m3

2.2. Research Method and Assessment of Thermal Protection

- Analysis of available construction documentation with a focus on thermal protection. Objective: supplement or recreate documentation, update it for the purposes of further action.

- General study of the building during daytime, featuring the preparation of photographic and descriptive documentation. Objective: determine the building’s technical condition and the possibility of performing non-destructive testing in places displaying considerable wear or visible damage. Thermovision analysis of the entire building from the outside during nighttime in suitable atmospheric conditions. Objective: identification of places on the building’s facades showing significant heat leakage, preparation of documentation in the form of thermograms.

- Detailed study of selected wall connections, places with identified linear and point thermal bridges, performed using thermal vision cameras. Objective: identification of the place of occurrence and geometric dimensions of thermal defects and anomalies, including airtightness breaches. Identifying thermal transmittance measurement sites.

- Thermal transmittance measurements using proper measuring equipment. Objective: identify the actual thermal transmittance of the envelope (walls).

- Airtightness testing of the building’s air penetration using a Blower Door measurement system. Objective: determine the actual air exchange rate for calculation purposes, confirm airtightness breach locations and their impact on heat loss within the building.

- Indoor microclimate testing in selected spaces. Objective: collect data to account for the individual character of each space and its appropriate use in energy calculations and analyses using numerical simulation of water content changes in elements.

2.2.1. Thermovision Analysis

- The indoor air temperature was 22–26 °C; the outdoor air temperature was 2–3 °C

- The relative indoor air humidity measured at a level of about 1 m above the floor was 40%. The wind speed was below 0.2 m/s. The sky was overcast when the measurement was taken.

- The resolution of photos results from the technical parameters of the thermovision camera.

2.2.2. Building Envelope Airtightness Testing

- n50 ≤ 3.0 1/h for buildings with gravitational ventilation,

- n50 ≤ 1.5 1/h for buildings with mechanical ventilation.

2.2.3. Testing of the Actual Thermal Transmittance U

- Internal/external surface temperature sensor ± 0.1 °C,

- heat stream sensor ± 3%.

2.2.4. Indoor Microclimate Testing

- ta—air temperature;

- tg—black globe temperature;

- tnw—natural wet-bulb temperature;

- RH—relative air humidity;

- Va—air velocity.

−0.42 · [(M − W) − 58.15] − 1.7 10−5 M · (5867 − pa) − 0.0014 ·M · (34 − ta)

−3.96 · 10−8 · fcl · [(tcl + 273)4 − (t–r + 273)4] − fcl · hc · (tcl − ta))

tcl = 35.7 − 0.028 · (M − W) − Icl{3.96 · 10−8 · fcl · [(tcl + 273)4 − (t–r + 273)4] + fcl · hc · (tcl − ta)}

- M—metabolic rate (W/m2),

- W—the density of energy loss in the form of mechanical work (W/m2),

- Icl—clothing insulation (m2K/W),

- fcl—clothing area factor (m2),

- ta—air temperature (°C),

- t–r—mean radiant temperature (°C),

- tcl—clothing surface temperature (°C).

- ta,l—local air temperature °C,

- va,l—average air speed m/s,

- Tu—local turbulence intensity %.

2.3. Numerical Analyses

- Condensation risk and water content increase within selected planes of the partition,

- A selected thermal bridge by determining selected parameters that describe heat flow within areas of geometry shifts,

- Risk of mould growth expressed by fRsi.

- Linear thermal coupling coefficient L2D W/(mK),

- Linear thermal transmittance coefficient determining additional heat loss due to linear thermal bridges Ψ W/(mK),

- Temperature factor determined on the basis of minimal partition surface temperature at the site of the thermal bridge fRsi (-). The following qualities were accepted as boundary conditions: outdoor air temperature te: −20 °C, indoor air temperature ti: +20 °C, thermal surface coefficients he = 25.0 W/(m2 K), hi = 7.69 W/(m2 K), a fRsi hi = 4.0 W/(m2 K) value was assumed for calculations.

3. Results

3.1. Thermovision Analysis

- Airtightness breaches at points where external walls connected with wooden decks,

- Airtightness breaches at points where wooden windows connect to the walls,

- Lower thermal insulation at the joints between external wall beams (logs), seals in the form of a ‘plait’ woven from wood shavings were observed to have crumbled in some places. Slight cavities in the seals were observed,

- No damp was observed on the thermograms and during macroscopic examination.

