Research on the Critical Issues for Power Battery Reusing of New Energy Vehicles in China

Abstract

:1. Introduction

2. Strategic Value of Power Battery Reusing

3. Main Modes of Power Battery Reusing

4. Research on the Key Issues of Power Battery Echelon Utilization

4.1. Scenario Selection of Power Battery Echelon Utilization

4.2. Economic Benefit Analysis of Power Battery Echelon Utilization

4.2.1. Economic Benefit Evaluation Model of Echelon Utilization

4.2.2. Economic Benefit Analysis of Echelon Utilization

5. Research on the Recycling Value of Power Battery

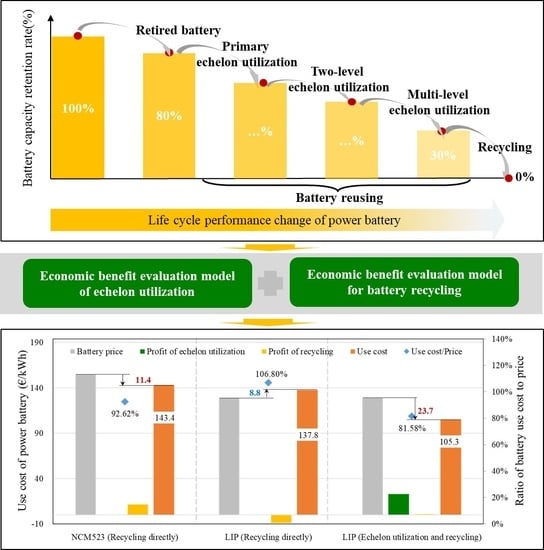

6. Overall Analysis of Retired Power Battery Reusing

7. Policy Suggestion

8. Conclusions and Limitation

- Power battery reusing has three aspects strategic values such as protecting the environment and eliminating potential safety problems of retired power batteries, realizing resource recovery and reducing the risk of battery material supply and reducing the use cost of power battery and then improving the competitiveness of NEVs.

- The echelon utilization of retired LIP batteries would be profitable if the relevant industry chain could be coordinated. The primary echelon utilization of retired LIP could obtain the maximum profit in the E-Bike application scenario of 30.21 €/kWh. While the profits of two-level echelon utilization are relatively lower. Thus, more attention should be paid to the first level echelon utilization in the future.

- The TL battery (NCM523) has a high recycling income with a profit of about 11.41 €/kWh, while the LIP battery is recycled directly, causing a loss of 8.77 €/kWh for LIP recycling directly. Instead, if the LIP battery is first used in echelon utilization and then disassembled for recycling, the profit of 0.79 €/kWh from battery recycling can be realized.

- The use cost of the LIP battery after echelon utilization and recycling could be 38.2 €/kWh lower than the TL (NCM523) battery recycling directly. This would further improve the cost advantage of the lithium iron phosphate battery. Hence, the best reusing mode for the TL battery is recycling directly, while the LIP battery is suitable for echelon utilization and recycling at present.

- The use costs of power batteries are decreased, with the battery prices decreased regardless of the varieties of batteries. The TL battery could reduce to 89.1 €/kWh in 2030 by recycling directly. The LIP battery could reduce to 72.5 €/kWh in 2030 by recycling after echelon utilization.

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

Abbreviations

| NEV | New Energy Vehicle |

| ICEV | Internal Combustion Engine Vehicles |

| MEV | Micro Electric Vehicle |

| ESV | Electric Special Vehicle |

| E-Bike | Electric Bike |

| CBS | Communication Base Station |

| REPS | Renewable Energy Power Station |

| PMG | Parallel Micro-grid |

| LIP | Lithium Iron Phosphate batteries |

| TL | Ternary Lithium battery |

| LA | Lead-acid battery |

| DOD | Depth of Discharge |

| NCM523 | Ni0.5Co0.2Mn0.3 ternary lithium battery |

| NREL | National Renewable Energy Laboratory |

References

- Chen, K.; Zhao, F.; Hao, H.; Liu, Z. Synergistic impacts of China’s subsidy policy and new energy vehicle credit regulation on the technological development of battery electric vehicles. Energies 2018, 11, 3193. [Google Scholar] [CrossRef] [Green Version]

- Hao, H.; Cheng, X.; Liu, Z.; Zhao, F. China’s traction battery technology roadmap: Targets, impacts and concerns. Energy Policy 2017, 108, 355–358. [Google Scholar] [CrossRef]

- Liu, F.; Zhao, F.; Liu, Z.; Hao, H. China’s electric vehicle deployment: Energy and greenhouse gas emission impacts. Energies 2018, 11, 3353. [Google Scholar] [CrossRef] [Green Version]

- CAAM. China’s Automotive Industry Satus in 2019; China Association of Automobile Manufacturers: Beijing, China, 2020. [Google Scholar] [CrossRef]

- China Battery Enterprise Alliance. Available online: http://pba.cbea.com/ (accessed on 15 January 2020).

