Feedstock Security Analysis for Wood Pellet Production in Thailand

Abstract

:1. Introduction

2. Materials and Methods

2.1. Evaluation of Wood Pellet Production

2.2. Sensitivity Analysis

2.3. Evaluating the Potential Amount and Proportion of Feedstocks

2.4. Shannon Index—The Diversity of Supply

3. Results and Discussion

3.1. Wood Pellet Production in Thailand

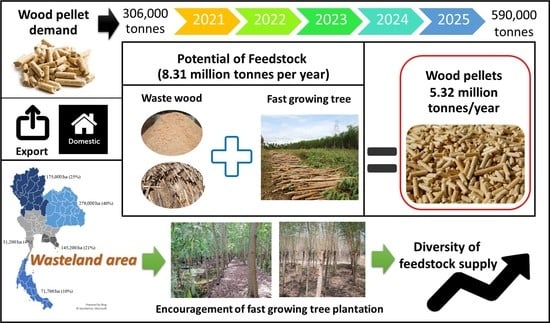

3.2. Evaluating of Wood Pellet Demand in Thailand

3.3. Feedstock Supply for Wood Pellet Production

3.4. Diversity of Feedstock Supply

3.5. Recommendations for Enhancing Long-Term Security of Feedstock Supply

3.5.1. Encouragement for Increasing the Domestic Use of Wood Pellets

3.5.2. Encouraging Cultivation of Fast-Growing Trees in Wasteland

3.5.3. Logistics Management

4. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Thrän, D.; Peetz, D.; Schaubach, K. Global Wood Pellet Industry and Trade Study 2017; IEA Bioenergy: Paris, France, 2017; ISBN 9781910154328. [Google Scholar]

- Bajwa, D.S.; Peterson, T.; Sharma, N.; Shojaeiarani, J.; Bajwa, S.G. A review of densified solid biomass for energy production. Renew. Sustain. Energy Rev. 2018, 96, 296–305. [Google Scholar] [CrossRef]

- Strauss, W. 2020 Global Pellet Markets Outlook. Available online: https://www.canadianbiomassmagazine.ca/2020-global-pellet-markets-outlook/ (accessed on 25 January 2020).

- European Pellet Council World Pellet Map. Available online: https://epc.bioenergyeurope.org/about-pellets/pellets-statistics/world-pellet-map/ (accessed on 20 January 2020).

- Asia Biomass Office The Demand for Wood Pellets in South Korea. Available online: https://www.asiabiomass.jp/english/topics/1211_03.html (accessed on 20 January 2020).

- Bossler, A. Sailing into Japan: Wood Pellet Demand in a Changing Energy Market. Available online: http://biomassmagazine.com/articles/16733/sailing-into-japan-wood-pellet-demand-in-a-changing-energy-market (accessed on 25 January 2020).

- Kasikorn Research Center Market Opportunity of Wood Pellet in Thailand. Available online: https://kasikornresearch.com/th (accessed on 25 March 2019).

- Using Wood Pellet for Small Boiler in Industry, Bangkok: Department of Alternative Energy Department and Efficiency; Department of Alternative Energy Development and Efficiency and King Mongkut’s Institute of Technology Ladkrabang: Bangkok, Thailand, 2016.

- Department of Alternative Energy Development and Efficiency ADEP2015. Available online: http://www.dede.go.th/ewt_news.php?nid=42195 (accessed on 5 January 2019).

- Kotrba, R. Asian Wood Pellet Producer Market Snapshot. Available online: http://biomassmagazine.com/articles/13880/asian-wood-pellet-producer-market-snapshot (accessed on 15 March 2019).