3.2. Results of Envelope Airtightness Tests for the Stara Polana Building

3.3. Results of Determining the Actual U Thermal Transmittance for External Walls Made of Wooden Logs

- R—partition thermal resistance calculated based on measurements W/(m2K),

- Tsij—sequential temperature value measured on the internal surface of a partition °C,

- Tsej—sequential temperature value measured on the external surface of a partition °C,

- qj—sequential measured value of heat stream density W/m2.

- Δt is the time interval between measurements s,

- δTi is the difference between internal temperature from the 24 h preceding the measurement and the internal average temperature for the first 24 h of measurements,

- δTe—difference between internal temperature from the 24 h preceding the measurement and the external average temperature for the first 24 h of measurements,

- Fi; Fe—correction coefficients calculated using Equations (5) and (6).

3.4. Microclimate Measurement Results

3.5. Results of Numerical Analyses

- No water increase was observed for any type of design solution (mineral wool insulation or light aerated concrete insulation) (Figure 26, Figure 27, Figure 28 and Figure 29). The level of water content decreased by about 66 (kg/m3) after one year of simulations in the local climate for each type of the wall insulation (Figure 20 and Figure 21);

- A decrease in water content to the level of 14% of the mass humidity was observed for the wooden log walls after one year of simulation. This level is safe in the context of the risk of the development of biological corrosion, which occurs in wooden elements at over 20% of their mass humidity, Figure 22 and Figure 23;

4. Discussion

5. Conclusions

- –

- Research quality improvement, via introducing two new types of testing and assessment of historic buildings: structural system assessment accounting for fungi and moulds, as well as wall mass humidity testing. Mycological testing shall be based on assessing indoor air quality and screening the outer surfaces of partitions for the presence of fungi and moulds. The tests shall be performed using aspiration utilising mycological growth media: Malt Extract Agar (Biomaxima) and Rose Bengal Agar (Biomaxima), utilising a MAS 100 Air Sampler (Merck). Material samples shall be collected from the partitions and seeded onto a base of Sabouraud Glucose Agar (SGA) and Rose Bengal Agar with a yeast extract (RBA). Fungus and mould spore identification shall be performed by studying colony morphology and sporulation structures of the isolated strains using microscopic fungi identification keys. The partition humidity tests shall be performed using a TESTO 635-2 measurement device with a rapid humidity measurement probe. Both tests shall be used to perform in-depth diagnostics of the technical condition of historical building timber partitions. Should high damp levels (>22%) or mould or fungus presence be detected in the partition, a report shall be prepared, outlining the repair procedures to be performed on the historic structure prior to thermal retrofitting. We also want to add to our future tests the indoor air quality (IAQ). Additional analyzes will concern many aspects of the comfort of using historic buildings and indoor air quality (IAQ). Unfortunately, we were unable to include these tests in the diagnostic of the case analysed in the paper (the time for preparing a revised version of the manuscript was very short).

- –

- developing procedures that would allow for a fuller diagnostic of the technical condition of historic buildings intended for modernisation (e.g., by using a 3D laser scanner with thermovision capabilities, developed at the Malopolska Energy-Efficient Building Laboratory of the Cracow University of Technology—a device that can combine a building survey with a complete thermal retrofitting documentation).

- –

- developing an algorithm for the selection of optimal thermal retrofitting procedures based on architectural design documentation, on-site test results and the findings of analyses proposed by the authors in this paper.

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Dudzik, M.; Jagiello, A.; Drapik, S.; Prusak, J. The selected real tramway substation overload analysis using the optimal structure of an artificial neural network. In Proceedings of the SPEEDAM 2018—Proceedings: International Symposium on Power Electronics, Electrical Drives, Automation and Motion, Amalfi, Italy, 20–22 June 2018; pp. 413–417. Available online: https://ieeexplore.ieee.org/document/8445340 (accessed on 2 September 2020).

