1. Introduction

Hydrogen has been used in various forms of human activity for over 200 years. Originally, it was used in steam engines and also for lifting balloons and airships in the 18th and 19th centuries. It is often said that hydrogen is the “fuel of the future”. This sentence seems to be justified. The physical properties of hydrogen make it interesting and attractive in comparison to other fuels and energy sources. For example, hydrogen density is one tenth (1:10) of natural gas, its energy per unit of mass (Lower Heating Value—LHV) is three times higher than that of gasoline, flame velocity is eight times higher than that for methane and its autoignition temperature is 585 °C (ignition energy is 1/10 of methane). This makes hydrogen light, storable and reactive, with high energy content per unit mass; it can be readily produced at an industrial scale. In recent times, there have been some other reasons enforcing the popularity and development of the hydrogen market, such as: steadily falling cost of hydrogen supply, the observed shift in attention and interest from the automobile industry to other hydrogen applications (aviation, shipping, heating) and, finally, hydrogen is considered a clean, ecological fuel, especially when it is produced from renewables [

1]. It should also be added that at present the development of the hydrogen sector is strongly supported by government programs amounting to hundreds of millions of dollars yearly [

2].

A dynamically increasing demand for hydrogen has been observed since the 1970s. The demand for pure H

2 reached 75 MM g in 2019 (a further 45 MM g of hydrogen by-products are used as an input for fuels or feedstock without prior separation). Hydrogen can be used in its pure form or can be converted to hydrogen-based fuels such as synthetic methane, liquid fuels, ammonia or methanol. The pure form of hydrogen is used mostly for oil refining and ammonia manufacturing for fertilizers. Hydrogen gas mixtures are also used in the chemical sector, steel production, heating, electricity production and the transport sector [

2].

The majority of hydrogen is produced from fossil fuels, where the dominating role is that of natural gas at 75% (20–25% comes from coal-to-hydrogen facilities, the rest is a primary product of oil and electricity production installations; electrolysis accounts for only 2% of global H2 production). This means that over 200 Bm3 of natural gas and 105 MM g of coal are consumed every year to meet the global demand for hydrogen.

There are many expert opinions indicating that hydrogen technologies will also be developed in the future for achieving better overall effectiveness [

3,

4]. New technological solutions are expected to have high efficiency of energy conversion into products to minimize the negative impact on the environment or to demonstrate high operational flexibility, and in the use of various types of raw materials. Recently, political factors have also played an important role in defining energy security and environmental standards, whose role seems to be increasing [

5,

6]. Among the relatively new technologies (in development since the 1990s), methane splitting is potentially a new way to produce hydrogen from natural gas (it requires high-temperature plasma, methane as feedstock and electricity, and offers pure hydrogen and solid carbon with no CO

2 emissions) [

7,

8,

9]. On the other hand, interesting up-to-date Polish studies have also emerged, which discuss efficient production of pure hydrogen using photovoltaic panels [

10]. Yet, from the economic point of view, new technologies based on fossil fuels are more efficient [

11]. For example, the electrolysis of methanol to hydrogen can have up to 65% lower energy consumption than the electrolysis of water [

12,

13]. However, taking into account the environmental aspects and the regulatory changes following them, supporting fully renewable technologies, it is understandable that the interest in solutions based on the electrolysis of water will not decrease [

11]. The main reason for this is that the electrolysis of water is the only renewable and feasible technology for large-scale hydrogen production to date [

14].

International Renewable Energy Agency (IRENA) road map indicates that the use of hydrogen in the economy will have a 6% share in total energy consumption by 2050 [

1], while the Hydrogen Council estimates an 18% share to be achieved in the next 30 years [

15], which is quite challenging. In Poland, the demand for natural gas in the hydrogen and ammonia production segment is estimated at 2.1 Bm

3 per year [

16]. In addition to the use of hydrogen as a feedstock in the chemical industry, its use is widely analyzed for the production of energy in fuel cells or for the automotive sector [

17]. The potential for hydrogen use, the perspective of its development and applications [

18,

19] are, considering the present state of technology advancement, limited by the economic efficiency, storage and transport restrictions.