- Forest Industry Organization. Annual Report 2018; Forest Industry Organization: Bangkok, Thailand, 2018. [Google Scholar]

- Njakou Djomo, S.; Ac, A.; Zenone, T.; De Groote, T.; Bergante, S.; Facciotto, G.; Sixto, H.; Ciria Ciria, P.; Weger, J.; Ceulemans, R. Energy performances of intensive and extensive short rotation cropping systems for woody biomass production in the EU. Renew. Sustain. Energy Rev. 2015, 41, 845–854. [Google Scholar] [CrossRef] [Green Version]

- Yan, P.; Xiao, C.; Xu, L.; Yu, G.; Li, A.; Piao, S.; He, N. Biomass energy in China’s terrestrial ecosystems: Insights into the nation’s sustainable energy supply. Renew. Sustain. Energy Rev. 2020, 127, 109857. [Google Scholar] [CrossRef]

- Silalertruksa, T.; Gheewala, S.H. Security of feedstocks supply for future bio-ethanol production in Thailand. Energy Policy 2010, 38, 7476–7486. [Google Scholar] [CrossRef]

- Usmani, R.A. Potential for energy and biofuel from biomass in India. Renew. Energy 2020, 155, 921–930. [Google Scholar] [CrossRef]

- Smyth, C.; Kurz, W.A.; Rampley, G.; Lemprière, T.C.; Schwab, O. Climate change mitigation potential of local use of harvest residues for bioenergy in Canada. GCB Bioenergy 2017, 9, 817–832. [Google Scholar] [CrossRef]

- Dias, G.M.; Ayer, N.W.; Kariyapperuma, K.; Thevathasan, N.; Gordon, A.; Sidders, D.; Johannesson, G.H. Life cycle assessment of thermal energy production from short-rotation willow biomass in Southern Ontario, Canada. Appl. Energy 2017. [Google Scholar] [CrossRef]

- Stolarski, M.J.; Szczukowski, S.; Tworkowski, J.; Wróblewska, H.; Krzyżaniak, M. Short rotation willow coppice biomass as an industrial and energy feedstock. Ind. Crops Prod. 2011, 33, 217–223. [Google Scholar] [CrossRef]

- Quirion-Blais, O.; Malladi, K.T.; Sowlati, T.; Gao, E.; Mui, C. Analysis of feedstock requirement for the expansion of a biomass-fed district heating system considering daily variations in heat demand and biomass quality. Energy Convers. Manag. 2019. [Google Scholar] [CrossRef]

- Zhang, X.; Luo, K.; Tan, Q. A feedstock supply model integrating the official organization for China’s biomass generation plants. Energy Policy 2016. [Google Scholar] [CrossRef] [Green Version]

- Bentancor, L.; Hernández, J.; del Pino, A.; Califra, Á.; Resquín, F.; González-Barrios, P. Evaluation of the biomass production, energy yield and nutrient removal of Eucalyptus dunnii Maiden grown in short rotation coppice under two initial planting densities and harvest systems. Biomass Bioenergy 2019, 122, 165–174. [Google Scholar] [CrossRef]

- Whittaker, C.; Shield, I. Short rotation woody energy crop supply chains. Biomass Supply Chain. Bioenergy Biorefin. 2016, 217–248. [Google Scholar] [CrossRef]

- Iniyan, S.; Sumathy, K.; Suganthi, L.; Samuel, A.A. Sensitivity analysis of optimal renewable energy mathematical model on demand variations. Energy Convers. Manag. 2000, 41, 199–211. [Google Scholar] [CrossRef]

- Taylor, M. What Is Sensitivity Analysis. Available online: http://meds.queensu.ca/medicine/obgyn/pdf/what_is/WhatisSensitivityAnalysis.pdf (accessed on 15 January 2020).

- Fischer, G.; Hizsnyik, E.; Prieler, S.; Van Velthuizen, H. Assessment of Biomass Potentials for Bio-Fuel Feedstock Production in Europe: Methodology and Results; International Institute for Applied Systems Analysis (IIASA): Laxenburg, Austria, 2007. [Google Scholar]

- Odum, H.T. Systems Ecology; Wiley: Hoboken, NJ, USA, 1983. [Google Scholar]

- Lo, L. Diversity, Security, and Adaptability in Energy Systems: A Comparative Analysis of Four Countries in Asia. In Proceedings of the World Renewable Energy Congress, Linköping, Sweden, 8–13 May 2011; Volume 57, pp. 2401–2408. [Google Scholar]

- Department of Industrial Works Factories Database. Available online: https://www.diw.go.th/hawk/content.php?mode=data1search (accessed on 10 January 2020).

- Thai Customs Statistic Report. Available online: http://www.customs.go.th/statistic_report.php?tab=by_statistic_code (accessed on 1 May 2019).