- Radziszewska-Zielina, E.; Rumin, R. Analysis Of The Profitability of Investment In Renewable Energy Sources On The Example of A Semi-Detached House. E3S Web Conf. 2016, 10, 79. [Google Scholar] [CrossRef] [Green Version]

- Romanska-Zapala, A.; Bomberg, M.; Dechnik, M.; Fedorczak-Cisak, M.; Furtak, M. On Preheating of the Outdoor Ventilation Air. Energies 2019, 13, 15. [Google Scholar] [CrossRef] [Green Version]

- European Parliament. Directive 2002/91/EC of the European Parliament And of the Council of 16 December 2002 on the Energy Performance of Buildings; European Parliament: Brussels, Belgium, 2002. [Google Scholar]

- European Parliament. Directive 2010/31/EU of the European Parliament and of the Council of 19 May 2010 on the Energy Performance of Buildings; European Parliament: Brussels, Belgium, 2010. [Google Scholar]

- Minister of Infrastructure. Holling of the Minister of Infrastructure and Development of 17 July 2015 on the Announcement of the Consolidated Text of the Regulation of the Minister of Infrastructure on the technical conditions to be Met by Buildings and Their Location; Minister of Infrastructure: Warsaw, Poland, 2015. [Google Scholar]

- Chancellery of the Sejm of the Republic of Poland. Law of 7 July 1994 Building Law; Chancellery of the Sejm of the Republic of Poland: Warsaw, Poland, 2010. [Google Scholar]

- Radziszewska-Zielina, E.; Śladowski, G. Proposal of the Use of a Fuzzy Stochastic Network for the Preliminary Evaluation of the Feasibility of the Process of the Adaptation of a Historical Building to a Particular Form of Use. IOP Conf. Ser. Mater. Sci. Eng. 2017, 245, 072029. [Google Scholar] [CrossRef]

- Radziszewska-Zielina, E.; Śladowski, G. Supporting the selection of a variant of the adaptation of a historical building with the use of fuzzy modelling and structural analysis. J. Cult. Herit. 2017, 26, 53–63. [Google Scholar] [CrossRef]

- Radziszewska-Zielina, E.; Śladowski, G.; Sibielak, M. Planning the reconstruction of a historical building by using a fuzzy stochastic network. Autom. Constr. 2017, 84, 242–257. [Google Scholar] [CrossRef]

- Krentowski, J.; Chyzy, T.; Dunaj, P. Sudden collapse of a 19th-century masonry structure during its renovation process. Eng. Fail. Anal. 2017, 82, 540–553. [Google Scholar] [CrossRef]

- Krentowski, J.R.B.; Mlonek, S.; Zimiński, K.T.A. Structural and Technological Aspects of the Historical Floors Replacement. Available online: https://www.researchgate.net/publication/331314077_Structural_and_Technological_Aspects_of_the_Historical_Floors_Replacement (accessed on 9 May 2020).

- Yarbrough, D.W.; Bomberg, M.; Romanska-Zapala, A. Buildings with environmental quality management, part 3: From log houses to environmental quality management zero-energy buildings. J. Build. Phys. 2019, 42, 672–691. [Google Scholar] [CrossRef]

- Romanska-Zapala, A.; Bomberg, M.; Yarbrough, D.W. Buildings with environmental quality management: Part 4: A path to the future NZEB. J. Build. Phys. 2019, 43, 3–21. [Google Scholar] [CrossRef]

- European Parliament. Directive (EU) 2018/844 of the European Parliament And of the Council of 30 May 2018 amending Directive 2010/31/EU on the Energy Performance of Buildings and Directive 2012/27/EU on Energy Efficiency (Text with EEA relevance); European Parliament: Brussels, Belgium, 2018. [Google Scholar]

- Piasecki, M. Practical Implementation of the Indoor Environmental Quality Model for the Assessment of Nearly Zero Energy Single-Family Building. Buildings 2019, 9, 214. [Google Scholar] [CrossRef] [Green Version]

- Piasecki, M. Kostyrko Combined Model for IAQ Assessment: Part 1—Morphology of the Model and Selection of Substantial Air Quality Impact Sub-Models. Appl. Sci. 2019, 9, 3918. [Google Scholar] [CrossRef] [Green Version]

- Rejestr Zabytków Nieruchomych—Otwarte Dane. Available online: https://dane.gov.pl/dataset/1130 (accessed on 23 April 2020).