- Tang, Y.; Zhang, Q.; Li, Y.; Wang, G.; Li, Y. Recycling mechanisms and policy suggestions for spent electric vehicles’ power battery—A case of Beijing. J. Clean. Prod. 2018, 186, 388–406. [Google Scholar] [CrossRef]

- Huang, B.; Pan, Z.; Su, X.; An, L. Recycling of lithium-ion batteries: Recent advances and perspectives. J. Power Sources 2018, 399, 274–286. [Google Scholar] [CrossRef]

- MIIT. Policy Document. Available online: http://www.miit.gov.cn/n1146295/n1652858/index.html (accessed on 16 December 2019).

- SAE-China. Technology Roadmap for Energy-Saving and New Energy Vehicles; Chinese Society of Automotive Engineers: Beijing, China, 2016. [Google Scholar] [CrossRef]

- Orient Securities. Power Battery Recycling. Available online: http://www.nxny.com/stype_54_p153/ (accessed on 23 October 2018).

- Mayyas, A.; Steward, D.; Mann, M. The case for recycling: Overview and challenges in the material supply chain for automotive li-ion batteries. Sustain. Mater. Technol. 2019, 19. [Google Scholar] [CrossRef]

- Sonoc, A.; Jeswiet, J.; Soo, V.K. Opportunities to improve recycling of automotive lithium ion batteries. Procedia Cirp 2015, 29, 752–757. [Google Scholar] [CrossRef]

- Pagliaro, M.; Meneguzzo, F. Lithium battery reusing and recycling: A circular economy insight. Heliyon 2019, 5. [Google Scholar] [CrossRef] [Green Version]

- Wang, T.; Song, D.; Li, G.; Huang, J.; Zhu, H.; He, W. Recycling Potential for Waste Electric Vehicle Lithium-ion Batteries in China. Available online: https://pdfs.semanticscholar.org (accessed on 10 October 2018).

- China Automotive Technology & Research Center. China New Energy Vehicle Power Battery Recycling Industry Development Report; Publishing House of Electronics Industry: Beijing, China, 2019. [Google Scholar] [CrossRef]

- Ahmadi, L.; Yip, A.; Fowler, M.; Young, S.B.; Fraser, R.A. Environmental feasibility of re-use of electric vehicle batteries. Sustain. Energy Technol. Assess. 2014, 6, 64–74. [Google Scholar] [CrossRef]

- Steward, D.M.; Mayyas, A.T.; Mann, M.K. Economics and challenges of Li-ion battery recycling from end-of-life vehicles. Procedia Manuf. 2019, 33. [Google Scholar] [CrossRef]

- Unterreiner, L.; Jülch, V.; Reith, S. Recycling of battery technologies—Ecological impact analysis using life cycle assessment (LCA). Energy Procedia 2016, 99, 229–234. [Google Scholar] [CrossRef] [Green Version]

- Liu, Z.; Hao, H.; Cheng, X.; Zhao, F. Critical issues of energy efficient and new energy vehicles development in China. Energy Policy 2018, 115, 92–97. [Google Scholar] [CrossRef]

- Reinhardt, R.; Christodoulou, I.; Gassó-Domingo, S.; García, B.A. Towards sustainable business models for electric vehicle battery second use: A critical review. J. Environ. Manag. 2019, 245, 432–446. [Google Scholar] [CrossRef] [PubMed]

- Qiao, Q.; Zhao, F.; Liu, Z.; Hao, H. Recycling-based reduction of energy consumption and carbon emission of China’s electric vehicles: Overview and policy analysis. WCX World Cong. Exp. 2018, 1. [Google Scholar] [CrossRef]

- Qiao, Q.; Zhao, F.; Liu, Z.; Hao, H. Electric vehicle recycling in China: Economic and environmental benefits. Resour. Conserv. Recycl. 2019, 140, 45–53. [Google Scholar] [CrossRef]

- Casals, L.C.; Amante Garcia, B.; Canal, C. Second life batteries lifespan: Rest of useful life and environmental analysis. J. Environ. Manag. 2019, 232, 354–363. [Google Scholar] [CrossRef]

- Madlener, R.; Kirmas, A. Economic viability of second use electric vehicle batteries for energy storage in residential applications. Energy Procedia 2017, 105, 3806–3815. [Google Scholar] [CrossRef]