- Office of Foreign Trade Promotion in Seoul Wood Pellet Market in South Korea. Available online: https://ditp.go.th/contents_attach/212428/212428.pdf (accessed on 25 March 2018).

- Office of Agricultural Economics. Agricultural Economic Information. Available online: http://www.oae.go.th/view/1/Information/EN-US (accessed on 15 January 2020).

- Ahmed, A.; Abu Bakar, M.S.; Azad, A.K.; Sukri, R.S.; Mahlia, T.M.I. Potential thermochemical conversion of bioenergy from Acacia species in Brunei Darussalam: A review. Renew. Sustain. Energy Rev. 2018, 82, 3060–3076. [Google Scholar] [CrossRef]

- Commission National Reform Steering Assembly. Promotion of Electricity Production from Fast Growing Wood Biomass to Create a Foundation Economy for Farmers to Build Forests and Enhance Energy Security; Commission National Reform Steering Assembly: Bangkok, Thailand, 2017. [Google Scholar]

- Haruthaithanasan, M.; Patumsawad, S.; Poolsiri, R.; Vanitsanee, T.; Junkhiaw, S.; Suphamitmongkol, W.; Ninpan, S.; Pisapak, S.; Premsamai, S.; Thanavat, A. The Potential of Degraded Land for Fast Growing Tree Plantation for Power Generation; Thailand Science Research and Innovation, and Electricity Generating Authority of Thailand: Bangkok, Thailand, 2014. [Google Scholar]

- Department of Industrial Works Statistics Data of Factories. Available online: https://www.diw.go.th/hawk/content.php?mode=dataservice (accessed on 25 June 2019).

- Haruthaithanasan, M.; Poolsiri, R.; Kuntangkul, P.; Suphamitmongkol, W.; Luangviriyasaeng, V. Literature Review of Fast Growing Species Planting for Establishment of Road Map of Research on Fast Growing Species Planting for Energy; Thailand Science Research and Innovation, and Electricity Generating Authority of Thailand: Bangkok, Thailand, 2016. [Google Scholar]

- Saosee, P.; Sajjakulnukit, B.; Gheewala, S.H. Environmental and Socio-economic Assessment of Wood pellet Production from Fast growing trees in Thailand. In Proceedings of the International Conference on Sustainable Energy and Green Technology, Bangkok, Thailand, 11–14 December 2019. [Google Scholar]

- Saosee, P.; Sajjakulnukit, B.; Gheewala, S.H. Life cycle assessment of wood pellet production in Thailand. Sustainability 2020, 12, 6996. [Google Scholar] [CrossRef]

- Spiegel, A.; Britz, W.; Djanibekov, U.; Finger, R. Policy analysis of perennial energy crop cultivation at the farm level: Short rotation coppice (SRC) in Germany. Biomass Bioenergy 2018, 110, 41–56. [Google Scholar] [CrossRef]

- Saosee, P.; Sajjakulnukit, B.; Gheewala, S.H. Life cycle assessment of wood pellet from para-rubber tree residues. In Proceedings of the 18th International Conference on Sustainable Energy Technologies (SET 2019), Kuala Lumpur, Malaysia, 20–22 August 2019; p. 552. [Google Scholar]

| Factories | A | B | C | D | F |

|---|---|---|---|---|---|

| Raw material (tonne) | 23 | 150 | 217 | 112 | 60 |

| Product (tonne) | 14 | 110 | 128 | 70 | 40 |

| Conversion factor (Raw material/one tonne of wood pellets) | 1.64 | 1.36 | 1.70 | 1.60 | 1.50 |