- Nowogońska, B. The Method of Predicting the Extent of Changes in the Performance Characteristics of Residential Buildings. Arch. Civ. Eng. 2019, 65, 81–89. [Google Scholar] [CrossRef]

- Fedorczak-Cisak, M.; Kowalska, A.; Radziszewska-Zielina, E.; Śladowski, G.; Pachla, F.; Tatara, T. A multi-criteria approach for selecting the utility function of the historical building “Stara Polana” located in Zakopane. MATEC Web Conf. 2019, 262, 07002. [Google Scholar] [CrossRef]

- Fedorczak-Cisak, M.; Kotowicz, A.; Radziszewska-Zielina, E.; Sroka, B.; Tatara, T.; Barnaś, K. Multi-Criteria Optimisation of an Experimental Complex of Single-Family Nearly Zero-Energy Buildings. Energies 2020, 13, 1541. [Google Scholar] [CrossRef] [Green Version]

- Fedorczak-Cisak, M.; Kowalska-Koczwara, A.; Nering, K.; Pachla, F.; Radziszewska-Zielina, E.; Śladowski, G.; Tatara, T.; Ziarko, B. Evaluation of the criteria for selecting proposed variants of utility functions in the adaptation of historic regional architecture. Sustainability 2019, 11, 1094. [Google Scholar] [CrossRef] [Green Version]

- Dudzik, M.; Mielnik, R.; Wrobel, Z. Preliminary analysis of the effectiveness of the use of artificial neural networks for modeling time-voltage signal of the combination wave generator. In Proceedings of the 18th International Symposium on Electromagnetic Fields in Mechatronics, Electrical and Electronic Engineering, ISEF 2017, Lodz, Poland, 14–16 September 2017; Institute of Electrical and Electronics Engineers Inc.: Lodz, Poland, 2017. [Google Scholar]

- Józef, T. Styl alpejski w środkowej Europie i polska kontrakcja wobec niego—Styl zakopiański—Estetyka i Krytyka—Issue 2(25) (2012)-CEJSH-Yadda. Estetyka Krytyka 2012, 2, 232–246. [Google Scholar]

- “Dawne Zakopane” Nasza Politechnika. Available online: http://riad.pk.edu.pl/~naszapol/np53/str36b.shtml (accessed on 25 April 2020).

- International Organization for Standardization. ISO 13788:2012 Hygrothermal Performance of Building Components and Building Elements—Internal Surface Temperature to Avoid Critical Surface Humidity and Interstitial Condensation—Calculation methods; International Organization for Standardization: Geneva, Switzerland, 2012. [Google Scholar]

- Deutsches Institut für Normung. DIN 4108-3 Grenzen der Anwendbarkeit im Feuchteschutz|Bauphysik|Feuchteschutz|Baunetz_Wissen; Deutsches Institut für Normung: Berlin, Germany, 1996. [Google Scholar]

- Orlik-Kożdoń, B. Interior insulation of masonry walls-selected problems in the design. Energies 2019, 12, 3895. [Google Scholar] [CrossRef] [Green Version]

- Orlik-Kożdoń, B.; Steidl, T. Impact of internal insulation on the hygrothermal performance of brick wall. J. Build. Phys. 2017, 41, 120–134. [Google Scholar] [CrossRef]

- Orlik-Kożdoń, B.; Szymanowska-Gwiżdż, A. Impact of envelope structure on the solutions of thermal insulation from the inside. Archit. Civ. Eng. Environ. 2018, 11, 123–134. [Google Scholar] [CrossRef] [Green Version]

- Kozakiewicz, P.; Matejak, M. Wydawnictwo Szkoły Głównej Gospodarstwa Wiejskiego. In Klimat a Drewno Zabytkowe: Dawna i Współczesna Wiedza o Drewnie; Wydawnictwo Warsaw University of Life Sciences: Warsaw, Poland, 2013; ISBN 9788375835076. [Google Scholar]

- Künzel, H. Criteria defining rain protecting external rendering systems. In Energy Procedia; Elsevier Ltd.: Amsterdam, The Netherlands, 2015; Volume 78, pp. 2524–2529. [Google Scholar]

- WTA. Eßmann Innendämmung Nach WTA I Planungsleitfaden Merkblatt 6-4 Inside insulation Acco–Rding to WTA I: Planary Guide Isolation Thermique par l´Intérieur Selon WTA I: Guide de Planification Deskriptoren; Fraunhofer IRB Verlag: Stuttgart, Germany, 2016; ISBN 9783816780861. [Google Scholar]

- Biolek, V.; Hanák, T. LCC Estimation Model: A Construction Material Perspective. Buildings 2019, 9, 182. [Google Scholar] [CrossRef] [Green Version]

- Multipor Ocieplenie od Wewnątrz Zeszyt Techniczny. Available online: https://www.ytong-silka.pl/pl/docs/Zeszyt-techniczny-Multipor-Ocieplenie-od-wewnatrz-2017-03.pdf (accessed on 24 April 2020).