Hydrogen from Coal and Its Perspectives

Following the European Union (EU) Green Policy, carbon dioxide is mostly considered a waste material and in order to meet global CO

2 reduction limits, it should be captured and then chemically sequestrated or stored underground. The rapid increase in the number of carbon capture and storage (CCS) demonstrations and industrial installations was identified as a necessary condition for green policy implementation [

20]. “Blue hydrogen” is commonly used to refer to the hydrogen extracted from fossil fuels in installations equipped with carbon capture, utilization and storage (CCUS) infrastructure. This process is also cost intensive. According to Muradov [

21], a relatively low hydrogen-to-carbon ratio (of 0.1:1) from coal (vs. 4:1 from methane) makes it very attractive, although the gasification process is mostly associated with a high level of impurities in the feedstock that must be eliminated afterwards.

However, CCS technologies have not been widely implemented. At present, there are only 19 operating installations globally. The International Energy Agency (IEA) estimations, outlined by 2030, assume that CCS will reach a level of 750 MM g CO

2 stored annually (currently only 5% of that amount has been achieved) [

22]. That seems to be an optimistic scenario. Currently, two of the operating CCS projects are dedicated to hydrogen production [

1]. As mentioned by Rock et al. [

23], achieving a capture rate of 80% is still a challenge. It is also crucial to ensure CO

2 retention after injection, which largely depends on the formation type [

24]. Currently, there are no CCS installations in Poland. Although there are geological formations where CO

2 could be stored, all efforts in this respect are still at the conceptual stage [

25,

26,

27]. On the other hand, there are technological and economic reasons for the gasification of coal to hydrogen, especially where the costs of feedstock are relatively low. Coal gasification technologies for hydrogen production are among the most advanced and well established in the world. They seem to be the cheapest alternative for hydrogen production. Based on IEA [

2], the total production cost (involving capital expenditures; CAPEX) is five times lower than in the case of grid electricity technologies, three times lower than in electricity generation from renewables and 2–2.5 lower than in steam methane reforming processes (hereinafter SMR). In China, the expected hydrogen production cost is about USD 1/kg of H

2. In relation to those facts, the production of every 1 Mg of H

2 causes the release into the atmosphere of nearly 20 Mg of CO

2 (without CCS systems), two times more than from natural gas, but 1.5 times less than in grid electricity systems. Yet, the amount of CO

2 produced from coal may also raise some concerns.

The technological and economic efficiency of coal gasification was discussed by Gnanapragasam et al. [

4], who analyzed the effectiveness of the coal gasification process with the application of a CCS unit in classical integrated gasification combined cycle (IGCC) solutions and in syngas-to-hydrogen systems. According to the authors of that study, syngas-to-hydrogen systems are more effective then IGCC systems. An interesting comparison of technologies focused on hydrogen production, for all primary fuels, has been made by Muritala et al. [

28], who pointed out the advantage of SMR over coal gasification (operating at industrial scale),which strongly depends upon the availability of cheap gas. Similar conclusions have been made by Xuet al. [

29]. Additionally, Guban et al. [

30] have agreed with that conclusion, adding that the development of an effective CCS system shall enhance the development of hydrogen production technologies based on gas and other fossil fuels. Similar aspects have also been discussed by Ren et al. [

31], who commented that in the regions with access to cheap coal, efficient CCS systems may reveal the advantage of coal gasification over SMR technologies. This opinion was also supported by Cloete and Hirh [

32] and Collodi et al. [

33]. The abovementioned studies can be summarized by the statement that the final success of hydrogen production based on fossil fuels depends on the production scale and fuel price, the latter being the most important cost component. Thus, the key problem is to answer the question concerning the level at which these factors should be for fully commercial applications of these technologies. An attempt to answer this question for clean hydrogen technologies in Polish conditions is provided in the work of Ceren [

10], which is a multi-criteria analysis of these solutions. In turn, the work of Bartel et al. [

34] discusses the economic factors behind the development of CCS technology in combination with combined heat and power (CHP) installations. An interesting work analyzing the gasification of coal to hydrogen and the transit of the Polish economy towards a hydrogen economy is given in the study by Murray et al. [

35]. The authors discuss various possible technological solutions, analyzing their impact on the Polish economy. However, none of the mentioned studies answers the question: for which economic conditions is it possible to commercially use the coal gasification technology with CSS for hydrogen production?