| Average of conversion factor | 1.56 ± 0.13 | ||||

| Wood Pellet Production | Increasing of Domestic Use | ||||||

|---|---|---|---|---|---|---|---|

| Increasing of Export | 10% | 25% | 50% | 75% | 100% | 120% | 150% |

| 10% | 398,000 | 409,000 | 427,000 | 445,000 | 463,000 | 477,000 | 499,000 |

| 25% | 441,000 | 452,000 | 470,00 | 488,000 | 506,000 | 521,000 | 542,000 |

| 50% | 514,000 | 524,000 | 542,000 | 561,000 | 579,000 | 593,000 | 615,000 |

| 75% | 586,000 | 597,000 | 615,000 | 633,000 | 651,000 | 665,000 | 687,000 |

| 100% | 658,000 | 669,000 | 687,000 | 705,000 | 723,000 | 738,000 | 759,000 |

| 120% | 716,000 | 727,000 | 745,000 | 763,000 | 781,000 | 796,000 | 817,000 |

| 150% | 803,000 | 814,000 | 832,000 | 850,000 | 868,000 | 882,000 | 904,000 |

| 2020 | 2021 | 2022 | 2023 | 2024 | 2025 | |

|---|---|---|---|---|---|---|

| Forecast of Wood Pellet Industrial Demand in South Korea and Japan [3] | ||||||

| Japan | 2,200,000 | 3,100,000 | 4,300,000 | 5,100,000 | 6,600,000 | 6,800,000 |

| South Korea | 3,400,000 | 3,700,000 | 4,100,000 | 4,500,000 | 5,200,000 | 5,500,000 |

| Japan [7] | ||||||

| Total Import | 1,870,000 | 1,870,000 | 4,870,000 | 4,870,000 | 4,870,000 | 4,870,000 |

| Import from Thailand 1 | 89,000 | 89,000 | 232,000 | 232,000 | 232,000 | 232,000 |

| South Korea [30] | ||||||

| Total Import 2 | 3,230,000 | 3,520,000 | 3,900,000 | 4,280,000 | 4,940,000 | 5,230,000 |

| Import from Thailand 3 | 129,000 | 141,000 | 156,000 | 171,000 | 198,000 | 209,000 |

| Demand from main exporters | 218,000 | 230,000 | 388,000 | 403,000 | 430,000 | 441,000 |

| Demand from domestic use 4 | 87,500 | 96,300 | 106,000 | 116,000 | 128,000 | 141,000 |

| Total wood pellet Demand in Thailand | 305,500 | 326,300 | 494,000 | 519,000 | 558,000 | 582,000 |

| Wood | Waste Wood 3 | |

|---|---|---|

| Domestic use1 | ||

| 1. Forest Industry Organization | ||

| -Economic wood | 69,820 | 36,400 |

| -Fast-growing trees | 57,430 | - |

| 2. Private sector | ||

| -Economic wood | 352,500 2 | 158,600 |

| -Fast-growing trees | 26,600 2 | - |

| Total | 506,350 | 195,000 |

| Import4 | ||

| -Economic wood | 7769 | 3500 |

| -Fast-growing trees | 22,485 | - |

| Total wood for wood pellet raw materials | ||

| -Economic wood | - | 198,500 |

| -Fast-growing trees | 106,515 | - |

| Region | Number of Wood Pellet Factories 1 | Para-Rubber Tree Plantation Area 2 (%) | Economic Wood Plantation 2 (%) | Proportion of Raw Material (%) | Para | FGT | EW 5 | |