- Epatherm, Renowacje, Ocieplenia od Wewnatrz. Available online: http://www.epasit.pl/php/start.php (accessed on 24 April 2020).

- Radziszewska-Zielina, E.; Czerski, P.; Grześkowiak, W.K.-S.P. Comfort of Use Assessment in Buildings with Interior Wall Insulation based on Silicate and Lime System in the Context of the Elimination of Mould Growth. Arch. Civ. Eng. 2020, 2, 89–104. [Google Scholar]

- Karta Badań Skuteczności AERO-THERM®. Available online: http://www.aerotherm.eu/wp-content/uploads/2015/08/Karta-bada%C5%84-skuteczno%C5%9Bci-dzia%C5%82ania-AT-2014.pdf (accessed on 2 September 2020).

- Kożuch, B.; Tatara, T. Impact of the vibrations on the environment caused by passages of trains at variable speed. E3S Web Conf. 2016, 10, 00047. [Google Scholar] [CrossRef] [Green Version]

- Polish Standardization Committee. PN-EN ISO—ISO 6946:2017—Building Components and Building Elements—Thermal Resistance and Thermal Transmittance—Calculation Methods; Polish Standardization Committee: Warsaw, Poland, 2017. [Google Scholar]

- Polish Standardization Committee. PN-EN 12524:2003 Building Materials and Products—Thermal and Humidity Characteristics—Tabulated Design Values; Polish Standardization Committee: Warsaw, Poland, 2003. [Google Scholar]

- Radziszewska-Zielina, E.; Kania, E.; Śladowski, G.X. Problems of the selection of construction technology for structures in the centres of urban agglomerations. Arch. Civ. Eng. 2018, 64, 55–71. [Google Scholar] [CrossRef]

- Radziszewska-Zielina, E.; Kania, E. Problems in Carrying Out Construction Projects in Large Urban Agglomerations on the Example of the Construction of the Axis and High5ive Office Buildings in Krakow. MATEC Web Conf. 2017, 117, 00144. [Google Scholar] [CrossRef]

- Polish Standardization Committee. PN-EN 13187 “Thermal Performance of Buildings—Qualitative Detection of Thermal Defects in Building Envelope—Infrared Method”; Polish Standardization Committee: Warsaw, Poland, 2001. [Google Scholar]

- Henryk, N. Zastosowanie Badań Termowizyjnych w Budownictwie. Oficyna Wydawnictwo Politechniki Wrocławskiej; Wydawnictwo Politechniki Wrocławskiej: Wrocław, Poland, 2012. [Google Scholar]

- Steidl, T.; Belok, T.; Krause, P.; Nowoświat, A.; Orlik-Kożdoń, B.; Wojewódka, D. Poradnik Diagnostyki Cieplnej Budynków: Praca Zbiorowa Diagnostyka In Situ Izolacyjności Cieplnej Budynków, Tom 1; Politechnika Śląska, Wydział Inżynierii Środowiska i Energetyki: Gliwice, Poland, 2013. [Google Scholar]

- Polish Standardization Committee. PN ISO 6781:1983. Thermal Insulation–Qualitative Detection of Thermal Irregularieties Inbuilding Envelopes—Infrared Method; Polish Standardization Committee: Warsaw, Poland, 1983. [Google Scholar]

- D’Ambrosio Alfano, F.; Dell’Isola, M.; Ficco, G.; Palella, B.; Riccio, G. Experimental Air-Tightness Analysis in Mediterranean Buildings after Windows Retrofit. Sustainability 2016, 8, 991. [Google Scholar] [CrossRef] [Green Version]