- Cusenza, M.A.; Guarino, F.; Longo, S.; Mistretta, M.; Cellura, M. Reuse of electric vehicle batteries in buildings: An integrated load match analysis and life cycle assessment approach. Energy Build. 2019, 186, 339–354. [Google Scholar] [CrossRef]

- Diouf, B.; Pode, R.; Osei, R. Recycling mobile phone batteries for lighting. Renew. Energy 2015, 78, 509–515. [Google Scholar] [CrossRef]

- Neubauer, J.; Pesaran, A. The ability of battery second use strategies to impact plug-in electric vehicle prices and serve utility energy storage applications. J. Power Sources 2011, 196, 10351–10358. [Google Scholar] [CrossRef]

- Song, Z.; Feng, S.; Zhang, L.; Hu, Z.; Hu, X.; Yao, R. Economy analysis of second-life battery in wind power systems considering battery degradation in dynamic processes: Real case scenarios. Appl. Energy 2019, 251. [Google Scholar] [CrossRef]

- Boyden, A.; Soo, V.K.; Doolan, M. The environmental impacts of recycling portable lithium-ion batteries. Procedia Cirp 2016, 48, 188–193. [Google Scholar] [CrossRef] [Green Version]

- Harper, G.; Sommerville, R.; Kendrick, E.; Driscoll, L.; Slater, P.; Stolkin, R.; Walton, A.; Christensen, P.; Heidrich, O.; Lambert, S. Recycling lithium-ion batteries from electric vehicles. Nature 2019, 575, 75–86. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Martinez-Laserna, E.; Gandiaga, I.; Sarasketa-Zabala, E.; Badeda, J.; Stroe, D.I.; Swierczynski, M.; Goikoetxea, A. Battery second life: Hype, hope or reality? A critical review of the state of the art. Renew. Sustain. Energy Rev. 2018, 93, 701–718. [Google Scholar] [CrossRef]

- Guo, Y.; Luo, M.; Zou, J.; Liu, Y.; Kang, J. Temperature Characteristics of Ternary-Material Lithium-Ion Battery for Vehicle Applications; 0148-7191; SAE Technical Paper: Warrendale, PA, USA, 2016. [Google Scholar]

- Tredeau, F.P.; Salameh, Z.M. Evaluation of lithium iron phosphate batteries for electric vehicles application. In Proceedings of the 2009 IEEE Vehicle Power and Propulsion Conference, Dearborn, MI, USA, 7–10 September 2009; pp. 1266–1270. [Google Scholar]

- China Automotive Technology & Research Center. Annual Report on the Development of New Energy Vehicle Power Battery Industry in China; Social Sciences Academic Press: Beijing, China, 2019. [Google Scholar]

- Gilbert, J.A.; Bareño, J.; Spila, T.; Trask, S.E.; Miller, D.J.; Polzin, B.J.; Jansen, A.N.; Abraham, D.P. Cycling behavior of NCM523/graphite lithium-ion cells in the 3–4.4 V range: Diagnostic studies of full cells and harvested electrodes. J. Electrochem. Soc. 2017, 164, A6054–A6065. [Google Scholar] [CrossRef]

- Wang, W.; Wu, Y. An overview of recycling and treatment of spent LiFePO 4 batteries in China. Resour. Conserv. Recycl. 2017, 127, 233–243. [Google Scholar] [CrossRef]

- Liu, J. Second use potential of retired EV batteries in power system and associated cost analysis. Energy Storage Sci. Technol. 2017, 6, 243–249. [Google Scholar]

- Li, M.; Yang, J.; Liang, S.; Hou, H.; Hu, J.; Liu, B.; Kumar, R.V. Review on clean recovery of discarded/spent lead-acid battery and trends of recycled products. J. Power Sources 2019, 436. [Google Scholar] [CrossRef]

- Yang, Y.; Zhu, W.; Xie, C.; Shi, Y.; Liu, F.; Li, W.; Tang, Z. A layered bidirectional active equalization method for retired power lithium-ion batteries for energy storage applications. Energies 2020, 13, 832. [Google Scholar] [CrossRef] [Green Version]

- Liu, X.; Deng, X.; He, Y.; Zheng, X.; Zeng, G. A dynamic state-of-charge estimation method for electric vehicle lithium-ion batteries. Energies 2019, 13, 121. [Google Scholar] [CrossRef] [Green Version]

- Schuster, F.S.; Bach, T.; Fleder, E. Nonlinear aging characteristics of lithium-ion cells under different operational conditions. J. Energy Storage 2015, 1, 44–53. [Google Scholar] [CrossRef]