|---|---|---|---|---|---|---|---|---|

| South | 19 | 70 | 30 | Para 3 | 100 | 1900 | 0 | 0 |

| North | 5 | 34 | 66 | Para + FGT 4 + EW | 35/15/50 | 175 | 75 | 250 |

| North-East | 3 | 90 | 10 | Para + FGT 4 + EW | 90/5/5 | 270 | 15 | 15 |

| East | 5 | 40 | 60 | Para + FGT 4 + EW | 45/15/40 | 225 | 75 | 200 |

| Central | 12 | 20 | 80 | Para + FGT 4 + EW | 25/40/35 | 300 | 480 | 420 |

| Total | 44 | - | - | 2870 | 645 | 885 | ||

| (%) | 65 | 15 | 20 | |||||

| Quantity | |

|---|---|

| Export 1 (tonne) | 289,300 |

| Domestic use 2 (tonne) | 72,300 |

| Wood pellet production 3 (tonne) | 361,600 |

| Conversion factor 4 (CF) | 1.56 |

| Total amount of feedstock; TQ (tonne) | 8,305,000 |

| -Para-rubber waste wood 5 | 8,000,000 |

| -FGT woods 6 | 106,500 |

| -Economic waste wood 7 | 198,500 |

| Potential amount of feedstock; PQ (tonne) | 7,741,000 |

| -Para-rubber waste wood (65%) | 7,633,300 |

| -FGT wood (15%) | 22,000 |

| -Economic waste wood (20%) | 85,700 |

| Quantity (tonne) | CF | TQ (tonne) | PQ (tonne) | |

|---|---|---|---|---|

| Wood pellet production | 470,000 | 1.56 | 8,305,000 | 7,572,000 |

| Para wood (65%) | 305,500 | 1.56 | 8,000,000 | 7,523,000 |

| Fast-growing tree wood (15%) | 70,500 | 1.56 | 106,500 | −3500 |

| Economic wood (20%) | 94,000 | 1.56 | 198,500 | 52,000 |

| Quantity (tonne) | (1) p = n/N | (2) Ln p | (1) × (2) | Shannon–Wiener Index (I) | |

|---|---|---|---|---|---|

| Para-rubber waste wood | 8,000,000 | 0.955720 | −0.03 | −0.0337 | |

| FGT | 0.17 | ||||

| Leucaena | 376 (0.45%) | 0.000045 | −10.00 | −0.0005 | |

| Acacia | 7980 (9.49%) | 0.000963 | −6.95 | −0.0067 | |

| Eucalyptus | 75,055 (89.3%) | 0.009060 | −4.70 | −0.0426 | |

| Other FGTs 1 | 636 (0.76%) | 0.000077 | −9.47 | −0.0007 | |

| Economic waste woods | 199,928 | 0.024134 | −3.72 | −0.0899 | |

| Total | 8,386,303 |

| % Increase in FGT Plantation Area in Wasteland | |||||

|---|---|---|---|---|---|

| 15% | 25% | 50% | 75% | 100% | |

| Wasteland (ha) | 16,800 | 28,100 | 56,200 | 84,200 | 112,300 |

| Quantity of FGTs (tonne) | 79,000 | 131,700 | 263,200 | 394,900 | 526,400 |

| Leucaena 1 | 7900 | 13,200 | 26,300 | 39,500 | 52,600 |

| Acacia 1 | 7900 | 13,200 | 26,300 | 39,500 | 52,600 |

| Eucalyptus 2 | 62,400 | 104,000 | 208,000 | 312,000 | 415,900 |

| Other FGTs 3 | 800 | 1300 | 2600 | 3900 | 5300 |

| Shannon–Wiener index | 0.16 | 0.20 | 0.27 | 0.33 | 0.38 |

| Case 1 | Case 2 | ||

|---|---|---|---|

| Para-Rubber Wood Pellets 1 | FGT Cultivation | FGT Wood Pellets | |

| Job opportunity [37] | 0.0019 person-year per tonne | 0.13 person-year per ha | 0.0019 person-year per tonne |

| GHG emissions (kg CO2 eq) per tonne of wood pellets | 144.4 [40] | - | 88.8–94.4 4 [37] |

| +Train 1600 km | +62.2 | - | - |

| +Truck 1600 km | +458.0 | - | - |

| Increase in cost | |||

| +Train 2 1600 km | +660 THB/tonne | - | - |

| +Truck 3 1 km | +2 THB/tonne | - | - |

| +Truck 4 1600 km | +3150 THB/tonne | - | - |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Saosee, P.; Sajjakulnukit, B.; Gheewala, S.H. Feedstock Security Analysis for Wood Pellet Production in Thailand. Energies 2020, 13, 5126. https://doi.org/10.3390/en13195126

Saosee P, Sajjakulnukit B, Gheewala SH. Feedstock Security Analysis for Wood Pellet Production in Thailand. Energies. 2020; 13(19):5126. https://doi.org/10.3390/en13195126

Chicago/Turabian StyleSaosee, Piyarath, Boonrod Sajjakulnukit, and Shabbir H. Gheewala. 2020. "Feedstock Security Analysis for Wood Pellet Production in Thailand" Energies 13, no. 19: 5126. https://doi.org/10.3390/en13195126

APA StyleSaosee, P., Sajjakulnukit, B., & Gheewala, S. H. (2020). Feedstock Security Analysis for Wood Pellet Production in Thailand. Energies, 13(19), 5126. https://doi.org/10.3390/en13195126