- Polish Standardization Committee. PN-EN ISO 9972: 2015-10. Thermal Properties of Buildings—Determination of Air Permeability Of Buildings—Pressure Measurement Method with the Use of a Fan; Polish Standardization Committee: Warsaw, Poland, 2015. [Google Scholar]

- Polish Standardization Committee. PN ISO 9869-1:2014—Thermal Insulation—Building Elements—In-Situ Measurement of Thermal Resistance and Thermal Transmittance—Part 1: Heat Flow Meter Method; Polish Standardization Committee: Warsaw, Poland, 2014. [Google Scholar]

- Polish Standardization Committee. PN-EN 16798-1:2019-06 Energy Performance of Buildings—Ventilation for Buildings—Part 1: Indoor Environmental Input Parameters for Design and Assessment of Energy Performance of Buildings Addressing Indoor Air Quality, Thermal Environment, Lighting a; Polish Standardization Committee: Warsaw, Poland, 2019. [Google Scholar]

- Polish Standardization Committee. PN EN 15251: 2007. Indoor Environmental Input Parameters for Design and Assessment of Energy Performance of Buildings Addressing Indoor Air Quality, Thermal Environment, Lighting and Acoustics; Polish Standardization Committee: Warsaw, Poland, 2007. [Google Scholar]

- Fanger, P.O. Thermal Comfort: Analysis and Applications in Environmental Engineering; Danish Technical Press: Copenhagen, Denmark, 1970; ISBN1 8757103410. ISBN2 9788757103410. [Google Scholar]

- D’Ambrosio Alfano, F.R.; Palella, B.I.; Riccio, G.; Toftum, J. Fifty years of Fanger’s equation: Is there anything to discover yet? Int. J. Ind. Ergon. 2018, 66, 157–160. [Google Scholar] [CrossRef]

- Polish Standardization Committee. PN-EN ISO 7730: 2006. Ergonomics of The Thermal Environment—Analytical Determination and Interpretation of Thermal Comfort Using the Calculation of PMV and PPD Indicators and Criteria of Local Thermal Comfort; Polish Standardization Committee: Warsaw, Poland, 2005. [Google Scholar]

- Polish Standardization Committee. PN ISO 7726: 2001. Ergonomics of the Thermal Environment. Instruments for Measuring Physical Quantities; Polish Standardization Committee: Warsaw, Poland, 2001. [Google Scholar]

- WTA. Innendämmung Nach WTA I Planungsleitfaden, Referat 6 Bauphysik und Bauchemie; Wissenschaftlich-Technische Arbeitsgemeinschaft für Bauwerkserhaltung und Denkmalpflege, Ed.; Fraunhofer IRB Verlag: Stuttgart, Germany, 2009. [Google Scholar]

- Polish Standardization Committee. PN EN ISO 10211:2017 Thermal Bridges in Building Construction—Heat Flows and Surface Temperatures—Detailed Calculations; Polish Standardization Committee: Warsaw, Poland, 2017. [Google Scholar]

- European Committee for Standardization. EN 15026; Hygrothermal Performance of Building Components and Building Elements—Assessment of Moisture Transfer by Numerical Simulation; European Committee for Standardization: Brussels, Belgium, 2012. [Google Scholar]

- Nowoświat, A.; Skrzypczyk, J.; Krause, P.; Steidl, T.; Winkler-Skalna, A. Estimation of thermal transmittance based on temperature measurements with the application of perturbation numbers. Heat Mass Transf. 2018, 54, 1477–1489. [Google Scholar] [CrossRef] [Green Version]

| No. | Building Element | Scheme (-) | U Coefficient Assumed for Calculations W/(m2K) |

|---|---|---|---|

| 1 | Basement wall |  | 1.73; 2.20; 2.35 |

| Parameters assumed as for a crushed stone wall with a 35% mortar content by volume, with a stone density of kg/m3 | |||

| 2 | Ground floor wall |  | 2.59; 0.50 |

| (as above); wood (pine/spruce, across the fibres) |

| Type of Wall | Extant U W/m2K | W1 * | W2 * | W3 * | W4 * | W5 * |

|---|---|---|---|---|---|---|

| λ = 0.04 | λ = 0.022 | λ = 0.042 | λ = 0.047 | λ = 0.067 | ||

| Thickness of each thermal insulation material necessary for attaining U = 0.2 W/(m2K) for the entire partition | ||||||