- Li, L.; Dababneh, F.; Zhao, J. Cost-effective supply chain for electric vehicle battery remanufacturing. Appl. Energy 2018, 226, 277–286. [Google Scholar] [CrossRef]

- Newbauer, J.; Pesaran, A. NREL’s PHEV/EV Li-Ion Battery Secondary-Use Project; National Renewable Energy Lab.(NREL): Golden, CO, USA, 2010. [Google Scholar]

- Manzetti, S.; Mariasiu, F. Electric vehicle battery technologies: From present state to future systems. Renew. Sustain. Energy Rev. 2015, 51, 1004–1012. [Google Scholar] [CrossRef]

- Baron, C.; Al-Sumaiti, A.S.; Rivera, S. Impact of energy storage useful life on intelligent microgrid scheduling. Energies 2020, 13, 957. [Google Scholar] [CrossRef] [Green Version]

- Gaines, L. The future of automotive lithium-ion battery recycling: Charting a sustainable course. Sustain. Mater. Technol. 2014, 1–2, 2–7. [Google Scholar] [CrossRef] [Green Version]

- Ordoñez, J.; Gago, E.J.; Girard, A. Processes and technologies for the recycling and recovery of spent lithium-ion batteries. Renew. Sustain. Energy Rev. 2016, 60, 195–205. [Google Scholar] [CrossRef]

- Wang, X.; Gaustad, G.; Babbitt, C.W.; Richa, K. Economies of scale for future lithium-ion battery recycling infrastructure. Resour. Conserv. Recycl. 2014, 83, 53–62. [Google Scholar] [CrossRef]

| Echelon Utilization Scenarios | Power Battery | Energy Storage Battery | ||||

|---|---|---|---|---|---|---|

| MEV | ESV | E-Bike | CBS | REPS | PMS | |

| Depth of discharge | 80% | 80% | 100% | 80% | 80% | 80% |

| Cycle | 450 | 450 | 180 | 600 | 800 | 650 |

| Capacity (kWh) | 13.5 | 13.5 | 1 | - | - | - |

| Current price (€/kWh) | 65 | 65 | 90 | 31 | 58 | 39 |

| Performance | LA | LIP | TL |

|---|---|---|---|

| Specific energy (mAh/g) | 40–70 | 130–165 | 150–210 |

| Cycle life (cycle) | 400–800 | 2000–6000 | 800–2000 |

| Echelon Utilization Schemes | Primary Echelon Utilization Scheme | Two-level Echelon Utilization Scheme | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| F-1 | F-2 | F-3 | F-4 | F-5 | F-6 | S-1 | S-2 | S-3 | S-4 | S-5 | S-6 | |

| MEV | X | X | X | X | ||||||||

| ESV | X | X | X | X | ||||||||

| E-Bike | X | |||||||||||

| CBS | X | XX | XX | |||||||||

| REPS | X | XX | XX | |||||||||

| PMG | X | XX | XX | |||||||||

| DOD | |

|---|---|

| 60% | 99.98% |

| 80% | 99.97% |

| 100% | 99.96% |

| Element Type | Lithium | Cobalt | Nickel | Manganese | Aluminum |

|---|---|---|---|---|---|

| Average price (€/t) | 117,828 | 77l,769 | 3600 | 1858 | 1845 |

| Recovery rate | 85% | 98% | 98% | 98% | 90% |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Liu, Z.; Liu, X.; Hao, H.; Zhao, F.; Amer, A.A.; Babiker, H. Research on the Critical Issues for Power Battery Reusing of New Energy Vehicles in China. Energies 2020, 13, 1932. https://doi.org/10.3390/en13081932

Liu Z, Liu X, Hao H, Zhao F, Amer AA, Babiker H. Research on the Critical Issues for Power Battery Reusing of New Energy Vehicles in China. Energies. 2020; 13(8):1932. https://doi.org/10.3390/en13081932

Chicago/Turabian StyleLiu, Zongwei, Xinglong Liu, Han Hao, Fuquan Zhao, Amer Ahmad Amer, and Hassan Babiker. 2020. "Research on the Critical Issues for Power Battery Reusing of New Energy Vehicles in China" Energies 13, no. 8: 1932. https://doi.org/10.3390/en13081932

APA StyleLiu, Z., Liu, X., Hao, H., Zhao, F., Amer, A. A., & Babiker, H. (2020). Research on the Critical Issues for Power Battery Reusing of New Energy Vehicles in China. Energies, 13(8), 1932. https://doi.org/10.3390/en13081932