A literature review shows that the interest in the topic has not declined over the years, with ever more modern technological solutions emerging which improve the efficiency of both coal gasification [

36] as well as CCS systems [

4,

37]. Some of the advanced, new and ecological energy technologies are very promising indeed, but because of the limited scale, they cannot be developed to a mass production scale very quickly. They need technological advancement but can be applied locally. The research conducted also indicates that the direction of the development of hydrogen generation technologies depends on the criteria assumed. Kwaśniewski et al. [

36] point out that meeting the country’s energy needs should be, first of all, based on the domestic resource base, assuming that local resources are the cheapest ones. On the other hand, highly developed countries are focused on producing hydrogen based on renewables. At the same time, EU law clearly promotes clean coal technologies, hence the question arises as to whether the economic efficiency of coal gasification to hydrogen in Polish conditions (taking into account environmental aspects and the quality of end products) may favor coal gasification technologies sufficiently enough. The importance of the coal gasification scenario in Poland is also supported by the availability of coal reserves (hard coal and lignite), amounting to 5.77 billion Mg [

38]. Additionally, having in mind the current problems encountered by the mining sector (reduced output, loss of profitability, depletion of resources), the analyses provided make a contribution to the ongoing discussion concerning the future of coal in Poland and in the European Union.

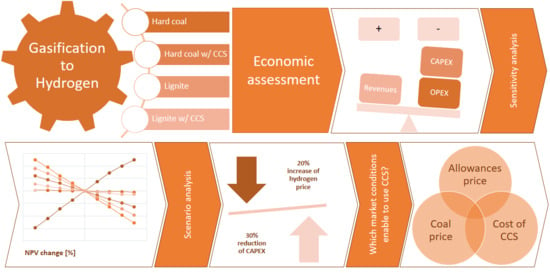

Based on a literature review, our research objectives comprise several important issues and problems connected with the assessment of the economic efficiency of hard coal and lignite gasification to hydrogen in Polish conditions. The studies documented in this paper attempt to answer several fundamental questions, namely:

First research objective. What is the economic efficiency of hard coal and lignite gasification with and without CCS units at the current level of hydrogen prices, the cost of its production and investment outlays for specific technologies?

Second research objective. At which levels of hydrogen price and coal feedstock is the economic efficiency of the best systems positive?

Third research objective. At which price of CO2 emission allowances is the investment in a CCS system for both hard coal and lignite more profitable?

Fourth research objective. In which market conditions is it possible to use CCS systems efficiently when gasifying coal to hydrogen?

The formulation of an opinion concerning the economic efficiency of hard coal and lignite gasification to hydrogen, identification of the key factors influencing the results and discussion concerning the balance between the level of CSS capital expenditures and the price of CO2 emission allowances are the research goals.

3. Description of Coal Gasification Process

As mentioned before, the gasification process in a shell reactor was chosen for analysis (

Figure 1). To the best of our knowledge, the selected technology is among the most popular worldwide; it is characterized by high efficiency and technological maturity. In shell technology, coal is initially dried by tail gas (remaining after hydrogen separation from syngas) to 5% in the case of hard coal or 12% in the case of lignite. Dried coal is fed into the dispersive reactor, with a supply of fuel in dry conditions in which, at a temperature of 1430 °C and pressure of 4.2 MPa, the gasification process takes place. Purified synthesis gas (syngas), from which 99.9% of solid particles, 90% of chlorides and all the alkaline compounds have been removed, goes to a water gas shift (WGS) reactor (in that process, carbon monoxide, in reaction with steam generated in the gas cooling process, is converted to CO