| Basement wall—stone d = 1.02 m | 1.73 | 0.17 | 0.10 | 0.19 | 0.21 | 0.30 |

| Basement wall—stone d = 0.71 m | 2.20 | 0.17 | 0.10 | 0.19 | 0.21 | 0.30 |

| Basement wall—stone d = 0.64 m | 2.35 | 0.18 | 0.10 | 0.19 | 0.21 | 0.31 |

| Ground floor wall—stone d = 0.54 m | 2.59 | 0.18 | 0.10 | 0.19 | 0.22 | 0.31 |

| Ground floor wall—wood d = 0.30 m | 0.49 | 0.11 | 0.07 | 0.12 | 0.14 | 0.20 |

| Class of Building Depending on Attained Value of U W/(m2K) | U W/(m2K) |

|---|---|

| class A | 0.00–0.15 |

| class B | 0.16–0.22 |

| class C | U ≥ 0.23 |

| Type of Sensor | Measurement Range | Scale | Accuracy |

|---|---|---|---|

| Temperature sensors | −20 °C + 50 °C (wet thermometer 0 °C + 50 °C) | 0.01 °C | ±0.4 °C |

| Humidity sensors | 0–100% | 0.1 RH (relative humidity) | ±2% RH (relative humidity) |

| Air velocity sensors | 0–5 m/s | 0.01 m/s | for 0–1 m/s ± 0.05 + 0.05 Va m/s, for 1–5 m/s ± 5% |

| Material | λ W/mK | µ | C | ρ | Technological Water Content (Initial) kg/m3 |

|---|---|---|---|---|---|

| - | J/kg K | kg/m3 | |||

| Wooden beams | 0.16 | 200 | 1400 | 650 | 98.0 |

| Mineral wool | 0.038 | 1 | 840 | 32 | 0.8 |

| Light aerated concrete | 0.04 | 4 | 850 | 115 | 8.1 |

| Gypsum plasterboard | 0.32 | 200 | 1400 | 400 | 15.5 |

| Vapour barrier | 2.30 | 27,000 | 2300 | 130 | - |

| Thermal Transmittance U | Uninsulated Wall | Insulated Wall (11 cm) | |

|---|---|---|---|

| Calculations | 0.49 | 0.20 | |

| W/(m2K) | Measurements | 0.60–0.65 | - |

| Indicator Values | Uninsulated Wall | Insulated Wall (11 cm) |

|---|---|---|

| fRsi (-) | 0.835 | 0.88 |

| L2D W/mK | 0.761 | 0.326 |

| Ψi W/mK | −0.37 | −0.14 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Fedorczak-Cisak, M.; Radziszewska-Zielina, E.; Orlik-Kożdoń, B.; Steidl, T.; Tatara, T. Analysis of the Thermal Retrofitting Potential of the External Walls of Podhale’s Historical Timber Buildings in the Aspect of the Non-Deterioration of Their Technical Condition. Energies 2020, 13, 4610. https://doi.org/10.3390/en13184610

Fedorczak-Cisak M, Radziszewska-Zielina E, Orlik-Kożdoń B, Steidl T, Tatara T. Analysis of the Thermal Retrofitting Potential of the External Walls of Podhale’s Historical Timber Buildings in the Aspect of the Non-Deterioration of Their Technical Condition. Energies. 2020; 13(18):4610. https://doi.org/10.3390/en13184610

Chicago/Turabian StyleFedorczak-Cisak, Małgorzata, Elżbieta Radziszewska-Zielina, Bożena Orlik-Kożdoń, Tomasz Steidl, and Tadeusz Tatara. 2020. "Analysis of the Thermal Retrofitting Potential of the External Walls of Podhale’s Historical Timber Buildings in the Aspect of the Non-Deterioration of Their Technical Condition" Energies 13, no. 18: 4610. https://doi.org/10.3390/en13184610

APA StyleFedorczak-Cisak, M., Radziszewska-Zielina, E., Orlik-Kożdoń, B., Steidl, T., & Tatara, T. (2020). Analysis of the Thermal Retrofitting Potential of the External Walls of Podhale’s Historical Timber Buildings in the Aspect of the Non-Deterioration of Their Technical Condition. Energies, 13(18), 4610. https://doi.org/10.3390/en13184610