2). After conversion, the synthesis gas is cooled to about 35 °C and purified in a Selexol unit from coal oxysulfide, mercury and acid gases, including hydrogen sulfide, with an efficiency of 99.9%, and from carbon dioxide, with an efficiency of 90%. In the case of installations provided with a CCS system, the separated carbon dioxide is compressed and subsequently pumped underground via a pipeline system and ultimately stored. The remaining gas is combusted in a boiler, providing the heat necessary to generate steam. The steam is used for driving the turbine coupled with a generator of electric energy, and it is entirely used for internal consumption, which amounts to 33.1 MW in the case of the gasification of hard coal and 34.6 MW for lignite (higher energy consumption is associated with the coal handling process). In the case of installations equipped with a CCS system, the electricity consumption for both coals amounts to 51.6 MW and 53.4 MW, respectively) [

44].

To compare the effectiveness of the technologies discussed, we assumed the same amount of chemical energy of about 1935 GJ/h in coal feedstock (at the beginning of the gasification process). In the analyses, we used steam coal with a calorific value (HHV) of 21.3 GJ/Mg and lignite with a calorific value of 12.4 GJ/Mg (typical in the Polish mining sector). The availability of the plant was assumed to be 0.9, resulting in on-stream times of 7 884 h/y. Based on that, mass and energy balances were calculated for all variants. Because it was assumed that some of the chemical energy will be used for internal consumption, the yearly net production capacity varied between 63–73 thousand Mg of H2 for lignite consumption of about 1.59 million Mg and was in the range of 74–81 thousand Mg of H2 for hard coal consumption of about 0.84 million Mg.

It was also assumed that technologies without CCS emit CO

2 to the atmosphere in amounts typical for chemical and thermal reactions, as well as the energy conversion characteristics for a given technology with respect to the analyzed coals. For installations with a CCS system, 90% of CO

2 would be captured and stored geologically. The basic information for the analyzed technologies with values of average yearly emissions of carbon dioxide is presented in

Table 1.

5. Results

Table 8 and

Figure 2 present the results for the analyzed variants in the basic scenario.

On the basis of the table provided, taking into account the NPV criterion, it can be noted that the gasification of hard coal, and subsequently of lignite for the production of hydrogen, is not economically efficient for the basic values of the assumptions.

The best result was achieved in the case of the hard coal gasification without CCS (HC_H2_0), resulting in an NPV value of EUR −142 million and an approximate IRR at the level of 5.7%. Negative NPV and IRR, lower than the discount rate assumed, indicate, however, the existence of economic efficiency for the assumed input variables. The most promising result applies to the variant characterized by the lowest capital expenditures (EUR 818 million) and highest revenues (EUR 193 million yearly). The second best result was achieved in the case of hard coal gasification technology with CCS units (HC_H2_1). That variant has an NPV of EUR −366 million due to the internal consumption of energy in the CCS unit (here we noticed an increase in CAPEX for CCS of EUR 122 million, as well as lower revenues, amounting to EUR 176 million). The approximated IRR for this variant equaled 5.1% and was lower than the discount rate assumed.

For the lignite gasification without CCS (L_H2_0), the NPV achieved was EUR −662 million, which was caused by higher capital expenditures (EUR 985 million) and a simultaneous increase in costs, resulting from the unfavorable price relation between lignite and hard coal. For the fourth technology analyzed, lignite gasification with a CCS system (L_H2_1), the NPV amounted to EUR −904 million, which was due to a higher level of capital expenditures (EUR 1133 million), an expensive CCS system and a lower efficiency of lignite conversion to syngas. For both of those technological variants, a negative IRR was determined. It can be noted that for all four variants, the increase in expenditures related to CCS was relatively greater that the influence of the prices of CO2 allowances (the variants with CCS systems demonstrated less economic efficiency in each case).